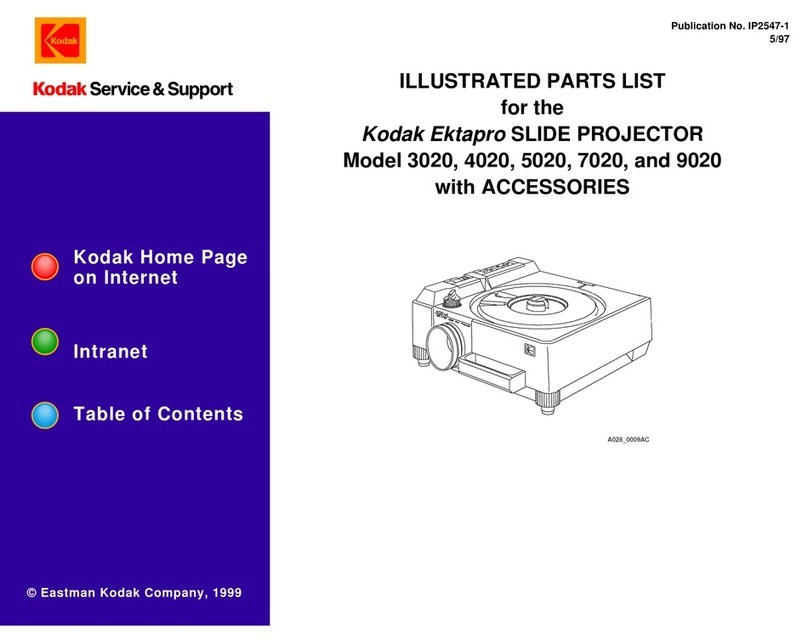

Table of contents

TABLE OF CONTENTS

1. Safety................................................................................................................. 3

1.1 Safety Instructions.................................................................................................................... 3

1.2 Extra safety instruction ............................................................................................................... 5

2. Spare parts .......................................................................................................... 7

2.1 Consumables ......................................................................................................................... 7

2.2 Lamps................................................................................................................................. 7

3. General information................................................................................................ 9

3.1 Servicing the SIM 7C................................................................................................................. 9

3.2 Conventions .......................................................................................................................... 9

3.3 General instructions .................................................................................................................. 9

3.3.1 Connector instructions ......................................................................................................... 9

3.3.2 Wires and cable ties ..........................................................................................................10

3.3.3 EMC shielding clamps........................................................................................................10

3.4 Tools ................................................................................................................................. 11

4. Covers...............................................................................................................13

4.1 Lens cover top .......................................................................................................................13

4.1.1 Removing the lens cover top .................................................................................................13

4.1.2 Installing the lens cover top. ..................................................................................................13

4.2 Lens cover bottom . . .................................................................................................................14

4.2.1 Removing the lens cover bottom............................................................................................. 14

4.2.2 Installing the lens cover bottom ..............................................................................................14

4.3 Top filter cover .......................................................................................................................15

4.3.1 Removing the top filter cover.................................................................................................15

4.3.2 Installing the top filter cover ..................................................................................................16

4.4 Side filter cover ......................................................................................................................17

4.4.1 Removing the side filter cover................................................................................................17

4.4.2 Installing the side filter cover .................................................................................................17

4.5 Lamp cover ..........................................................................................................................17

4.5.1 Removing the lamp cover ....................................................................................................17

4.5.2 Installing the lamp cover ......................................................................................................18

5. Projector software (firmware)...................................................................................21

5.1 Description of the software..........................................................................................................21

5.2 Projector software version...........................................................................................................21

5.3 Upgrading the projector software ................................................................................................... 22

6. Optical parts and servicing procedures.......................................................................25

6.1 Lamp.................................................................................................................................25

6.1.1 Description of the lamp .......................................................................................................25

6.1.2 Removing the lamp cover ....................................................................................................26

6.1.3 Removing the lamp door...................................................................................................... 26

6.1.4 Removing the lamp ...........................................................................................................27

6.1.5 Installing the lamp.............................................................................................................28

6.1.6 Installing the lamp door .......................................................................................................29

6.1.7 Reset the lamp runtime.......................................................................................................30

6.1.8 Installing the lamp cover ......................................................................................................31

7. Maintenance procedures.........................................................................................33

7.1 Maintenance: introduction. . .........................................................................................................33

7.2 Filter replacement ................................................................................................................... 33

7.2.1 Removing the side filter.......................................................................................................33

7.2.2 Mounting the side filter........................................................................................................35

7.2.3 Removing the top filter........................................................................................................36

7.2.4 Mounting the top filter.........................................................................................................37

7.3 Cleaning the projector lens..........................................................................................................37

7.4 Cleaning the optical path . . . ......................................................................................................... 37

Index......................................................................................................................39

R59770119 SIM 7C 28/05/2008 1