97227 v.7.0 3

Limitation of Warranty

Gale Banks Engineering Inc. (hereafter

“SELLER”), gives Limited Warranty as

to description, quality, merchantability,

fitness for any particular purpose,

productiveness, or any other matter of

SELLER’s product sold herewith. The

SELLER shall be in no way responsible

for the product’s open use and service

and the BUYER hereby waives all rights

except those expressly written herein.

This Warranty shall not be extended

or varied except by written instrument

signed by SELLER and BUYER.

Please see enclosed warranty

information card, or go to

www.bankspower.com/warranty,

for warranty information regarding

your product. Parts or devises outside

the products kit, such as the Palm®

Tungsten™ E2, are not covered under

Gale Banks Engineering warranty. The

warranty for the Palm Tungsten E2

is determined by the manufacturer’s

warranty terms and conditions, and

limited to a period of 90 days from

purchase. All products that are in

question of Warranty must be returned

shipping prepaid to the SELLER and

must be accompanied by a dated proof

of purchase receipt. All Warranty claims

are subject to approval by Gale Banks

Engineering Inc.

WARNING: The PDA may be

susceptible to damage as a

result of extended exposure

to sunlight, heat or extreme

cold. It is highly recommended

that the PDA be removed from

its mounting location if the

vehicle will be subjected to high

concentrations of sunlight, heat

or cold for an extended period

of time. Gale Banks Engineering

is not responsible for damage to

PDAs resulting from exposure

conditions.

Under no circumstance shall the SELLER

be liable for any labor charged or travel

time incurred in diagnosis for defects,

removal, or reinstallation of this product,

or any other contingent expense.

Under no circumstances will the SELLER

be liable for any damage or expenses

incurred by reason of the use or sale of

any such equipment.

In the event that the buyer does

not agree with this agreement:

The buyer may promptly return

this product, in a new and unused

condition, with a dated proof-of-

purchase, to the place-of-purchase

within thirty (30) days from date-

of-purchase for a full refund, less

shipping and/or restocking fee.

The installation of this product

indicates that the buyer has read

and understands this agreement

and accepts its terms and

conditions.

Table of Contents

General Installation .............4

Practices

Section 1 ......................6

Installation of Banks SpeedBrake Wire

Harness

Section 2 .....................16

Mounting The Docking Station and

Connecting The Banks PowerPDA

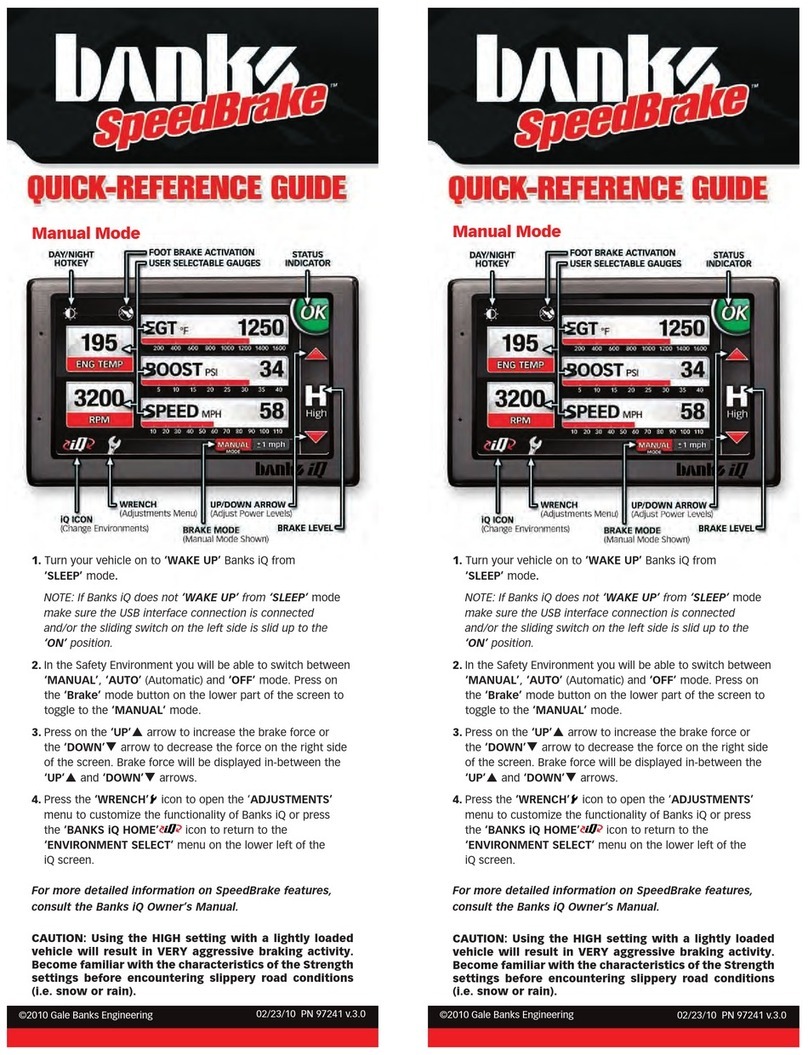

Section 3 .....................20

Banks SpeedBrake PowerPDA Software

& Installation

Section 4 .....................22

Placement of the Banks Power Decal