FLOJET N5100-010 Guide

This manual suits for next models

7

Other FLOJET Water Pump manuals

FLOJET

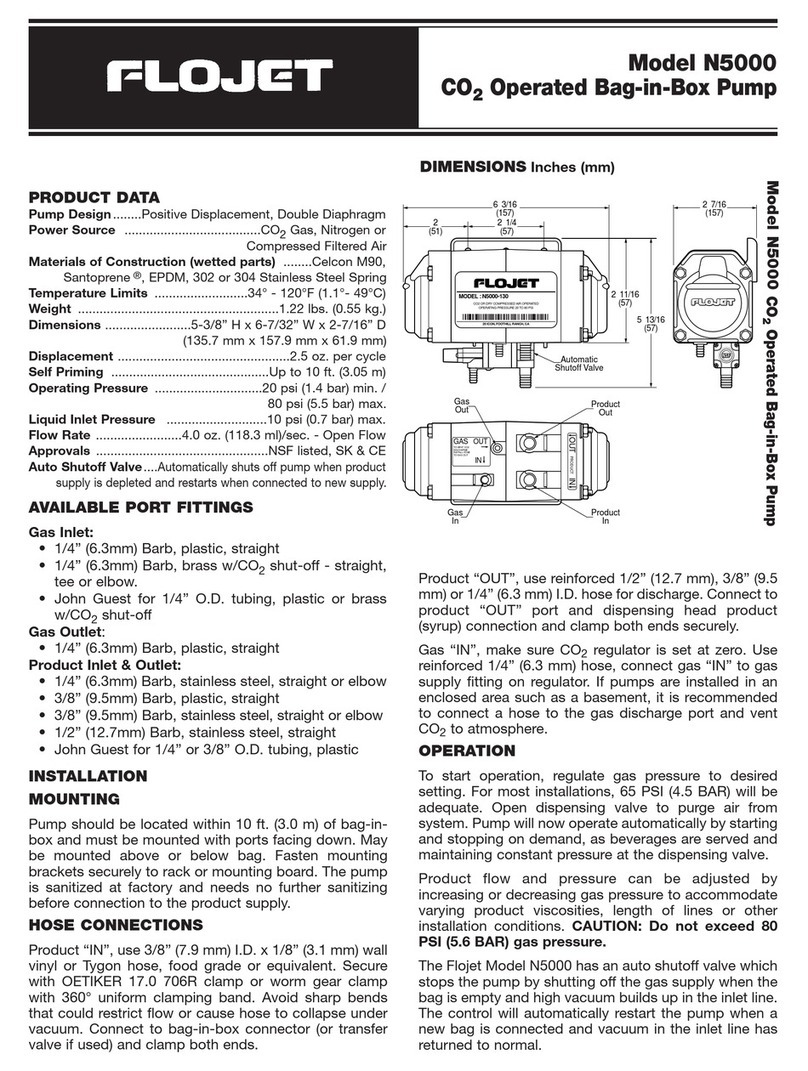

FLOJET N5000 Series Operation manual

FLOJET

FLOJET G-57 Series Installation instructions

FLOJET

FLOJET 03526-144 User manual

FLOJET

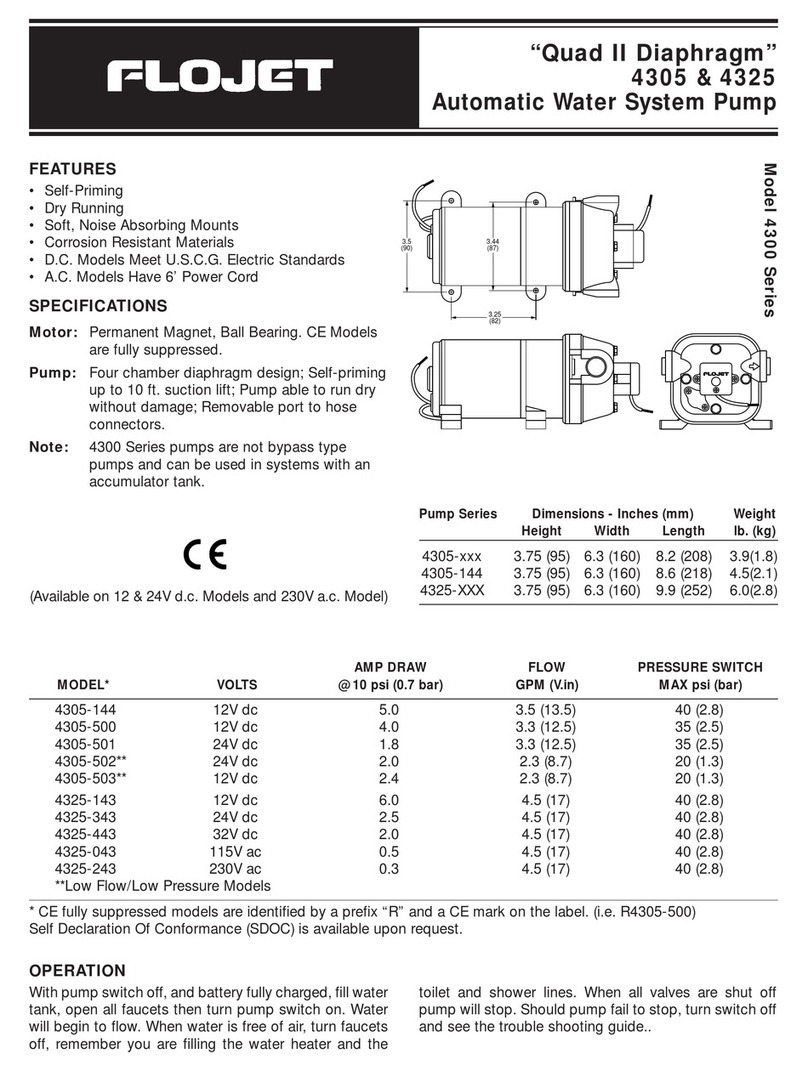

FLOJET 4300 Series User manual

FLOJET

FLOJET R4515-743 User manual

FLOJET

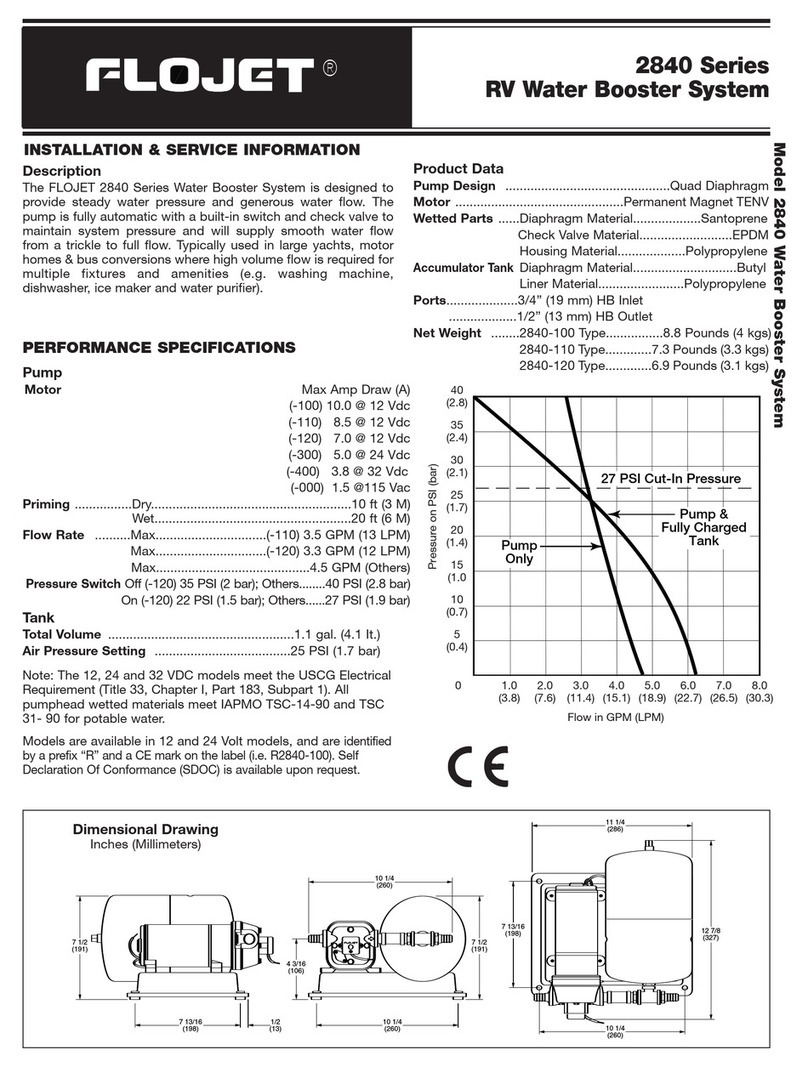

FLOJET 02840100A Operating and installation instructions

FLOJET

FLOJET 3426 series User manual

FLOJET

FLOJET 4305-144 User manual

FLOJET

FLOJET BevJet Compact User manual

FLOJET

