Table of contents

20.2.4 Cooling Fans..................................................................................................................89

20.2.4.1 Fan PSU................................................................................................................89

20.2.4.2 Fan PCB................................................................................................................90

20.2.4.3 Fan Optics..............................................................................................................90

20.2.5 Laser Clusters Blue (2pcs) ...................................................................................................91

20.2.6 Cleaning the cooling pump surface .. ........................................................................................94

20.2.7 Cooling pump connection map ...............................................................................................95

20.3 40000 hours service .................................................................................................................95

20.3.1 Fan laser driver ............................................................................................................... 96

20.3.2 Liquid Cooling System 40.000hrs . . . . ........................................................................................96

20.3.3 Remove Frame Radiator Left Module........................................................................................ 98

20.3.4 Remove Frame radiator center module . . . ...................................................................................98

20.3.5 Frame radiator right module ..................................................................................................99

20.3.6 Reassembly of radiator modules . . . . . .......................................................................................100

21. DMD, DMD Board, CLGA & DMD heatsink elements...................................................... 103

21.1 DMD assembly .....................................................................................................................103

21.2 DMD Board, CLGA & DMD heatsink elements. . ..................................................................................103

21.3 GP6 PCB DMD Board..............................................................................................................104

21.4 CLGA & DMD.......................................................................................................................105

21.5 Re-assembly after PCB DMD or DMD/CLGA repair ..............................................................................105

21.6 GP6 Heatsink DMD Front & Rear Assemblies ....................................................................................106

21.7 GP6 Heatsink DMD Front assembly...............................................................................................106

21.8 Remove the Laser Interface........................................................................................................108

21.9 Install new Laser Interface .........................................................................................................109

22. TI Loop .............................................................................................................111

22.1 General .............................................................................................................................111

22.2 Overview Engine assembly ........................................................................................................112

22.2.1 TI Loop Left . . ................................................................................................................112

22.2.2 Overview of TI loop left ......................................................................................................113

22.2.3 Dichroic Filter B/Y............................................................................................................113

22.2.4 Barrel PW Lens assy ........................................................................................................113

22.2.5 Mirrors Blue ..................................................................................................................114

22.2.6 390 Blue loop lens 3 .........................................................................................................114

22.2.7 390 Blue loop lens 4 .........................................................................................................114

22.2.8 Diffusor blue loop ............................................................................................................115

22.2.9 390 RGBY Converging Lenses..............................................................................................115

22.2.9.1 Converging Lens (Entrance) . . . .......................................................................................115

22.2.9.2 Converging Lens (Exit)................................................................................................116

22.2.10 Adjusting Mirror ..............................................................................................................116

22.3 TI Loop Right .......................................................................................................................116

22.4 Rod Carrier Assy ...................................................................................................................117

23. Illumination Engine front....................................................................................... 119

23.1 Iris assembly........................................................................................................................119

23.2 Relay Tube assy....................................................................................................................120

23.3 PCB CLO (Constant Light Output). ................................................................................................120

23.4 Folding Mirror assembly............................................................................................................121

23.4.1 Removing Folding Mirror assembly .........................................................................................121

