Engine Specifications

Engine Data

Manufacturer Perkins

Model 3.1524

Cylinders 3 in-line

Cycle 4-stroke

Induction system Natural

Displacement, L (cu. in.) 2.5 (152 cu. in.)

Bore and Stroke 91.4 x 127.0

Compression Ratio 16.5:1

Lubrication capacity 6.17 Quarts

Cooling capacity (incl. radiator) 11.85 Quarts

Weight without fuel - Net 685

Weight without fuel - Shipping 950

Warranty: 2 year limited per manufacturer

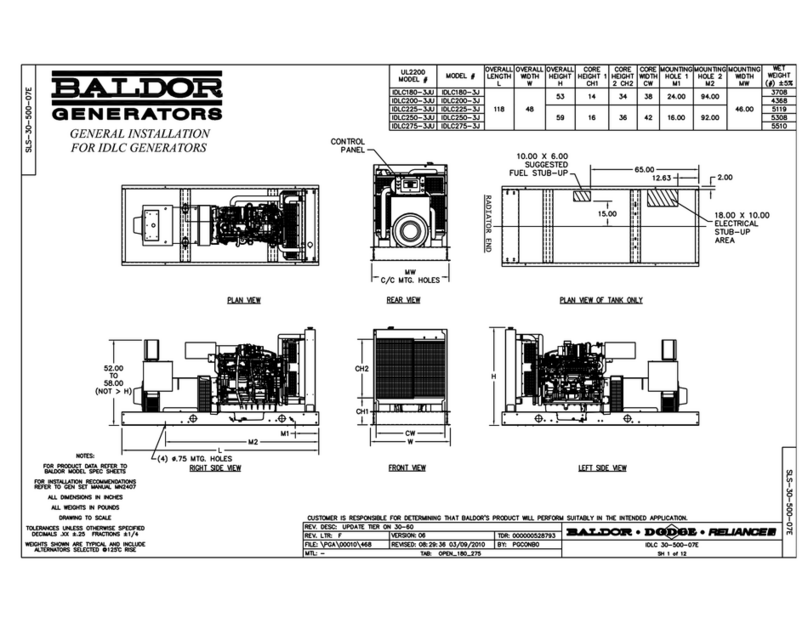

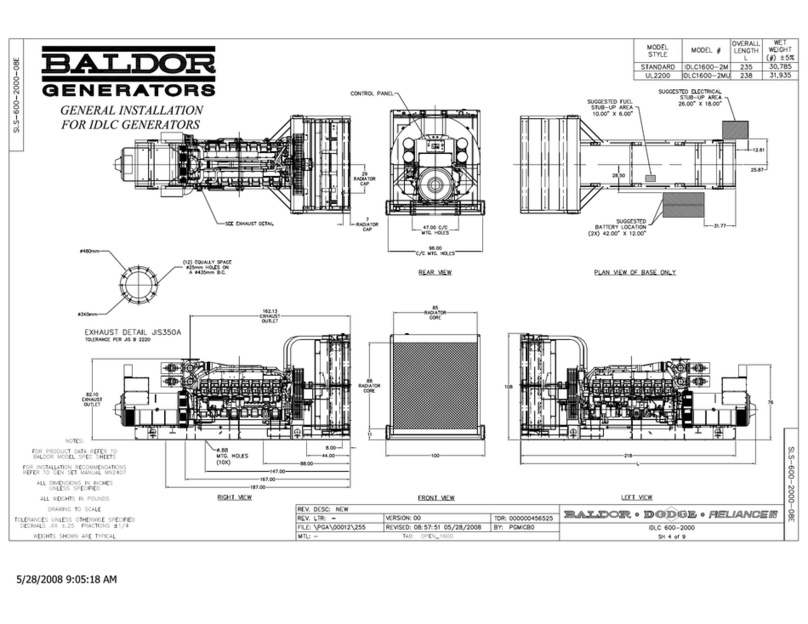

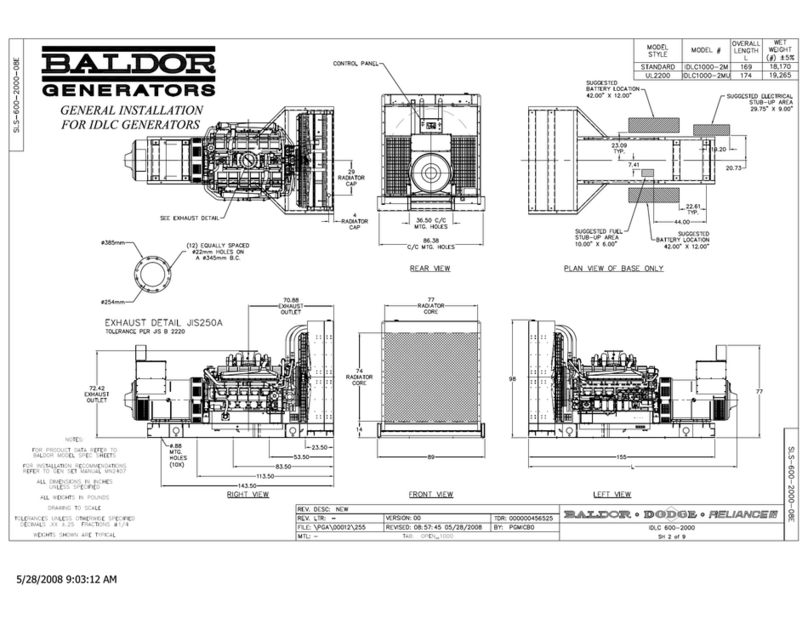

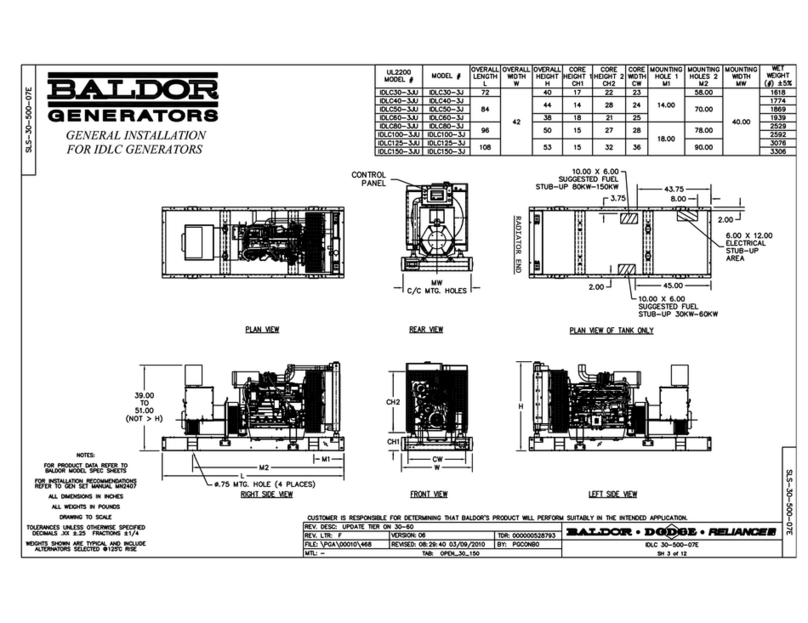

Size: Length x Width x Height

61" x 36 x 38 1/2

Drawing is for reference only: Contact your dealer for detailed information.

Farm Duty 1-Phase Model: DLC25

Alternator Specifications

Manufacturer Stamford/Newage

Type 4-Pole, Revolving field

Model BCI184F

Leads 4

Voltage regulator AVR

Voltage regulation 1/2%

Insulation material: Rotor Class H

Insulation material: Stator Class H

Temperature rise 125C, Standby

Total harmonic distortion <5%

Bearing: quantity, type 1, Sealed

Coupling type Flexible disc

One step load acceptance 100% of Rating

Warranty: Limited 3 year warranty.

1 year or 3000 hours parts and labor.

