Contents

Copyright statement .................................................................................................................................... 1

Matters needing attention ............................................................................................................................ 2

1. Product profile........................................................................................................................................... 3

2. Introduction .............................................................................................................................................. 4

2.1 Unpacking and inventory of parts ............................................................................................... 4

2.2 Printer component ......................................................................................................................... 5

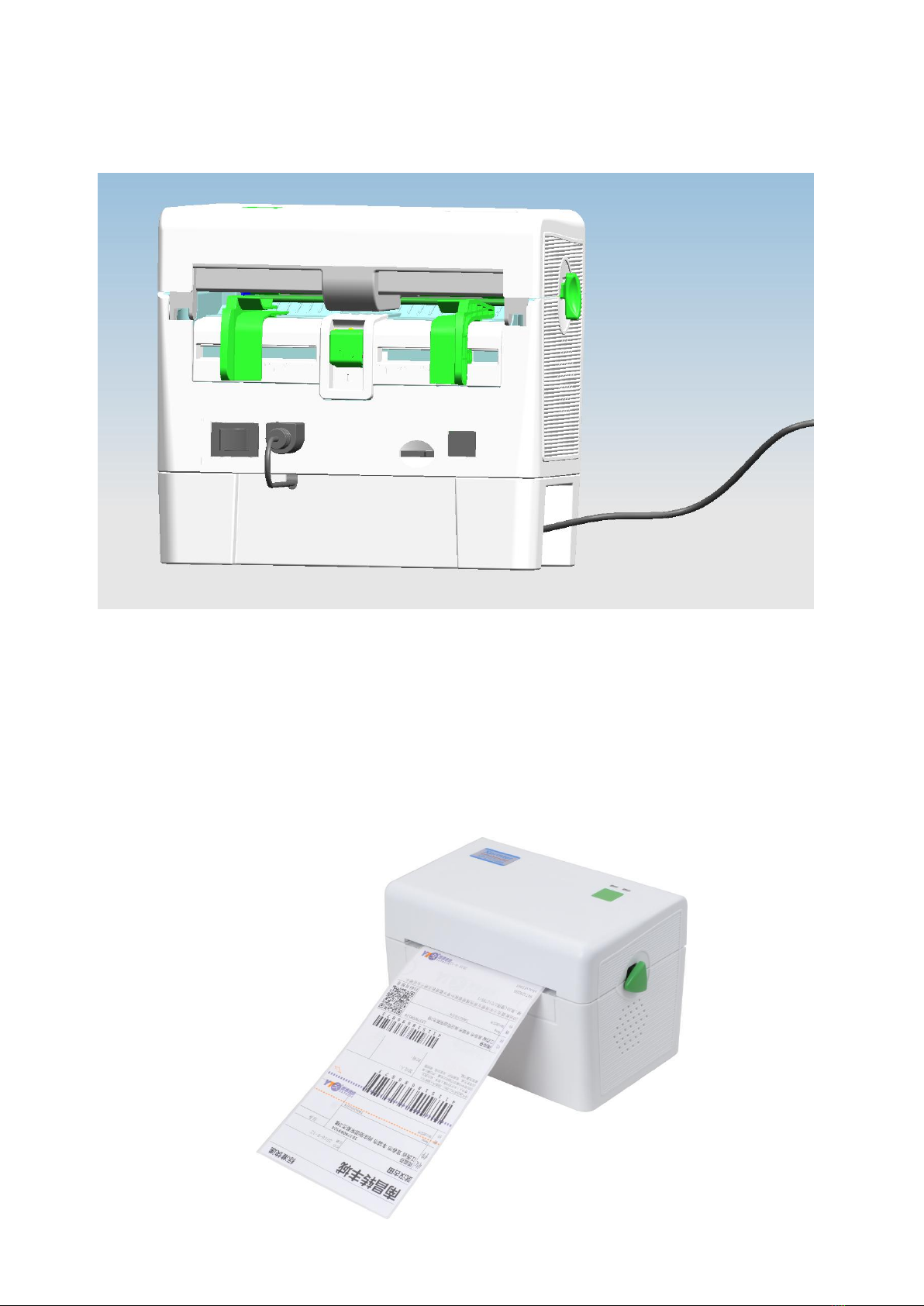

2.2.1 Front view .................................................................................................................................. 5

2.2.2 Rear view ................................................................................................................................... 5

3. install ........................................................................................................................................................ 6

3.1 install a printer................................................................................................................................. 6

3.2 Mounting sheet ............................................................................................................................... 7

