22

CONTENTCONTENT

FOREWORDFOREWORD……………………..............………………………………………………………………………………………………………………………………………………..3..3

1 1 GENERAGENERAL .............................................................L ................................................................................................................................................................................................................. ................ 44

1.1 1.1 INTRODUCTIOINTRODUCTIONN

––MAINTENANCE MAINTENANCE SAFETY SAFETY PRECAUTIO PRECAUTIO ................................................................................................................ 44

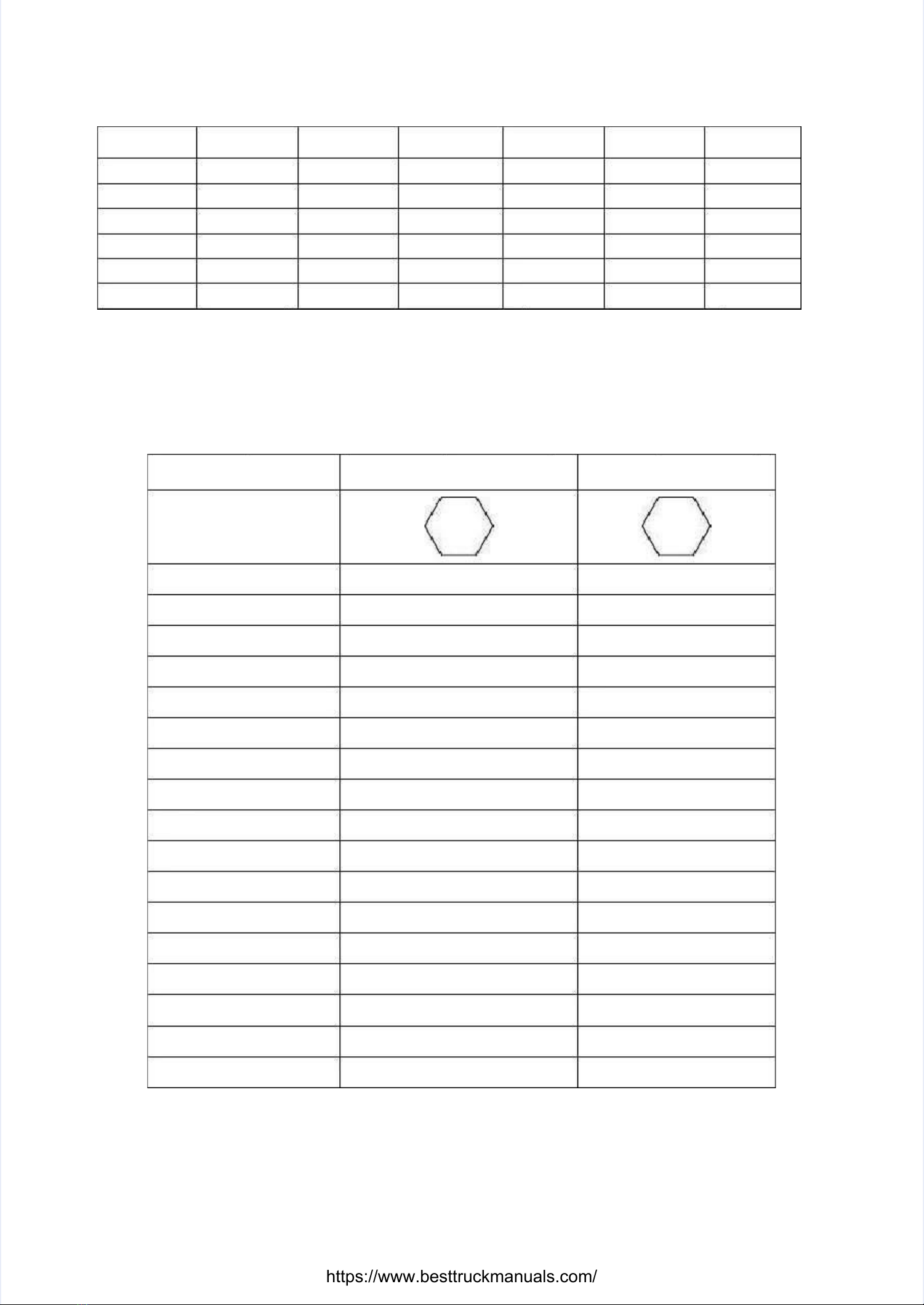

1.2 1.2 MEASUREMEASUREMENT MENT CONVERCONVERSIONS .......................SIONS ................................................................................................................................................................ ..... 77

2 2 SPECIFICASPECIFICATION ........................................TION ........................................................................................................................Errore. Il segnalibro non è Errore. Il segnalibro non è definito.definito.

