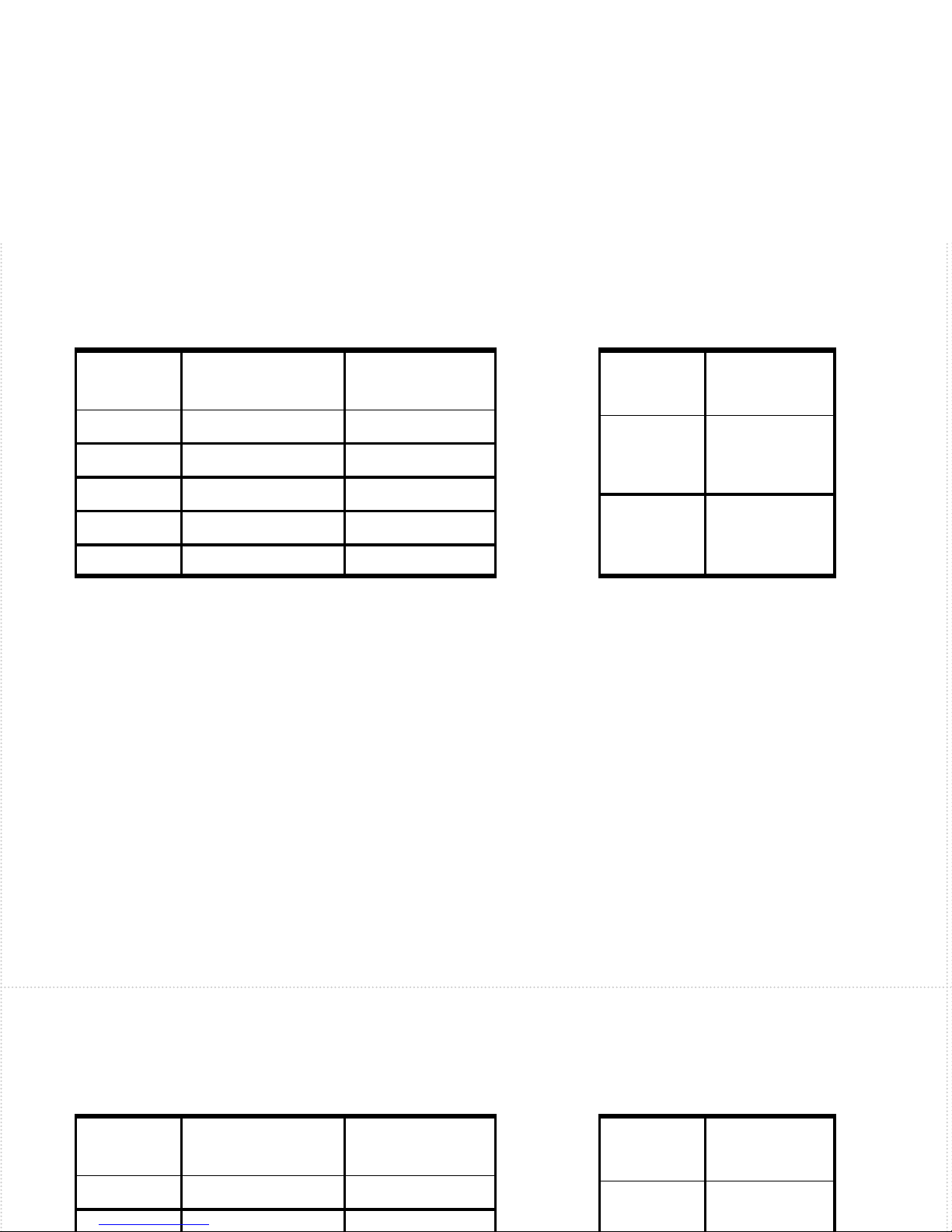

PRESSURE

MODEL

PRESSURE RANGE

PSI (BAR)

PROOF PRESSURE

PSI (BAR)

220 - 120 (1.4 - 8.3) 9000 (600)

390 - 250 (6.2 - 17.2) 9000 (600)

4250 - 950 (17.2 - 65.5) 9000 (600)

5700 - 1900 (48.3 - 131) 9000 (600)

61000 - 3000 (69 - 207) 9000 (600)

OPERATING CHARACTERISTICS ELECTRICAL RATINGS

SET POINT ADJUSTMENT:

The switch is factory set at approximately 50% of the maximum pressure range.

In order to change the setting of the switch follow the instructions below.

Caution: The adjustment screw is electrically conductive to the contacts. Therefore, to prevent an electric shock,

always use insulated tools and only monitor the circuit with a digital multimeter or low voltage (<12 VDC) LED light

while adjusting the setpoints. Never contact any conductive object, wire, cable, connector pin, or terminal blade

with a conductive portion of the adjusting tool while adjusting the switch.

Step 1: Insert a 1/8” allen key through the opening on the top center of the switch.

Step 2: Turn the allen key clockwise to increase the pressure setting and counter-

clockwise to decrease.

Note: If your product contains flying leads, you will have to remove the two pan Phillip head screw on the top of

the switch and remove the cap in order to access the

adjustment screw.

