barfield 1811G Operator's manual

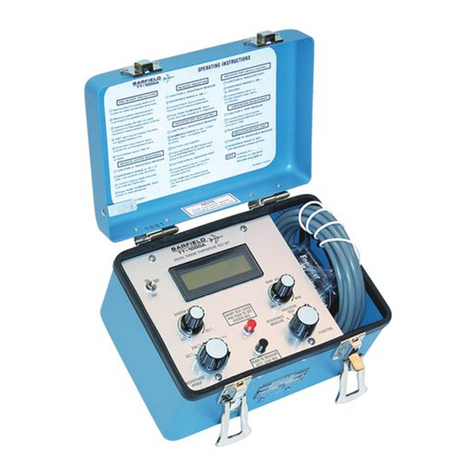

1811G/H PITOT-STATIC TEST SET

USER INSTRUCTION MANUAL

M/N: 1811G/H, P/Ns: 101-00165

101-00168

101-00169

Doc. P/N: 56-101-00165/168/169

Revision A

September 9, 2009

__________________________________

BARFIELD, INC.

Corporate Headquarters

4101 Northwest 29th Street

Miami, Florida 33142

www.barfieldinc.com

Email: [email protected]

http://www.avionteq.com/Barfield-1811-PN-101-00168-Pitot-Static-Test-Set.aspx

www.avionteq.com

THIS PAGE INTENTIONALLY LEFT BLANK

THIS PAGE INTENTIONALLY LEFT BLANK

1811G /H INSTRUCTION MANUAL

56-101-00165 /168 /169 Rev. A Page iv

CONTACT INFORMATION

Users are requested to notify the manufacturer of any discrepancy, omission, or error found in

this manual. Inquiries should include specific questions and reference the publication title,

number, chapter, page, figure, paragraph, and effective date.

Please send comments to:

TECHNICAL CUSTOMER SUPPORT - GSTE

BARFIELD, INC.

P.O. BOX 025367

MIAMI, FL 33102-5367

USA

Telephone (305) 894-5400

(800) 321-1039

Fax (305) 894-5401

THIS PAGE INTENTIONALLY LEFT BLANK

1811G /H INSTRUCTION MANUAL

56-101-00165 /168 /169 Rev. A Page vi

ATTENTION

Although every effort has been made to provide the end user of this equipment with the most

current and accurate information, it may be necessary to revise this manual in the future. Please

be sure to complete and return the enclosed OWNER WARRANTY REGISTRATION CARD to

Barfield in order to validate the warranty and to ensure that you will receive updated information

when published. You MUST have your name and address on file at Barfield as a registered

user of this equipment, to be able to obtain the service covered by the warranty.

Visit the company website, http://barfieldinc.com/, for publication updates.

Please send the Registration Card to:

Barfield, Inc.

P.O. Box 025367

Miami, FL 33102-5367

USA

THIS PAGE INTENTIONALLY LEFT BLANK

1811G /H INSTRUCTION MANUAL

56-101-00165 /168 /169 Rev. A Page viii

REVISION RECORD

REV. ECO # REV. DATE DESCRIPTION OF CHANGE

A 260-00729 September 9, 2009

Initial Release, prepared from Technical Manual

57-101-00165/00168/00169 (TM1811G/H-8111,

revised on March 12, 1991), to update company

logo, contact information and format.

THIS PAGE INTENTIONALLY LEFT BLANK

1811G /H INSTRUCTION MANUAL

56-101-00165 /168 /169 Rev. A Page x

MAINTENANCE AND REPAIR INFORMATION

The manufacturer of this equipment does not recommend the user to attempt any maintenance

or repair. In case of malfunction, contact the manufacturer, to obtain the list of approved repair

facilities worldwide, ensuring that this equipment will be serviced using proper procedures and

certified instruments. A Return Maintenance Authorization (RMA) number will be assigned

during this call, to keep track of the shipment and the service.

BARFIELD PRODUCT SUPPORT

DIVISION

Shipping Address:

Telephone (305) 894-5400

(800) 321-1039

Fax (305) 894-5401

Barfield, Inc.

4101 NW 29th Street

Miami, Florida 33142

USA

Mailing Address:

Barfield, Inc.

