BA RoofOn V30 R16 12_2012 GB mit CE BAK.doc 3

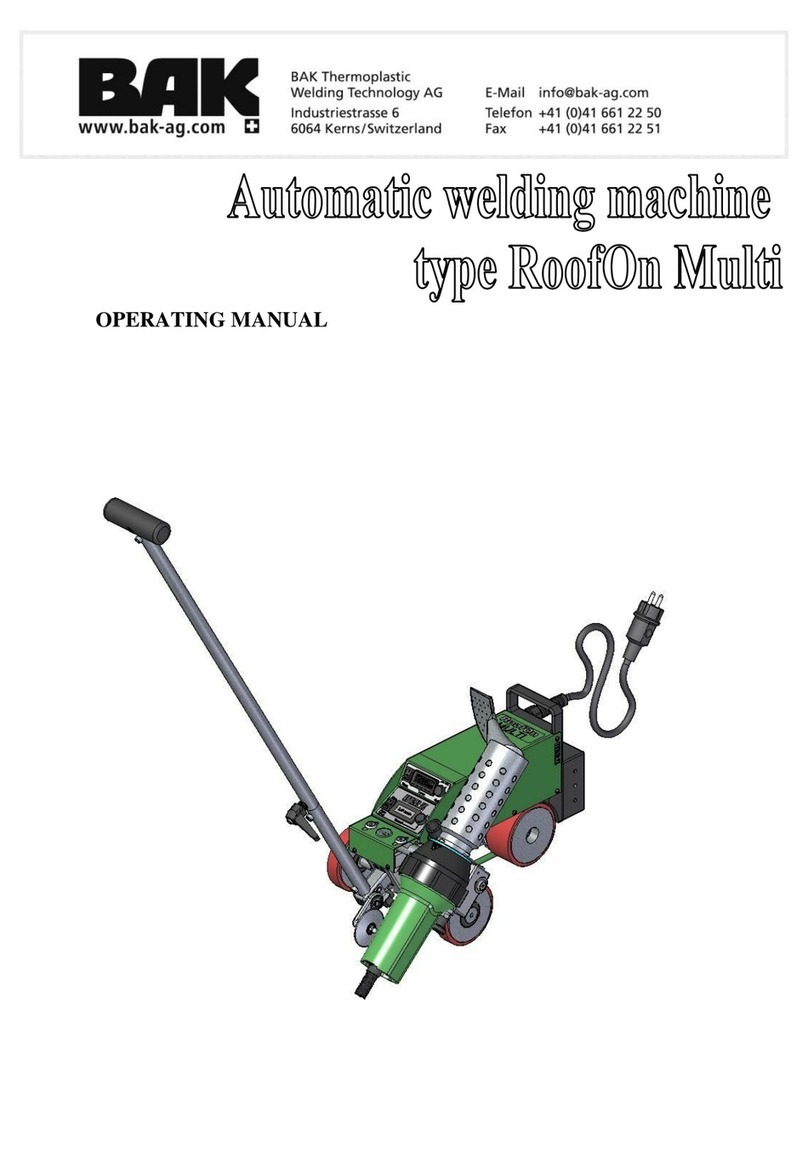

INTENDED USE

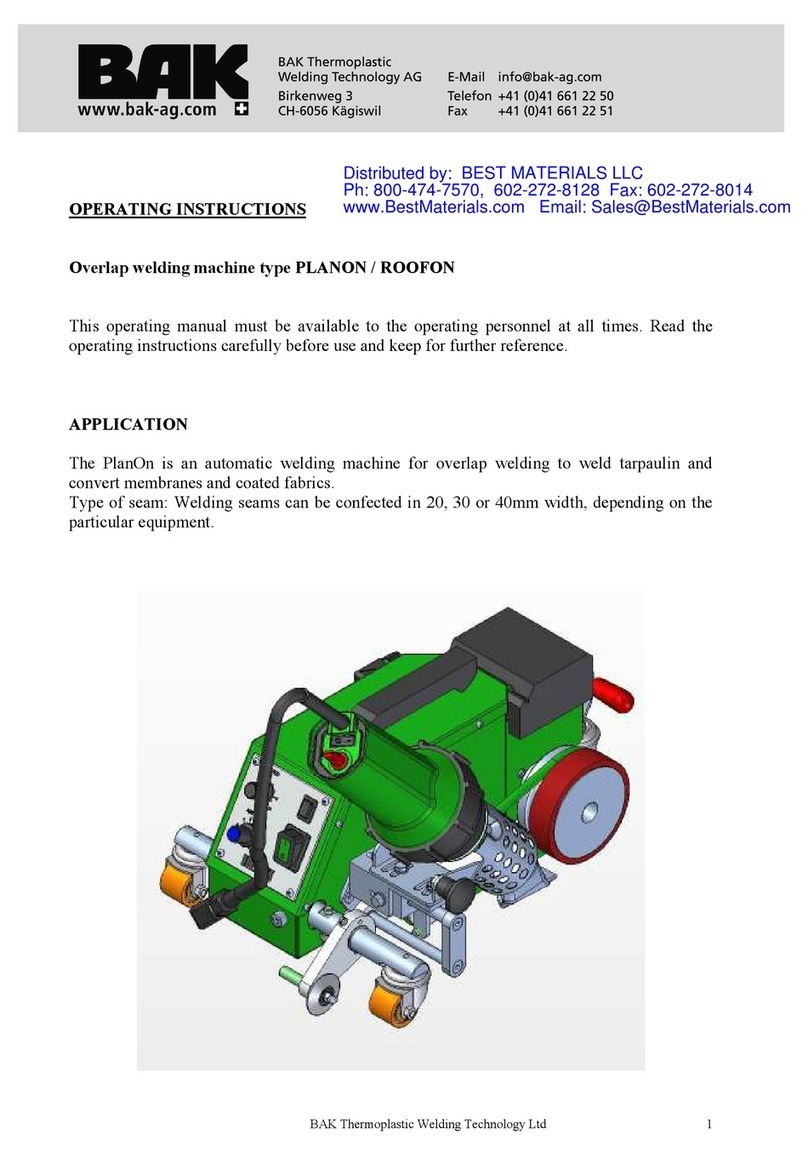

This device is an automatic elding machine for overlap/tape elding of eld tarpaulin and the production of

plastic film and coated fabrics.

eld shape overlap: Welding lines ith a idth of 20, 30 or 40 mm are produced depending on the

applicable configuration.

eld shape tape: Tapes ith a idth of 40 or 50 mm are produced depending on the applicable

configuration.

eld shape protection against vandalism: A tape ith integrated steel cable is elded on.

eld shape measuring tape: A profiled tape is elded on for sealing an overlap elding line.

