2

Safety Information ........................................................................................................................................................3

Alert Signals ..........................................................................................................................................................3

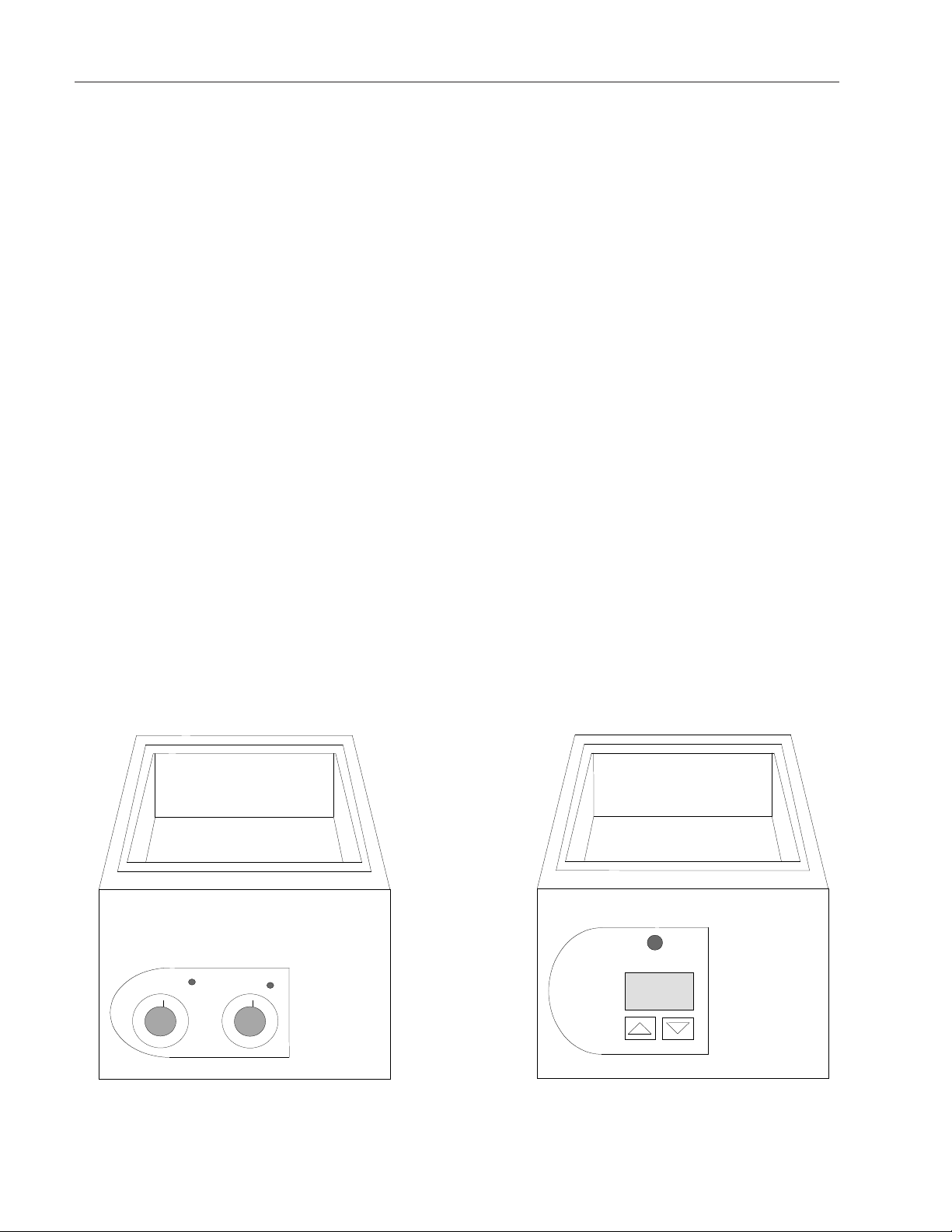

Description....................................................................................................................................................................4

