barfield TT1200A Operator's manual

Copyright © 2022 Barfield Inc. All Rights Reserved

USER INSTRUCTION MANUAL

M/N: TT1200A, P/N: 101-00930

M/N: OH58D, P/N: 101-00930-OH58D

Doc P/N: 56-101-00930

Revision H

June 3, 2022

______________________________________

TT1200A & OH58D

Turbine Temperature Test Set

56-101-00930 Revision H Page ii

Corporate Headquarters

4101 Northwest 29thStreet

Miami, Florida 33142

www.barfieldinc.com

Email: [email protected]

Barfield Inc. Confidential and Proprietary Information.

This document and all the information contained herein is the sole property of Barfield Inc.

No intellectual property rights are granted by the delivery of this document or the disclosure of its content.

This entire document is proprietary information and shall not be reproduced or disclosed to a third party without

the express written consent of Barfield Inc.

This document and its content shall not be used for any purpose other than that for which it is supplied.

56-101-00930 Revision H Page iii

CONTACT INFORMATION

Users are requested to notify the manufacturer of any discrepancy, omission, or error found in this

manual. Inquiries should include specific questions and reference the publication title, number, chapter,

page, figure, paragraph, and effective date.

Please send comments to:

TECHNICAL CUSTOMER SUPPORT - GSTE

BARFIELD, INC.

P.O. BOX 025367

MIAMI, FL 33102-5367

USA

Telephone (305) 894-5400

(800) 321-1039

Fax (305) 894-5401

Email gsesales@barfieldinc.com

56-101-00930 Revision H Page iv

MAINTENANCE AND REPAIR INFORMATION

The manufacturer of this equipment does not recommend the user to attempt any maintenance or repair.

In case of malfunction, contact the manufacturer to obtain the list of approved repair facilities worldwide,

ensuring that this equipment will be serviced using proper procedures and certified instruments.

BARFIELD PRODUCT SUPPORT DIVISION

Telephone (305) 894-5400

(800) 321-1039

Fax (305) 894-5401

Email gsesales@barfieldinc.com

Shipping Address:

Barfield, Inc.

4101 NW 29th Street

Miami, Florida 33142

USA

Mailing Address:

Barfield, Inc.

P.O. Box 025367

Miami, FL 33102-5367

USA

Vector Aerospace

Shipping Address:

Telephone 33 (0)1 30 18 53 48

Fax 33 (0)1 30 18 53 45

Vector Aerospace

1 Boulevard du 19 Mars 1962 –BP50064

F95503 GONESSE Cedex,

France

56-101-00930 Revision H Page v

REVISION RECORD

REV.

ECO #

REV. DATE

DESCRIPTION OF CHANGE

A

N/A

February 28, 2003

Initial Release.

B

260-00722

May 9, 2008

Specifications, Company Contact

Information, and Logo were Updated.

Chapters and Sections were reorganized.

C

260-00807

November 16, 2010

Update style; add the note that this also

relates to M/N OH58D.

D

260-00829

April 12, 2011

Updated warranty information

E

260-00914

May 21, 2012

Updated recertification to include 101-

00930-OH58D.

F

260-00914

September 25, 2014

Updated Barfield logo & warranty info.

G

260-01254

April 20, 2020

Removal of CE label on Figure 1. Figure 2

updated. Revision of General Description,

item 10. Document reformatted. Minor

grammar revisions.

H

260-01375

June 3, 2022

Addition of note below item 13 on p. 6 and

section C. to p. ix. Updated formatting and

reordered items.

