3 | Baker Hughes Copyright 2023 Baker Hughes Company. All rights reserved.

Unpacking

Care must be exercised when unpacking the valve to prevent

damage to the accessories and component parts. Contact the local

Baker Hughes Sales Office or Service Center with any issues or

problems. Be sure to note the Masoneilan valve model number and

serial number in all correspondences.

Installation

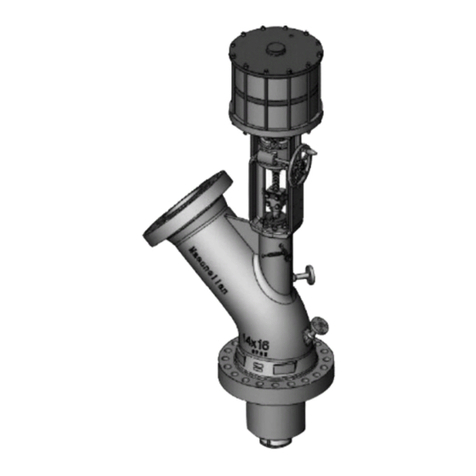

The 78400/18400 Series valve must always be installed

with the ow tending to open the valve plug. For appli-

cations where insulation of the valve body is required,

do not insulate the valve bonnet.

Recommended Installation

It is recommended to install the 78400/18400 Series valves in the

vertical position with the actuator extended up whenever possible.

This orientation eliminates the need for additional pipe support,

reduces the side load friction on the actuator, and provides ease of

removal of the trim during maintenance for weld-end construction

designs.

Piping Cleanliness

Before installing the valve in the line, clean piping and valve of all

foreign material such as welding chips, scale, oil, grease or dirt.

Gasket mating surfaces must be thoroughly cleaned to ensure

leak-free joints. Sacrificial start-up fixtures can be purchased from

Baker Hughes to protect the operational trim during the installation

and line flushing phases.

If major system or piping modications (or repairs) are

performed, thorough ushing and blowdown of the sys-

tem will be required prior to reinstalling the LincolnLog

trim. Sacricial ushing trim should be installed in the

valve to protect the integrity of the ow passages. Failure

to follow this warning will violate the valve warranty

agreement and could result in control instability, exces-

sive noise levels, and valve leakage.

Isolation Bypass Valve

To allow for in-line inspection, maintenance and removal of the

valve without service interruption, provide a manually operated

shutoff valve on each side of the control valve and a manually

operated throttling valve in the bypass line.

Heat Insulation

In case of a heat-insulated installation, do not insulate the valve

bonnet and take protective measures relative to personal safety.

Hydrostatic Testing and Line Cleaning

During this operation, the control valve must not be used as an

isolating valve. This means that the valve must always be opened

before carrying out pressure tests in the process line, cleaning

of pipes, etc. Otherwise equipment damage or failure of the seal

rings could result. If the value is to remain installed during line

cleaning, flushing trim MUST be installed to prevent damage to

trim components..

Flow Direction

The valve must be installed so that the process fluid will flow through

the valve in the direction indicated by the flow arrow located on the

body.

Welded Connections

Carefully review the information in this section prior to

welding any valves inline. Refer any additional ques-

tions to the local Baker Hughes Sales Oce or Service

Center.

Pre-Weld Preparation

Carefully follow the installation steps defined in the sections noted

above prior to performing weld procedures.

Welding Process

Perform welding process in accordance with the standard

requirements for the materials and weld construction of the specific

valve. Apply post weld heat treatment if required.

Internal valve components should be removed prior

to performing welding or pre/post weld heat treatment

in order to prevent damaging any soft goods (such

as PTFE seals). If unable to remove the elastomeric

components, then other methods must be employed

to prevent the local temperature around the seals from

exceeding the maximum material limits (typically 450°F /

232°C for PTFE-based materials).

Post Weld Cleaning & Assembly

Inspect the body, bonnet, and trim components for cleanliness and

surface condition. Remove any foreign materials, such as weld

chips, slag or scale. Make sure there are no nicks, scratches, burrs

or sharp corners on sealing and sliding surfaces. Clean all gasket

interface surfaces and reassemble using new gaskets to ensure

sealing integrity.

Actuator Assembly

Assemble the actuator onto the control valve using the appropriate

instructions for the specific actuator model and type. Connect air

pressure lines to the actuator ports to meet intended operating

mode (i.e., air-to-extend, air-to-retract, or double-acting).