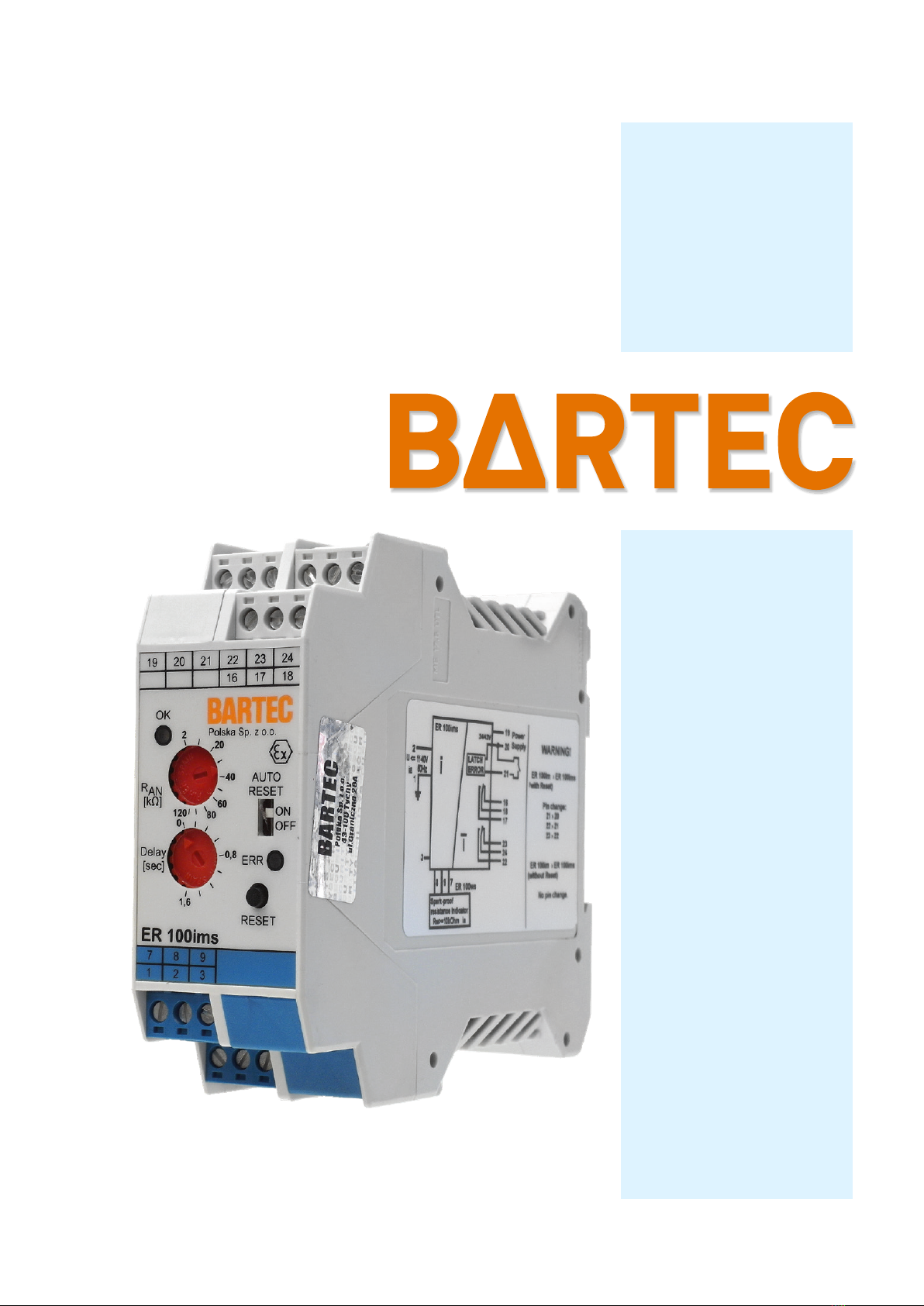

Operation Manual no. BP/IO/21/16 ed. 5.2.1

4 Intended use

Annex 3 to the OBAC 06 ATEX 059U certificate introduces a number of changes in the struc-

ture of ER 100ims leakage protection, which are designed to adapt to the current standards and

to change the method for processing the measurement signal. In addition, two variants (with and

without reset button) were replaced with one universal design. The manual reset function is ac-

tivated by means of the switch on the front of the unit. In this way, backward compatibility has

been maintained. The new version replaces previous versions of the device.

The ER 100ims type safety device is used to control the insulation state in insulated low

voltage electricity networks. Depending on the method of safety device connection to the con-

trolled network it may fulfil the following functions:

• Central leakage protection of three-phase alternating voltage network. In this case it is

preferable to connect the device through three chokes which ED 100i are connected with

one end to three phases of the network and with second end are connected in one point

creating „artificial zero” layout to which the measuring relay ER 100ims of the protection is

connected or directly to the N terminal of the transformer. It is possible to connect by one

choke connected at one end to the neutral point of the transformer (alternative connection).

• Central leakage safety device of a single phase voltage network. In this case it is preferable

to connect the device through two ED 100i chokes are connected by one end to phase

conductors of the network and by the other end are connected in one point, to which the

measuring relay ER 100ims of the safety device is connected or directly to the N terminal of

the transformer. It is possible to connect by one choke connected at one end to the neutral

point of the transformer (alternative connection).

• Interlocking leakage safety device in three- and single phase networks.

The measuring circuit of the measuring relay ER 100ims can work with the network controlled

only through chokes ED 100i or ED 100.

The following functions are fulfilled in the applications specified:

• Signalling and/or disconnecting at deterioration of the insulation state below the preset ref-

erence value, at the same time a controlled dropout time relay is released, which by its

contacts signals the operation and/or disconnects a circuit breaker or relay.

• Measurement and indication of the insulation state, where the spark-proof analogue input

may be connected with a spark-proof voltage indicator (0÷10 V) rescaled to the insulation

resistance reading, e.g. ER 100ws and/or spark-proof voltage transducer to another ana-

logue signal to transmit this information to other control and monitoring systems.

A non-spark-proof circuit consists of relay contacts and coil and also of safety device power

supply. The analogue output may be connected to spark-proof circuits of the ia protection level

(e.g. ER 100ws or spark-proof signal separator), while its measuring circuit, through the system

of ER 100i chokes, sends a spark-proof signal of ia protection level to the controlled network.

WARNING: For connecting the ER 100ims in place of the previous version without reset

button, terminals connection of the device remains unchanged. In the case of installing

the ER 100ims in place of the previous version with reset button, change the connections

of the terminals (tab. 1).

ER 100ims Page 7