Installation and Operating Instructions

Delta Style Room Humidity Transmitter with Optional Temp. Sensor

BA/#-Hxxx-R

Building Automation Products, Inc., 750 North Royal Avenue, Gays Mills, WI 54631 USA

T

el:+1-608-735-4800 • Fax+1-608-735-4804 • E-mail:

[email protected] • Web:www

.bapihvac.com

Specications subject to change without notice.

27417_ins_Delta_RH

3 of 4

rev. 04/15/14

10 Second Toggle Humidity Display Only

Temp. Display Only

J2 Jumper “On”

Degrees = °F

°F or °C Indication (for display units only)

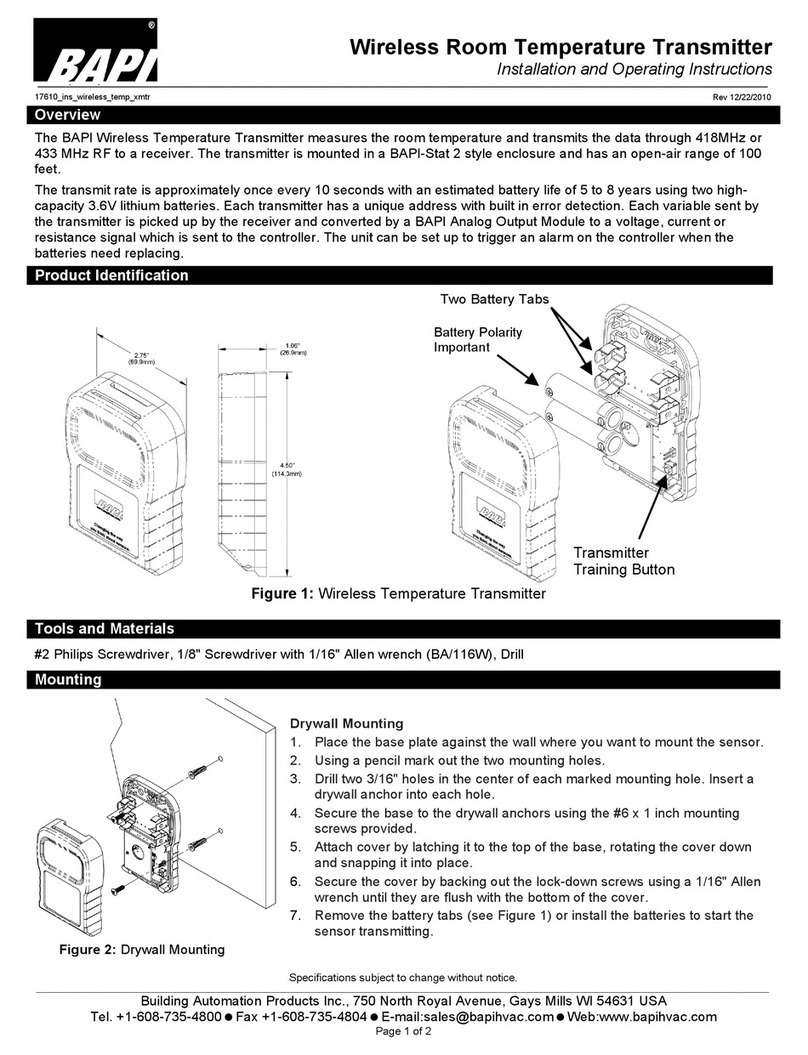

The jumper on J2 determines whether the unit will

display in Fahrenheit or Celcius. With the jumper

“On”, the unit displays in Fahrenheit which is the

factory default. (See diagrams at right.)