56-101-00930 Revision H Page vi

TABLE OF CONTENTS

Contact Information

Maintenance and Repair Information

Revision Record

Table of Contents

List of Figures

List of Tables

PAGE

INTRODUCTION.................................................................................................................... viii

1. PUBLICATION BREAKDOWN..................................................................................................viii

2. INFORMATION PROVIDED WITH THE TEST SET..................................................................viii

3. RECERTIFICATION....................................................................................................................ix

CHAPTER 1: GENERAL........................................................................................................... 1

1. INTENDED USE .........................................................................................................................1

2. DESCRIPTION............................................................................................................................ 1

3. SPECIFICATIONS...................................................................................................................... 3

4. CAPABILITIES............................................................................................................................ 4

CHAPTER 2: OPERATION....................................................................................................... 5

1. OPERATING CONTROLS ..........................................................................................................5

2. GENERAL OPERATING INSTRUCTIONS..................................................................................7

3. POWER UP (INITIALIZATION)................................................................................................... 8

4. MENU DISPLAYS.......................................................................................................................9

CHAPTER 3: TEST PROCEDURES....................................................................................... 11

1. MOVING COIL TYPE INDICATOR TEST PROCEDURES........................................................ 11

2. POTENTIOMETRIC OR SERVO-TYPE INDICATOR TEST PROCEDURE..................................

(Without Lead Resistance) ..................................................................................................... 14

CHAPTER 4: RECEIVING, SHIPPING & STORAGE............................................................. 16

1. RECEIVING.............................................................................................................................. 16

2. SHIPPING................................................................................................................................. 16

3. STORAGE ................................................................................................................................ 16

56-101-00930 Revision H Page vii

LIST OF FIGURES

PAGE

Figure 1 Identification Label...............................................................................................................viii

Figure 2 Owner Warranty Registration Card ........................................................................................ix

Figure 3 Limited One Year Warranty.................................................................................................... x

Figure 4 TT1200A Test Set..................................................................................................................1

Figure 5 TT1200A Front Panel & Switches .......................................................................................... 5

Figure 6 Power Up Message Display Sequence ..................................................................................9

Figure 7 Display Menu Flowchart......................................................................................................... 9

LIST OF TABLES

PAGE

Table 1 Physical Characteristics........................................................................................................... 3

Table 2 Temperature Measurement .....................................................................................................3

Table 3 Lead Resistance Measurement ...............................................................................................3

Table 4 Insulation Measurement ..........................................................................................................3

Table 5 Simulated System Resistance Measurement........................................................................... 3

56-101-00930 Revision H Page viii

INTRODUCTION

1. PUBLICATION BREAKDOWN

A. This user instruction manual establishes the standards of operation for the TT1200A Turbine

Temperature Test Set.

Its purpose is to provide sufficient information for the personnel unfamiliar with this Tester to

understand this equipment, identify its parts, and operate it in accordance with proper

procedures, operating techniques, precautions, and limitations.

Note: The manufacturer has designed this equipment to be safe when operated using the

procedures and instructions detailed in this manual. Do not use this equipment for any

other purpose than that stated, as the protection provided by the equipment may be

impaired.

2. INFORMATION PROVIDED WITH THE TEST SET

In addition to this User Instruction Manual, the Test Set is delivered with the items described below.

A. The identification label located on the front bulkhead of the Test Set (Figure 1), provides the

following information:

Manufacturer Name

Designation of Equipment

Equipment Part Number

Equipment Model Number Equipment Serial Number

Equipment Modification (if applicable) Equipment Options (if applicable)

Figure 1 Identification Label

TURBINE TEMPERATURE TEST SET

101-00930

TT1200A

56-101-00930 Revision H Page ix

B. Each new or re-certified unit is delivered with a Certificate (not pictured) that shows the date

when the unit was tested by the manufacturer, its serial number and when the next certification

is due. This certificate confirms that the unit performed according to its design specifications.

C. The Owner’s Warranty Registration card (refer to Figure 2) is to be completed by the owner and

returned to Barfield, Inc. within ten (10) days of purchase to ensure automatic update of printed

matter and validation of warranty.

To register your unit, please visit https://www.barfieldinc.com/warranty_registration or scan the

QR code on the supplied Warranty Registration.

Figure 2 Owner Warranty Registration Card

D. The TT1200A Limited One Year Warranty can be seen in Figure 3.

3. RECERTIFICATION

A. The Test Set P/N 101-00930 and 101-00930-OH58D has a one-year recertification requirement.

Maintenance required by this unit must be performed by qualified technicians in a shop

equipped with the necessary tooling and facilities.