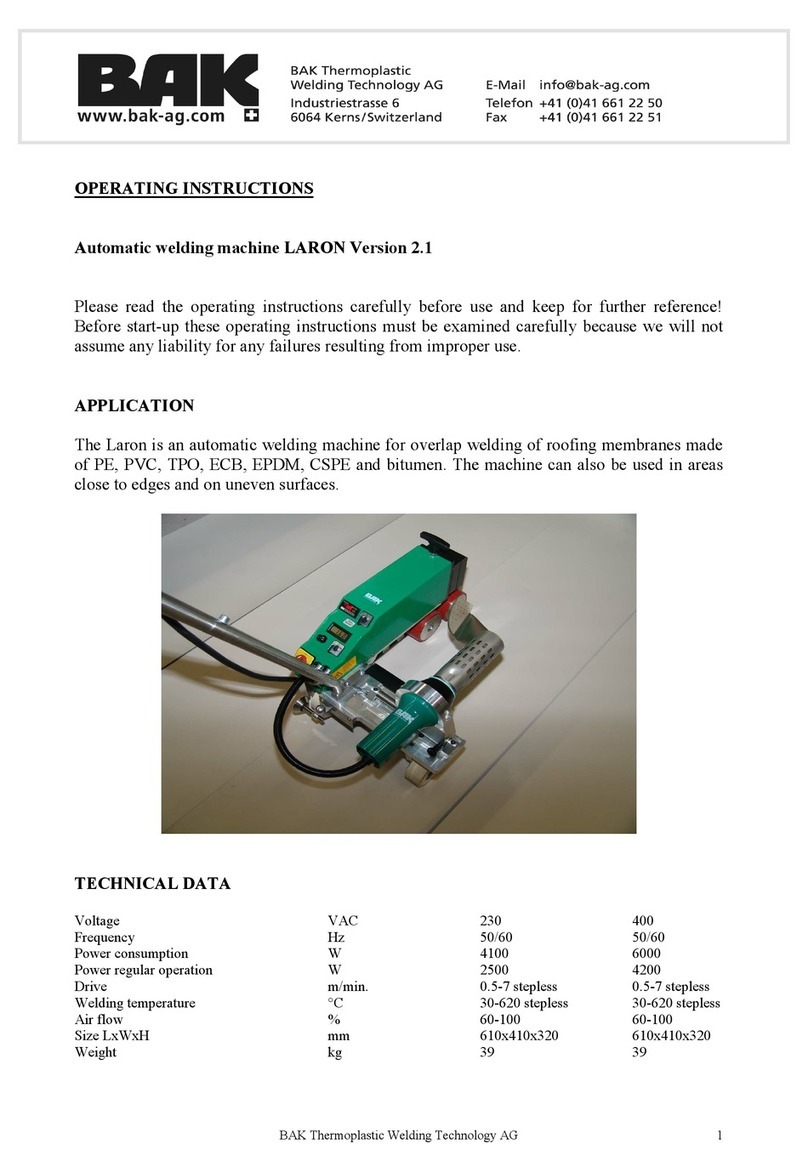

DESCRIPTION OF FUNCTIONS

Heating system:

The hot air temperature is steplessly adjustable and electronically controlled. According to the material

thickness, the nozzle position can be adjusted steplessly.

elding pressure:

The elding pressure can be changed by adding or reducing eight.

Drive:

The drive is steplessly adjustable and electronically controlled. The control system is designed in a ay that

the set speed remains constant, independent of the load.

ARNING

• If the po er supply cable gets damaged, it has to be replaced by the manufacturer, its customer

service or by a qualified person in order to avoid danger.

• The device must not be used by personnel (including children) ith limited physical, sensory or

mental capabilities or lack of experience and/or kno ledge, except hen supervised by a person

ho is responsible for their safety or hen advised ho to use the device by that person.

• Children must be supervised in order to ensure that they do not play ith the device.

• Because of the enormous fire danger, the operating personnel must be specially briefed and

regularly instructed.

• Fire can occur if the device is not used carefully.

• Do not leave the device unobserved hile it is in operation.

• Demonstrate the necessary caution hen operating the device near inflammable materials. Do not

operate on the same surface for longer periods of time.

• A fire extinguisher must al ays be ithin reach in the ork area.

• The device must not be used in explosive atmospheres.

• Heat may reach inflammable materials that are not readily visible.

• There is a very significant risk of fire hen the machine stops because of any disturbance and the

hot air device is still running (max. temperature of the air flo 650 °C). Therefore, special attention

should be placed on the subsurface and the material to be processed.

• The elding machine must not be used on inflammable surfaces (e. g. ooden roofs and floors

made of ood)

• The device bears the protection mark IP20 and must therefore be protected from damp and rain.

• When using the device on roofs and tables, it could fall do n due to its automatic drive system. In

order to avoid a fall, necessary precautions must be taken.

• The elding machine can be operated up to a maximum incline or slope of 30°.

• Warning: danger of poisoning! While processing thermoplastics or similar material, gases occur

hich can be aggressive or poisonous. Avoid inhaling fumes even if they seem to be harmless.

Make sure the orkplace is ell ventilated or ear respiratory protection.