2

Table of Contents

Introduction..........................................................................................................................................................4

Operation Overview......................................................................................................................................4

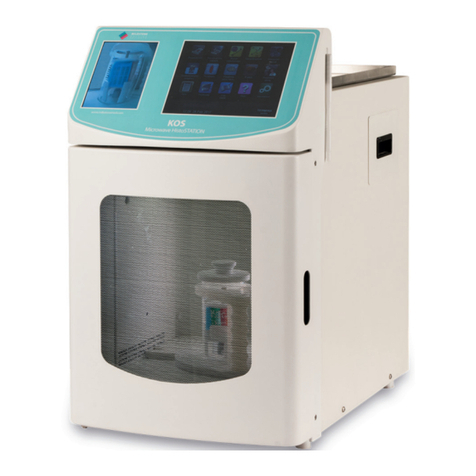

Hydroclave MC8 and MC10 Steam Sterilizer ........................................................................................4

Drying Cycle ..........................................................................................................................................5

Operator Maintenance..................................................................................................................................6

Daily ......................................................................................................................................................6

Weekly....................................................................................................................................................6

Safety Information ..............................................................................................................................................7

Declaration of Conformity ............................................................................................................................7

Description of Symbols on the Equipment ..................................................................................................8

General Description ..........................................................................................................................................10

Intended Use ..............................................................................................................................................10

General Usage............................................................................................................................................10