J2 Jumper “Off”

Degrees = °C

Humidity Reading Offset (for display units only)

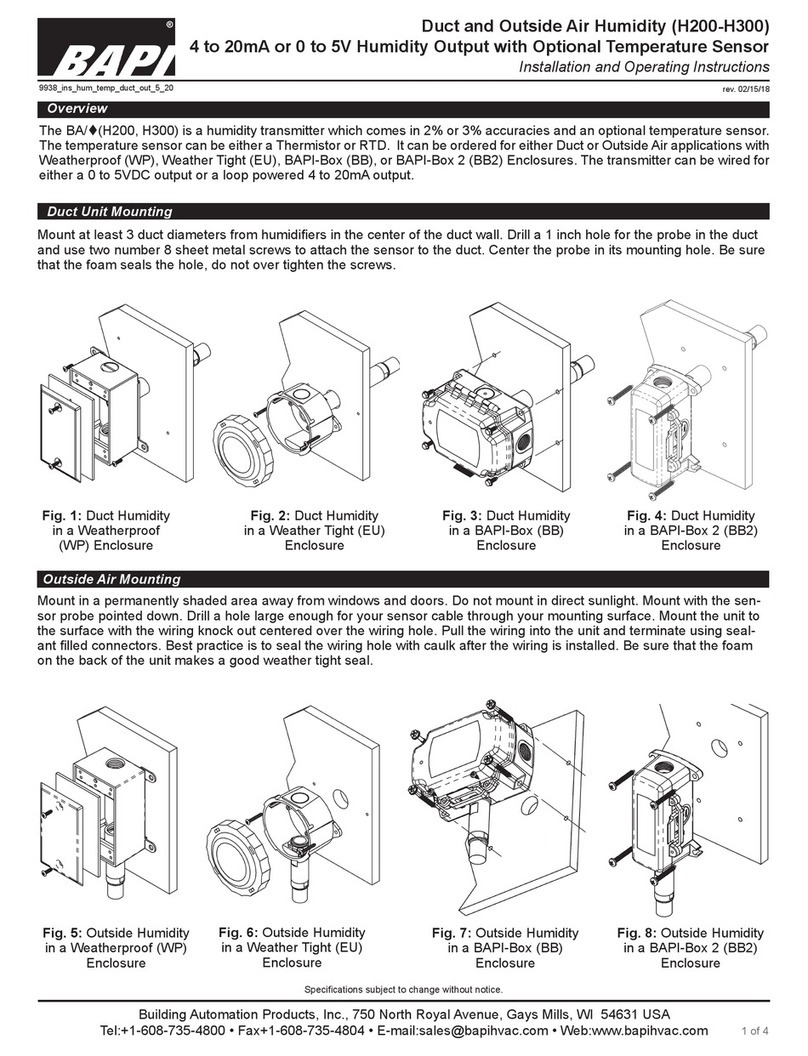

The Humidity reading can be offset by ±5% by turning

POT R20. (See diagram at right.)

Zero Humidity Offset (centered) is the factory

default. Turning clockwise increases the Humidity

Offset by up to +5%. Turning counterclockwise

decreases the Humidity Offset by up to -5%.

Unit Interval Toggle Rate Between Display of Temperature and Humidity (for display units only)

