1 (E)

WLL-CA50

Table of Contents

Manual Structure

Purpose of this manual ........................................................................................ 5 (E)

Relative manuals ................................................................................................. 5 (E)

Contents ............................................................................................................... 6 (E)

1. Service Overview

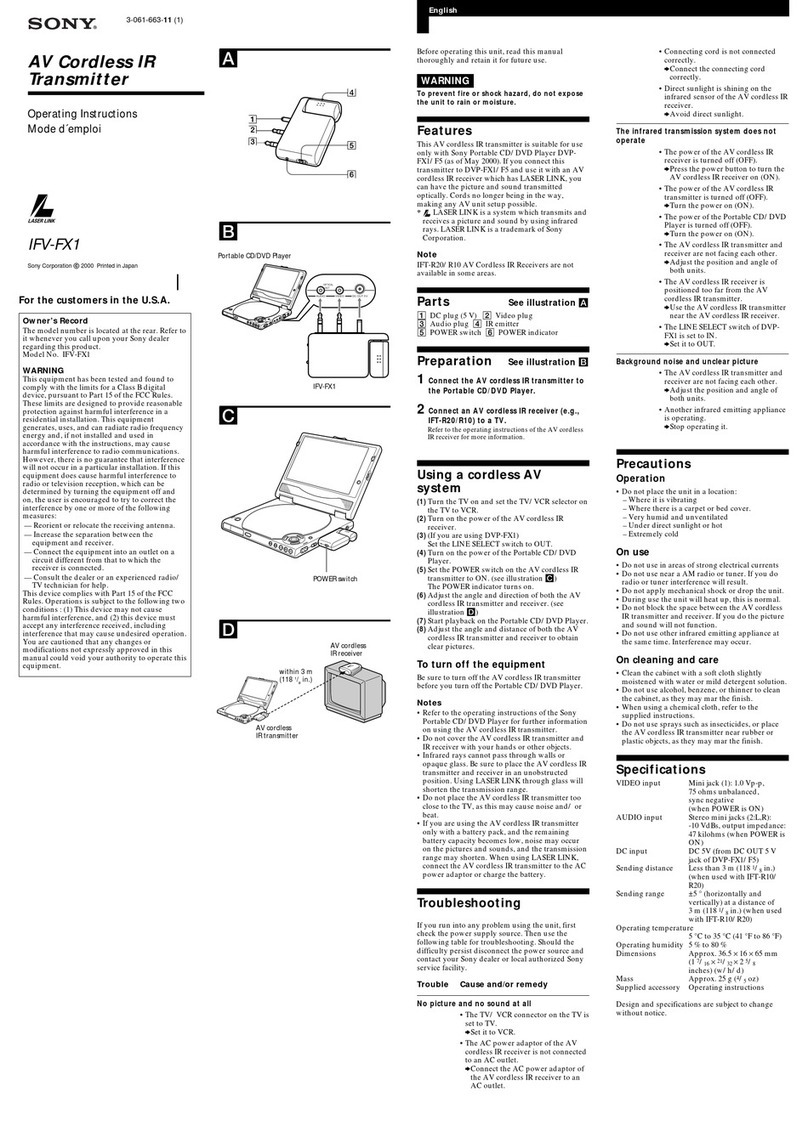

1-1. Connector Input/Output Signals............................................................1-1 (E)

1-2. Connection Connector/Cable ................................................................1-2 (E)

1-3. Removing/Reinstalling the Exterior Parts.............................................1-2 (E)

1-4. Board Location......................................................................................1-3 (E)

1-5. Circuit Description ................................................................................1-3 (E)

1-5-1. Video/Audio Signals (DPR-231 Board)...............................1-3 (E)

1-5-2. System Control (IF-914 Board) ..........................................1-4 (E)

1-5-3. Power Supply Block (PS-645 Board) ..................................1-4 (E)

1-6. Setting of Internal Switches ..................................................................1-5 (E)

1-7. Flexible Card Wire ................................................................................1-5 (E)

1-7-1. Removing/Reinstalling the Flexible Card Wires .................1-5 (E)

1-7-2. Forming the Flexible Card Wire ..........................................1-6 (E)

1-8. Removing/Reinstalling the PS-645 board and Transmitter ..................1-6 (E)

1-9. Removing/Reinstalling the 40-pin Connector.......................................1-9 (E)

1-10. Notes on Replacement of V Shoe .......................................................1-10 (E)

1-11. Settings after Replacing the Boards and EL Display ..........................1-10 (E)

1-12. Writing and Rewriting the PLD Internal Data ....................................1-11 (E)

1-13. Updating the Software.........................................................................1-12 (E)

1-14. Setting of Serial Number.....................................................................1-13 (E)

1-15. Resetting the Timer .............................................................................1-14 (E)

1-16. Optional Fixtures.................................................................................1-15 (E)

1-17. Note on Service ...................................................................................1-16 (E)

1-17-1. Error Message ....................................................................1-16 (E)

1-17-2. Notes on RF OUT Connector.............................................1-16 (E)

1-17-3. Note on Replacing the EL Display.....................................1-16 (E)

1-17-4. Circuit Protection Device ...................................................1-16 (E)

1-17-5. Notes on Disconnecting/Connecting the Coaxial Cable ....1-17 (E)

1-17-6. Unleaded Solder .................................................................1-17 (E)

1-17-7. Notes on Repair Parts .........................................................1-17 (E)