Data Signs PTL Compact 1 User manual

PTL OPERATIONS MANUAL 1

PTL Compact Type 1 Operations

and Maintenance Manual

Your Portable Traffic Lights are compact lightweight traffic lights. As such correct

operation for Set-up and Take-down procedure is essential. Please ensure this

manual is read and understood before attempting to operate the Data Signs’ Portable

Traffic Lights (PTL).

Set-up and Maintenance requirements of the PTL are covered by this Manual.

CAUTION:

The Data Sign Portable Traffic Lights should only be operated by qualified

traffic managers.

If you have hired out this PTL, contact the Hire Company for assistance.

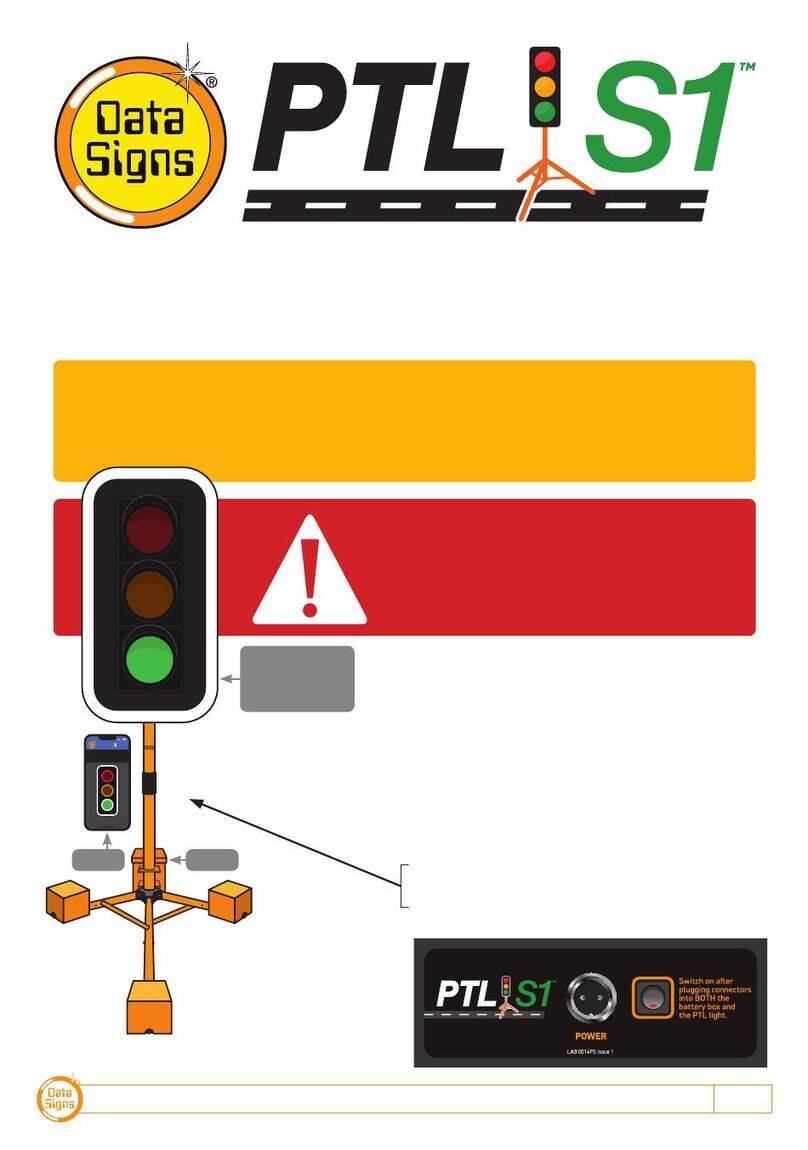

The PTL Compact TYPE 1 is

intended to be used to control

localized vehicular traffic flow

as a safer substitute for STOP/

SLOW (lollipop) signs. It does

not incorporate features such as

Vehicle Detection or solar powered

operation.

It is powered by a LiPo maintenance

free battery that needs to be

recharged at the end of the day. It is

not intended to be left unattended

on site and can only be operated via

the Remote Control which places

a safe distance between the actual

Traffic Light and the operator.