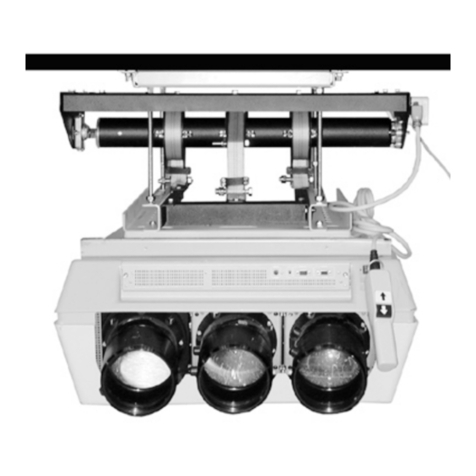

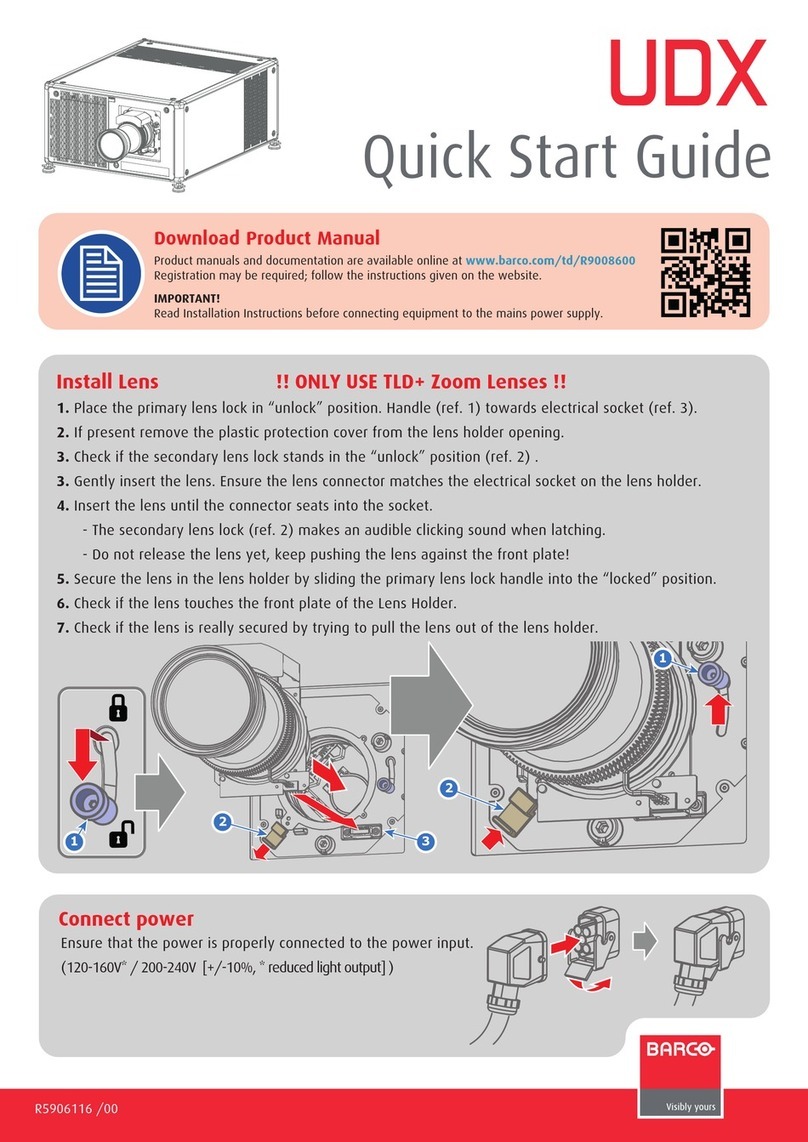

24. Lens shift assembly ............................................................................................ 123

24.1 Lens shift assembly motors ........................................................................................................124

24.2 Lens position sensors (Horizontal and Vertical) ...................................................................................125

24.3 PCB lens connectors ...............................................................................................................125

24.4 Lens Lock screws. . . ................................................................................................................126

24.5 Scheimpflug screws ................................................................................................................126

24.6 Lens shift assembly and optical actuator .. . .......................................................................................126

24.7 TIR Prism ...........................................................................................................................127

24.7.1 Remove the TIR prism.......................................................................................................127

24.7.2 Cleaning the TIR prism ......................................................................................................128

24.7.3 Reassemble the TIR prism ..................................................................................................129

25. Prism Housing ................................................................................................... 131

25.1 Prism Housing ......................................................................................................................131

26. Technical Operations ........................................................................................... 133

26.1 PCB Bracket bottom and Bracket fan..............................................................................................133

26.2 PCB Main ...........................................................................................................................133

26.3 PCB Thermal Hub board.......................................................................................................... .134

26.4 PSU .................................................................................................................................136

26.5 PCB Laser Drivers..................................................................................................................137

26.5.1 Remove the Laser driver cage ..............................................................................................137

26.5.2 Remove the Laser driver PCB board. .......................................................................................138

26.5.3 Remove the Bottom laser driver PCB board................................................................................138

723–0016 F90 01/12/2017 3