2.1 OVERVIEW OF 2.1 OVERVIEW OF MAIN COMPONENTS .....................MAIN COMPONENTS ...............................................Errore. Il segnalibro non è Errore. Il segnalibro non è definito.definito.

2.2 2.2 TECHNICATECHNICAL L PARAMETEPARAMETER R TABLE .....................TABLE ............................................................................................................................................................ 14... 14

2.3 2.3 LUBRICATIOLUBRICATION N ............................................................................................................................................................................................................................. 16......................... 16

3 3 ELECTRICAELECTRICAL L SYSTEM SYSTEM ............................................................................................................................................................................................................................. ................... 1717

3.1 3.1 ELECTRIC ELECTRIC DIAGRAM DIAGRAM .................................................................................................................................................................................................................... ............ 1717

3.2 3.2 ELECTRIC ELECTRIC INSTALLATIOINSTALLATION..................................N........................................................................................................................................................................... . 1818

3.3 3.3 DRIVING DRIVING WHEEL ...............WHEEL ............................................................................................................................................................................................................................ ... 2020

3.4 3.4 HYDRAULIC HYDRAULIC POWER POWER UNIT UNIT ...................................................................................................................................................................................................... 21........ 21

3.5 3.5 BATTERY BATTERY COMPONCOMPONENTS ........................................ENTS .......................................................................................................................................... 23.............................. 23

3.6 3.6 CONTROLLCONTROLLER ER ............................................................................................................................................................................................................................. ......................... 2424

3.7 3.7 BATTERY CHARGING BATTERY CHARGING AND AND REPLACEMEREPLACEMENT NT ........................................................................................................................................... 26....... 26

3.8 3.8 ELECTRICAELECTRICAL L COMPONECOMPONENTS NTS REPLACEMEREPLACEMENT NT ......................................................................................................................................... 31. 31

3.9 TOOL 3.9 TOOL FOR REPAIRING THE PIN FOR REPAIRING THE PIN OF ELECTRIC PLUG...........................................OF ELECTRIC PLUG......................................................... 37.............. 37

4 4 HYDRAULIC HYDRAULIC SYSTEM .........................................SYSTEM ........................................................................................................................................................................................... 38.............. 38

4.1 CLEANING TA4.1 CLEANING TANK AND FILTER.................................................................................NK AND FILTER...............................................................................................39..............39

4.4.2 CHANGE OF PUMP 2 CHANGE OF PUMP STATION..................................................................................................40STATION..................................................................................................40

4.3 REPLACE THE HYDRA4.3 REPLACE THE HYDRAULIC OIL...................................................ULIC OIL.............................................................................................41..........................................41

4.4 REPLACE THE FILTER.............................................................................................................424.4 REPLACE THE FILTER.............................................................................................................42

4.5 REPLACE CARBO4.5 REPLACE CARBON BRUSH.....................................................................N BRUSH....................................................................................................43...............................43

4.6 ADJUST THE PUMP PRESS4.6 ADJUST THE PUMP PRESSURE.............................................................................................45URE.............................................................................................45

5 DRIVING WHEEL.5 DRIVING WHEEL.................................................................................................................................46................................................................................................................................46

5.1 REPLACE THE DRIVE WHEE5.1 REPLACE THE DRIVE WHEELS.........................................................................................LS..............................................................................................47.....47

5.2 ADJUST THE BRAKE OF THE AIR GAP.................................................................................495.2 ADJUST THE BRAKE OF THE AIR GAP.................................................................................49

6 HAND SHANK.6 HAND SHANK......................................................................................................................................50.....................................................................................................................................50

6.1 REMOVE THE HANDLE............................................................................................................516.1 REMOVE THE HANDLE............................................................................................................51

6.2 REPLACE THE GAS SPRING6.2 REPLACE THE GAS SPRING..........................................................................................................................................................52............................................52

6.3 CHANGE THE INTERLOC6.3 CHANGE THE INTERLOCK SWITCH.......................................................................................53K SWITCH.......................................................................................53

6.4 REPLACE THE HANDLE HEA6.4 REPLACE THE HANDLE HEAD.....................................................D...............................................................................................55..........................................55

7 CASTER.7 CASTER...............................................................................................................................................57..............................................................................................................................................57

7.1 CASTER OPERA7.1 CASTER OPERATION......................................................................................TION..............................................................................................................57........................57

8 8 LABELS LABELS ................................................................................................................................................................................................................................................................................................ 6060

9 9 MAINTENANCE MAINTENANCE LIST ...........................................LIST ........................................................................................................................................................................................................... 6262

10 10 FAULT FAULT ANALYSIANALYSIS S .......................................................................................................................................................................................................................................................... 6464