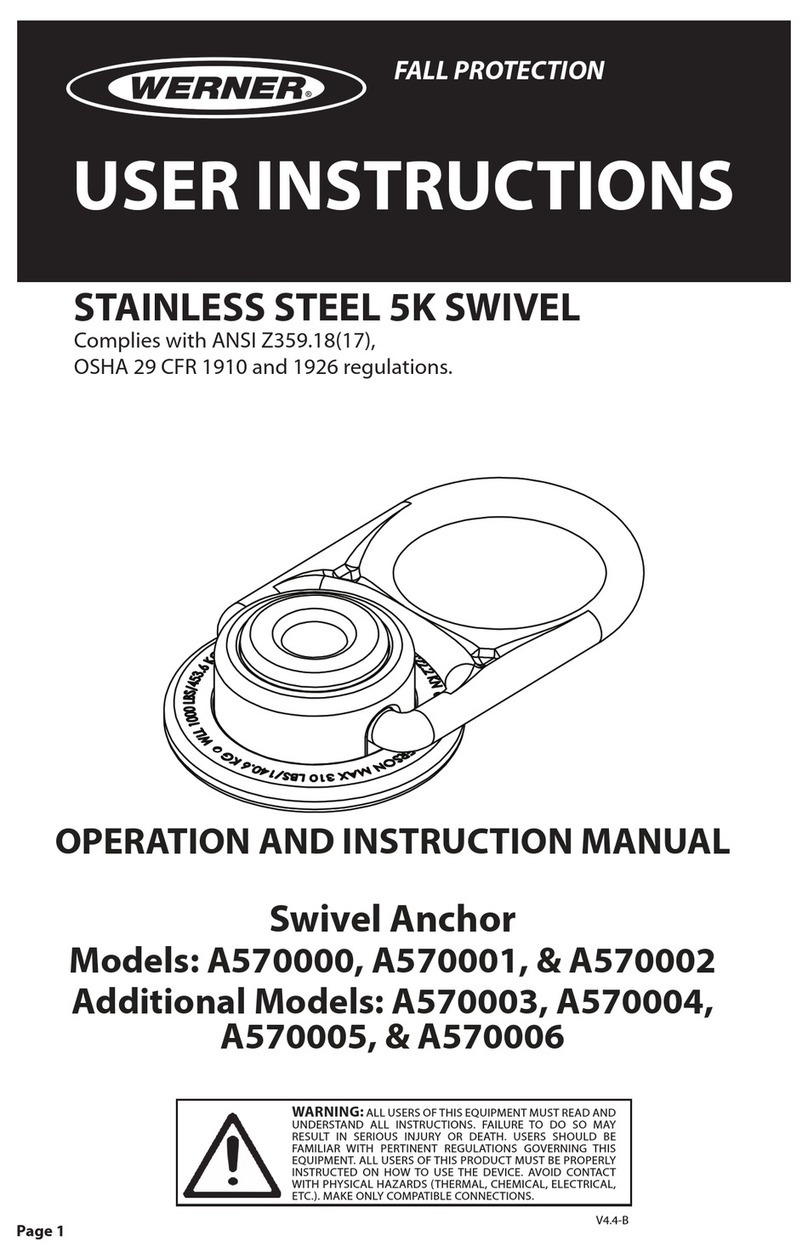

An overview of the layout of

the PTL Compact equipment is

provided here.

© 2020 Data Signs Pty Ltd. All rights reserved |UNCONTROLLED WHEN PRINTED |MAN 0019I Issue 3 |Rev: 22-05-2020

Beacon

Lantern

Shroud

Adjustable

Post

PTL Controller

Battery

PTL Remote

Stabiliser

Legs x 3

Aspects

Battery

Charger

Key Switches

Optional

Target Board

DATA SIGNS AUSTRALIA PTY LTD

2

Installation - Setting Up for Operation

Complete the setup

procedure as per the

steps below.

Suitable location:

Ensure that a level

surface is chosen for

setup.

Once all feet are down,

pull the center post

upwards to lock each

foot into place.

Once the stabilizers are

fixed into position, place

the Control Box onto

the post.

Align the notches in

the control box over the

metal bracket and lower

onto it.

Remove the light from

the carry bag.

Place it on the post

until the pin locks it into

place.

Do this for all sides as

shown.

Push with your feet on

the levers to allow the

stabilizer feet to fall

downwards.

Take care when the

feet fall downwards!

If high winds are

expected, place 20Kg

sand bags on each leg.