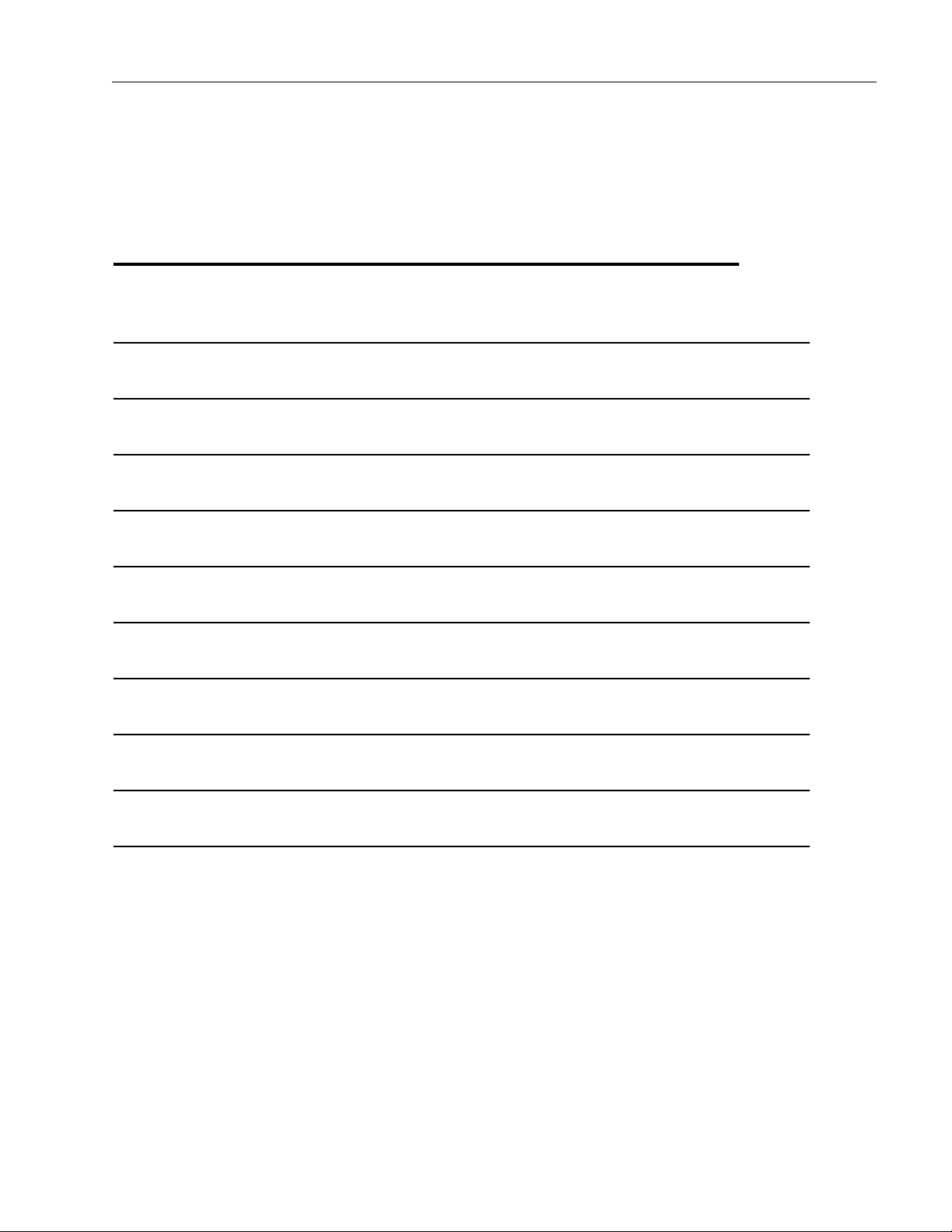

Specifications .............................................................................................................................................................. 5

Digital Water Baths ................................................................................................................................................5

Electrical Requirements..................................................................................................................................5

Temperature Range ........................................................................................................................................5

Uniformity ...................................................................................................................................................... 5

Control .......................................................................................................................................................... 5

Basic Water Baths ................................................................................................................................................5

Electrical Requirements..................................................................................................................................5

Temperature Range ........................................................................................................................................5

Uniformity ...................................................................................................................................................... 5

Control .......................................................................................................................................................... 5

Tank Capacity and Dimensions Digital Water Baths ............................................................................................6

Tank Capacity and Dimensions Basic Water Baths ..............................................................................................7

Declaration of Conformity ......................................................................................................................................8

Unit’s Environmental Operating Conditions ..........................................................................................................8

Unpacking and Installation ..........................................................................................................................................9

Electrical Requirements ........................................................................................................................................9

Setup ....................................................................................................................................................................9

Operation....................................................................................................................................................................10

Controls, Digital Water Baths ..............................................................................................................................10

Bath Temperature is Maintained by Microprocessor Controller ..........................................................................11

Setting the Temperature, Digital Water Baths......................................................................................................11

Temperature Calibration, Digital Water Baths......................................................................................................11

Controls-Basic Water Baths ................................................................................................................................12

Water Bath Temperature is Regulated by Two Thermostats ..............................................................................12

Setting the Temperature, Basic Water Baths ......................................................................................................13

Models 18020 and 18020-1 ................................................................................................................................13

Maintenance ..............................................................................................................................................................14

Draining the Tank ................................................................................................................................................14

Routine Tank Cleaning ........................................................................................................................................14

The Alloy Called Stainless ..................................................................................................................................14

Some Stainless Guidelines to Consider ..............................................................................................................15

The pH Factor......................................................................................................................................................15

Special Considerations........................................................................................................................................15

Cleansing Agents ................................................................................................................................................16

Cleaning Methods................................................................................................................................................16

Materials Effective in Disinfecting........................................................................................................................17

Refilling the Tank ................................................................................................................................................17

Troubleshooting ..........................................................................................................................................................18

Over Temperature Protection ..............................................................................................................................18

Replacement Parts ....................................................................................................................................................19

Ordering Procedures ..................................................................................................................................................21

Two Year Limited Warranty ........................................................................................................................................24

Table of Contents