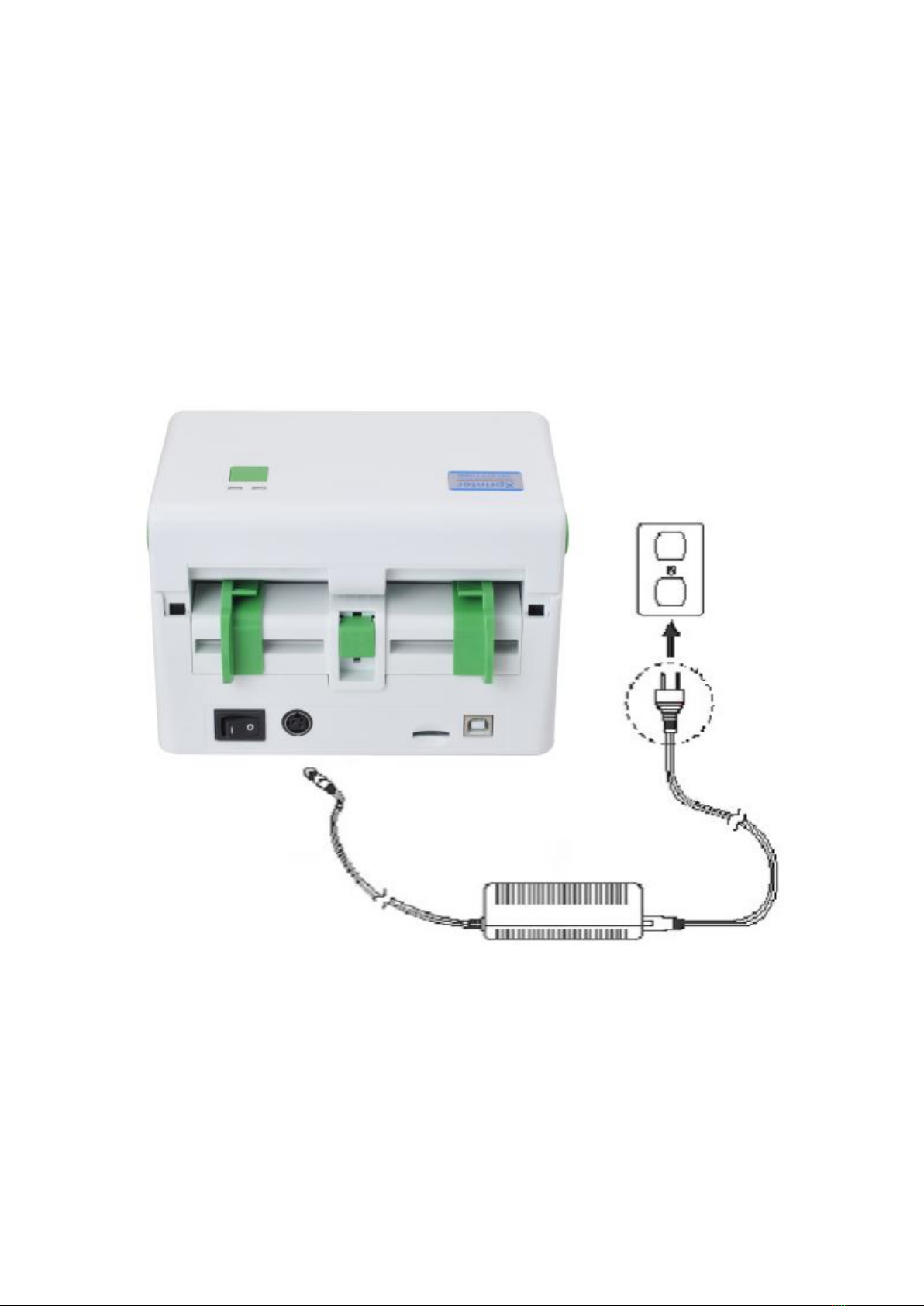

3.3 Built in power supply...................................................................................................................... 8

3.4 Single print function..... ................................................................................................................. 8

4. LED indicator and key function ............................................................................................................... 9

4.1 LED Indicator light............................................................................................................................ 9

4.2 General button function ................................................................................................................... 9

4.3 Internal Network Adaper Boot.......................................................................................................... 9

5. Printer diagnostic tool ........................................................................................................................... 16

5.1 Enable printer diagnostic utility ...................................................................................................... 16

5.2 Printer settings .............................................................................................................................. 17

5.3 Correction of paper sensor with printer diagnostic tool ................................................................ 18

6. Trouble shooting ................................................................................................................................. 19

6.1 Common problem ..................................................................................................................... 19

7. Printer simple maintenance ................................................................................................................ 22

Update record.................................................................................................................................. 23