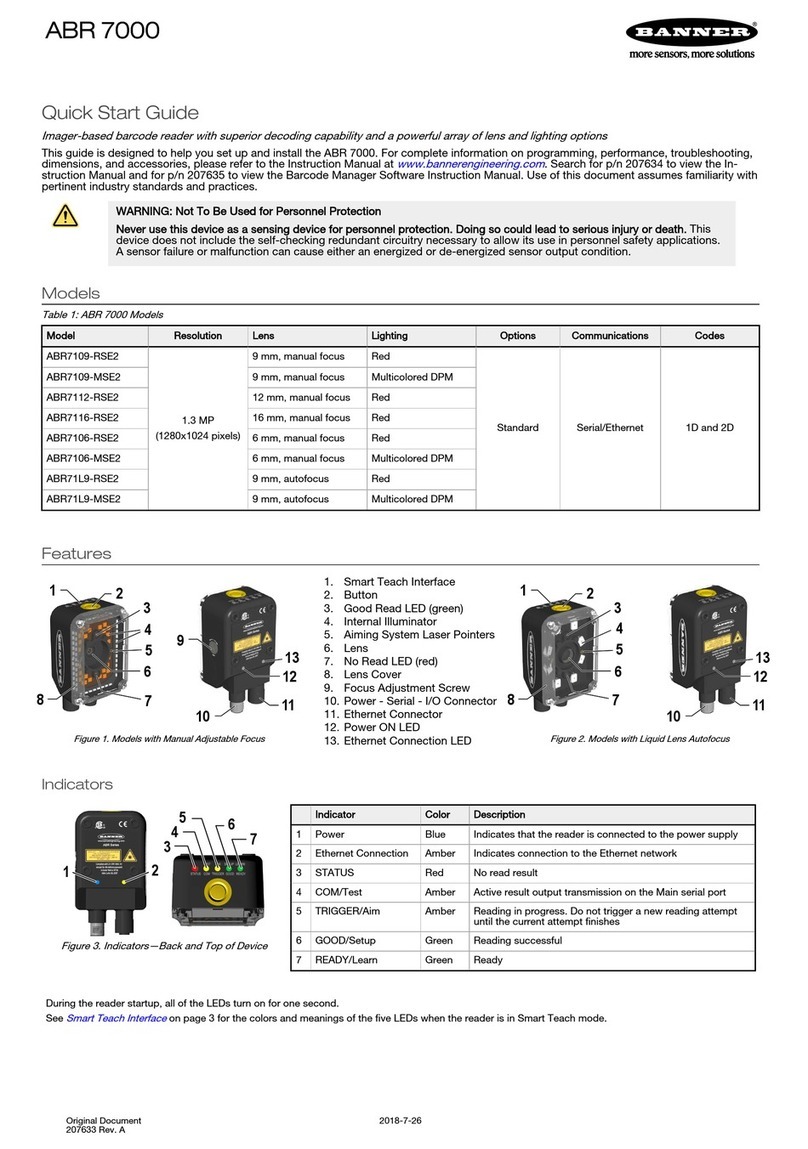

Specifications

Supply Voltage

10 V dc to 30 V dc

Consumption

0.7 A (at 10 V dc) to 0.2 A (at 30 V dc) maximum

Communication Interface

Main RS232 or RS422 full duplex: 2400 bit/s to 115200 bit/s

Auxiliary - RS232: 2400 to 115200 bit/s

Ethernet 10: 10/100 Mbit/s

Inputs

Input 1 (External Trigger) and Input 2 opto-isolated and polarity insensitive

Outputs

3 NPN/PNP/Push-Pull software selectable, reverse polarity and short circuit protec-

ted outputs available (2 Opto-isolated outputs instead if using TCNM-ACBB1)

