Table of contents

TABLE OF CONTENTS

1. Safety................................................................................................................. 3

1.1 General considerations............................................................................................................... 4

1.2 Important safety instructions ......................................................................................................... 6

1.3 Product safety labels ................................................................................................................. 9

1.4 High Brightness precautions: Hazard Distance (HD) ..............................................................................10

1.5 HD for fully enclosed projection systems ...........................................................................................12

1.6 HD in function of modifying optics ..................................................................................................13

2. Getting started.....................................................................................................15

2.1 Installation requirements . . . .........................................................................................................16

2.2 Unpacking the projector .............................................................................................................18

2.3 Initial inspection......................................................................................................................20

2.4 Communicator PC version . .........................................................................................................21

2.5 Commander & Web Commander ...................................................................................................22

3. Installation process...............................................................................................23

3.1 Installation process overview........................................................................................................24

3.2 Software upgrade. . . .................................................................................................................25

3.3 Starting up and adjusting the system ...............................................................................................26

4. Physical installation ..............................................................................................27

4.1 Positioning the DP2K SLP-series projector at port window........................................................................28

4.2 Connecting the projector with the power net .......................................................................................31

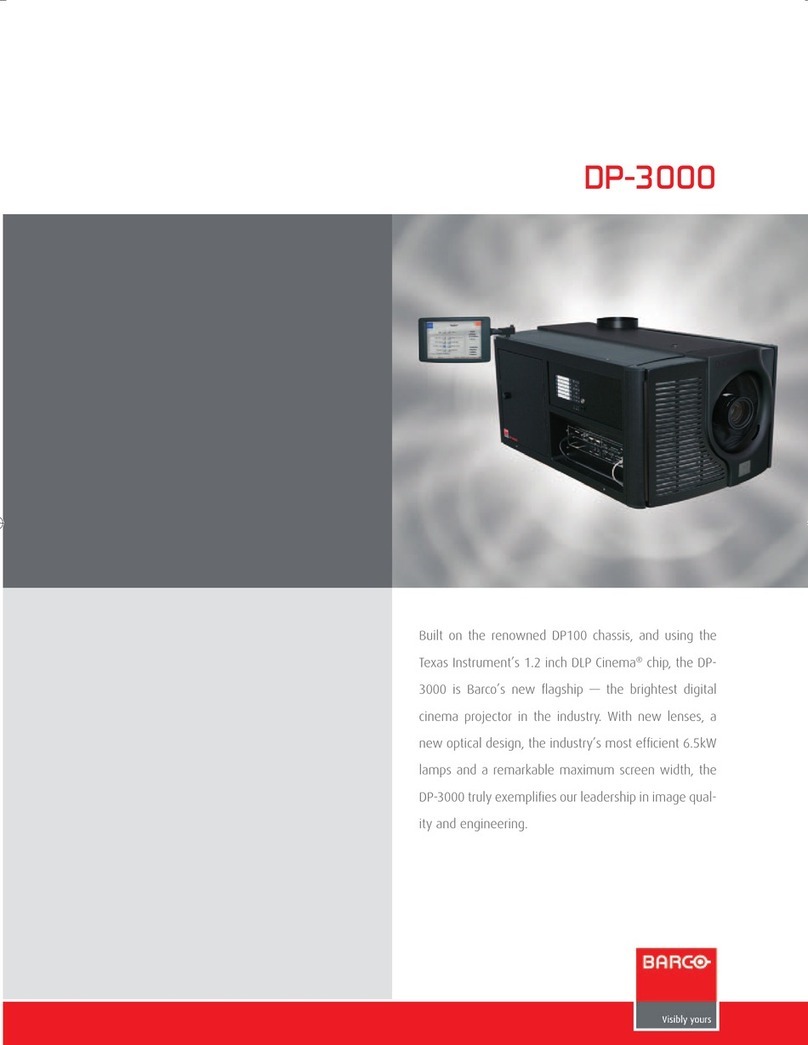

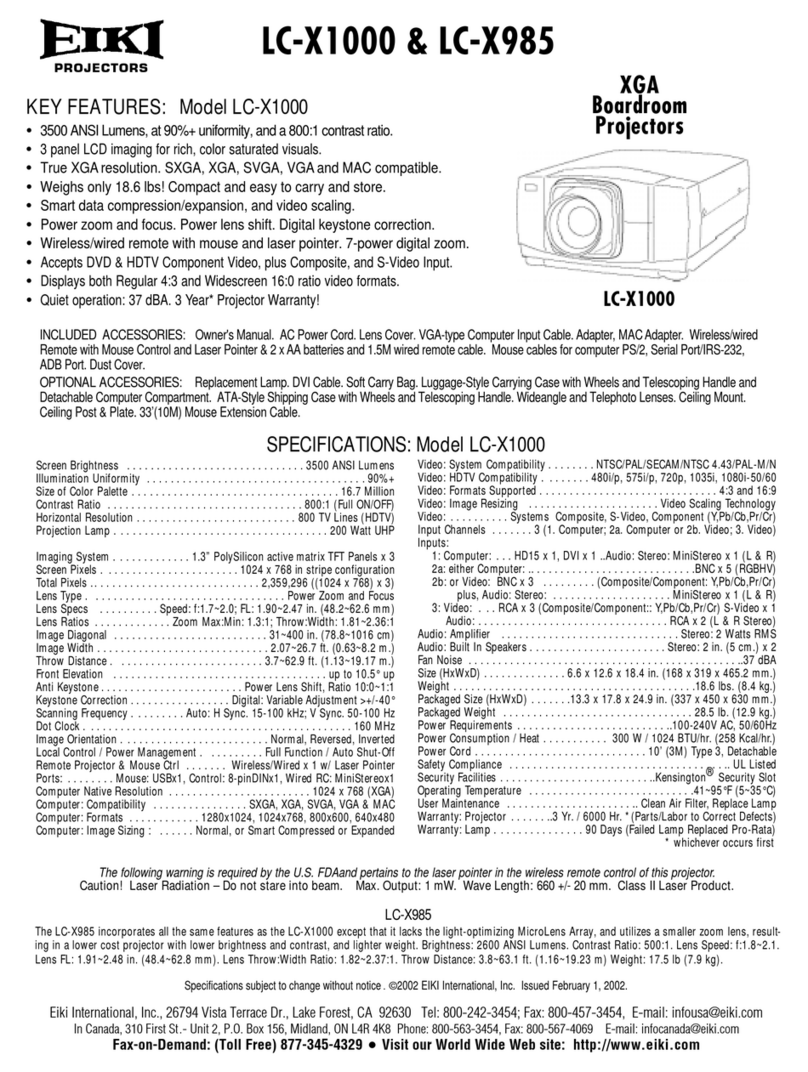

5. Lenses & Lens selection.........................................................................................33

5.1 Available lenses .....................................................................................................................34

5.2 Lens selection .......................................................................................................................35

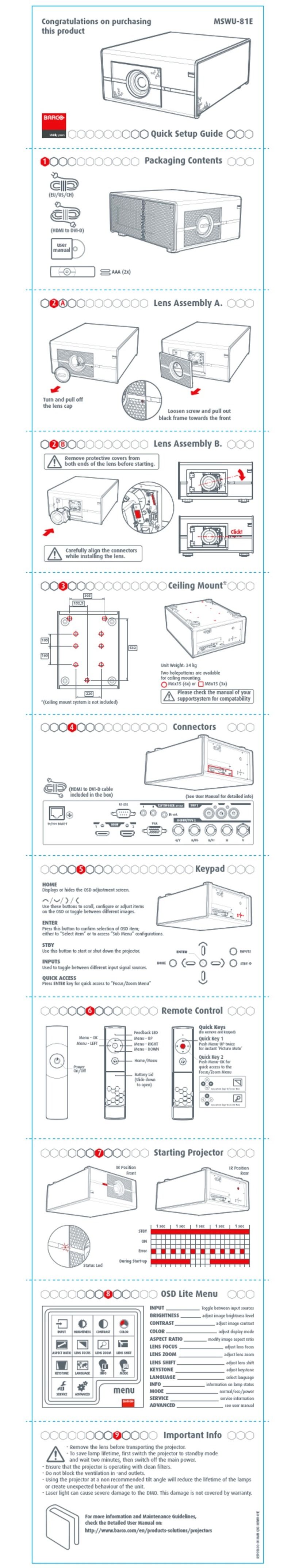

5.3 Lens installation .....................................................................................................................36

5.4 Lens removal ........................................................................................................................37

5.5 Lens shift, zoom & focus . . . .........................................................................................................38

6. Input & Communication..........................................................................................41

6.1 Introduction ..........................................................................................................................42

6.2 Local Keypad ........................................................................................................................43

6.3 Projector Status......................................................................................................................45

6.4 Integrated Cinema Processor (ICP) ................................................................................................46

