When making gas pipe connections, only pipe joint compound resistant to the action of liquefied petroleum

gases should be used.

The broiler and its individual shut-off valve must be disconnected from the gas supply system during any

pressure testing of that system at test pressure in excess of ½ psig (3.45 kpa).

The broiler must be isolated from the gas supply piping system by closing its individual manual shut-off

valve during any pressure testing of the gas supply piping system at test pressures equal to or less than ½

psig (3.45 kpa).

4. BURNERS:

Air-Mixer caps on the front of all burners are adjusted and tightened before the unit leaves the factory. If it is

necessary to adjust the Air-Mixer caps, the adjustment must be done by a factory authorized technician

only, who should tighten and seal the adjustment screw after the adjustment. (See Figure “D”)

(i) Place the front venturi end of the burner onto valve assembly by fitting the center hole of the Air-

Mixer cap over the brass orifice accessible through holes in the Chamber Front.

(ii) Drop the rear end flange of the burner into the corresponding slot in the burner support at the rear of

the chamber.

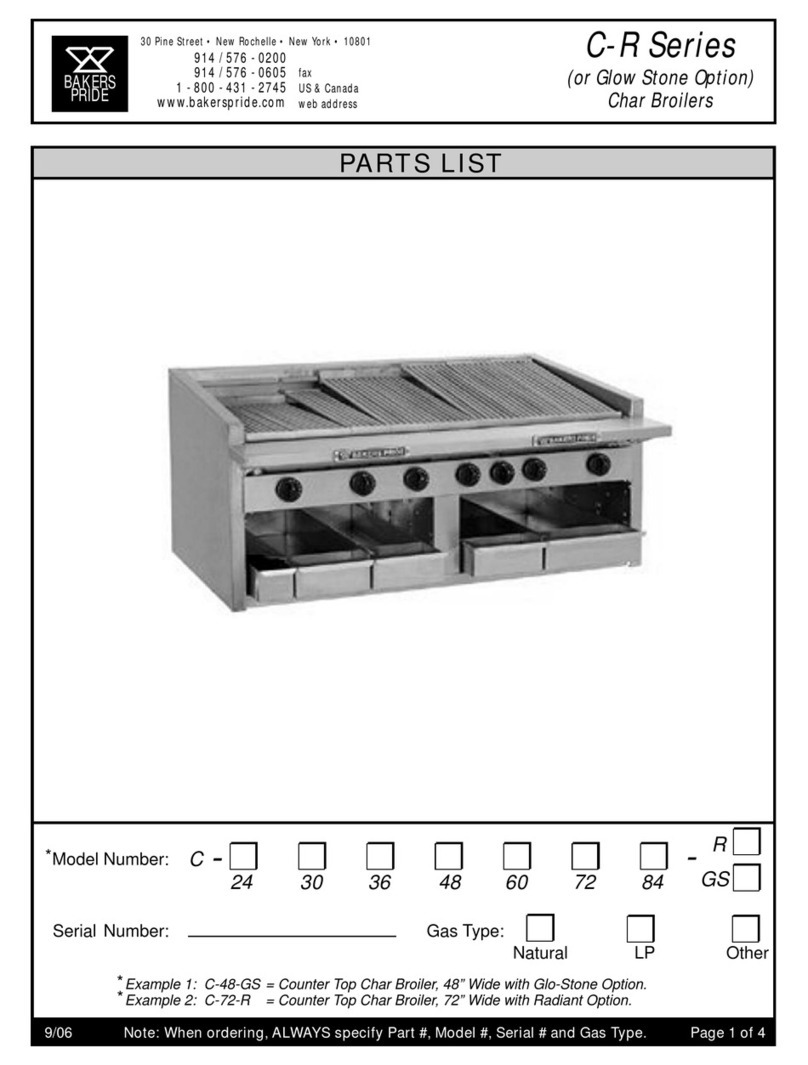

(iii) While most of the Burners are H-shaped Double Burners, the 24”, 48” and 72” models come with

one additional single Burner each. Place all of the H-shaped Burners first, then insert the single

burner into the remaining space.

5. RADIANT UNITS:

(i) If the Broiler was ordered with Grease Catches, place them with the slotted front end over the

upturned fingers of the radiant support in front and rest the back end on top of the upturned

fingers in the rear.