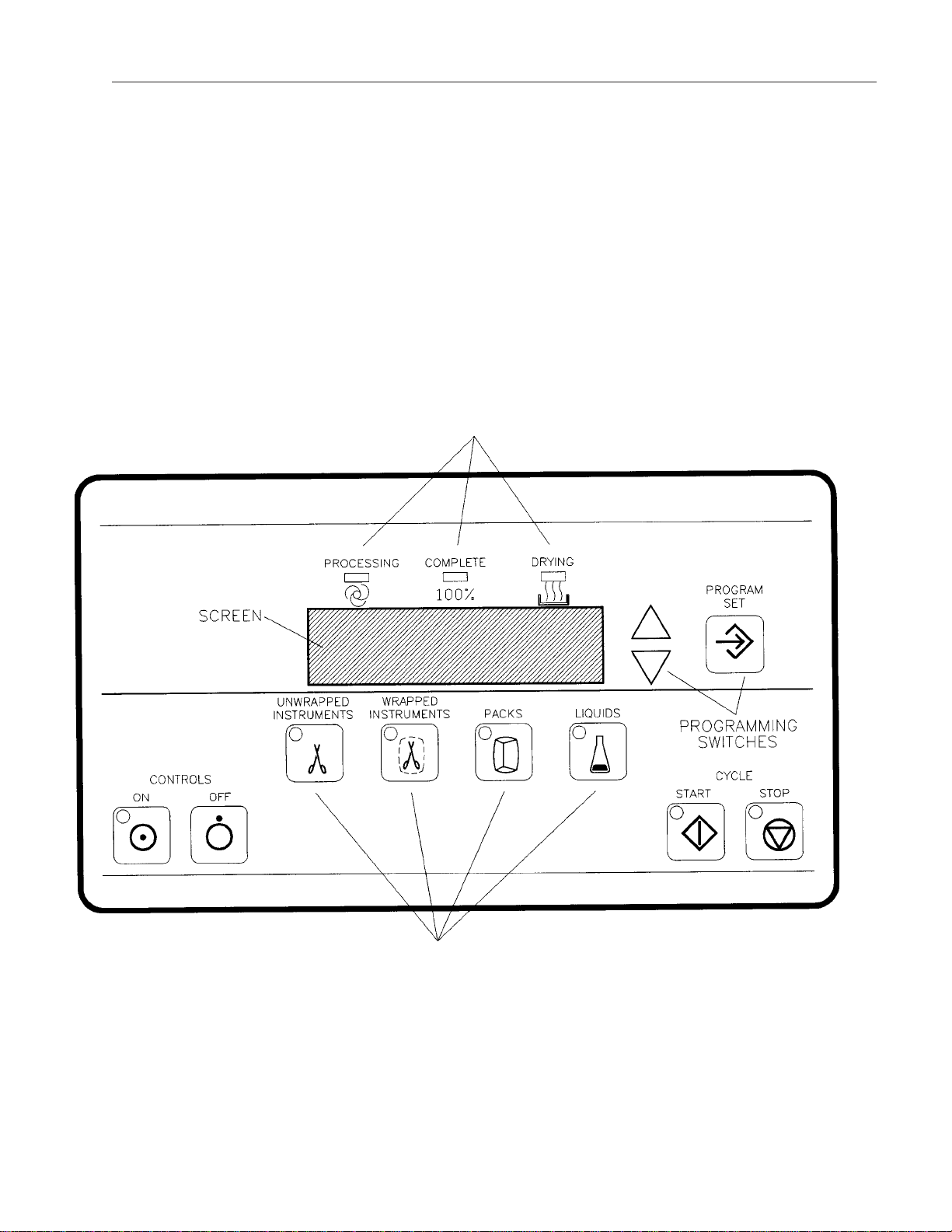

Operating Features ....................................................................................................................................10

