Barnstead EASYpure RO 742 Series User manual

EASYpure™ RO

Reverse Osmosis System

Series 742

INSTALLATION,

OPERATION,

SERVICE AND REPAIR MANUAL,

AND PARTS LIST

Model Voltage

D7422-33 230

D7429-33 230 Low Pressure

1

LT742X16 • 7/16/02

Safety Information ..............................................................................................................................................3

Alert Signals..................................................................................................................................................3

General Usage..............................................................................................................................................3

Warnings ......................................................................................................................................................3

General Specifications ........................................................................................................................................5

Feedwater Requirements ............................................................................................................................5

Product Water Specifications........................................................................................................................5

Membrane Rejection Rates ..........................................................................................................................5

Electrical Requirements................................................................................................................................6

Environmental Conditions ............................................................................................................................6

Declaration of Conformity ............................................................................................................................6

Unpacking ..........................................................................................................................................................7

Installation ..........................................................................................................................................................8

Locating your EASYpure RO ........................................................................................................................8

Bench Mounting............................................................................................................................................8

Wall Mounting ..............................................................................................................................................9

Utility Connections ......................................................................................................................................10

Feedwater Connection ........................................................................................................................10

Reject Water Connection......................................................................................................................11

Tank Overflow Connection ..................................................................................................................12

Connections to Equipment Supplied By the EASYpure RO.......................................................................12

Installing The Prefilter and Membranes......................................................................................................13

Prefilter Installation ..............................................................................................................................13

Membrane Installation ..........................................................................................................................14

Electrical Connections ................................................................................................................................16

Membrane Flush ........................................................................................................................................16

Set "Replace Prefilter" Indicator ................................................................................................................17

Operation ..........................................................................................................................................................19

Indicators ....................................................................................................................................................19

Pressure Gauge ..................................................................................................................................19

LED's ....................................................................................................................................................19

Maintenance......................................................................................................................................................22

Caring For Your EASYpure RO ................................................................................................................22

System Sanitization..............................................................................................................................22

Ventgard® Filter Replacement ..................................................................................................................25

Service and Repair............................................................................................................................................26

General Cleaning Instructions ....................................................................................................................26

Normal Unit Operation ................................................................................................................................26

Fuse Replacement ..............................................................................................................................28

Membrane Replacement ......................................................................................................................28

Prefilter Replacement ..........................................................................................................................29

Parts List ..........................................................................................................................................................30

Recommended Spare Parts ......................................................................................................................30

Troubleshooting ................................................................................................................................................32

Ordering Procedures ........................................................................................................................................33

Wiring Diagrams................................................................................................................................................34

Exploded View ..................................................................................................................................................37

One Year Limited Warranty ..............................................................................................................................40

2

Table of Contents

Your Barnstead EASYpure RO has been

designed with function, reliability, and safety

in mind. It is your responsibility to install it in

conformance with local electrical codes. For

safe operation, please pay attention to the

alert signals throughout the manual.

General Usage

Do not use this product for anything other

than its intended usage.

Warnings

To avoid electrical shock, always:

1. Use a properly grounded electrical

outlet of correct voltage and current

handling capacity.

2. Do not mount the EASYpure RO

directly over equipment that requires

electrical service. Routine mainte-

nance of this unit may involve water

spillage and subsequent electrical

shock hazard if improperly located.

3. Replace fuses with those of the same

type and rating.

4. Disconnect from the power supply

prior to maintenance and servicing.

3

Safety Information

Alert Signals

Warning

Warnings alert you to a possibility of per-

sonal injury.

Caution

Cautions alert you to a possibility of dam-

age to the equipment.

Note

Notes alert you to pertinent facts and

conditions.

Hot Surface

Hot surfaces alert you to a possibility of

personal injury if you come in contact

with a surface during use or for a period

of time after use.

To avoid personal injury:

1. Do not use in the presence of flamma-

ble or combustible materials; fire or

explosion may result. This device con-

tains components which may ignite such

materials.

2. Ensure all piping connections are tight

to avoid leakage of chemicals.

