PRECAUTIONS

Never place the helmet or the autodarkening welding filter on hot surface.

Scratched or damaged protection screens should be regularly replaced by original BALDER

ones. Before using the new protection screen, make sure to remove any additional protection

foil from both sides.

Use only BALDER BH3 within the temperature range of -10°C to +60°C.

Do not expose the autodarkening welding filter to liquids and protect it from dirt.

Use only original BALDER spare parts. In case of doubt, please contact your BALDER author-

ized dealer.

Failure to follow these instructions will invalidate the warranty. BALDER does not accept

responsibility for any problems which may arise from applications other than welding, or if

the instructions for use are not strictly followed. The BALDER BH3 welding helmet is manu-

factured to protect the welder’s face against spatters and hazardous ultraviolet and infrared

rays emitted during the welding process. It is not intended to be used as a protection against

impact, flying particles, molten metals, corrosive liquids or hazardous gases.

Materials which may come into contact with the wearer’s skin could cause allergic reactions to

susceptible individuals.

Welding helmet worn over standard ophthalmic spectacles may transmit impact, thus create a

hazard to the wearer.

If the helmet and the protection screen both do not carry the B marking, then only the S mark-

ing is valid.

BEFORE WELDING

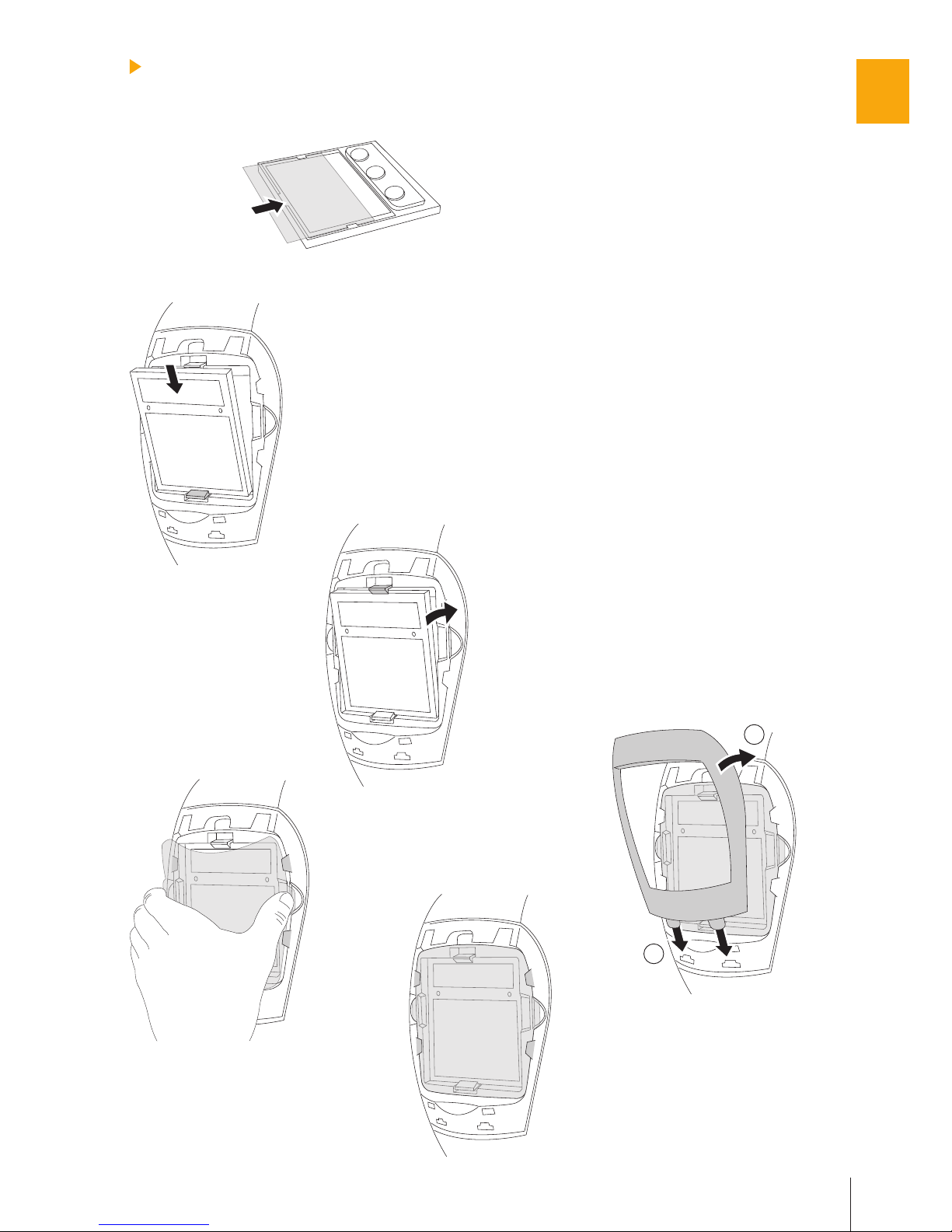

Ensure that the helmet is correctly assembled and that it completely blocks any accidental

light. In the front, light may enter the helmet only through the viewing area of the autodarken-

ing welding filter.