6.5 HD-SDI Input Module (optional). . . ..................................................................................................47

6.6 Integrated Media Block/Server (optional) .. . ........................................................................................50

6.7 Cinema Controller ...................................................................................................................51

7. ICMP .................................................................................................................53

7.1 ICMP introduction. . . .................................................................................................................54

7.2 ICMP HDD...........................................................................................................................56

7.3 ICMP communication ports .........................................................................................................57

7.4 ICMP source input ports.............................................................................................................59

7.5 ICMP DisplayPort specifications ....................................................................................................60

7.6 ICMP SDI specifications.............................................................................................................62

7.7 ICMP HDMI 2.0 specifications ......................................................................................................66

7.8 ICMP HDMI 1.4 specifications ......................................................................................................69

7.9 ICMP status LEDs...................................................................................................................71

7.10 ICMP HDD status LEDs.............................................................................................................72

7.11 ICMP device certificate..............................................................................................................74

7.12 ICMP configuration via Communicator .............................................................................................76

7.13 ICMP reset...........................................................................................................................77

7.14 Obtaining the Barco ICMP certificate ...............................................................................................78

7.15 Removing a HDD from the ICMP ...................................................................................................79

7.16 Installing a HDD into the ICMP......................................................................................................80

8. Communicator Touch Panel.....................................................................................83

8.1 Communicator Touch Panel.........................................................................................................84

8.2 Installing the Touch Panel interface.................................................................................................86

8.3 Repositioning the Touch Panel interface . . . ........................................................................................88

9. Starting up..........................................................................................................89

9.1 Switching the DP2K SLP-series ON................................................................................................90

9.2 Switching the DP2K SLP-series OFF...............................................................................................91

10. Scheimpflug........................................................................................................93

10.1 Scheimpflug introduction . . . .........................................................................................................94

10.2 Scheimpflug adjustment.............................................................................................................96

10.3 Fixation of the Lens Holder front plate ..............................................................................................98

10.4 Back Focal Length adjustment .....................................................................................................100

R5906847 DP2K SLP SERIES 02/06/2017 1