3. Ensure adequate ventilation when using

chemicals for cleaning.

4. Follow carefully the manufacturer’s’

safety instructions on labels of chemical

containers and Material Safety Data

Sheets (M.S.D.S.).

5. Refer servicing to qualified personnel.

To ensure safe mounting:

1. Wall composition and construction, as

well as fastener type, must be consid-

ered when mounting this unit. The

mounting surface and fasteners select-

ed must be capable of supporting a min-

imum of 120 lbs.; inadequate support

and/or fasteners may result in damage

to mounting surface and/or equipment.

If you are unsure of mounting surface

composition, condition and construction,

or correct fasteners, consult your build-

ing maintenance group or contractor.

4

SAFETY INFORMATION

Dimensions

30.5 cm W x 46.7 cm W x 46 cm H.

Feedwater Requirements*

Max. Temperature: 48.8°C

Min. Pressure (standard unit): 30 psig (2.1 bar)

Min. Pressure (low pressure unit): 9 psig (0.62 bar)

Max. Pressure (standard unit): 100 psig (6.8 bar)

Max. Pressure (low pressure unit): 15 psig (1.1 bar)

Inlet Flow Requirements: 53.5 lph

pH: 4 - 11

TDS (Max. ppm as CaCO3): 500

Silt Density Index: <5%

Free Chlorine: <0.1 ppm*

Langlier Saturation Index: Negative

Turbidity: <1 NTU

Iron (Total as Fe): <0.5 ppm

Product Water Specifications*

Product Water Flow Rate: 12 lph*

% Recovery: 20%-26%

Membrane Rejection Rates*

Monovalent Ions: 90-95%

Polyvalent Ions: 95-99%

Particles: >99%

Microorganisms: >99%

Dissolved Organics (300 MW): >99%

Reject Water Flow Rate: 650 ml/min

at 60 PSIG

±5 PSIG

5

General Specifications

* Notes:

1 Feedwater suitability must be determined by a water analysis.

2Free chlorine removed by pretreatment cartridge.

3±1.5 lph, feedwater at 25°C and 60 psig pressure.

4Membrane performance is dependent on condition, pressure, recovery, water temperature and water com

position. Listed membrane performance for a new membrane is based on optimum operating conditions of

60 psig, 15% recovery, 25°C (77°F) feedwater temperature and feedwater composition of a maximum of

500 ppm NaCl at a pH of 6.0-6.5.

5 Membrane performance, flowrates and recovery information are nominal values. Variations in the

feedwater temperature, pumps and reject orifice may slightly alter these results.

Electrical Requirements

Model D7422-33 - 230 VAC ±10%, 47-63 Hz

Model D7429-33 - 230 VAC ±10%, 47-63 Hz

Environmental Conditions

Operating: 17°C - 27°C; 20% - 80% relative

humidity, non-condensing. Installation

Category II (over-voltage) in

accordance with IEC 664. Pollution

Degree 2 in accordance with IEC

664. Altitude limit: 5,000 meters.

Storage: -25°C - 65°C; 20% - 80% relative

humidity.

Declaration of Conformity

Barnstead International hereby declares under its

sole responsibility that this product conforms with

the technical requirements of the following stan-

dards:

EMC: EN50081-1 Generic Emission

Standard;

EN 50082-1 Generic Immunity

Standard.

Safety: IEC 1010-1-92 Safety requirements for

electrical equipment for measurement,

control and laboratory use; Part 1:

General Requirements

per the provisions of the Electromagnetic

Compatibility Directive 89/336/EEC, as amended

by 92/ 31/EEC and 93/68/EEC, and per the

provisions of the Low Voltage Directive 73/23/EEC,

as amended by 93/68/EEC.

The authorized representative located within the

European Community is:

Electrothermal Engineering Ltd.

419 Sutton Road

Southend On Sea

Essex SS2 5PH

United Kingdom

Copies of the Declaration of Conformity are

available upon request.

6

GENERAL SPECIFICATIONS

Carefully remove the unit from its shipping

container.