3 years or 3000 hours parts.

Baldor reserves the right to repair or replace unit.

Alternator Features

Brushless design

Class H insulation used throughout

Solid-state voltage regulation

Sealed bearings

All wound components impregnated with varnishes

and resins to protect against harsh environment

Alternator complies with temperature rise standards:

NEMA, IEEE and ANSI

Dynamically balanced rotors

Controller Features

PowerPAC 4

Hi temp, low oil pressure, overspeed and

overcrank indicators

AC Voltage, amperage and hertz meters

Oil pressure, water temperature and battery gauges

Hour meter

Panel lights

Engine Features

• Mechanical governor - speed control to ISO 3046-4 Class A1

• Spin-on full fuel flow filter

• Fuel pre-filter

• Spin-on full flow oil filter

• Oil cooler

• Thermostat controlled cooling system

• Gear driven water pump

• 12V engine alternator

• 12V starter motor

• Single side servicing

Engine Performance Continuous Standby

60 HZ

Rated RPM 1800 1800

Net BHP at rated 38.4 42.2

Baldor Generators

3815 Oregon Street

Oshkosh, WI 54902

800-872-7697 • 920-236-4200

Fax 920-236-4219

www.baldor.com

Distributed by:

36.00"

38.50"

61.00"

SAL-245-5M-DP