Masoneilan 37002 Series MiniTork II Valve (w/actuator Model 33) Instruction Manual | 7

Copyright 2020 Baker Hughes Company. All rights reserved.

Installation - Assembly

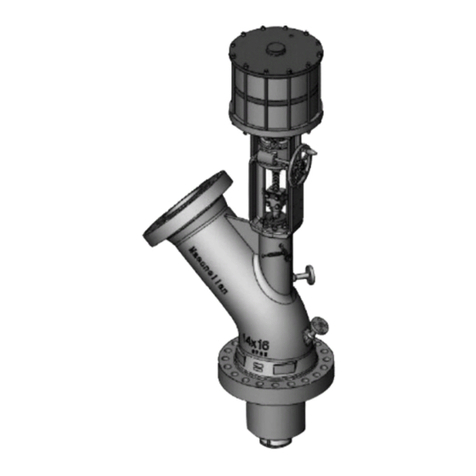

5. Where insulation of the valve body is required, do not

insulate the valve bonnet. Figure 2 shows a recommended

method tor insulation.

Figure 2

6. Special bosses are provided on the valve body to center

the valve in the line and prevent rotation prior to tightening

the flange bolts. Before placing the valve in the line, install

the lower flange bolting to provide a kind of cradle, this will

support the valve while installing the remaining bolts.

CAUTION

Due to the different actuator to body congurations,

the center of gravity for lifting the valve will change. It

is recommended that the valve be test lifted to ensure

it will not shift suddenly, possibly causing injury or

damage.

7. Where possible, use welding neck or flat face flanges with

a full line bore. When the valve has an elastomer liner, the

l.D. of the mating flanges must match the l.D. of the liner and

cover the entire face of the liner.

Note: Refer to Installation Alignment section for the

recommendations on valve alignment as well as

installation in standard commercial wrought steel pipe,

and tubing, and heavy wall pipe.

CAUTION

When the valve is installed in lines constructed with

standard commercial wrought steel pipe or heavy wall

pipe, slip-on or screwed anges are not recommend-

ed with lined valves.

8. Regardless of valve action (air to close or air to open) the

valve should be installed in the line with the vane in the

closed position. The following are recommended means for

closing the vane for valve installation:

A. If the valve is equipped with a handwheel, close the valve

using the handwheel.

Note: For lined valves, the closed position is achieved

when the vane makes full contact with the liner.

B. If the valve is not equipped with a handwheel, a portable

regulated air supply may be used lo supply pressure to the

actuator and close the vane.

Note: On lined valves only enough air pressure should

be supplied to ensure that the vane makes full contact

with the liner.

C. The following method is highly recommended and should

be used whenever possible. Rotate the hand wheel to the

disengaged position. Refer to Figure 19 and remove side

covers (56). remove retaining rings (11) and push out pivot

pin (12). The actuator is now disengaged from the valve

shaft and allows for manu ally closing the valve by rotating

lever (33) in proper direction.

Note: If the valve s equipped with a handwheel, remove

spacers (10) and rotate the handwheel so that the lever

arm (37) will not interfere with manual movement of

the lever (33). On lined valves rotate the vane until full

contact is made with the liner.

CAUTION

Ensure that the valve is operating in the quadrant

shown in Figure 11.

9. Center the valve in the pipe line (install gaskets if an unlined

valve) and tighten bolting evenly and in criss-cross fashion.

Note: Gaskets are not used for lined valves. The elas-

tomer liner is flangeless and acts as its own controlled

compression gasket, therefore it should be tightened

until the flanges meet evenly with the valve body.

10. At this time the vane should be rotated manually a few times

to ensure that it clears adjacent internal piping and flanges.

It is not recommended that the vane be stroked, either using

handwheel or actuator; it should be stroked manually so that,

should interference occur, this will be readily determined

and will prevent damage to the vane.

11. If Step C, previously mentioned, was used, refer to

Reassembly of Actuator to Bracket Section, to reassemble

pivot pin (12), retaining ring (11) and spacer (10).