2 | Baker Hughes Copyright 2020 Baker Hughes Company. All rights reserved.

Installation

1) The Flexflo Surge Reliever may be installed in either a

vertical or horizontal line. Flow must be in the direction of

the flow arrows.

2) The pressure source for charging the Jacket and Annular

volume must be dry nitrogen, natural gas, or compressed air

at a pressure higher than the desired pressure in the Jacket

Space (the Jacket Pressure Set Point).

DO NOT USE OXYGEN or liquids to pressurize the

Flexo’s Jacket Space.

3) All connections for the Jacket supply gas must have no

leaks.

4) The range of the Jacket Pressure gauge should be

approximately twice the desired Set Point Pressure.

5) Allow sufficient space for accessing and servicing the Flexflo

Surge Reliever with lifting equipment.

Methods to adjust and hold pressure in the jacket

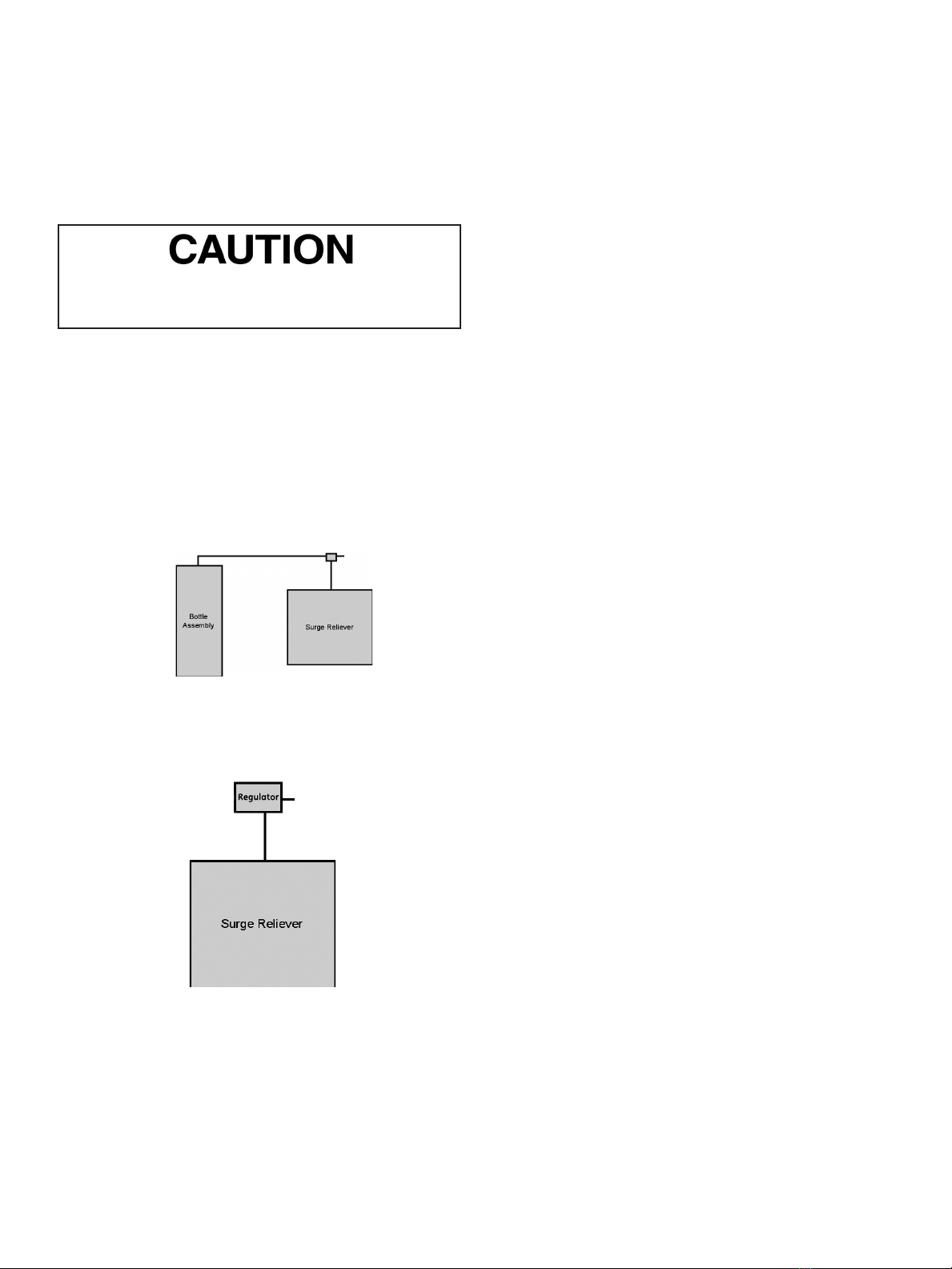

A. Bottle assembly (See Figure 2). The bottle assembly

provides a convenient method to hold pressure in the jacket

See adjusting pressure with a bottle assembly on page 3.

Figure 2

B. See figure 3. With a pressure source at a higher pressure a

pressure regulator can regulate pressure to the jacket. See

instruction W-887-15LH-B00-1 if this method is chosen.

Figure 3

Temperature changes

Temperature changes in the jacket will change the pressure

when the surge reliever will open. This is important to consider

because the surge reliever could open at a higher pressure than

desired. A few things should be considered for the day to night

and week to week changes in temperature around the surge

reliever.

Ways to deal with temperature changes:

1. Chosen Jacket pressure could be low enough that even with

temperature and pressure changes the surge reliever will

open when needed.

2. A method could be provided by the customer to keep the

temperature around the surge relieve constant.

3. Bottle assembly can be buried in the ground.

4. Shade the surge reliever and bottle assembly.

5. Method B with a hard adjustable regulator could be used.

The pressure regulator can remove excess pressure or add

pressure as needed to the jacket however it also will change

pressure over time so adjustments will be needed. See

instruction W-887-15LH-B00-1 if this method is chosen.

Adjusting pressure with a bottle assembly Installation:

1. Bottles assemblies are coated to allow them to be buried in

the ground with only the top of the bottle(s) exposed. The

purpose of embedding the bottles in the ground is to support

the bottles and to stabilize the temperature of the bottles. If

the Bottles are not buried, the Bottle Assembly should be

secured properly and protected from damage to the bottle(s)

or the pressurized lines.