Adjust the headgear to ensure maximum comfort and to provide the largest field of vision.

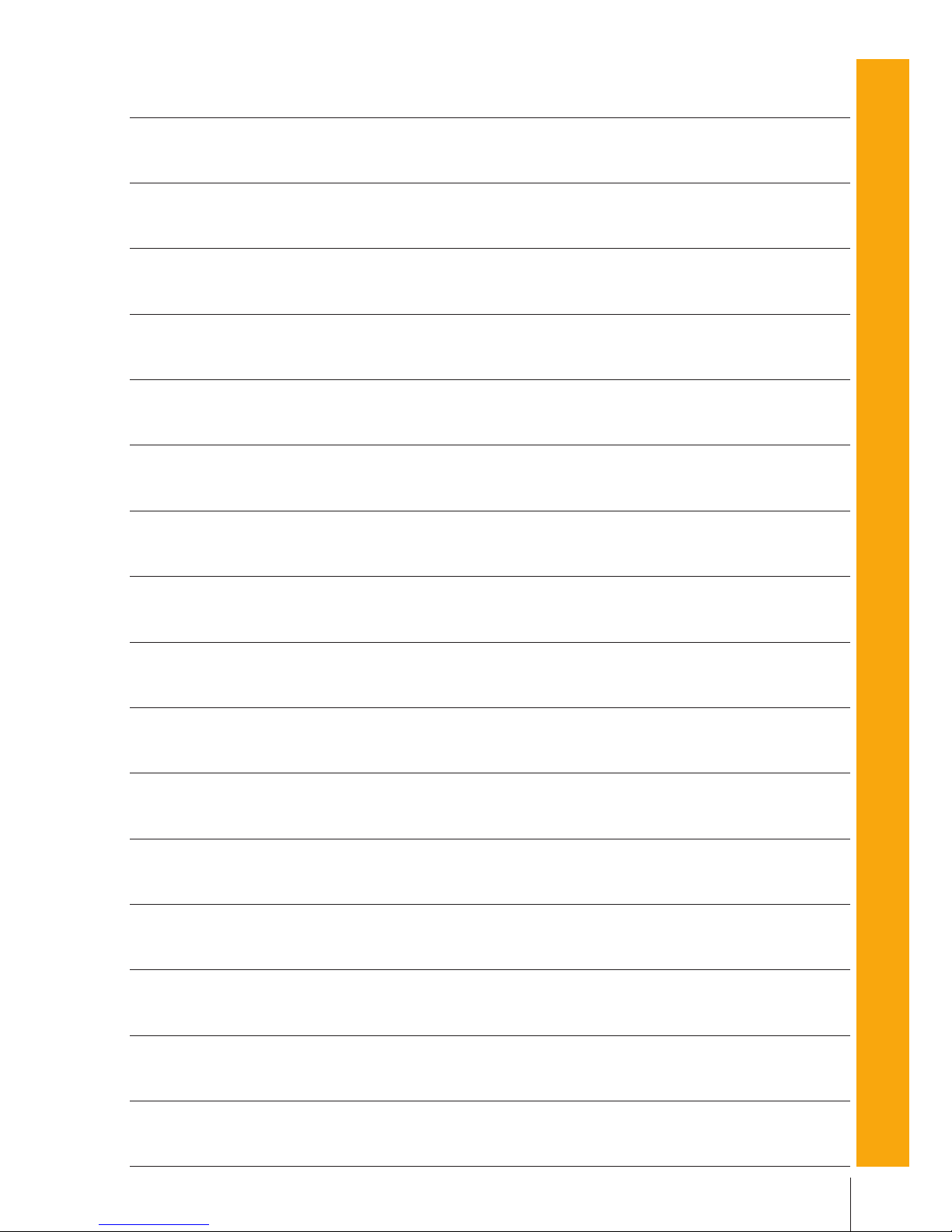

Select a suitable welding filter for the shield. Dimensions of the filter: 110x110 mm (see

BALDER leaflet).

Check the prescribed shade level for your welding application and adjust your autodarkening

filter accordingly (see the table with recommended shade levels).

STORAGE

When not in use the filter should be stored in a dry place within the temperature range of -20°C to

+65°C. Prolonged exposure to temperatures above 45°C may decrease the battery lifetime of the

autodarkening

welding filter. It is recommended to keep the solar cells of the

autodarkening

weld-

ing filter in the dark or not exposed to light during storage in order to maintain power down mode.

This can be achieved by simply placing the filter face down on the storage shelf.

MAINTENANCE AND CLEANING

It is always necessary to keep the solar cells and the light sensors of the autodarkening welding

filter free of dust and spatters: cleaning can be done with a soft tissue or a cloth soaked in mild

detergent (or alcohol). Never use aggressive solvents such as acetone. BALDER filters should

always be protected from both sides by protection screens (polycarbonate or CR39), which

should also be only cleaned with a soft tissue or cloth. If protection screens are in any way dam-

aged, they must be immediately replaced.

For your protection and maximum efficiency, please read this informa-

tion carefully before use.

•

•

•

•

•

•

•

•

•

•

•

•

•

4

GB