Table of contents

TABLE OF CONTENTS

1. General Information.................................................................................................3

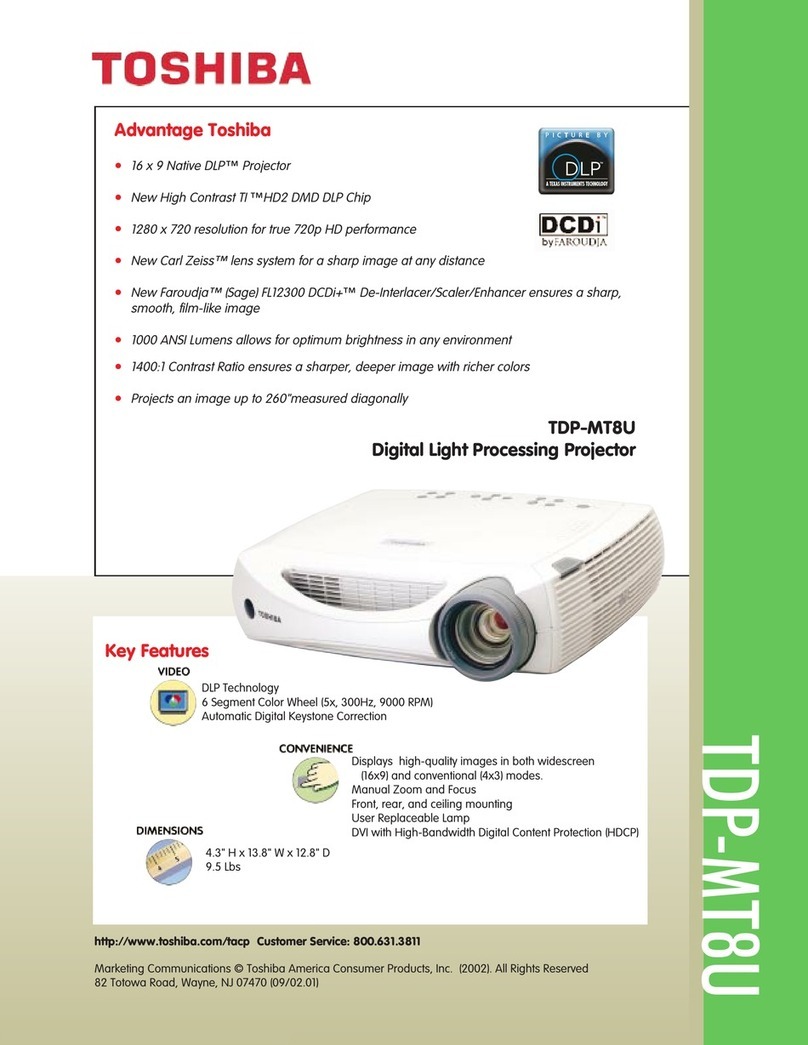

1.1 RLMR5Performer.................................................................................................................... 3

2. Safety..................................................................................................................5

2.1 SafetyInstructions .................................................................................................................... 5

3. Safety Symbols...................................................................................................... 9

3.1 OverviewusedSafetySymbols....................................................................................................... 9

4. BlockDiagramRLM R5Performer..............................................................................11

4.1 SimplifiedBlock Diagram ............................................................................................................11

4.2 Expanded Block Diagram............................................................................................................12

5. TechnicalInformations............................................................................................13

5.1 Conventions..........................................................................................................................13

5.2 ConnectorRemovalInstructions.....................................................................................................13

6. SparePartslist .....................................................................................................15

6.1 SparePartslist.......................................................................................................................15

7. ProjectorCoverRemovalto accessModules.................................................................17

7.1 Top Access Modules .................................................................................................................17

7.1.1 RemovaloftheRearcover....................................................................................................17

7.1.2 Removal of the Button panel cover ...........................................................................................17

7.1.3 Removalofthetopcover......................................................................................................18

7.1.4 Topshieldremoval.............................................................................................................19

7.2 Side Access Modules ................................................................................................................20

7.2.1 SideCoverleft.................................................................................................................20

7.2.1.1 RemovaloftheSidecover..............................................................................................20

7.2.1.2 Sideshieldremoval.....................................................................................................21

7.2.2 SideCoverRight...............................................................................................................21

7.2.2.1 RemovaloftheSidecover..............................................................................................21

7.2.2.2 SideShieldremoval.....................................................................................................21

7.2.2.3 PMPShieldRemoval...................................................................................................22

8. Module/Unit Identification ........................................................................................23

8.1 TopViewProjector...................................................................................................................23

8.2 OverviewinstalledFANS.............................................................................................................24

8.2.1 LocationoftheFansintheprojector..........................................................................................24

8.2.2 FunctionoftheinstalledFans.................................................................................................25

8.2.3 OrdernumberfortheFans....................................................................................................25

8.3 PowerBoxComplete.................................................................................................................26

8.3.1 PowerBoxAccess.............................................................................................................26

8.3.2 PartsofthePowerBoxAssembly ............................................................................................27

8.3.3 Power Box Swapping..........................................................................................................28

8.4 Input Box Complete ..................................................................................................................31

8.4.1 Input Box Swapping ...........................................................................................................31

8.4.2 PartsoftheinputBoxAssembly..............................................................................................33

8.5 LampBox.............................................................................................................................33

8.5.1 LampunitRemoval............................................................................................................33

8.5.2 PartsoftheLampbox.........................................................................................................34

8.6 IRReceiverFront ....................................................................................................................35

8.6.1 IRReceiverFrontswapping...................................................................................................35

8.7 Motor/ControlBoard..................................................................................................................35

8.7.1 Motor/Controlboardswapping................................................................................................35

8.7.2 Motor/Control board connections .............................................................................................36

8.8 Keypad&LED+IRBoard ............................................................................................................37

8.8.1 Keypad swapping..............................................................................................................37

8.8.2 LED+IRBoard.................................................................................................................37

8.9 SealedEngine........................................................................................................................37

8.9.1 SealedEngineremoval........................................................................................................38

8.9.2 Sealed Engine mounting ......................................................................................................41

8.10 Lens Holder...........................................................................................................................41

8.10.1 Lens Holder swapping.........................................................................................................41

8.11 LightPipe.............................................................................................................................42

8.11.1 PartstoberemovedtoallowLightPipeswapping...........................................................................42

8.11.1.1 LightpipeFocusadjustablescrewcoverremoval. ....................................................................42

8.11.1.2 LampburnerblowerFAN9removal....................................................................................43

8.11.1.3 LampHouseremoval...................................................................................................43

8.11.2 ReplacementoftheLightpipe................................................................................................44

8.11.2.1 LightpipeRemoval .....................................................................................................44

8.11.2.2 Light pipe Mounting .....................................................................................................44

8.12 Coldmirror............................................................................................................................45

R5976766 RLM G5 22/04/2004 1