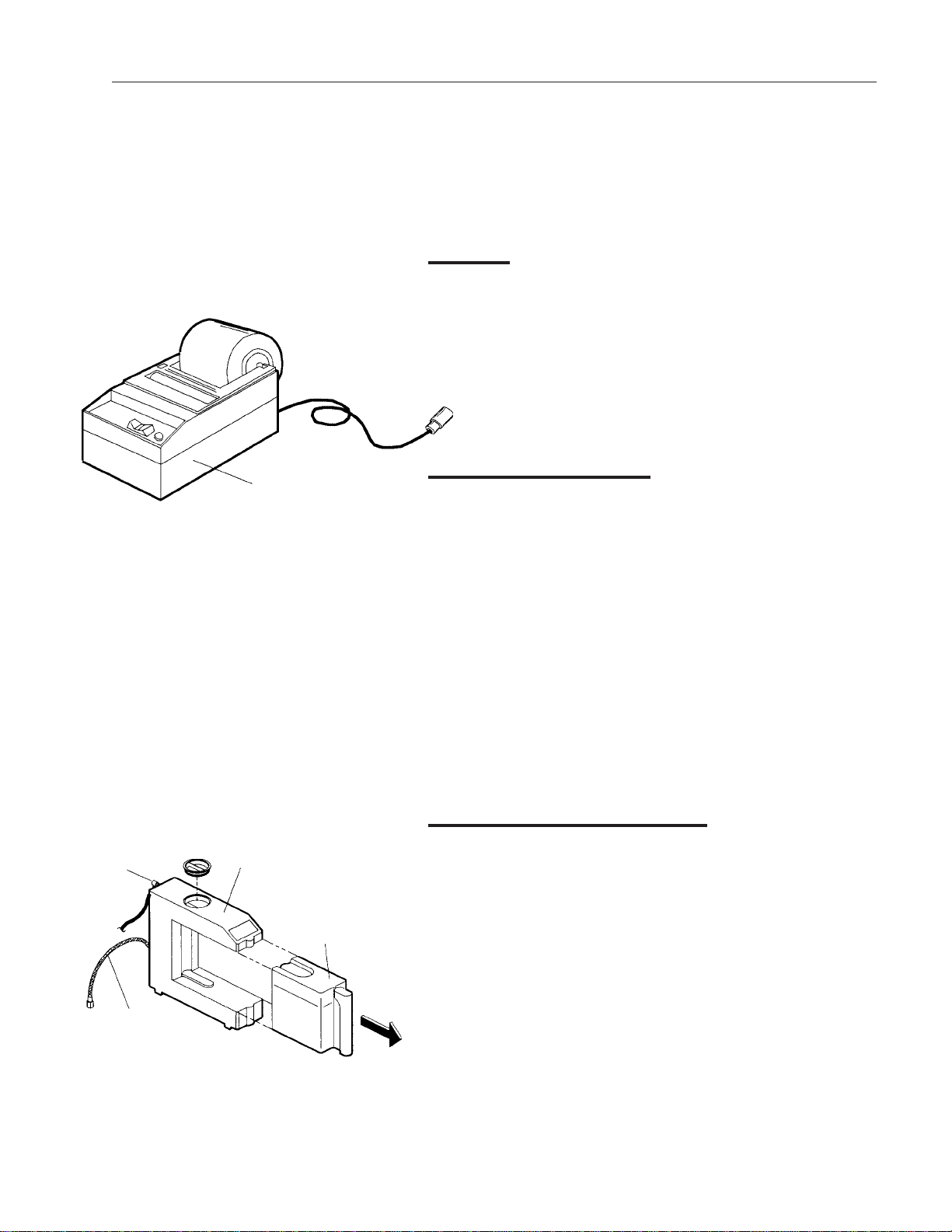

Printer ........................................................................................................................................................13

