6. RFID Controller Connection: Connect the male end of a 5-pin,

male-to-female, ThinNet drop cable to the female end on your

Drop-T connector(s). Attach the remaining female end of the

ThinNet drop cable to the 5-pin, male, M12 connector on a

BIS U

,

BIS M-6xx

or

BIS M-41x (RS485 models)

. Repeat

Step 5

for

each RFID controller you plan to install.

Note: maximum drop cable length is 2 m.

Subnet16™ Power Supply Wiring: For ThinNet Networks: Using a 5-

pin, female, M12, ThinNet connector (

P/N: BCC06ZF

), make a power

cable and connect it to your power supply (SHIELD wire connected to

Earth). Attach the female, ThinNet end to the 5-pin, male, ThinNet end

on a Drop-T connector (

P/N: BCC07WR).

7. Gateway Power and Host Connection: Connect the Gateway to

the DeviceNet network via a DeviceNet-compatible interface

cable. The Gateway must be powered through pins V+ and V- of

the DeviceNet connector.

8. Power On: Turn both power supplies ON. The POWER LED on

the Gateway will remain lit while power is applied to the unit

through the DeviceNet connector.

9. Automatically Configure Subset16™ Node IDs: At this point all

controllers are powered and should have Node IDs set to 00, (all

controller Node LEDs = OFF), and Subnet16™ baudrate = 9600

(factory defaults).

a. Place the RFID Controller Configuration Tag in front of an

RFID Controller (the controller's RF Activity LED blinks once

indicating the tag has been read), and wait for the Gateway to

assign a valid Node ID to it. The controller's Node LEDs now

indicate a valid Node ID. Remove the Configuration Tag from

the controller.

b. Repeat this step for each node in the Subnet16™ network

(one controller at a time). The first is Node ID 1, then 2 and so

on up to 16 (binary).

The Subnet16™ network is now configured with the default values and

can communicate with the DeviceNet Gateway which in turn

communicates with the DeviceNet Master.

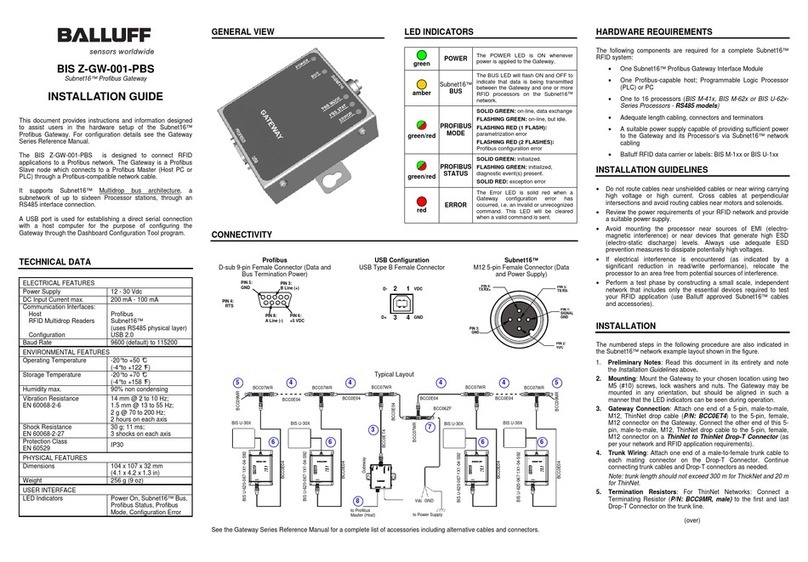

BIS Z-GW-001-DNT DEVICENET FACTORY DEFAULTS:

Node Address: 63; Baud Rate: 125 kbps

For further information or for application specific configuration using

the Dashboard Configuration Tool program, see the Gateway Manual.