FLOJET R3B21 Series User manual

FLOJET

FLOJET R3526144 User manual

FLOJET

FLOJET quad II diaphragm 4125 series User manual

FLOJET

FLOJET 4105 Series User manual

FLOJET

FLOJET G56 User manual

FLOJET

FLOJET N5100 Series Guide

FLOJET

FLOJET N5000 User manual

FLOJET

FLOJET G70C Series Owner's manual

FLOJET

FLOJET G257 Series Guide

FLOJET

FLOJET 2100-12 User manual

FLOJET

FLOJET 2125 Series User manual

Popular Water Pump manuals by other brands

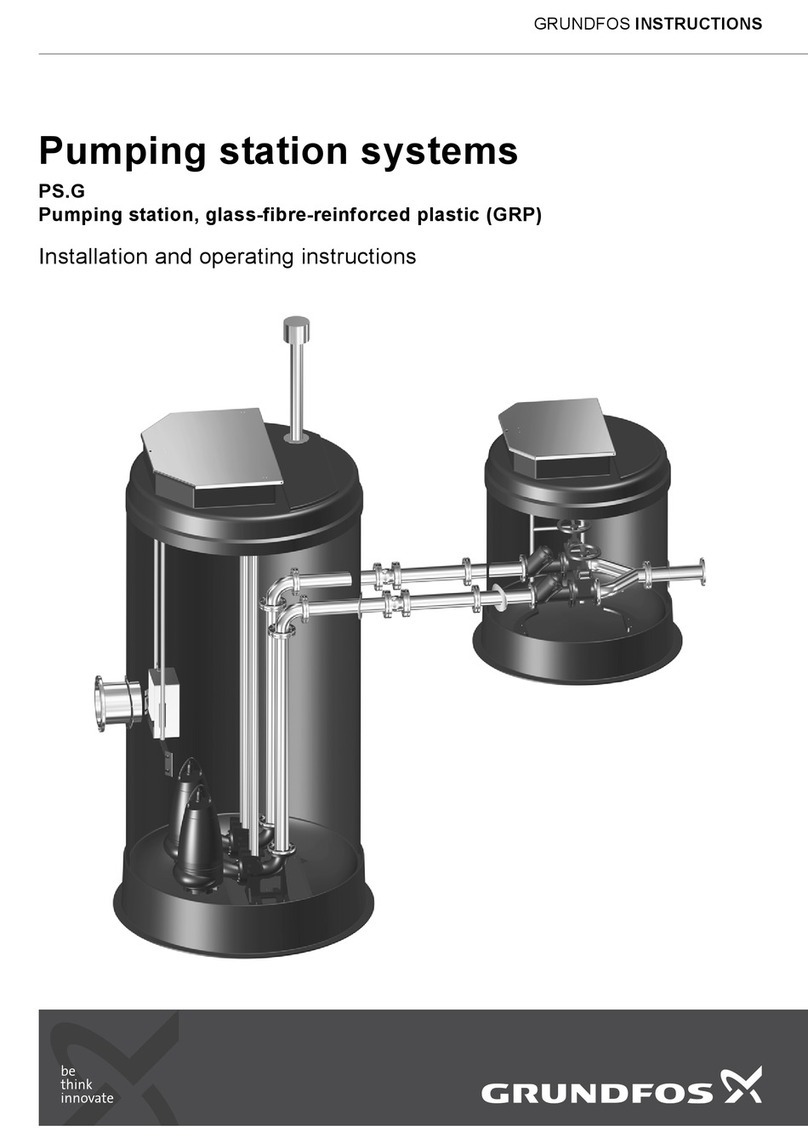

Grundfos

Grundfos PS.G Series Installation and operating instructions

Becker

Becker SV 5.250 operating instructions

KNF

KNF NF 25 Series Operating and installation instructions

Barnes

Barnes 3SE-DS Series Installation and operation manual

BOC Edwards

BOC Edwards E1M175S instruction manual

Wheaton

Wheaton OmniSpense ELITE Series instruction manual

Franklin Pump Systems

Franklin Pump Systems DDD Series owner's manual

BUSCH

BUSCH DOLPHIN LG 0890 A instruction manual

Pentair

Pentair SHURFLO 802 Series Installation and operation manual

Xylem

Xylem Bell & Gossett e-80SCXL Series instruction manual

GORMAN-RUPP PUMPS

GORMAN-RUPP PUMPS PA Series Installation, operation and maintenance manual

WilTec

WilTec PW600 instruction manual