56-101-00930 Revision H Page x

Figure 3 Limited One Year Warranty

56-101-00930 Revision H Page 1

CHAPTER 1: GENERAL

1. INTENDED USE

A. This publication contains the description and the operating procedures for:

1. TT1200A, Digital Turbine Temperature Test Set, P/N 101-00930

2. OH58D, Digital Turbine Temperature Test Set, P/N 101-00930-OH58D

The TT1200A is specifically designed to test and calibrate Chromel - Alumel (CH - AL)

temperature indicating systems.

2. DESCRIPTION

Note: It is recommended that the user read this manual through its entirety to become familiar with

the TT1200A Test Set and use the placard instructions as a quick reference only.

Additionally, it is advisable that the user reviews the specific aircraft system before performing

any tests or checks (refer to the Aircraft Maintenance Manual (AMM)).

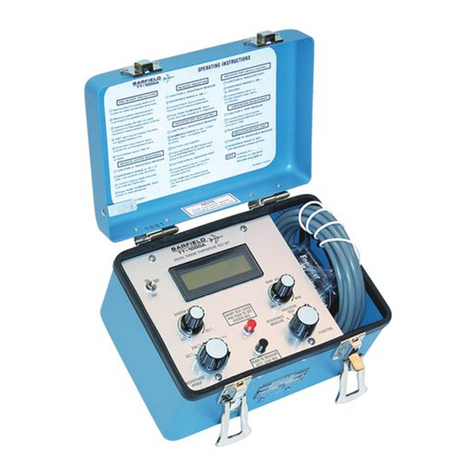

A. The TT1200A (refer to Figure 4) provides the means for quickly troubleshooting aircraft

temperature indicating systems. It has sufficient sensitivity and accuracy to test thermocouple

and system resistance, insulation, and indicator calibration. It features portability, simplicity of

operation, direct reading, and multifunctional versatility.

Figure 4 TT1200A Test Set

56-101-00930 Revision H Page 2

B. The main features of the T1200A are:

1. Microprocessor Based

2. Backlit 16-character alphanumeric LCD, which provides readings with applicable units and

instructional user prompts.

3. Specifically designed to meet all requirements for testing aircraft Chromel - Alumel (CH - AL)

temperature measuring systems, providing an accurate display of thermocouple outputs in

degrees Celsius (°C), Fahrenheit (°F) and Millivolt (mV).

4. Thermocouple and lead resistance measurements to 0.001 Ω and insulation measurements

up to 200 MΩ.

5. Simulates thermocouple outputs and system lead resistances from 2 to 25 Ω.

6. Completely self-contained, self-monitoring, easily portable temperature and resistance

measuring and simulating device for all CH - AL systems with the capability to bench test

indicators.

7. Human engineered for maximum ease of operation.

8. Automatic ambient test point temperature correction.

9. Carrying Case features:

a) Fabricated from high impact plastic

b) Provides a pouch for test lead storage.

c) The lid contains a placard of short operating instructions for the experienced technician.

10. Auto Detection of Cable: At power up, the TT1200A looks to see if the Standard Cable leads

are connected to the panel’s TEST receptacle and displays the prompt “TEST CABLE?” if

no cable is detected. If the Standard Cable leads are then connected to the TEST

receptacle, the prompt “Standard Cable” will be briefly displayed. If the TT1200A is powered

up with the Standard Cable leads already connected to the panel’s TEST receptacle, no

prompt is displayed.

11. Color Coded Function Keypad: For ease of use, the TT1200A keypad is color-coded to

indicate the function, setting, range, and/or mode (soft key) pairing.

12. Auto Off: To save battery power, this “automatic off” feature allows the user to set a turn off

time period for the unit in 5-minute increments (up to 1 hour). (If auto off is disabled, the Test

Set stays on until the batteries become low.)