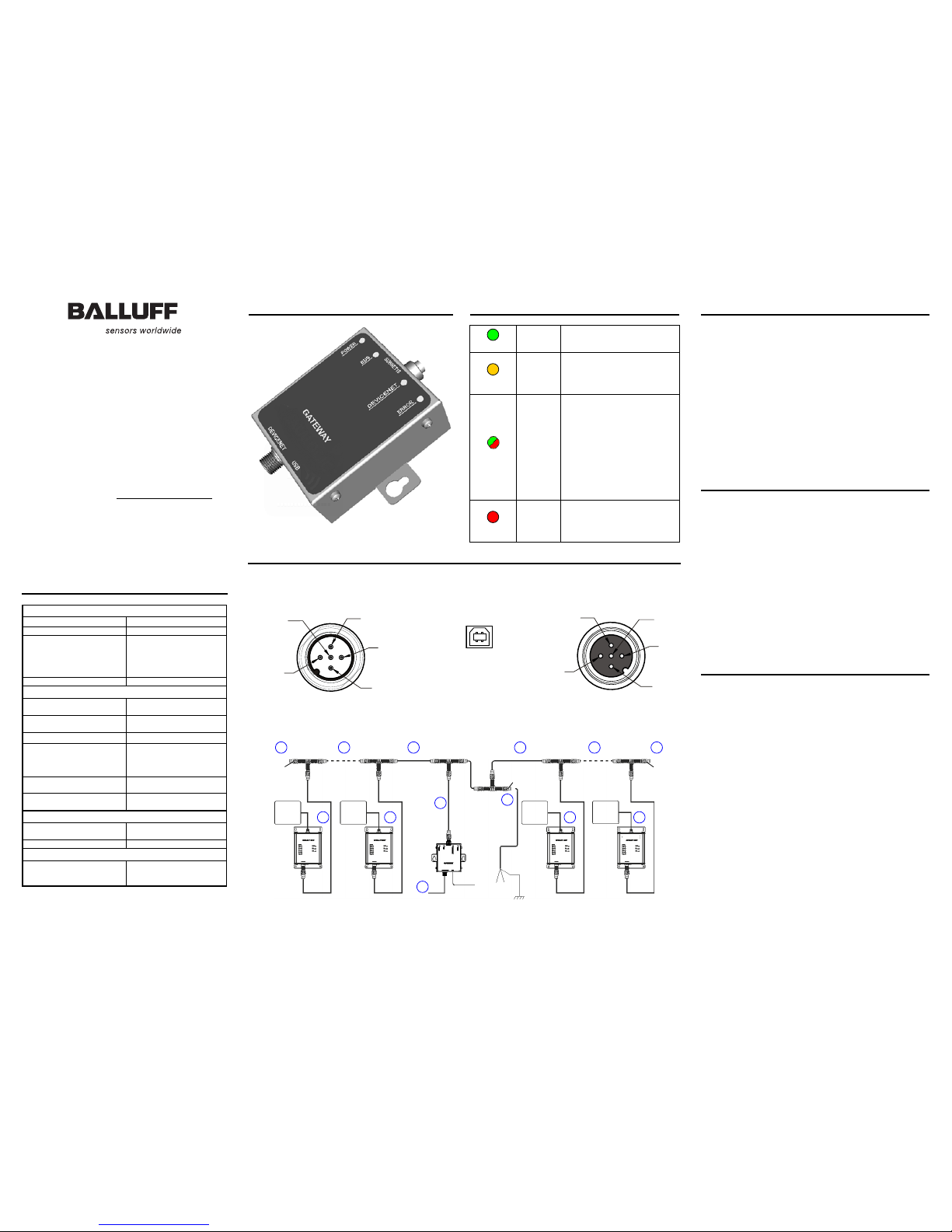

DIMENSIONS

POWER REQUIREMENTS

The DeviceNet Gateway requires an electrical supply voltage of

12 to 30 Vdc. It is powered through the DeviceNet network

connector.

In addition, each RFID controller connected to the Gateway via

the Subnet16™ network will also require power. This network is

powered separately. Use a regulated power supply that is

capable of delivering the requirements listed in the Technical

Features.