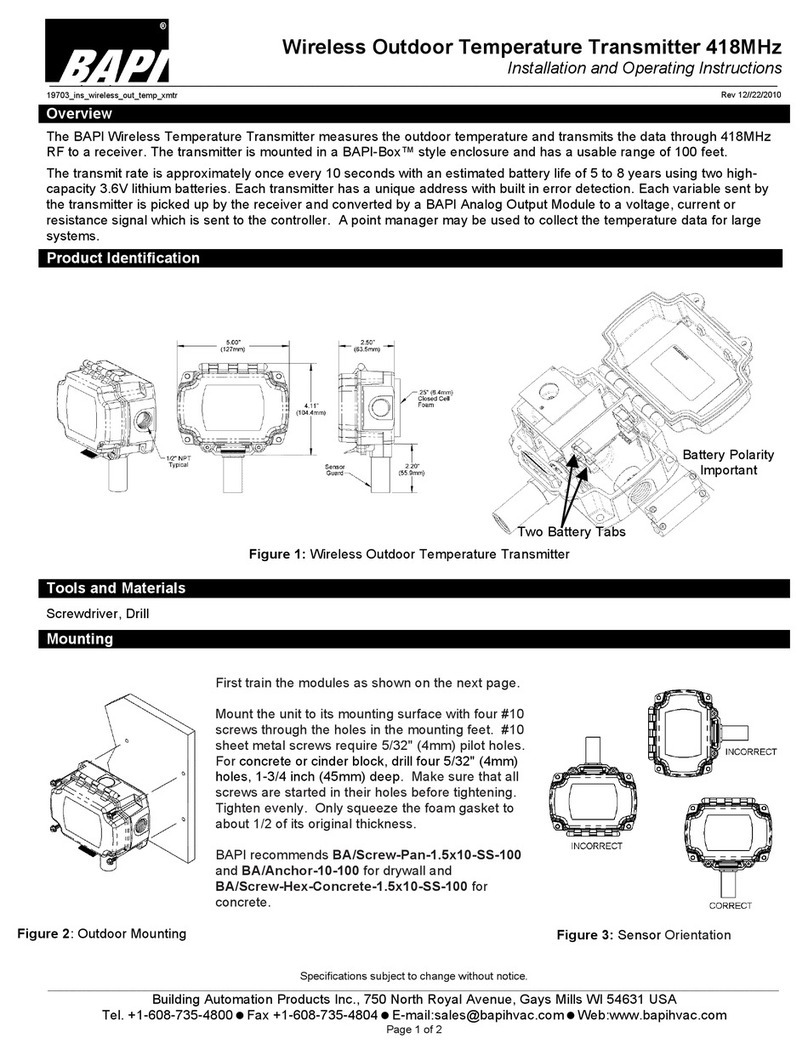

POT R6 sets the approximate toggle rate between

temperature and humidity display of 3 to 15 seconds. POT

R6 can also be used to set a constant display of either

temperature or humidity. (See diagram at right.)

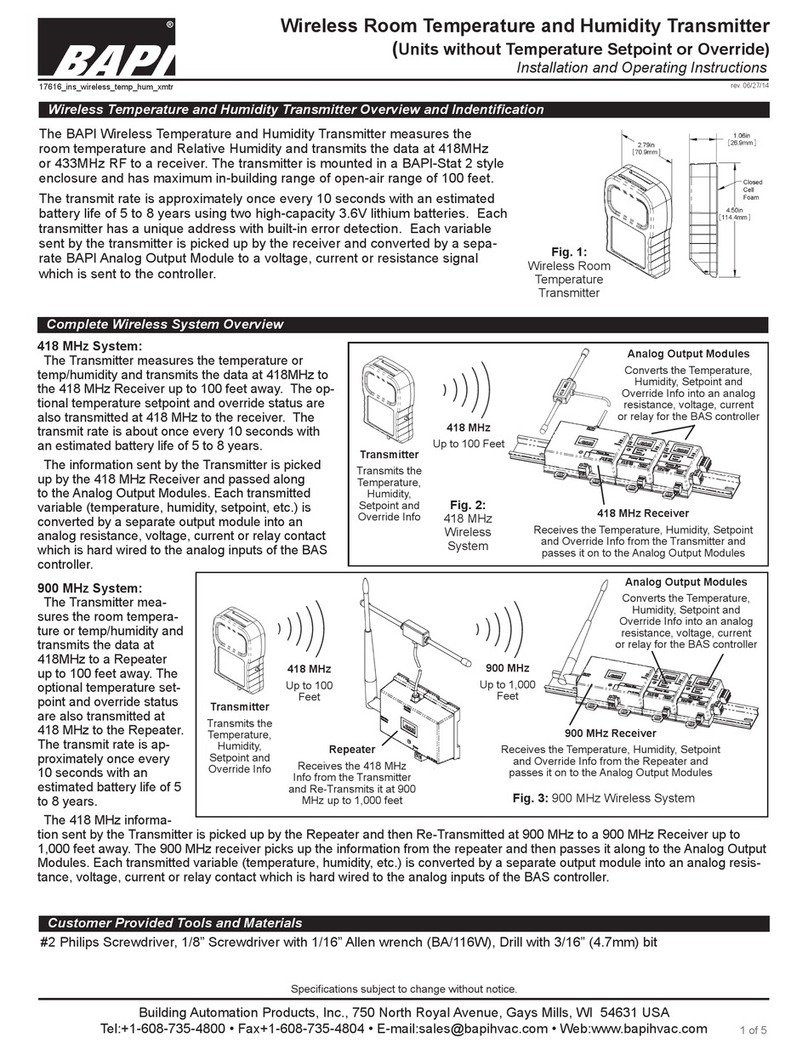

Specications

Power: Reverse polarity protected.