The following items are shipped separately

and must be removed from the packaging

prior to discarding the packaging:

1. EASYpure RO Ventgard air filter.

2. Power cord.

3. Pump interlock cord.

4. Membrane bypass tubing.

The following items are located inside the

membrane access door:

1. Feedwater tubing.

2. Reject water tubing.

3. Product tubing to connect accessory

reservoir.

4. Product tubing to connect another

EASYpure unit.

7

Unpacking

Locating your EASYpure RO

Your EASYpure RO must be located within six

feet of an electrical outlet appropriate for your

unit, within five feet of your feedwater supply

and close to an atmospherically vented drain. If

you are using the accessory 30 Liter Reservoir

(Part Number TY742X2A), the tank overflow on

the EASYpure RO's integral 6.5 liter tank should

be located below the level of the storage reser-

voir's overflow. This will ensure that the

EASYpure RO's internal float switches will con-

trol the operation of the system. If the

EASYpure RO is to be used with the accessory

30 Liter Reservoir, the reservoir must not be

mounted farther than 4 feet away from the

EASYpure RO. The EASYpure RO Bench Stand

(Part Number D7424) will be required for a

bench mounted installation with an accessory

30 Liter Reservoir.

Bench Mounting

If you are bench mounting the EASYpure RO

without the accessory 30 Liter Reservoir (Part

Number TY742X2A), simply place the

EASYpure RO on a bench.

If you are bench mounting the EASYpure RO

and using it in conjunction with the accessory

30 Liter Reservoir (Part Number TY742X2A),

the EASYpure RO Bench Stand (Part Number

D7424) must be added to the EASYpure RO to

ensure automatic operation. Install the

EASYpure RO Bench Stand as follows:

1. Remove the 4 feet from the EASYpure

RO and retain the screws.

8

Installation

Warning

Do not mount the EASYpure RO

directly over equipment that requires

electrical service. Routine mainte-

nance of this unit may involve water

spillage and subsequent electrical

shock hazard if improperly located.