PTL OPERATIONS MANUAL 3

Plug in the cable by

lifting the weather

flap and pushing the

connector in, then

pull up the flap until it

‘locks’ over the plug.

Raise light by extending

the post.

Pull out the lower

spring clip, lift lights

until it clicks back in.

Optional Target Board:

This is useful when the

sun is behind the lights.

Switch on the

Controller(s).

Use the PTL Remote to

turn on the lights.

Operate from a safe

distance.

DATA SIGNS AUSTRALIA PTY LTD

4

Both the Master and Slave Controllers are fitted with

ON/OFF key-switches for security reasons, however

operational control is ONLY possible via the Remote

Controller.

Insert the right-side key and turn the switch to the ON

position for both Master and Slave units.

The Master and the Slave controllers will begin to

establish a radio link as indicated by the TX and RX

green lights on the controllers.

The Lights will remain blank until the Remote is

switched on and the Power ON button is held down for 5

Seconds, after this the Lights will show Flashing Yellow

and progress to showing RED, during this process the

Controllers and Lights will complete a self-diagnosis.

SHUTTLE or PLANT CROSSING Control is selected with

the left side key-switch.

GATING MODE which is single light use is selected via

the MAIN MENU Screen. Scroll down until the GATING

CONTROL menu is shown and select ON/OFF.

For Gating Mode see page 11

If PROGRAM selection is activated with the left key-

switch, the Controller will wait for further input and all

connected traffic lights will display blank.

Note: The left side key cannot be removed from the

key-switch while in the PROGRAM position. For safe

operation, remove the keys after the PTL units have been

setup and are operating.

Turning the Controllers On 4

Master Controller: Operational MODE SELECT 5

QuickStart 5

Shuttle Control – Single-Lane Usage 6

Plant-Crossing Control (2-Way) 8

Cycle and Phase Intervals for Shuttle and

Plant Crossing 10

Gating Control 11

Type 1 PTSS — PTL Remote Usage 12

Type 1 PTSS — Startup and Shutdown

using the PTL Remote 13

Type 1 PTSS — Self-Test using the PTL Remote 13

Main Menu 14

Controller display screens for Master and Slave 15

Wireless Link (RF) Explained 16

Fault Conditions 17

Troubleshooting Guide 18

Contents

PTL Compact Controller Type 1 QuickStart Guide

PTL Remote PTL Controller

This QuickStart Guide covers the PTL Controller Operation as per Australian Standards AS-4191:2015 plus QLD MRTS264 and

Various State Authority requirements.

Ensure the units are setup as described in the first section of this booklet. This User Manual applies to Controllers operating on

firmware 05.00.XX or later.

Turning the Controllers On

PTL OPERATIONS MANUAL 5

QuickStart

This MAIN MENU item lets you quickly set up to get the PTL sets going.

1. Master or Slave.

Select Unit 0 (Master) or Unit 1 (Slave)

Press the button to save the selection.

2. Turn the Key switch to Shuttle or Plant Crossing to Begin operation

SETTINGS COMPLETE

T u r n k e y s

w

i t c h

t o d e s i r e d o p e r a t i n g

m

o d e t o b e g i n

Master Controller:

Operational MODE SELECT

Enter PROGRAM selection by using the left key-switch on the Master Controller which

then allows you to select all other controller programmable functions, use the Up or

Down buttons to scroll through the MENU selection, then press the Button to

select the MENU item.

Press the R button to exit the selected MENU.

M A I N M E N U

VIE

W

PTL STATUS

* QUICK START

U N I T S E T T I N G S

Note: The MODE SELECT buttons are not used for Type 1 Compact PTL.