56-101-00930 Revision H Page 3

3. SPECIFICATIONS

A. Physical Characteristics

Size (H, W, L)

7.0 in. (17.8 cm), 11.0 in. (27.9 cm), 10.0 in. (25.4 cm)

Weight

7.3 lbs. (3.3 kg)

Table 1 Physical Characteristics

B. Temperature

Type

K (CH –AL Thermocouple)

Range

-25°C to +1200°C (certified)

-50°C to +1372°C (extended)

Accuracy

Typical measurement error at 77°F (25°C) ambient: less

than ±0.5°C

Ambient Operating Range

14°F to 122°F (-10°C to +50°C)

Table 2 Temperature Measurement

C. Lead Resistance

Range

0-19.999 Ω in 0.001 Ω increments

0-199.99 Ω in 0.01 Ω increments

0-1.9999 kΩ in 0.0001 kΩ increments

0-19.999 kΩ in 0.001 kΩ increments

Accuracy

±0.05% of reading ±2 counts

Table 3 Lead Resistance Measurement

D. Insulation

Range

0-199.9 kΩ in 0.1 kΩ increments

0-1.999 MΩ in 0.001 MΩ increments

0-19.99 MΩ in 0.01 MΩ increments

0-200 MΩ in 5 MΩ increments

Accuracy

±5% of reading ± 5 counts (200 kΩ, 2 MΩ, and 20 MΩ (ranges)

± 10% of reading ± 5 counts (200 MΩ range)

Excitation

45 VDC nominal

Table 4 Insulation Measurement

E. Simulated System Resistance

Adjusted Range

Less than 2.00 Ω to greater than 25.00 Ω

Fixed Setting

Less than 0.01 Ω

Table 5 Simulated System Resistance Measurement

56-101-00930 Revision H Page 4

4. CAPABILITIES

A. Measures and displays resistance of thermocouples, thermocouple rings and system lead

circuits.

B. Measures and displays insulation resistance of system wiring and other components.

C. Simulates CH - AL thermocouples with or without simulated system lead resistance.

D. Measures and displays values of CH - AL thermocouples in terms of millivolts, millivolts with

ambient compensation, 1°F or 0.1°F, and 1°C or 0.1°C.

E. Automatically compensates for ambient temperature at test lead connection junction point or

indicates this cold junction temperature.

56-101-00930 Revision H Page 5

CHAPTER 2: OPERATION

1. OPERATING CONTROLS

A. The functions of the front panel switches and components are as follows (refer to Figure 5):

Figure 5 TT1200A Front Panel & Switches

1. The PWR (power) pushbutton, when pressed, applies power to the TT1200A and begins the

initialization process.

2. The BKLT (backlight) pushbutton, when pressed, provides a backlight to the LCD to

improve readability under dim lighting conditions. A second press of the key turns the

backlight off. (The backlight goes out automatically five minutes after activation to conserve

batteries, unless the “BKLT auto-off” feature is disabled by pressing the BKLT pushbutton

for 2 or more seconds.)

3. The TEMP ADJ control knob allows coarse adjustment of the temperature. When the

FUNCTION is in the IND Test position, the display shows millivolt readings.

4. The FINE control provides exact adjustment of the temperature or millivolt readings shown

on the display when the FUNCTION switch is in the IND TEST position.

5. The FUNCTION switch is a four-position rotary switch that allows selection of the four main

test functions:

a) RES MEAS (Resistance Measure)

b) INS MEAS (Insulation Measure)

c) IND TEST (Indicator Test)

1

12

13

14

15

16

17

10

9

8

7

6

5

11

2

3

4

56-101-00930 Revision H Page 6

d) TEMP MEAS (Temperature Measure)

6. The RANGE switch is a four-position rotary switch that allows selection of the resistance

and insulation ranges, 20 Ω, 200 Ω, 2 KΩ and 20 KΩ (for Resistance Measuring, RES

MEAS), or 200 KΩ, 2 MΩ, 20 MΩ and 200 MΩ (for Insulation Measuring, INS MEAS.) The

fourth position is also used for 0 Ω system resistance for the IND TEST function.