(ii) Place the 'A' shaped radiants over the burners with each end supported on the radiant supports in

front and rear of the chamber. Pushing the radiants all the way to the back will provide more heat in

the front, while pushing them all the way to the front will provide more heat in the back.

(iii) Place the Top Grates, wider flange toward the back, onto the top grate supports in the rear. Every

broiler is supplied with a sufficient number of Top Grates to cover the entire broiling area. Two of

them are 4-1/2” wide and the rest are 6” wide. Flipping these Top Grates upside down and choosing

between two supports in the rear, four positions are possible for different slopes desired.

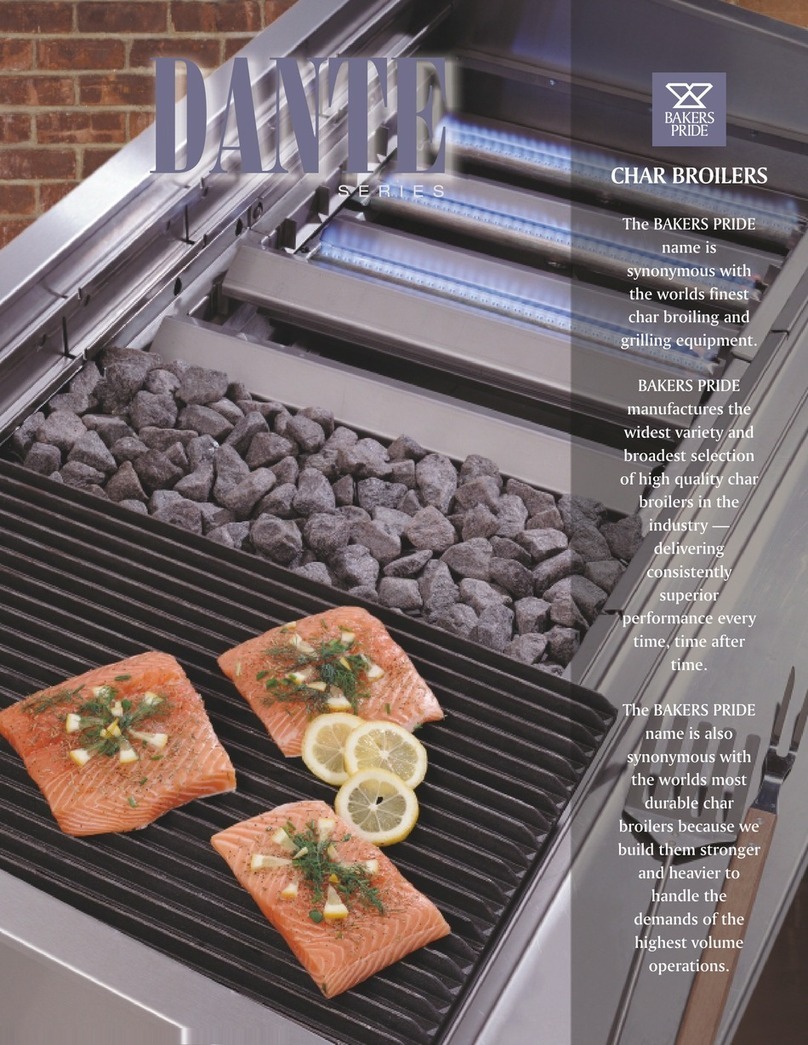

6. GLO-STONE UNITS:

(i) Hold the Glo-Stone Frame (one or more, depending on the size of the Broiler) over the desired

location and lower it slowly onto the Radiant Supports in the front and back of the chamber until it fits

in between the upturned fingers of the supports. Rock it back and forth to assure proper fit.

(ii) Spread one layer of Glo-Stones covering all of the expanded metal grate exposed.

IMPORTANT NOTE: DO NOT USE MORE THAN ONE LAYER OF GLO-STONES, AS THIS

WILL REDUCE THE AMOUNT OF HEAT REACHING THE TOP GRATES AND CAN CAUSE

OVERHEATING AND PERMANENT DAMAGE TO THE UNIT.

(iii) Place the Top Grates, wider flange toward the back, onto the top grate supports in the rear. Every

broiler is supplied with a sufficient number of Top Grates to cover the entire broiling area. Two of

them are 4-1/2” wide and the rest are 6” wide. Flipping these Top Grates upside down and choosing

between two supports in the rear, four positions are possible for different slopes desired.

4