DATA SIGNS AUSTRALIA PTY LTD

6

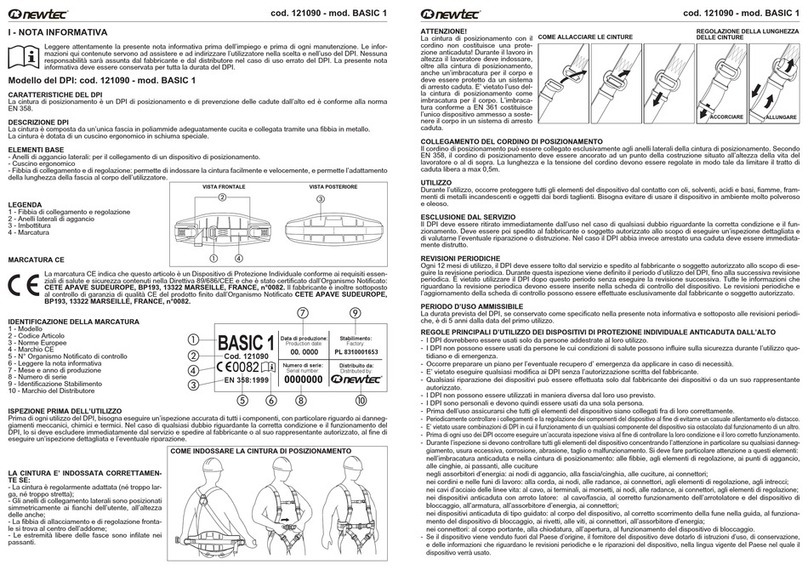

Shuttle Control – Single-Lane Usage

Shuttle Control is a form of traffic control used where a portion of the roadway is closed

so that only a single lane can be used alternatively by traffic from opposite directions.

Only one Traffic Light unit can show the Green signal phase at any time; either the Master

or the Slave. The diagram below illustrates the traffic control scenario where Shuttle

control would typically be used.

Note: This diagram should not be used as a guideline for setting up a roadwork site, it is

provided as an example only.

Each PTL unit will go to the Green signal phase in turn. See timing diagram later in this

manual.

Shuttle Control is active while the left key-switch on the Master Controller is in the

SHUTTLE position. Operating mode using Shuttle Control is described in more detail on

the following page.

ROADWORKS

SITE

= Rear Flashing Beacon

Unit ID: 0

Unit ID: 1

REMOTE

CONTROL

SHUTTLE CONTROL

These illustrations are intended to outline the different modes which can be used with Data Signs Portable Traffic Lights and should not be used as examples or guidelines on how to setup a

roadwork site − Separate documentation is available for these purposes. Copyright © 2020 Data Signs Pty Ltd. All rights reserved.

PTL OPERATIONS MANUAL 7

SHUTTLE MODE.

This can only be operated via the PTL Remote

Buttons used:

STOP or GO on PTL Remote.

A demand for Green or Red signal phase on the Master or Slave is entered on the Remote

Control unit. For Shuttle Control, on start-up, both the Master and Slave will rest on

Red until a demand for Green is entered.

To enter a demand for either Red or Green, press the STOP or GO buttons on the Remote

Control. The DEMAND LED is activated indicating a demand for either the Master or Slave.

Shuttle Control example:

1. Slave unit is currently showing the Green signal.

2. GO button is pressed for the Master side.

3. If the Green time has expired, the Slave will cycle immediately to Yellow and then Red

signal. The Master DEMAND LED will flash until the Green is lit.

4. Press the GO button on the Slave side to change the Cycle back in the reverse as per above.

5. Note: You can hold BOTH Master and Slave on Red indefinitely by pressing either Red Light.

To return to Green simply select either Master or Slave Green again, the lights will

change when the minimum Red time has expired.

The REMOTE ACTIVE indicator lights up on both the Master and Slave controllers when the PTL

remote is connected.

REAR BEACON LAMP:

The Beacon Lamps mounted behind the Traffic Lights flash on each unit when the Red

Lights are ON.