7. The PTM (Press To Measure) button, when pressed, activates the TT1200A excitation and

measuring processes (when the FUNCTION switch is set to the RES MEAS or INS MEAS

position).

Note: While the TT1200A is processing the measurements, a flashing “M”appears

on the right side of the display. When the process completes, a steady “H” replaces

the “M” on the display.

8. The PTS (Press To Set) button, when pressed, activates the SYS RES switch for system

resistance adjustment. When PTS is held pressed in while rotating the SYS RES, the user

may adjust resistance to the desired resistance setting.

9. The SYS RES (System Resistance) control knob is used to adjust system lead resistance

from 2 to 25 Ω.

10. The TEST connector provides the means for connecting the TT1200A's standard leads or

specifically designed interface cabling.

11. The Display is a 16-character alphanumeric LCD that shows the user prompts and all

readings with associated units.

12. The MENU pushbutton, when pressed, causes the display to show the remaining available

battery life (Battery ###%). In addition, the user may then use the soft keys mV ( ↑ ) or

°F ( ↓ ) to scroll through display messages and option menus.*

13. The CONT pushbutton when held in and used with the soft keys mV (↑) or °F (↓), allows the

user to adjust the display contrast level from 0 to 100. The pushbutton is also a soft key

(ESC) to cancel a function and return the unit to normal operation.*

Note: Units identified with Mod D use a different P/N LCD Display to replace the original P/N

(now obsolete) and will no longer retain adjusted contrast levels but instead will revert

to the factory default at each power up.

14. The mV (millivolt) pushbutton is a toggle which, when pressed, allows the user to select

between two millivolt modes: mV and mV amb. When used with the MENU display, it is a

soft key ( ↑ ) to scroll through MENU selections. When used with the CONT pushbutton, the

user may increase the display contrast.*

Note: The mV mode simulates a DVM function equivalent to having a DVM connected in

parallel at the Test Set’s red and black clips. The mV amb mode configures the

TT1200A for ambient temperature compensation performed at the point of

termination. The displayed millivolt is based on a reference junction at 0°C.

15. The °F(Fahrenheit) pushbutton is a toggle which allows selection between resolutions of

1°F and 0.1°F. The Display alternates between the resolutions with each button press.

When used with the MENU key, the soft key ( ↓ ) may be used to scroll to MENU selections.

When used with the CONT pushbutton, the user may decrease the display contrast. *

16. The °C (Celsius) pushbutton is a toggle that allows selection between resolutions 1°C and

0.1°C. The Display alternates between resolutions with each button press. The pushbutton

is also a soft key (ENT) to enter Menu confirmations.*

56-101-00930 Revision H Page 7

*Note: The soft keys referred to in item numbers 12-16 of Figure 4 may also be used as

numeric keys when entering a password.

17. Two battery holders contain six (6) C-cell alkaline batteries that provide the power for all test

set functions.

18. Standard Leads P/N 175-00215 for Test Set P/N 101-00930 or P/N 175-00217 for Test Set

P/N 101-00930-OH58D.

2. GENERAL OPERATING INSTRUCTIONS

Consult the temperature indicator system and/or engine manufacturer's instructions for procedures

and specifications.

Note: It is recommended that the complete TT1200A Operation procedures be read

before attempting to use the Test Set.

A. Protective Circuits

Although the TT1200A has input protection, do not connect the test set to an energized circuit.

B. Battery Installation and Verification

1. Remove the covers from the battery holders located on the right side of the case. Lift the left

side of the TT1200A so that the batteries slide out. Insert three (3) alkaline C-cell batteries

into each holder with all positive terminals facing outward. Reattach the covers to each tube.

2. At power-up the display shows the message “Battery ###%”, to indicate the remaining

available battery life.

3. The user may check battery condition at any time by pressing the MENU pushbutton.

4. When the available battery power goes below 15%, the Test Set displays the “Battery Low”

message approximately every minute. When the available battery power goes below 7%,

the T/S displays the “Battery Low” message every 30 seconds. In this case, replace the

batteries as was described above.

