BALMAR CENTERFIELDER-II

Installation & Operator’s Manual

INTRODUCTION

Designed for use in applications requiring balanced charge

control from two alternators and two regulators on twin

engines, the Centerfielder-II makes it possible to utilize the

combined output of both alternators to supply optimized

charging to a single large battery bank.

By monitoring the ignition and field voltages at port and

starboard regulators, the Centerfielder-II determines when

both engines are running, and directs field current from the

master (starboard) regulator to both alternators. By control-

ling both alternators with the same field source, the

Centerfielder-II ensures that alternators can work together

to ensure optimal charging at a single large battery bank.

INSTALLATION

The Centerfielder-II is easy to install. You will find, included

with the Centerfielder-II, a collection of wiring terminal

connectors as well as two fused 12-gauge RED wires

required to replace the standard 14-gauge (RED) power

wires in the Max Charge regulators’ wiring harnesses.

Use wire size calculation in alternator manual to determine

required wire size based on the length of wire run needed to

connect charging system components.

To install:

1. Disconnect batteries or turn battery switches to the

OFF position.

2. Install the Centerfielder-II on a bulkhead or other flat

surface that’s away from extreme heat or moisture.

Typically, the Centerfielder is mounted close to one or

the other voltage regulator.

3. Determine the distances and gauges required for wire

runs between the Centerfielder-II, the Max Charge

regulators and the port and starboard alternators.

4. Connect the supplied wiring connectors to their appro-

priate wires, as described to the right, and connect to

the Centerfielder, regulators and alternators as shown.

5. Remove the existing RED power wires from the Max

Charge wiring harnesses and replace with the

included, fused RED 12-gauge wires.

6. Re-connect batteries and start engines. Indicator LEDs

will light as the Centerfielder-II controls field output

from the regulators to the two alternators.

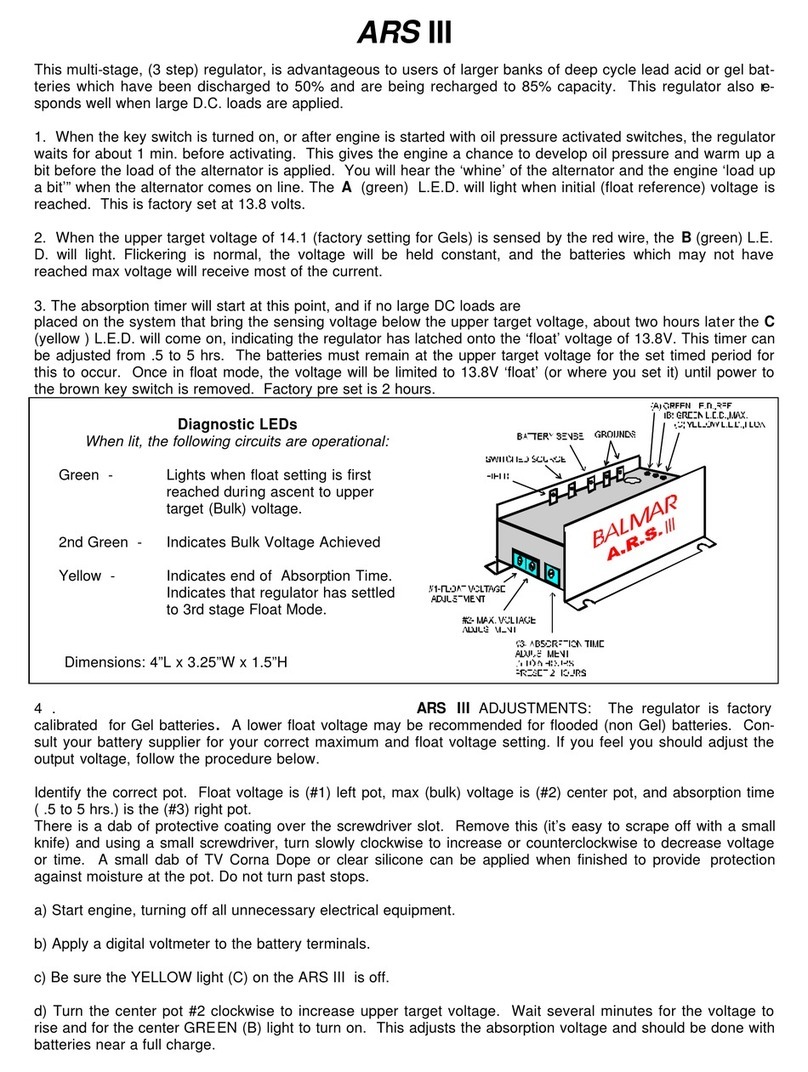

1

2

3

5

4

6

7 8 9 10 12

11

17

13

14

15

16

18

19

20

21

BALMAR CENTERFIELDER II

Terminal and Lamp Layout

NOTE: Starboard regulator is the MASTER regulator. The port regulator field

output is disconnected when both engines are running

1. PORT REGULATOR FIELD INPUT TERMINAL - Connect Terminal #1 to port voltage

regulator’s Field Output terminal via a user-supplied 12-gauge BLUE wire. A female 1/4”

spade terminal is supplied for connection to Terminal #1. The 12-gauge BLUE wire will

replace the regulator’s 14-gauge field wire.