Optical Features

See the Instruction Manual for details

LED Safety: LED emission according to EN 62471

Imager

1.3 MP: 1280 × 1024 pixels, SXGA, 60 frames/second

2.0 MP: 1600 × 1200 pixels, 45 frames/second

Construction

Aluminum, plastic window

Operating Conditions

Operating Temperature 11: 0 °C to +50 °C (+32 °F to +122 °F)

Liquid lens models Operating Temperature 11: 0 °C to +45 °C (+32 °F to +113 °F)

Storage Temperature: –20 °C to +70 °C (–4 °F to +158 °F)

90% maximum relative humidity (non-condensing)

Environmental Rating

IEC IP67 12

Parameter Storage

Permanent memory (Flash)

Other

Smart Teach Button (configurable via Barcode Manager), Beeper

Required Overcurrent Protection

WARNING: Electrical connections must be made by

qualified personnel in accordance with local and na-

tional electrical codes and regulations.

Overcurrent protection is required to be provided by end product application per the

supplied table.

Overcurrent protection may be provided with external fusing or via Current Limiting,

Class 2 Power Supply.

Supply wiring leads < 24 AWG shall not be spliced.

For additional product support, go to www.bannerengineering.com.

Supply Wiring (AWG) Required Overcurrent Protection (Amps)

20 5.0

22 3.0

24 2.0

26 1.0

28 0.8

30 0.5

Certifications

Barcode Types

1-D and stacked 2-D POSTAL

• PDF417 Standard and Micro

PDF417

• Code 128 (GS1-128)

• Code 39 (Standard and Full

ASCII)

• Code 32

• MSI

• Standard 2 of 5

• Matrix 2 of 5

• Plessey

• Interleaved 2 of 5

• Codabar

• Code 93

• Pharmacode

• EAN-8/13-UPC-A/E (includ-

ing Addon 2 and Addon 5)

• GS1 DataBar Family

• Composite Symbologies

• Data Matrix ECC 200 (Stand-

ard, GS1 and Direct Marking)

• QR Code (Standard and Di-

rect Marking)

• Micro QR Code

• MAXICODE

• Aztec Code

• Dotcode

• Australia Post

• Royal Mail 4 State Customer

• Kix Code

• Japan Post

• PLANET

• POSTNET

• POSTNET (+BB)

• Intelligent Mail

• Swedish Post

FCC Statement

Modifications or changes to this equipment without the expressed written approval of Banner Engineering could void the authority to use the equipment.

This device complies with PART 15 of the FCC Rules. Operation is subject to the following two conditions: (1) This device may not cause harmful interference, and (2) this device

must accept any interference received, including interference which may cause undesired operation.

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequen-

cy energy and, if not installed and used in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference in which case the user will be required to correct the interference at his own expense.

PC Requirements—Barcode Manager

Administrative rights are required to install the Barcode Manager software.

Operating System

Microsoft® Windows® operating system version 7, 8, or 10 13

Barcode Manager does not currently support Windows Embedded (often used in in-

dustrial PCs and/or PLCs)

System Type

32-bit or 64-bit

Hard Drive Space

2 GB hard disk for 64-bit machines; 1 GB hard disk for 32-bit machines

Memory (RAM)

1 GB RAM

Processor

2.00 GHz or faster microprocessor

Screen Resolution

One 19-inch or larger monitor, optimized for 1280×1024 resolution

Third-Party Software

Web Browser: Google Chrome, Mozilla Firefox, Microsoft Internet Explorer, Opera,

etc.

Connection

100 Base-T Ethernet

10 The Ethernet interface is compatible with the following application protocols: TCP/IP, EtherNet/lP™, MODBUS® TCP, SLMP, PROFINET®. (The ABR is PROFINET compatible but not PROFINET certified.)

11 High ambient temperature applications should use metal mounting bracket for heat dissipation.

12 IEC IP67 when correctly connected to IP67 cables with seals.

13 Microsoft and Windows are registered trademarks of Microsoft Corporation in the United States and/or other countries.

ABR 7000

P/N 207633 Rev. D 7