C. Precautions

1. Do NOT press the PTM or PTS pushbuttons with test clips connected to the aircraft

indicator. The applied current may damage the indicator.

2. Do NOT connect test clips to an energized circuit. Although the TT1200A is provided with

protective devices, not all damaging potentials may be completely safe.

3. Allow sufficient time for test clips to stabilize to the temperature of the terminals to which

they are connected for temperature tests.

4. For greatest accuracy, measure system and thermocouple resistance with a cold engine.

5. To conserve battery power, power down the Test Set when it is not in use.

6. The Test Set displays the message “Battery Low” indicating that the batteries should be

replaced.

56-101-00930 Revision H Page 8

D. Hot Engine Testing

A hot engine causes thermocouples to generate a small potential which produces errors in

measured resistance values. This effect is natural for any type of resistance measuring

instrument.

The effect, however, can be avoided by taking two measurements:

1. With test leads connected in one polarity;

2. Reversing the lead connections for the second measurement.

Add the two readings and divide by two. (The true value is equal to the average of the two

readings.) The two readings must be taken in quick succession so that the thermocouple

temperature will be the same for both readings. If the thermocouples are too hot, the readings

will be too far from nominal to provide sufficient accuracy. In this case, wait for the engine to

further cool.

E. Setting the System Resistance

1. Short the test lead clips together.

2. Set the FUNCTION switch to RES MEAS.

3. Set the RANGE switch to 200 Ω.

4. While pressing in the PTS pushbutton in, rotate the SYS RES knob to set the required

system resistance for the specific aircraft-under-test (refer to the specific AMM).

Note: While the PTS button is held in, the TT1200A shows the message “PTS”

on the right of the display.

5. Release the PTS button.

Note: The TT1200A replaces the message “PTS” with “SET” on the display.

3. POWER UP (INITIALIZATION)

A. At power up, the TT1200A displays a series of informational messages (refer to Figure 5),

including the unit’s software version (Ver ##.##.##.X); the available battery power percentage

(Battery ###%) and the calibration due date (Cal. Due, mm/yyyy).

Note: If the calibration due date is less than 30 days before the calibration is needed, the

message “Cal. In ## Days” displays. If the calibration due date has been exceeded,

the unit displays “Cal Required”.

B. If no errors are detected during power up, the instrument enters normal mode. If the function

switch is in the RES MEAS or INS MEAS position, the message “Push PTM” displays.

56-101-00930 Revision H Page 9

Figure 6 Power Up Message Display Sequence

4. MENU DISPLAYS

A. Once the MENU button is pressed, the user may use the mV ( ↑ ) or the °F ( ↓ ) soft keys to

scroll through the message display and option menus as shown (refer to Figure 7):

Figure 7 Display Menu Flowchart

1. Battery ###%

The display shows the available battery power percentage available.

2. Ver. ##.##.##.X

The display shows the current software version installed in the unit.

56-101-00930 Revision H Page 10

3. Cal Due mm/yyyy

The display shows the month and year when calibration is due.

4. Auto Off

This feature allows the user to set a time period for the unit to automatically turn off when

not in use. To activate the feature at the Auto ± display, press ENT (°C). Use the mV or °F

keys to set 5-minute increments (up to 60 minutes). Press ENT to accept entry. Press ESC

to exit from Menu options.

5. Maintenance

This menu option is password protected and allows other maintenance functions such as

setting the calibration due date.

This manual suits for next models

3

Table of contents

Other barfield Test Equipment manuals

barfield

barfield 2311FA Operator's manual

barfield

barfield TT-1000A Operator's manual

barfield

barfield TT-1000A Operator's manual

barfield

barfield DPS400 User manual

barfield

barfield 1811D Series Operator's manual

barfield

barfield DPS1000 Operator's manual

barfield

barfield DPS1000 Operator's manual

barfield

barfield DPS1000 Operator's manual

barfield

barfield 2548H Operator's manual

barfield

barfield 2548H Owner's manual