P.O. Box 025367

Miami, FL 33102-5367

USA

THIS PAGE INTENTIONALLY LEFT BLANK

1811G /H INSTRUCTION MANUAL

56-101-00165 /168 /169 Rev. A Page xii

TABLE OF CONTENTS

Contact Information

Attention Page

Revision Record Page

Maintenance and Repair Information

Table of Contents

Page

INTRODUCTION

1. PUBLICATION BREAKDOWN ...........................................................................1

2. INFORMATION PROVIDED WITH THE UNIT ..................................................1

3. RECERTIFICATION............................................................................................2

CHAPTER 1: DESCRIPTION

1. PURPOSE OF MANUAL.....................................................................................3

2. GENERAL DESCRIPTION .................................................................................4

3. SPECIFICATIONS ..............................................................................................5

4. PHYSICAL DESCRIPTION.................................................................................7

CHAPTER 2: OPERATION

1. GENERAL .................................................................................................. 11

2. PRESSURE /VACUUM SOURCE OPERATION........................................ 14

3. PREPARATION FOR TEST ....................................................................... 16

4. TESTER LEAK CHECKS ........................................................................... 17

5. STATIC SYSTEM LEAKS .......................................................................... 19

6. PITOT SYSTEM TESTS............................................................................. 21

7. COMBINED PITOT /STATIC SYSTEM TESTS.......................................... 23

8. MACHMETER TEST .................................................................................. 25

9. ENGINE PRESSURE RATIO (EPR) TEST ................................................ 26

10. MANIFOLD PRESSURE GAUGE TEST .................................................... 27

11. PRESSURE TESTS ................................................................................... 29

12. VACUUM TESTS ....................................................................................... 30

13. SHUTDOWN PROCEDURES .................................................................... 32

CHAPTER 3: SHIPPING

1. RECEIVING................................................................................................ 33

2. SHIPPING .................................................................................................. 33

1811G /H INSTRUCTION MANUAL

56-101-00165 /168 /169 Rev. A Page xiii

TABLE OF CONTENTS (continuation)

Page

CHAPTER 4: STORAGE

1. PROCEDURE............................................................................................. 35

CHAPTER 5: SERVICING

1. PERIODIC INSPECTION ........................................................................... 37

2. INSTRUMENT RECERTIFICATION........................................................... 38

APPENDIX: ENGINEERING SPECIFICATIONS ............................................... 39

SECTION 1. ALTIMETER........................................................................... 41

SECTION 2. AIRSPEED INDICATOR ........................................................ 49

SECTION 3. VERTICAL SPEED INDICATOR ........................................... 57

1811G /H INSTRUCTION MANUAL

56-101-00165 /168 /169 Rev. A Page 1 of 63

INTRODUCTION

1. PUBLICATION BREAKDOWN

This instruction manual establishes the operation standards for the 1811G /HPitot-Static

Test Set.

Its purpose is to provide sufficient information for the personnel unfamiliar with this unit to

understand this equipment, identify its parts, and operate it in accordance with proper

procedures, operating techniques, precautions and limitations.

2. INFORMATION PROVIDED WITH THE UNIT

Besides this User Instruction Manual, the 1811HA /GA Test Set is provided with the four

items described below.

A. An identification label, located on the front bulkhead of the Test Set, provides the

following information:

Manufacturer Name

Designation of Equipment

Equipment Part Number

Equipment Model Number Equipment Serial Number

Equipment Modification (if applicable) Equipment Options (if applicable)

B. The Owner's Warranty Registration card, (Figure 1), which is to be completed by the

owner and returned to the Barfield within ten (10) days of purchase to insure validation

of the warranty.

Figure 1 OWNER WARRANTY REGISTRATION CARD

1811G /H INSTRUCTION MANUAL

56-101-00165 /168 /169 Rev. A Page 2 of 63

C. The Limited Warranty Statement Card, (Figure 2), which lists the manufacturer's

obligation to the original purchaser.

Figure 2 LIMITED WARRANTY STATEMENT CARD

D. Each new or re-certified unit is delivered with a Certificate that shows the date when the

unit was tested by the manufacturer, its serial number, and when the next certification is

due. This certificate confirms that the unit performed according to its design

specifications.

3. RECERTIFICATION

The Test Sets P/Ns 101-00165, 101-00168, and 101-00169 have a 6-month recertification

period when analog instruments are installed.

It is strongly recommended that the manufacturer, Barfield Inc., service the Test Set. This

will ensure that all applicable engineering change orders are incorporated during the

required maintenance or recertification procedure.

Note: It is important that the customer ensures the Test Set is in compliance with the

Recertification requirement.

56-101-00165 / 168 / 169 Rev. A Page 3 of 63

1811G/H INSTRUCTION MANUAL

56-101-00165 / 168 / 169 Rev. A Page 4 of 63

1811G/H INSTRUCTION MANUAL

56-101-00165 / 168 / 169 Rev. A Page 5 of 63

1811G/H INSTRUCTION MANUAL

56-101-00165 / 168 / 169 Rev. A Page 6 of 63

1811G/H INSTRUCTION MANUAL

This manual suits for next models

4

Other barfield Test Equipment manuals

barfield

barfield DPS400 User manual

barfield

barfield 2311FA Operator's manual

barfield

barfield DPS1000 Operator's manual

barfield

barfield 2548H Owner's manual

barfield

barfield 1811NG Operator's manual

barfield

barfield TT-1000A Operator's manual

barfield

barfield 1811D Series Operator's manual

barfield

barfield TT-1000A Operator's manual

barfield

barfield DFQ40K Operator's manual

barfield

barfield DPS1000 Operator's manual