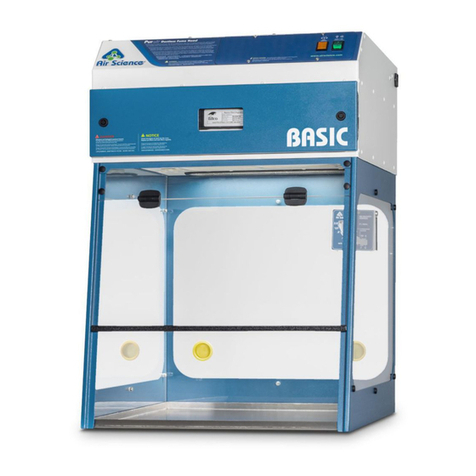

Non-Recirculating Water Accessory ..........................................................................................................13

Recommended Steam Sterilization Monitoring Program............................................................................13

Operation ..........................................................................................................................................................15

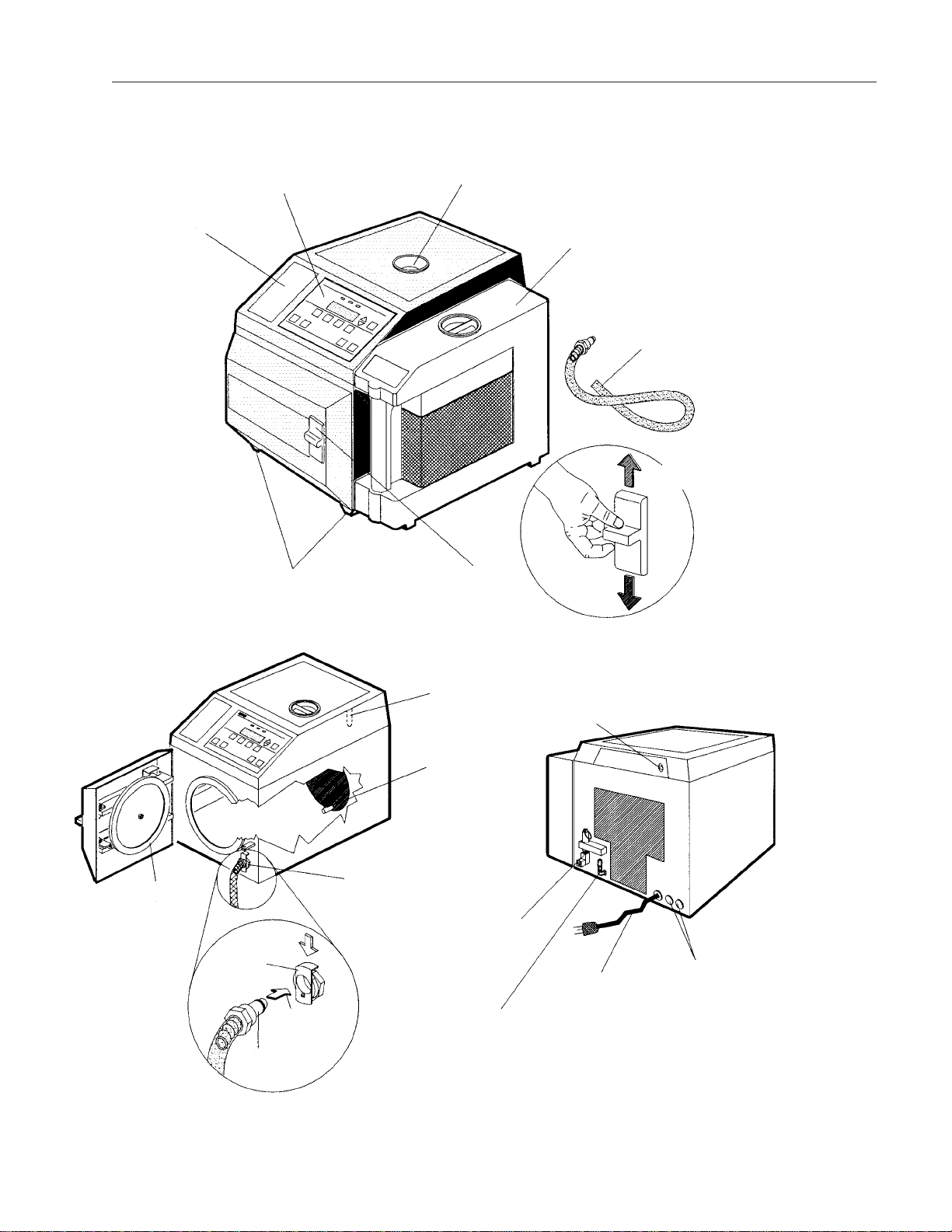

Power On/Controls On................................................................................................................................16

