900E Series

Installation Instructions

10070152 REV 1 - 10/19 4 800-533-3948 www.barronltg.com

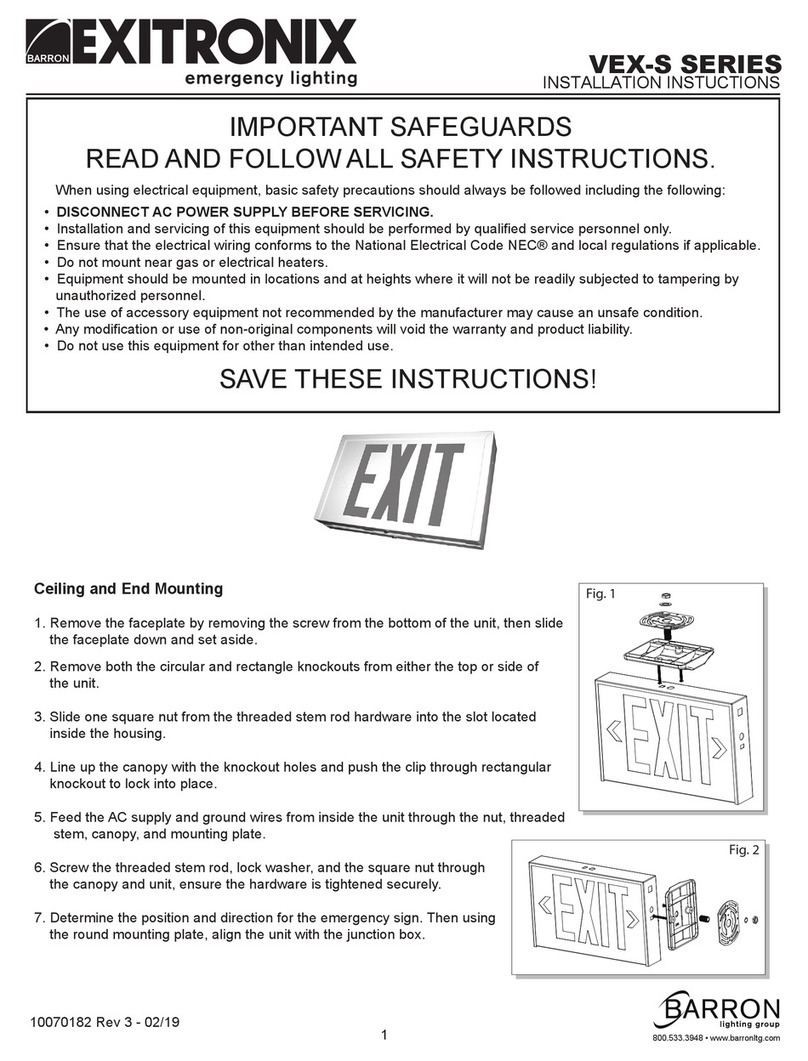

Recessed Ceiling or Recessed Wall Mount

Note: If the “Rough-in Kit” for the 900E Series has been

pre-installed, proceed to step 7 below.

1. Cut a 3" x 15" opening in the ceiling or wall. Ensure that

the opening is less than the trimplate dimensions of

3 7/8” x 15 7/8”.

2. Remove the homeplate assembly from the recessed

housing by loosening the (2) 6-32 screws and set aside

(Fig. 1).

3. If not already completed, punch out the knockout on top

of the recessed housing, then insert the plastic grommet

into the hole.

4. Route the wires through the knockout hole and make

electrical connections; see Electrical Connections

section.

5. Install the provided J-box on top of the recessed housing

by inserting the tab of the J-box into the bridge lance and

securing with a 6-32 x 1/4” screw (provided)

6. Install the recessed assembly:

a. If ceiling mounting, attach the hanger bars to the sides

of the recessed housing using 6-32 screws and wing

nuts (provided), as shown. Position the recessed

assembly between joists, making sure the hanger bars

are positioned correctly. Use the adjusting slots to

guide the hanger bars. The bottom of the recessed

housing should be level with the bottom of the joist.

Secure by hammering in the nail-in tabs. For T-bar

installation, hang the ends of the hanger bars over the

vertical part of the T-bar, as shown (Fig. 2).

b. If wall mounting, attach L-brackets using 6-32 screws

and nuts (not provided) to either side of the recessed

housing. Ensure that the L-brackets will not extend

beyond the trimplate. Position the recessed assembly

inside the wall. Secure the recessed assembly using

#6 screws and anchors (not provided) (Fig. 3).

7. Set the DIP switch on the PCB to the desired voltage.

Note: Units equipped with the Self-test/Self-diagnostics or

the 2CI option do not require DIP switch adjustment.

8.Connect the battery to the PCB. Red goes to positive (+) and black goes to negative (-).

Homeplate

Assembly

Recessed

Housing

Hanger

Bars

J-box

Grommet

Trimplate

Fig. 1

Fig. 2

Fig. 3

L-Brackets

Homeplate

Assembly

6-32

Screws

Recessed Box

L-Brackets

Hanger Bars

T-bar

Recessed

Assembly

Bridge

Lance

Bridge Lance