Installation and Operating Instructions

Duct and Outside Air Humidity (H200-H300)

4 to 20mA or 0 to 5V Humidity Output with Optional Temperature Sensor

Building Automation Products, Inc., 750 North Royal Avenue, Gays Mills, WI 54631 USA

T

el:+1-608-735-4800 • Fax+1-608-735-4804 • E-mail:

[email protected] • Web:www

.bapihvac.com

9938_ins_hum_temp_duct_out_5_20

3 of 4

rev. 02/15/18

Specications subject to change without notice.

Specications

Power:

10 to 35 VDC For 0 to 5 VDC or 4 to 20 mA Humidity Outputs

12 to 27 VAC For 0 to 5 VDC Humidity Output

Power Consumption:

22 mA max. DC For 0 to 5 VDC or 4 to 20 mA Humidity Outputs

0.53 VA max. AC For 0 to 5 VDC Humidity Output

Sensor: Factory corrected @17 RH points (10 to 90% RH)

Humidity Capacitive Polymer

RH Accuracy ±2% @ 73°F (23°C) from 10 to 90%

Drift 0.5% per year

Response time < 5 seconds in moving air

RH Linearity Negligible, factory corrected linear from 10 to 90%

RH Hysteresis Factory corrected to <1%

Opt. Temp. Passive RTD or Thermistor

Filter: 80 micron sintered stainless steel lter

Calibrated Accuracy: Calibration @17 RH points, (10% to 90%)

RH 2% 2% from 10 to 90% @ 73°F (23°C), Non-condensing

RH 3% 3% from 10 to 95% @ 73°F (23°C), Non-condensing

Thermistor ±0.36ºF (0.2ºC) from 32 to 158ºF (0 to 70ºC) - High accuracy units are available

RTD ±0.55ºF (0.31ºC) @ 32ºF (0ºC) - High accuracy units are available

Output: Selectable via wiring detail

Humidity 0 to 5VDC or 4 to 20mA at 0 to 100% RH

Opt. Temp. Resistance RTD or Thermistor

Humidity Output Impedance:

Current 700W@ 24VDC, Voltage drop is 10VDC

(Supply Voltage DC – Transmitter voltage drop 10VDC) / 0.02 Amps = Max load Impedance

Voltage 10KW

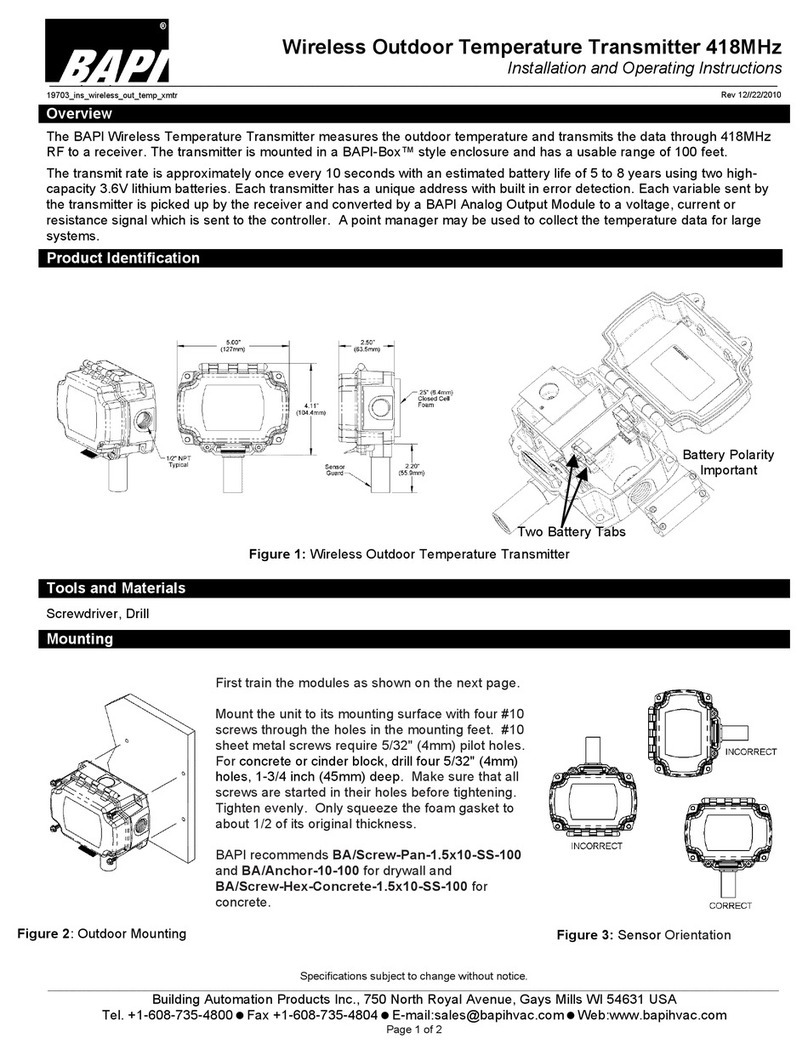

Probe Length:

Duct 5.3” (13.5cm) Duct Insertion, 1” diameter

Outside Air 2.4” (6.1cm) Below Enclosure, 1” diameter

Dimensions: W x H x D

Weatherproof (WP) 2.75” x 4.5” x 2.2”, (70 x 114 x 55 mm)

Weather Tight (EU) 4.1”x 3.8” x 2.1”, (105 x 97 x 54 mm)

BAPI-Box (BB) 4.15” x 5” x 2.5”, (105.4 x 127 x 63.5mm)

BAPI-Box 2 (BB2) 4.9” x 2.8” x 2.35”, (124.8 x 71.6 x 59.7mm)

Termination: Open wire

Crimp 18 to 26 AWG with Sealant Filled Crimp Connector (BA/SFC1000-x00)

Wire Nut 26 to 16 AWG with Sealant Filled Wire Nut (BA/SFC2000-x00)

Enclosure Material:

Weatherproof (WP) Cast Aluminum

Weather Tight (EU) ABS plastic, UV resistant

BAPI-Boxes (BB, BB2) Polycarbonate, UV resistant

Enclosures Ratings:

Weatherproof (WP) NEMA-3R

Weather Tight (EU) IP66, UL94V-0

BAPI-Boxes (BB, BB2) NEMA-4, IP66, UL94V-0

Environmental Operation Range: -40º to 158ºF (-40º to 70ºC) • 0% to 100% RH

Approvals: RoHs