R9001440/9

GRAPHICS

Contents Page

Date: 10/02/2000

6300

3

Contents

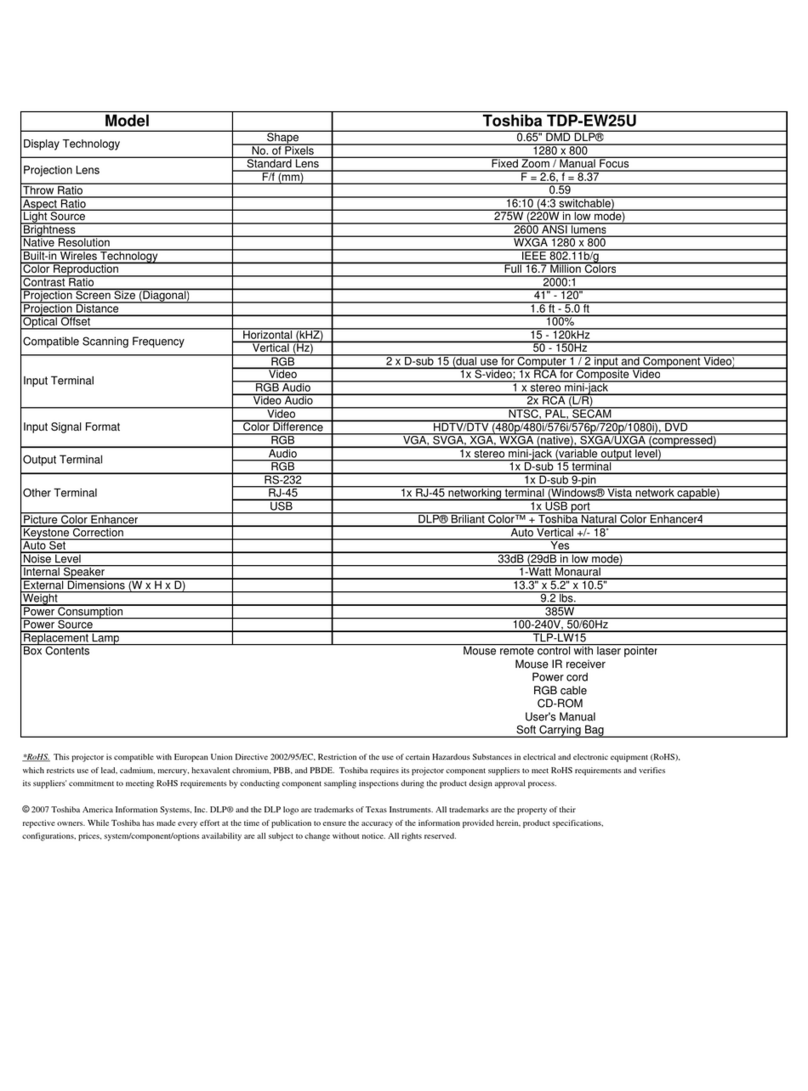

Panel Adjustments ...............................................................................................................5

Recommendation ................................................................................................................................................ 5

Caution ................................................................................................................................................................ 5

Reasons for Adjustment ...................................................................................................................................... 5

Projector settings ................................................................................................................................................. 5

Set Up ................................................................................................................................................................. 5

Starting up the Service Mode ............................................................................................................................... 5

Connection of the TCR tracker unit ..................................................................................................................... 6

Change Baudrate PC .......................................................................................................................................... 6

Change Projector Address ................................................................................................................................... 6

Starting the Panel adjustment .............................................................................................................................. 7

Uniformity Adjustment ......................................................................................................... 9

Software Validity .................................................................................................................................................. 9

Reason For Uniformity Correction ....................................................................................................................... 9

Preparation .......................................................................................................................................................... 9

Color Meter........................................................................................................................................................ 10

Line-up of the measurement apparatus ............................................................................................................. 10

RS232 Connection to color meter ...................................................................................................................... 10

Signal connection for Uniformity adjustment ....................................................................................................... 11

Setting Noise Reduction level at 0 ..................................................................................................................... 12

Running the Program ........................................................................................................................................ 12

Step 1 : Input projector data............................................................................................................................... 12

Automatict Adjustment Procedure: A ................................................................................................................ 14

Manual top-bottom-left-right Adjustment Procedure: M .................................................................................... 16

Overview of Commands .................................................................................................................................... 17

TCR Adjustment ................................................................................................................. 18

Related Item ...................................................................................................................................................... 18

Reason for TCR ................................................................................................................................................ 18

Line-up of the measurement apparatus ............................................................................................................. 19

Color Meter........................................................................................................................................................ 19

Running the Program ........................................................................................................................................ 19

Step 1: Input projector data................................................................................................................................ 19

Step 2: Green reduction ..................................................................................................................................... 22

Step 3: LCD transmission curves....................................................................................................................... 24

Step 4: adj. different color temperatures ............................................................................................................ 26

Step 4: adj. different color temperatures - preset input balance ......................................................................... 26

Automatic Adjustment (Color meter connected!!) ........................................................................................... 29

Manual Adjustment ......................................................................................................................................... 30

Step 5: checking color tracking .......................................................................................................................... 32

Step 7: exit - save settings ................................................................................................................................. 33

Contents

Important

All described procedures refer to a projector configuration Front/Table