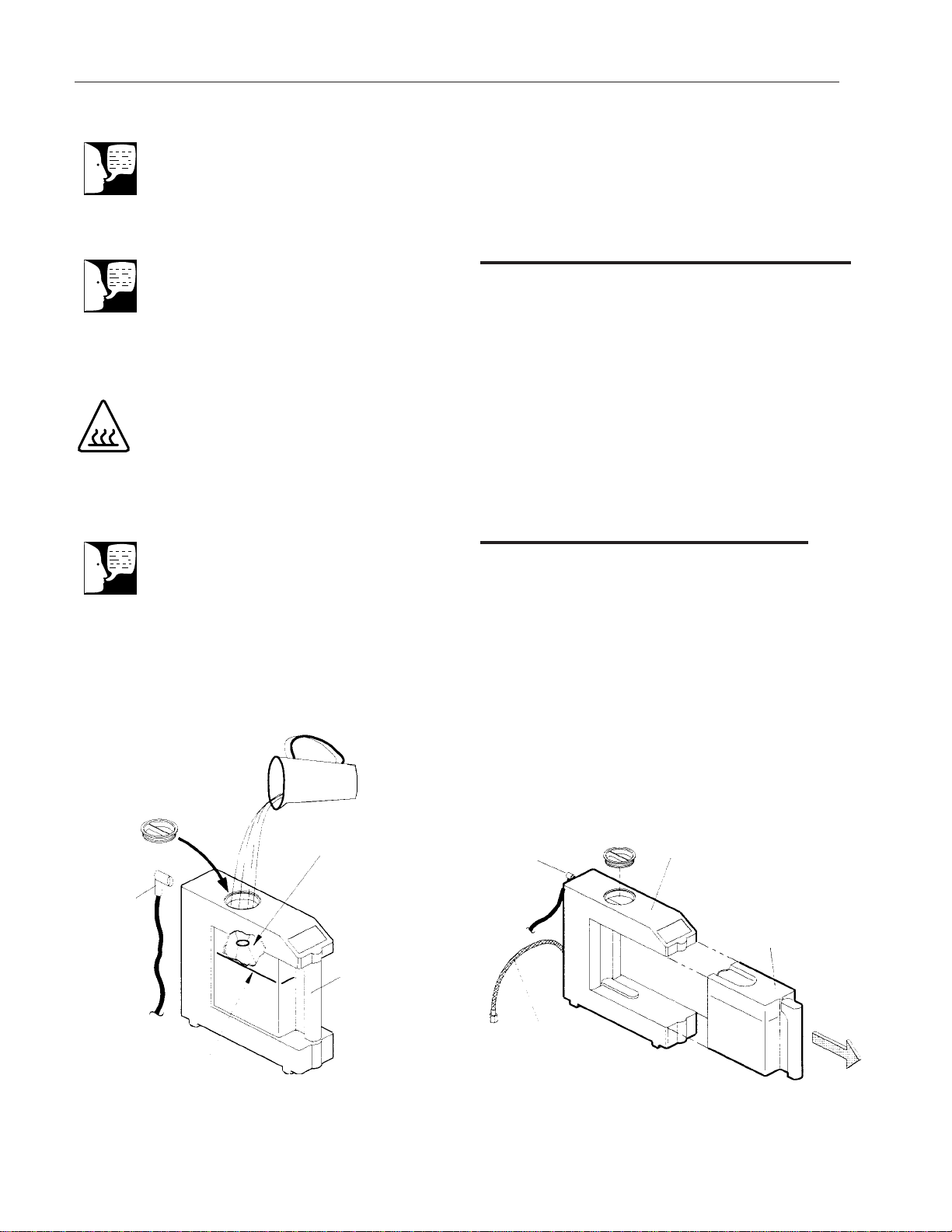

Filling Reservoir..........................................................................................................................................17

Filling Non-Recirculating Tank (Option)......................................................................................................18

Emptying Collection Bottle..........................................................................................................................18

Installing Overflow Tube (Optional) ............................................................................................................19