4 to 20 mA Output ........ 10 to 35 VDC, 22mA max

0 to 5 VDC Output ........ 10 to 35 VDC, 22mA max

12 to 24 VAC, 0.53VA max

0 to 10 VDC Output) ..... 15 to 40 VDC, 6mA max

15 to 28 VAC, 0.14VA max

Note: half wave DC power is recommended. If AC power is

used, it must be shielded from the signal wiring.

Sensor:

Humidity ............. Capacitive w/ temperature compensation

& digital output.

%RH resolution is 8 bit

Optional Temp. ... Passive Thermistor, RTD or

Semiconductor with bias of 5 to 30VDC

Filter: None

RH Accuracy: RH Sensor chip

200 ±2%, from 20% to 80%RH @77ºF

200 ±3%, from <20% to >80%RH @77ºF

300 ±3%, from 0% to 100%RH @77ºF

Resolution RH sensor 0.4%

Temp Display Accuracy: Temperature Chip only

Temperature ±0.6˚C @25˚C

Resolution Temp sensor 0.2˚

Optional Temp Sensor Accuracy: Passive 2 wire only

Thermistor* ......... (std) ±0.36ºF, (±0.2ºC)

(High) ±0.18ºF, (±0.1ºC), [XP] option

RTD ................... Platinum (PT), 3.85Ω/ºC for 1KΩ RTD

Platinum (PT), 0.385Ω/ºC for 100Ω RTD

Nickel (Ni), 2.95Ω/ºF for the JCI RTD

Solid State .......... AD592, bias 5-30VDC

Output: Updated every 2 seconds

RH (0 to 100%) 4 to 20mA, 0 to 5VDC or 0 to 10VDC

Temperature Passive Resistance or Semiconductor

Impedance:

Current 700Ω @ 24VDC minimum

Voltage 10KΩ maximum

Terminals: Cage clamp, 16 to 22 AWG

Wiring: 2 to 6 pair depending on options

Mounting:

Standard 2”x4” J-box or drywall, screws provided

Field Humidity Calibration Offset: (Factory calibrated)

%RH Adj. Potentiometer, ±5%

Enclosure Material: ABS Plastic, UL94V-HB

Optional Display: 3.5 digit LCD

Dimensions ......... 0.5”H x 1.1”W, Digits .4”H

(13.34 x 29.21mm), (Digits 10.29mm H)

Range ................ 0 to 100%, -58 to 199.5˚F (-50 to 150˚C),

factory set

Span ................... 0 to 100%, 32 to 122˚F (0 to 50˚C), factory set

Resolution .......... 0.5%RH or 0.5˚F or °C

Units ................... ˚F or ˚C, Board jumper (J2)

Update ................ Every 2 seconds, factory set

Alternating .......... Temp/RH, adjustable 3-15 seconds or xed

temperature or humidity

Power up ............ 0% RH & 0.0˚ at power up for OK

Then reads value after 2 seconds

Fault ...................

RH 100% or Temp 0% for sensor fault after 500 sec.

Optional Comm. Jack:

-C35 3.5mm Phono jack

Optional Test & Balance Switch:

-TB 3 position switch High/Normal/Low

Passive temp sensor output only

Environmental Ambient Range:

Temp 32º to 122ºF, (0º to 50ºC)

Humidity 5% to 95% RH (Non-Condensing)

Agency: RoHS, UL94V-HB,

CE* (EN50081-1:1998, EN61000-6-2)

*All passive thermistors 10KΩ and smaller

are CE Compliant