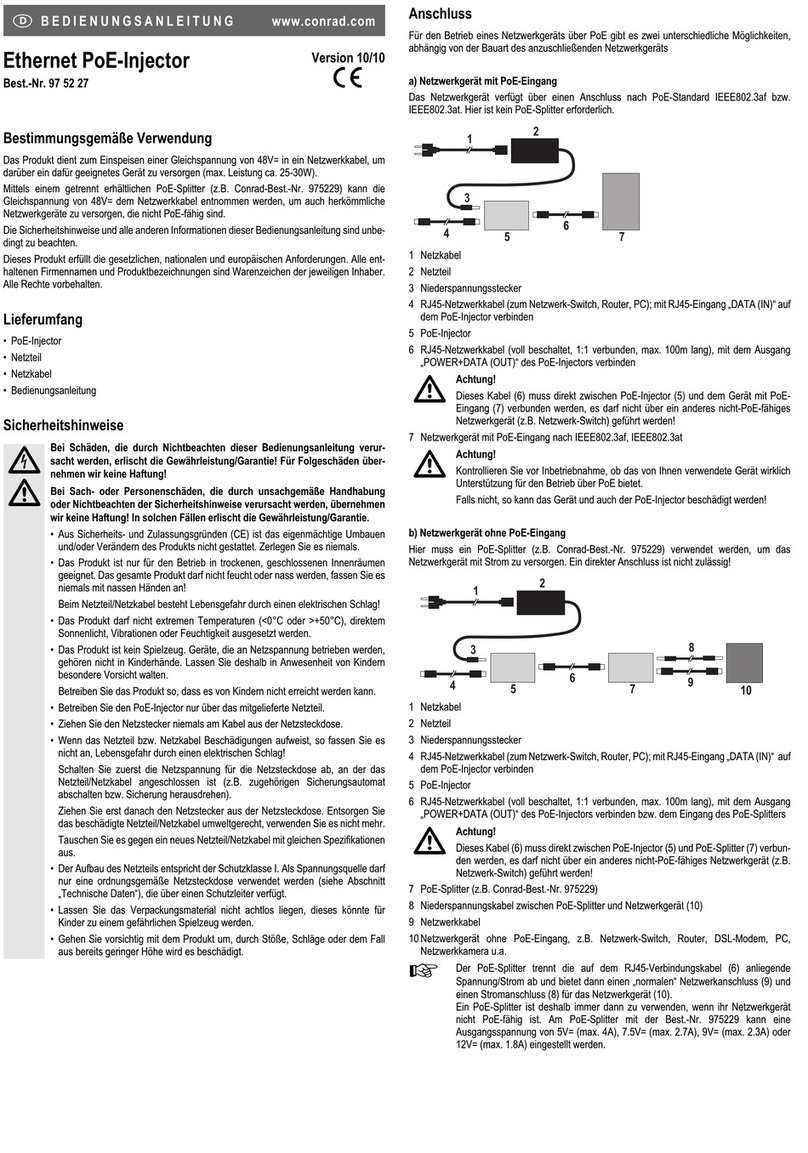

Figure 1: EASYpure RO.

2. Place the EASYpure RO on the

Bench Stand so that the screw holes

where the feet were attached line up

with the holes in the Bench Stand.

3. Install the 4 screws removed in step 1

through the bottom of the Bench

Stand and into the EASYpure RO.

4. Install the accessory 30 Liter

Reservoir according to the instruc-

tions in the accessory 30 Liter

Reservoir manual.

Wall Mounting

Wall composition and construction, as well as

fastener type, must be considered when

mounting this unit. The mounting surface and

fasteners selected must be capable of sup-

porting a minimum of 120 lbs.; inadequate

support and/or fasteners may result in dam-

age to mounting surface and/or equipment.

If you are wall mounting the EASYpure RO

using the optional wall mounting bracket,

mount the unit as follows:

Wall Mounting the EASYpure RO

1. Install the wall bracket (Part Number

D7384) on the wall in a location that

is accessible to water, power and an

atmospherically vented drain, and that

is convenient to use. A minimum of 4

fasteners must be used.

2. Remove the 4 feet from the

EASYpure RO. Retain the screws.

9

INSTALLATION

Warning

If you are unsure of mounting surface

composition, condition and construc-

tion, or correct fasteners, consult your

building maintenance group or

contractor.

Do not mount the EASYpure RO

directly over equipment that requires

electrical service. Routine mainte-

nance of this unit may involve water

spillage and subsequent electrical

shock hazard if improperly located.

Note

If you are bench mounting proceed to

“Utility Connections.”

3. Place the EASYpure RO on the wall

bracket swivel base so that the screw

holes where the feet were attached line

up with the holes in the wall bracket.

There are guides on the wall bracket

that will mate with the EASYpure RO.

4. Install the four screws removed in step

2 through the bottom of the wall bracket

and into the EASYpure RO.

Utility Connections

The EASYpure RO is supplied with four sepa-

rate lengths of tubing to be used for feedwater,

reject water, feed to accessory storage reservoir

and feed to another EASYpure unit's connec-

tions. Each length of tubing is six feet long and

has the necessary fittings installed.

Feedwater Connection

1. Locate the length of 3/8" O.D. tubing

provided with a quick disconnect insert

on one end and a 3/8" O.D. X 1/4 NPT

tubing adapter on the other.

2. Insert the quick disconnect insert into

the feedwater inlet on the EASYpure

RO. (See Figure 3 for location.) Install

the tubing adapter onto your incoming

water line. We recommend a customer

supplied shut off valve be installed in

your feed water line.

10

INSTALLATION

Note

We recommend a customer supplied

shut off valve be installed in your feed

water line.

Note

The quick disconnect fittings have

built-in shutoff valves in both the cou-

pling and the insert.

Figure 2: Wall Mounting the EASYpure RO.