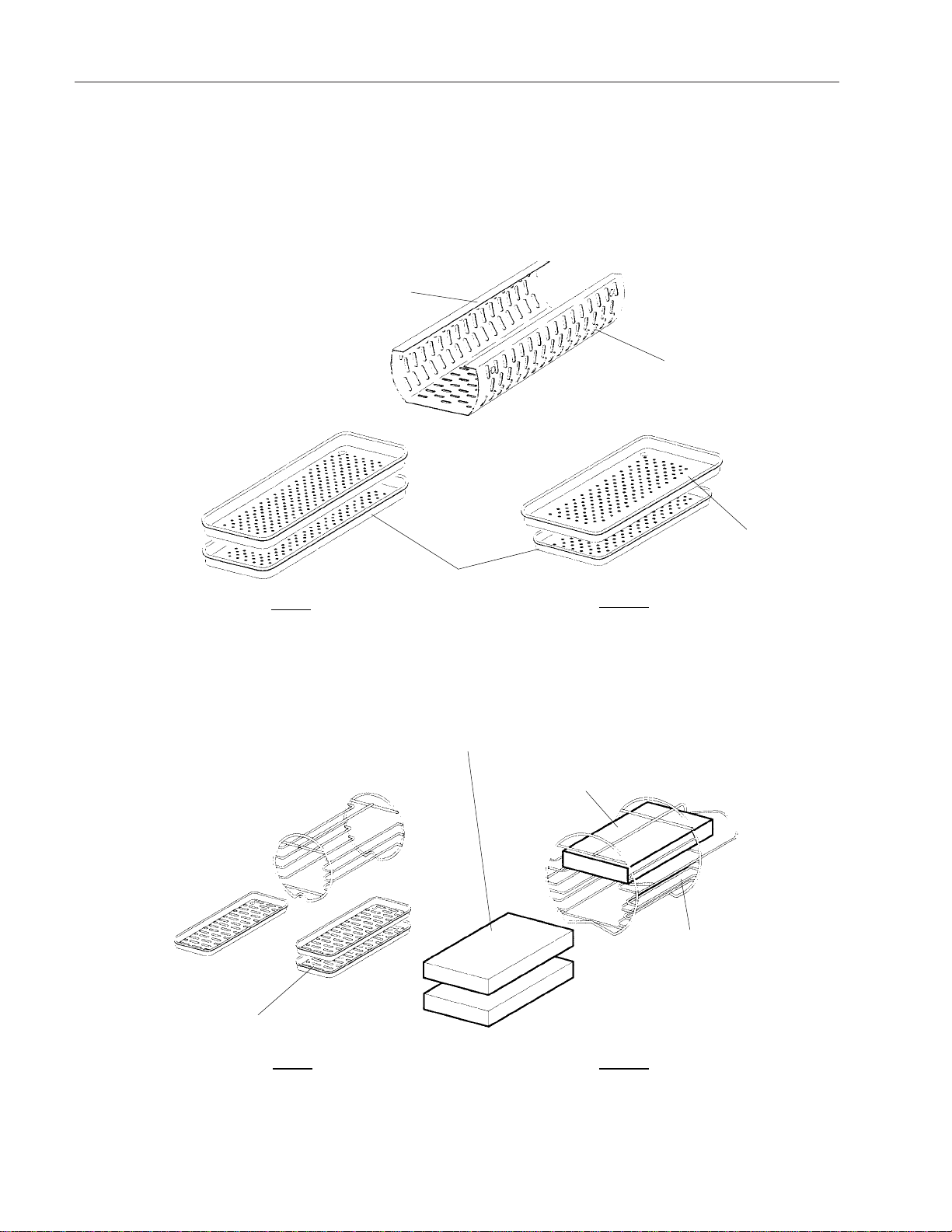

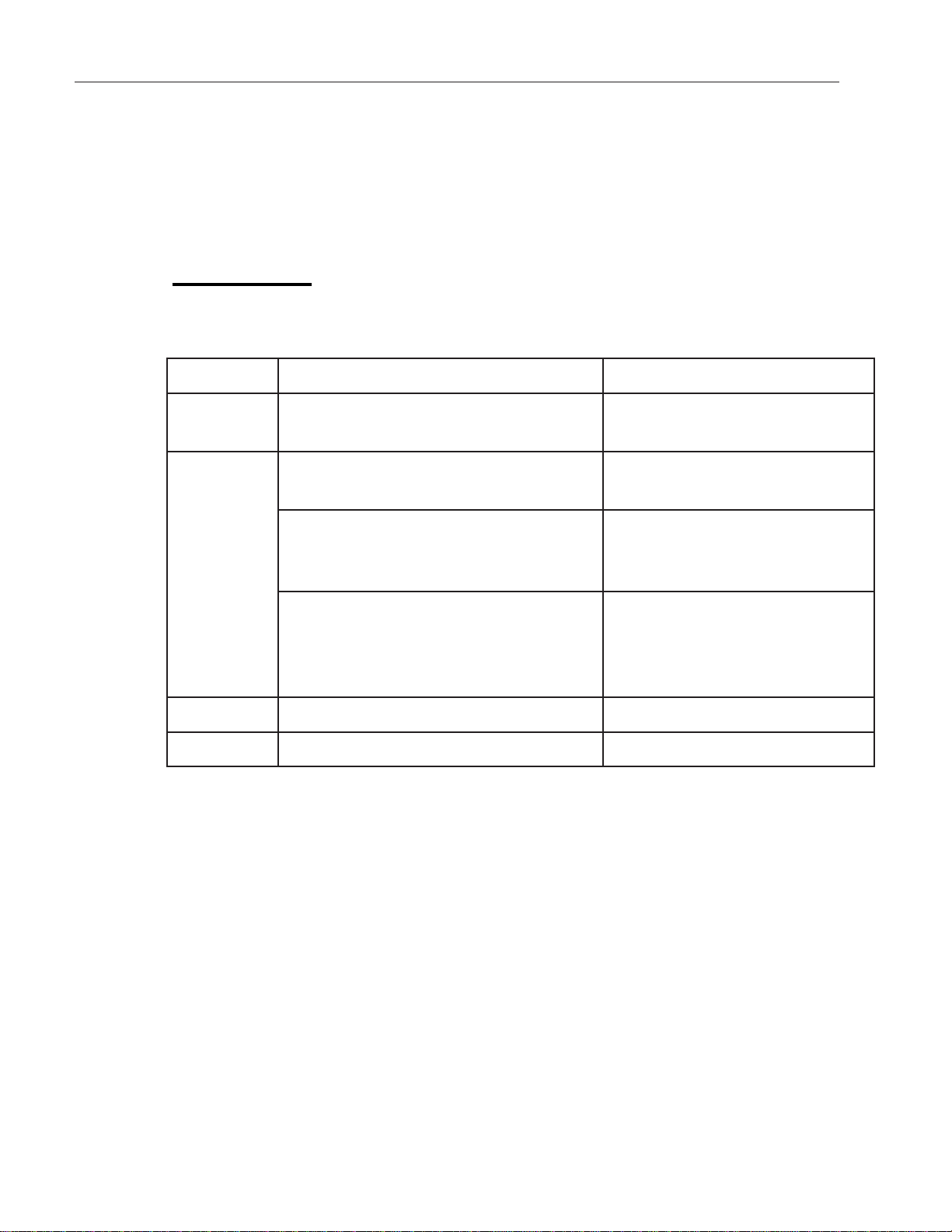

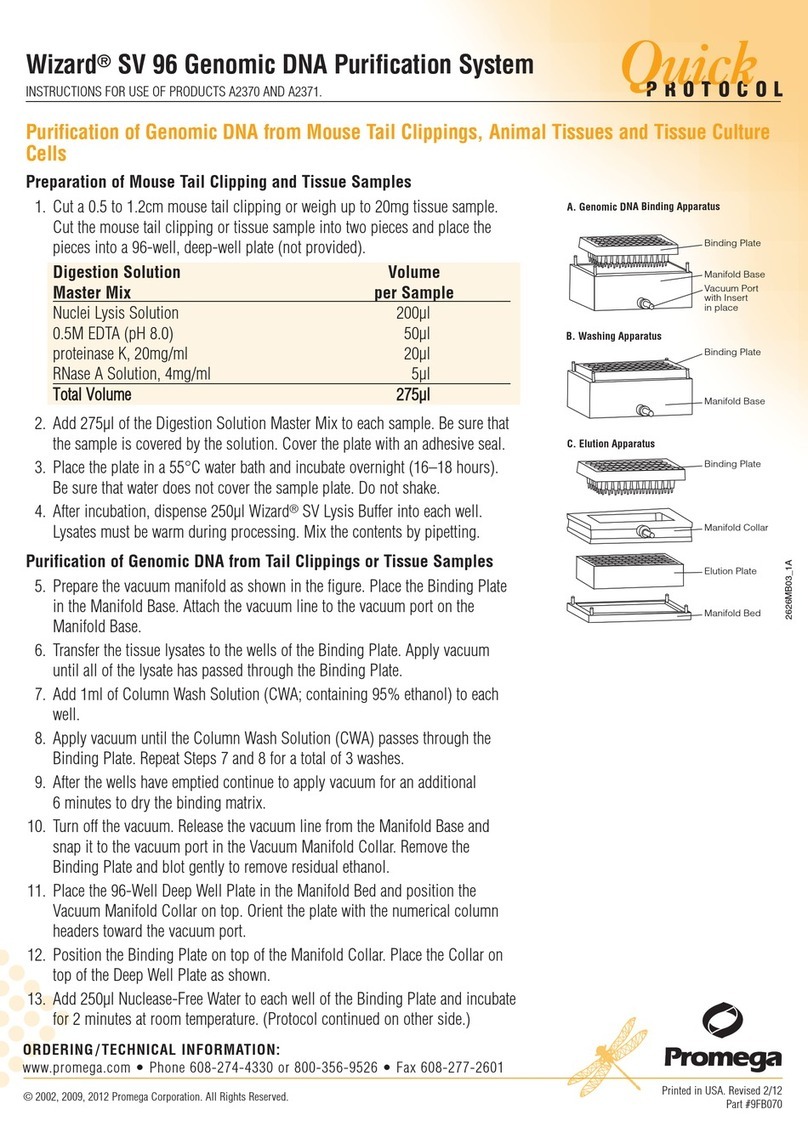

Load Chart..................................................................................................................................................20

Preparing Items for Sterilization ................................................................................................................21

Loading ......................................................................................................................................................21

Selecting Cycle ..........................................................................................................................................22

Starting Cycle ............................................................................................................................................23

Drying Phase..............................................................................................................................................23

Open Door Drying ......................................................................................................................................24

Removing Load...........................................................................................................................................24

Additional Information........................................................................................................................................25

Cancel Cycle ..............................................................................................................................................25

Emergency Power Off ................................................................................................................................25

Power Failure During Cycle........................................................................................................................25

Diagnostic Messages........................................................................................................................................26

Troubleshooting ................................................................................................................................................27

Printer................................................................................................................................................................28

Installation ..................................................................................................................................................28

MC8......................................................................................................................................................28

MC10....................................................................................................................................................28

Operation....................................................................................................................................................28

Paper Roll Replacement ............................................................................................................................29

Ribbon Replacement..................................................................................................................................29

Printer Removal (MC10) ............................................................................................................................30

Operator Maintenance ......................................................................................................................................31

Daily............................................................................................................................................................31