Caution: Failure to replace the adjustment screw cap will expose the user to the electrically live

adjustment screw Rev 6

ELECTRICAL RATINGS

1

8A @ 12VDC

4A @ 24VDC

2A @ 42VDC

2

33mA @ 12VDC

16mA @ 24VDC

13mA @ 30VDC

GOLD CONTACT

PRESSURE

MODEL

PRESSURE RANGE

PSI (BAR)

PROOF PRESSURE

PSI (BAR)

220 - 120 (1.4 - 8.3) 9000 (600)

390 - 250 (6.2 - 17.2) 9000 (600)

4250 - 950 (17.2 - 65.5) 9000 (600)

5700 - 1900 (48.3 - 131) 9000 (600)

61000 - 3000 (69 - 207) 9000 (600)

OPERATING CHARACTERISTICS ELECTRICAL RATINGS

SET POINT ADJUSTMENT:

The switch is factory set at approximately 50% of the maximum pressure range.

In order to change the setting of the switch follow the instructions below.

Caution: The adjustment screw is electrically conductive to the contacts. Therefore, to prevent an electric shock,

always use insulated tools and only monitor the circuit with a digital multimeter or low voltage (<12 VDC) LED light

while adjusting the setpoints. Never contact any conductive object, wire, cable, connector pin, or terminal blade

with a conductive portion of the adjusting tool while adjusting the switch.

Step 1: Insert a 1/8” allen key through the opening on the top center of the switch.

Step 2: Turn the allen key clockwise to increase the pressure setting and counter-

clockwise to decrease.

Note: If your product contains flying leads, you will have to remove the two pan Phillip head screw on the top of

the switch and remove the cap in order to access the

adjustment screw.

Caution: Failure to replace the adjustment screw cap will expose the user to the electrically live

adjustment screw Rev 6

ELECTRICAL RATINGS

1

8A @ 12VDC

4A @ 24VDC

2A @ 42VDC

2

33mA @ 12VDC

16mA @ 24VDC

13mA @ 30VDC

GOLD CONTACT

PRESSURE

MODEL

PRESSURE RANGE

PSI (BAR)

PROOF PRESSURE

PSI (BAR)

220 - 120 (1.4 - 8.3) 9000 (600)

390 - 250 (6.2 - 17.2) 9000 (600)

4250 - 950 (17.2 - 65.5) 9000 (600)

5700 - 1900 (48.3 - 131) 9000 (600)

61000 - 3000 (69 - 207) 9000 (600)

OPERATING CHARACTERISTICS ELECTRICAL RATINGS

SET POINT ADJUSTMENT:

The switch is factory set at approximately 50% of the maximum pressure range.

In order to change the setting of the switch follow the instructions below.

Caution: The adjustment screw is electrically conductive to the contacts. Therefore, to prevent an electric shock,

always use insulated tools and only monitor the circuit with a digital multimeter or low voltage (<12 VDC) LED light

while adjusting the setpoints. Never contact any conductive object, wire, cable, connector pin, or terminal blade

with a conductive portion of the adjusting tool while adjusting the switch.

Step 1: Insert a 1/8” allen key through the opening on the top center of the switch.

Step 2: Turn the allen key clockwise to increase the pressure setting and counter-

clockwise to decrease.

Note: If your product contains flying leads, you will have to remove the two pan Phillip head screw on the top of

the switch and remove the cap in order to access the

adjustment screw.

Caution: Failure to replace the adjustment screw cap will expose the user to the electrically live

adjustment screw Rev 6

ELECTRICAL RATINGS

1

8A @ 12VDC

4A @ 24VDC

2A @ 42VDC

2

33mA @ 12VDC

16mA @ 24VDC

13mA @ 30VDC

GOLD CONTACT

PRESSURE

MODEL

PRESSURE RANGE

PSI (BAR)

PROOF PRESSURE

PSI (BAR)

220 - 120 (1.4 - 8.3) 9000 (600)

390 - 250 (6.2 - 17.2) 9000 (600)

4250 - 950 (17.2 - 65.5) 9000 (600)

5700 - 1900 (48.3 - 131) 9000 (600)

61000 - 3000 (69 - 207) 9000 (600)

OPERATING CHARACTERISTICS ELECTRICAL RATINGS

SET POINT ADJUSTMENT:

The switch is factory set at approximately 50% of the maximum pressure range.

In order to change the setting of the switch follow the instructions below.

Caution: The adjustment screw is electrically conductive to the contacts. Therefore, to prevent an electric shock,

always use insulated tools and only monitor the circuit with a digital multimeter or low voltage (<12 VDC) LED light

while adjusting the setpoints. Never contact any conductive object, wire, cable, connector pin, or terminal blade

with a conductive portion of the adjusting tool while adjusting the switch.

Step 1: Insert a 1/8” allen key through the opening on the top center of the switch.

Step 2: Turn the allen key clockwise to increase the pressure setting and counter-

clockwise to decrease.

Note: If your product contains flying leads, you will have to remove the two pan Phillip head screw on the top of

the switch and remove the cap in order to access the

adjustment screw.

Caution: Failure to replace the adjustment screw cap will expose the user to the electrically live

adjustment screw Rev 6

ELECTRICAL RATINGS

1

8A @ 12VDC

4A @ 24VDC

2A @ 42VDC

2

33mA @ 12VDC

16mA @ 24VDC

13mA @ 30VDC

GOLD CONTACT