Reject Water Connection

1. Locate the reject water tubing. This is

the piece of 3/8" O.D. tubing that has

an adapter on one end and no con-

nector on the other end. Remove the

nut, grab ring, backup ring and o-ring

from the reject water fitting located at

the lower right of the unit. (See Figure

4 for part identification and Figure 3

for fitting location.)

2. Thread the nut, grab ring and backup

ring on the reject adapter. Do not use

the o-ring at this time.

3. Push the tubing through the hex nut

until it bottoms out in the adapter.

4. Remove the adapter nut and tubing.

Place the o-ring over the tubing. Be

careful not to push the backup ring or

grab ring further back on the tubing

when installing the o-ring. Connect

the tubing to the reject connection on

the EASYpure RO.

5. Route the other end of the reject

water tubing with the adapter installed

to an atmospherically vented drain.

Ensure there are no kinks in the tub-

ing and that it proceeds in a

downward plane.

6. If possible, use the tubing adapter to

permanently install the reject water

tubing in the drain.

11

INSTALLATION

Power Entry

Module/

ON-OFF

Switch

Product Water Outlets

Pump

Interlock

Tank

Overflow

Reject Water

Connection

Feedwater

Inlet

Figure 3: Connections

Figure 4: Typical Polypropylene Tubing Adapter Installation

Tank Overflow Connection

1. Refer to Figure 3 and attach a customer

supplied hose barb connector and 5⁄8"

O.D. tubing to the tubing located at the

lower right of the unit as you look at the

rear of the unit.

2. Route tubing to an atmospherically vent-

ed drain. Ensure there are no kinks in

the tubing and that it proceeds in a

downward plane.

Connections to Equipment

Supplied By the EASYpure RO.

Your EASYpure RO also includes two lengths of

tubing with quick disconnect inserts attached.

One is 1/4" O.D. tubing and one is 3/8" O.D.

tubing. Use the 1/4" tubing to feed directly from

the EASYpure RO to another EASYpure unit.

Use the 3/8" O.D. tubing to feed the accessory

30 Liter Reservoir if one is being used.

1. Install the quick disconnect insert

attached to the tubing into one of the

product water quick disconnect

couplings on the EASYpure RO.

2. Install the other end of the tubing into

the unit being fed by the EASYpure RO

according to the instructions in that

unit's manual.

3. Locate the pump interlock cord supplied

with the EASYpure RO. Plug one end of

the pump interlock cord into the pump

interlock on the EASYpure RO. (See

Figure 3.) Remove the jumper plug from

the pump interlock on the other

12

INSTALLATION

Note

Do not connect the product water tub-

ing to a connected EASYpure unit until

you have completed the membrane

flush procedure for the EASYpure RO.

Note

The product water quick disconnect

inserts can be installed in either prod-

uct water quick disconnect coupling.

The quick disconnect ends of the

inserts are the same size.

Note

If you are not now feeding another

EASYpure unit, save the pump inter-

lock cord for possible future use.

EASYpure unit and save it for future

use. Plug the other end of the cord

into the pump interlock on the other

EASYpure unit.

Installing The Prefilter and

Membranes

1. Disconnect the unit from the power

supply.

2. Pull the rear side of the door latch up

and toward the front of the unit until

the front of the door latch unhooks.

3. Lift the front of the door latch and

open door.

Prefilter Installation

Chlorine and particulates will damage your

membranes, resulting in premature mem-

brane failure. Therefore, your EASYpure RO

uses an extruded carbon prefilter to remove

chlorine and particulates from your feed

water.

Install the prefilter as follows:

1. Remove a new prefilter (Part Number

D50246) from its plastic bag.

2. Wet the o-rings on both end caps of

the prefilter.

3. Insert the upper end cap into upper

center position until it bottoms out in

the connector. (The upper end cap is

the one with the right angle turn and

the two flanges.) The two flanges on

13

INSTALLATION

the end cap slide down on each side of

the keyway wall. (See Figure 7.)

4. Lower the prefilter and insert the lower

end cap into the lower center socket

until it is firmly seated.