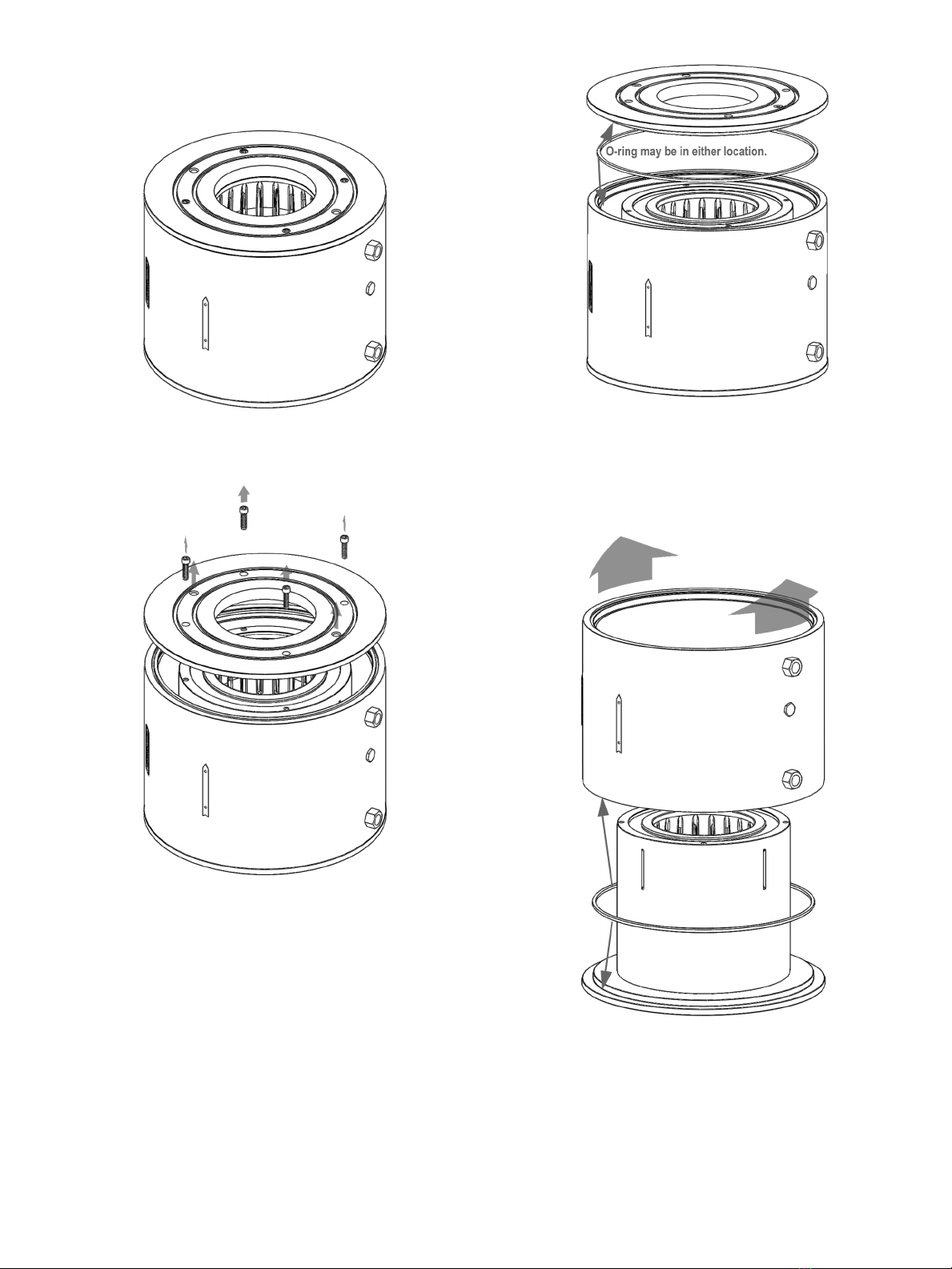

2. The 1/2” MNPT end, the end with the O-ring, of the Jacket

Connector Assembly, see Figure 4, will be threaded into the

1/2” FNPT Jacket Port of the surge reliever.

a. Clean and inspect the mating surfaces, the O-ring,

and O-ring sealing surfaces for any damage, debris,

or packing material that may interfere with proper

installation or with a pressure tight seal.

b. Thread the 1/2” MNPT end of the Jacket Connector

Assembly into the Jacket Port until it just bottoms out.

Do not tighten. Position the three 5/32 hex head valves

(labeled Supply, Vent, and Cylinder) so they can easily

be adjusted, but will not collect water; and position the

pressure gauge (if equipped) so that it can be easily

read and will not collect water. Tighten the 1-1/4” Lock

Nut with a 1 1/4” wrench against the body of the surge

reliever while holding the body of the Jacket Connector

Assembly. Maintain the proper position of the gauge

and valves.

3. A separate pressure supply source will be required to charge

the Jacket chamber/recharge the Bottle Assembly. When

not in use, insert a 1/4” MNPT pipe plug into the Charging

Supply Connection. The Pipe plug is recommended but not

required.

4. Install the tubing from the Cylinder Connection to the open

tube fitting of the Bottle Assembly. Secure the tubing so that

it is protected from damage and vibration.

5. Visually inspect the system for any open ports, loose

connections, or damaged tubing. Plug or tighten any open

ports or loose connections. Replace any damaged tubing.

6. Loosen the supply and cylinder lock nuts and back out the

threaded nut collars approximately 1 turn.