2. PORT ALTERNATOR FIELD OUTPUT TERMINAL - Connect Terminal #2 to the port

alternator’s field input terminal via a user supplied 12-gauge BLUE wire. A female 1/4” spade

terminal is supplied for connection to Terminal #2. Alternator-side termination will vary based

on alternator, and may require a user-supplied spade or ring terminal connector, depending

on the alternator configuration.

3. PORT “IGNITION ACTIVATED” LED (RED) - Indicates activation of port voltage regulator’s

ignition wire. If LED is illuminated, but the port voltage regulator is inactive, check for voltage

at the regulator’s ignition terminal.

4. PORT REGULATOR IGNITION - Connect Terminal #4 to the port voltage regulator’s

BROWN ignition wire. A BROWN 14-Gauge user-supplied wire is recommended. A female

1/4” spade terminal is supplied with the Centerfielder II.

5. PORT IGNITION INPUT - Connect Terminal #5 to the port engine ignition switch or port

engine oil pressure switch. Terminal #5 must see zero volts when the port engine is turned

off, and battery voltage when the port engine is running. BROWN 14-Gauge user-supplied

wire is recommended. A female 1/4” spade terminal is supplied for connection to Terminal

#5.

6. PORT REGULATOR DASH LAMP TERMINAL - Connect Terminal #6 to the port voltage

regulator’s dash lamp terminal via a user supplied 16-gauge wire. Female 1/4” spade termi-

nals are supplied for connection to Terminal #6.

7. PORT DASH LAMP TERMINAL - Connect Terminal #7 to the port dash lamp via a user

supplied 16-gauge wire. Female 1/4” spade terminals are supplied for connection to Termi-

nal #7.

8. PORT “DASH LAMP” LED (RED) - Indicates activation of port voltage regulator’s Dash

Lamp terminal. Activation of the Dash Lamp may occur as a result of high or low voltage,

high alternator or high battery temperature. If LED is illuminated, inspect the port voltage

regulator long display for advisory codes.

9. GROUND TERMINAL - Connect Terminal #9 to system ground via 14-gauge BLACK wire.

A female 1/4” spade terminal is supplied for connection to Terminal #9. Termination to

system ground will require a user-suppled spade or ring terminal connector, depending on

the ground location chosen. ALL GROUND CONNECTIONS MUST BE COMMON.

10. STARBOARD “DASH LAMP” LED (GREEN) - Indicates activation of starboard voltage

regulator’s Dash Lamp terminal. Activation of the Dash Lamp may occur as a result of high

or low voltage, high alternator or high battery temperature. If LED is illuminated, inspect the

starboard voltage regulator long display for advisory codes.

11. STARBOARD REGULATOR DASH LAMP TERMINAL - Connect Terminal #11 to the

starboard voltage regulator’s dash lamp terminal via a user supplied 16-gauge wire. Female

1/4” spade terminals are supplied for connection to Terminal #11.

12. STARBOARD DASH LAMP TERMINAL - Connect Terminal #12 to the starboard dash lamp

via a user supplied 16-gauge wire. Female 1/4” spade terminals are supplied for connection

to Terminal #12, and for connection to the starboard regulator’s dash lamp.

13. COMMUNICATIONS PORT - Factory use only.

14. COMMUNICATIONS PORT - Factory use only.

15. COMMUNICATIONS PORT - Factory use only.

16. STARBOARD IGNITION INPUT - Connect Terminal #16 to the starboard ignition switch

or starboard engine oil pressure switch. Terminal #16 must see zero volts when the

starboard engine is turned off, and battery voltage when the starboard engine is

running. BROWN 14-Gauge user-supplied wire is recommended. A female 1/4” spade

terminal is supplied for connection to Terminal #16.

17. STARBOARD REGULATOR IGNITION - Connect Terminal #17 to the starboard voltage

regulator’s BROWN ignition wire. A BROWN 14-Gauge user-supplied wire is recom-

mended. A female 1/4” spade terminal is supplied for connection to Terminal #17.

18. STARBOARD “IGNITION ACTIVATED” LED (GREEN) - Indicates activation of

starboard voltage regulator’s ignition wire. If LED is illuminated, but the starboard

voltage regulator is inactive, check for voltage at the regulator’s ignition terminal.

19. STARBOARD ALTERNATOR FIELD OUTPUT TERMINAL (MASTER) - Connect

Terminal #19 to the starboard alternator’s field input terminal via a user supplied

12-gauge BLUE wire. A female 1/4” spade terminal is supplied for connection to Termi-

nal #19. Alternator-side termination will require a user-supplied spade or ring terminal

connector, depending on the alternator configuration.

20. STARBOARD REGULATOR FIELD INPUT TERMINAL (MASTER) - Connect Terminal

#20 to starboard voltage regulator’s Field Output terminal via a user-supplied 12-gauge

BLUE wire. A female 1/4” spade terminal is supplied for connection to Terminal #20. The

12-gauge BLUE wire will replace the regulator’s 14-gauge field wire.

21. “COMBINE” LED (AMBER) - Indicates activation of port and starboard alternators and

voltage regulators. The Centerfielder-II will continue to supply balanced field current to

both port and starboard alternators when the LED is activated.

SUP-0200 | REVA