Membrane Installation

1. Remove the membrane bypass tubing

from the EASYpure RO (see Figure 5).

The membrane bypass tubing may be

stored inside the EASYpure RO case for

easy access when needed for the

system sanitization procedure.

2. Remove an RO membrane cartridge

(Part Number D7425) from its plastic

bag.

3. Remove the nut, stainless steel grab

ring, backup ring and o-ring from the

connectors on the membrane.

4. Connect the product and reject tubes in

the right-hand membrane position on

the EASYpure RO to the product and

reject outlet connectors on the RO

membrane cartridge. Ensure that the o-

ring, backup ring, stainless steel grab

ring and nut are in place on the product

and reject tubing on the EASYpure RO

(see Figure 4). Ensure that the product

tube is connected to the product

connector and the reject tube is con-

nected to the reject connector. Hand-

tighten the connections.

14

INSTALLATION

Figure 5: Membrane Bypass Tubing Installed

Note

The membrane by-pass tubing will be

needed for sanitizing the EASYpure

RO. DO NOT DISCARD IT.

Membrane By-Pass

Tubing

5. Wet the o-rings on the bottom of the

membrane cartridge. Insert the RO

membrane cartridge into the right-

hand spring metal retainer.

6. Slide the RO membrane cartridge

down until the lower end cap is firmly

seated in the lower right-hand socket.

7. Remove the second RO membrane

cartridge (Part Number D7425) from

its plastic bag. Install the second

membrane in the left hand membrane

position following the instructions in

steps 3-6 above for the left hand con-

nections.

8. Close and latch membrane access

door.

15

INSTALLATION

Caution

Do not use a wrench on the tubing

adapter connections. A sufficiently tight

connection can be made by hand.

Figure 6: Proper position of Prefilter and Membrane

Figure 7: Prefilter and Membrane Connections

Left-hand

Membrane

Prefilter

Spring

Metal

Membrane

Retainer

Right-hand

Membrane

Polish

Product

Product

Flanges on

either side

of keyway

wall

Reject Reject

Electrical Connections

1. Plug power cord into the unit's power

entry module.

2. Connect your EASYpure RO to a prop-

erly grounded outlet of correct voltage

and current handling capacity.

Membrane Flush

1. If not already done, disconnect the prod-

uct water tubing from any EASYpure

unit connected to your EASYpure RO.

Direct the product water tubing to drain.

If you are feeding an accessory 30 Liter

Reservoir, disconnect the product water

tubing from the accessory 30 Liter

Reservoir. Direct the product water tub-

ing to drain.

2. Disconnect the pump interlock cord from

the other EASYpure unit.

3. Open the customer-supplied feed water

valve.

4. Turn the unit on by depressing the

ON/OFF switch on the power entry

module in the rear of the EASYpure RO.

(See Figure 8)

5. Allow the unit to operate for

approximately one hour, sending all

water produced to drain.

16

INSTALLATION

Warning

Use a properly grounded electrical out-

let of correct voltage and current han-

dling capacity.

Figure 8: Power Cord Adjustment

Power Entry

Module

6. Turn unit power off. Reconnect the

product water tubing to the other

EASYpure unit. Reconnect the product

water tubing to the accessory 30 Liter

Reservoir. Reconnect the pump inter-

lock cord to the other EASYpure unit.

Set "Replace Prefilter" Indicator

The extruded carbon prefilter both filters partic-

ulates and absorbs free chlorine out of your

feedwater supply. After a certain point, the

extruded carbon will become saturated with

chlorine and will cease to effectively protect

your membrane from the damaging effects of

chlorine. The "Replace Prefilter" Indicator alerts

you when the prefilter requires changing.

To set the "Replace Prefilter" Indicator for your

feedwater supply:

1. Determine the free-chlorine level of your

feedwater (in ppm) using a commercial-

ly available test kit.

2. Disconnect the unit from the power sup-

ply.

3. Pull the rear side of the door latch up

and toward the front of the unit until the

front of the door latch unhooks.

4. Lift the front of the door latch and open

door.