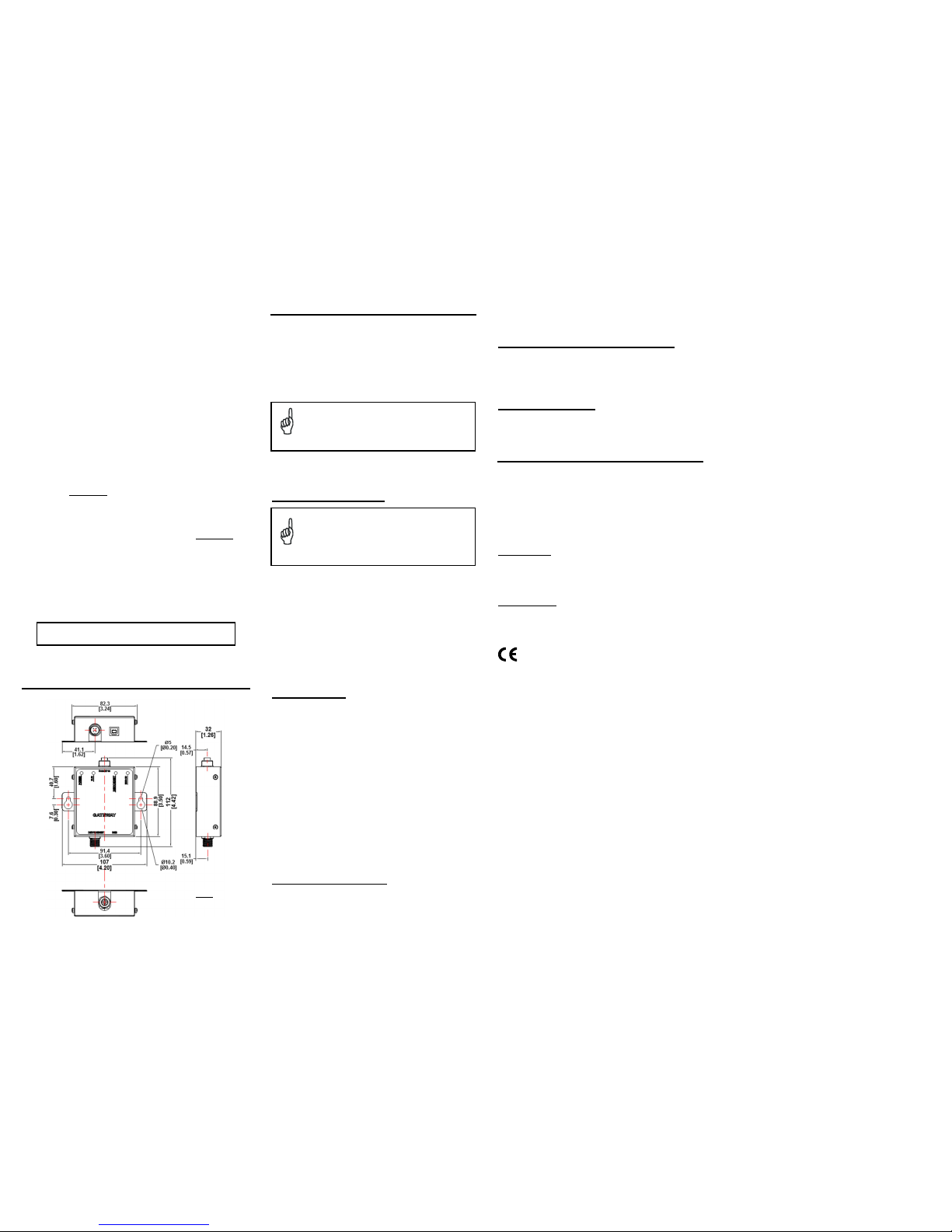

NOTE

Power is applied directly to the Subnet16™ Network

trunk and distributed through drop cables to the RFID

controllers. By positioning the power supply near the

middle of the network, you can limit voltage drop at the

ends, (see example layouts).

The following information is provided to assist you in

determining the power requirements of your RFID application.

System Current Consumption

NOTE

The current consumption values of each product are

given in the Technical Features paragraph of the relative

Installation manual and refer to the min and max input

voltage range. These values already include an

adequate safety margin. The consumption values given

in the following examples have been interpolated for an

input voltage of 24 Vdc.

Max Gateway Current: 200 mA @ 12 Vdc (133 mA @ 24 Vdc).

Max Processor Current: 366 mA @ 24 Vdc for BIS M-6xx-Series, 87

mA @ 24 Vdc for BIS M-41X-Series, etc. (refer to Processor ’s spec).

Calculating Subnet16™ System Current Consumption:

Subnet16™ System Current Consumption = (Max Controller

Current x Number of Controllers)

Example

A Subnet16™ network powered at 24 Vdc is composed of a BIS Z-GW-

001-DNT connecting eight BIS M-41X-485 Processor s.

Subnet16™ System Current Consumption = (0.087 A X 8)] = 0.696 A

Cable Voltage Drop

In addition, each RFID controller on the Subnet will experience a certain

amount of voltage drop dependingon the length of the cable.

Cable Resistance per Meter

•ThinNet = 0.058 ohms per meter per wire

•ThickNet = 0.0105 ohms per meter per wire

Calculating Voltage Drop

Voltage Drop = (Max Controller Current x Number of Controllers) x

(Cable Resistance per Meter perWire

1

x Cable length

in Meters)

Example

A Subnet16™ network is composed of a BIS Z-GW-001-DNT

connecting eight BIS M-41X-485 Processors (87 mA each @ 24 Vdc). A

total of 20 meters of ThinNet cables are used to connect the devices,

which have Cable Resistance = 0.058 Ohms per meter per wire. The

network power is 24 Vdc.

2

Voltage Drop = (0.087 A x 8 controllers) x [(0.058 x 2) x 20 meters] =

1.61 Vdc

24 Vdc - 1.61 = 22.39 Vdc at controller number 8

1

The resistance calculation must include both wires (Vdc and GND).

2

This example assumes the power supply is placed at the end of the

network, therefore controller #8 is the worst case. By placing the

power supply in the middle of the network the voltage drop at the

ends is reduced.

It is recommended that the voltage drop calculation be conducted on

the RFID controller that is farthest from the Gateway, as it will

experience the greatest voltage drop.

Max Supported Trunk and Drop Cable Lengths

•

ThickNet trunk length up to 300 m.

•

ThinNet trunk length up to 20 m.

•

ThinNet drop cable length up to 2 m.

Current Rating for Cables

The maximum current rating for the Subnet16™ network using

Balluff cables and accessories (BCCxxxx), is 4.0 A.

COMPLIANCE

This product is intended to be installed by Qualified

Personnel only.

This product must not be used in explosive environments.

See the Subnet16™ Gateway Manual for the Declaration of

Conformity.

Power Supply

This device is intended to be supplied by a UL Listed or CSA

Certified Power Unit with «Class 2» or LPS power source.

CE Compliance

Warning: This is a Class A product. In a domestic environment

this product may cause radio interference in which case the

user may be required to take adequate measures.

mm

in