5. Locate the switch panel on the upper

left sidewall of the membrane compart-

ment. (See Figure 9 for location.)

6. The four rocker switches on the switch

panel are numbered from left to right as

17

INSTALLATION

Figure 9 Switch Panel Location

Membrane

Bypass

Tubing

Switch

Panel

Prefilter Reset

Membrane

Reset

you face the switch panel. Each switch has

two possible positions: 1) top pressed in or

2) bottom pressed in. (See Figure 10.)

Set the switches for your free-chlorine level as fol-

lows:

Free-Chlorine

Range (ppm) Switch 1 Switch 2 Switch 3 Switch 4

0.05-0.80 ppm bottom in bottom in bottom in top in

0.80-1.40 ppm* top in top in bottom in top in

More than 1.40 ppm top in bottom in top in top in

Close and latch the membrane access door. Your

EASYpure RO is now ready for operation.

18

INSTALLATION

1234

Free Chlorine

1.4 ppm - Max.

Free Chlorine

0.8 - 1.4 ppm

Free Chlorine

0.05 - 0.80 ppm

1234 1234 1234

Figure 10: Switch Panel Settings

Your EASYpure RO was designed to operate au-

tomatically. The unit will automatically turn off

when the tank is full and will restart when the

tank empties slightly. The unit will restart auto-

matically for 5 minutes every 3 hours 55 minutes

of inactivity to flush the membrane during periods

of non-use. This flush water will automatically run

to the drain. Please ensure that the unit remains

on — if you need to de-energize the system for

longer then 48 hours contact Barnstead

International customer service. If water is not

drawn from the tank for 72 hours, empty tank

and refill with new RO water before using.

Indicators

(See Figure 11.)

Pressure Gauge

On initial start-up, the pressure gauge will briefly

indicate the feedwater pressure. Once the pump

starts, the pressure gauge will indicate the pres-

sure after the pump, which is the pressure on the

reverse osmosis membranes. During normal

operation, this gauge should read 55-65 psi.

LED's

There are five indicator lights on the EASYpure

RO front panel. Their significance is as follows:

Indicator Lights: These lights alert you of the

operating status of the unit. If your attention is re-

quired to correct a problem or maintain the sys-

tem, it will be indicated on the display (periodical-

ly check the panel to see if attention is required).

Alisting of the various indicator lights and their

meanings follow:

1. Reservoir full: Your EASYpure RO is

equipped with a float switch that will de-

energize the unit when the reservoir is 19

Operation

Warning

Do not use in the presence of flam-

mable or combustible materials; fire

or explosion may result. This device

contains components which may

ignite such materials.

full. This light will illuminate, indicating

the unit is in a standby mode. When the

reservoir’s water level is lowered about

five inches, the unit will re-energize and

the light will turn off.

2. Low pressure: If the incoming water

pressure at the pump drops below 5

psig, a switch will de-energize the

pump. This switch senses the pressure

after the prefilter and before the pump.

The EASYpure RO system will try to

restart after it initially senses low pres-

sure. If it senses low pressure the sec-

ond time, it will switch the EASYpure

RO off and will illuminate the low pres-

sure light. Once the fault is corrected,

the EASYpure RO must be manually

restarted. (Power down and power up).

3. Replace prefilter: The carbon used in

the extruded carbon cartridge has a

finite life. The function of this cartridge is

to remove particulates and chlorine from

the feedwater. The "Replace Prefilter"

Indicator notifies you when the prefilter

requires changing. The frequency with

which this light will illuminate will vary

depending on the feedwater free chlo-

rine level you have selected on the

switch panel on the inside rear left side

of the case. For proper operation and

protection of your membrane, it is

important that you accurately select

your feedwater free chlorine level on the

switch panel.

4. Service membrane: If the percent re-

jection rate of the membrane falls below

65% the light will illuminate, indicating

20

OPERATION

Figure 11: Display

Indicator

Lights

Pressure

Gauge

This manual suits for next models

2

Table of contents

Other Barnstead Laboratory Equipment manuals