REMOTE

ACTIVE

PTL Remote Screen

Master / Slave Controller

For display use only

DATA SIGNS AUSTRALIA PTY LTD

8

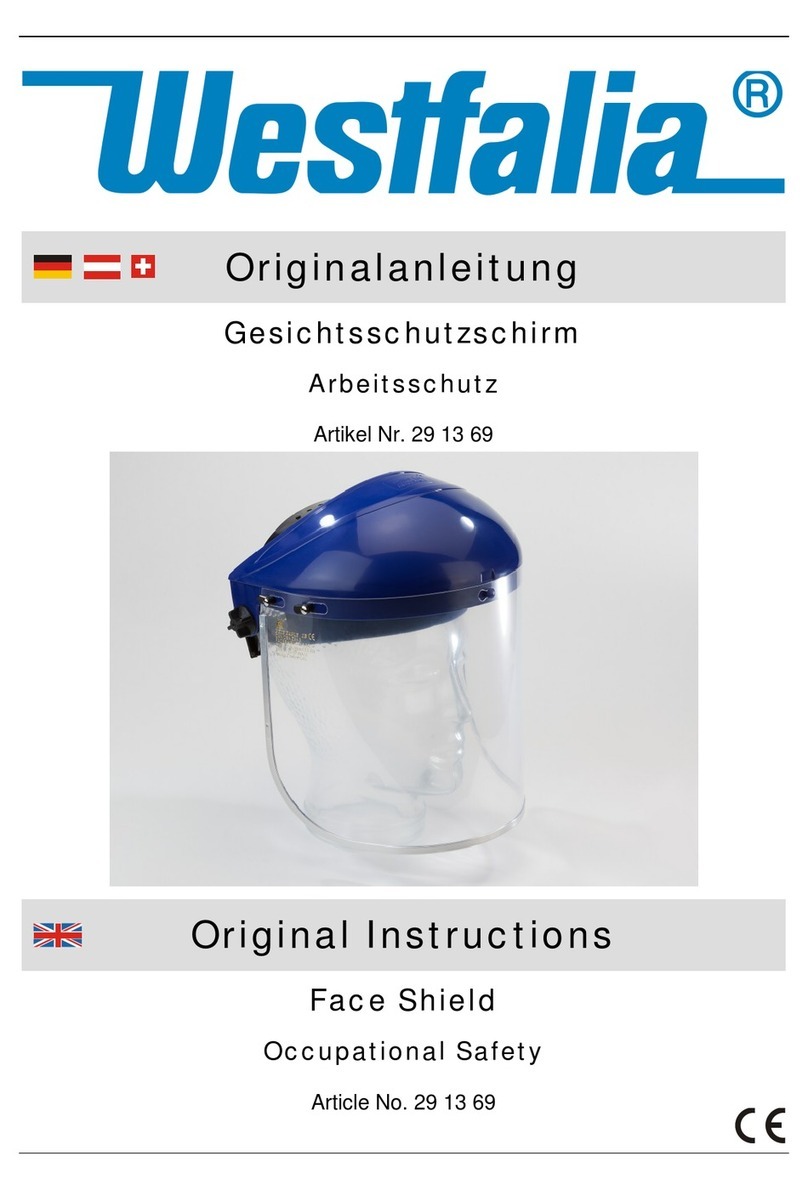

Plant-Crossing Control (2-Way)

Plant-Crossing control is used to enable both directions of traffic flow along a roadway to

be simultaneously stopped, e.g. to allow road construction vehicles to cross. The diagram

below illustrates Plant-Crossing control usage.

Note: This diagram should not be used as a guideline for setting up a roadwork site, it is only

provided as an example.

Plant-Crossing Control is active while the left key-switch is in the PLANT CROSSING

position on the Master Controller.

REAR BEACON LAMP

The Beacon Lamps mounted behind the Traffic Lights flash on each unit when the Red

lights are ON. This acts as a visual indicator to the Plant (vehicles) Crossing the road that

it is safe to do so.

SIDE / HAUL

ROAD

= Rear Flashing Beacon

REMOTE

CONTROL

PLANT-CROSSING CONTROL

Both units show the same signal phase.

These illustrations are intended to outline the different modes which can be used with Data Signs Portable Traffic Lights and should not be used as examples or guidelines on how to setup a

roadwork site − Separate documentation is available for these purposes. Copyright © 2020 Data Signs Pty Ltd. All rights reserved.

Unit ID: 0

Unit ID: 1

PTL OPERATIONS MANUAL 9

PLANT CROSSING MODE.

This can only be operated via the PTL Remote

Buttons used:

STOP or GO on PTL Remote.

On start-up, both the Master and Slave will rest on Green signal phase for Plant-Crossing

Control until a demand for Red signal is entered by the operator.

The operator can enter a demand for Red signal using either STOP buttons on the Remote.

Both the Master and Slave units will then cycle to Yellow and the Red signal phase.

To change back to Green signal, either the Master: GO or Slave: GO button is pressed.

When the Red time has expired, the lights will cycle back to the Green signal. If the

Master: STOP or Slave: STOP button is pressed and the Green time has not expired, the

DEMAND LED will flash.

Plant-Crossing Control, Manual mode example:

1. Both the Master and Slave are on Green.

2. Either the Master: STOP or Slave: STOP buttons can be pressed on the PTL Remote.

3. If the Green time has expired both the Master and Slave will cycle immediately to

Yellow and then to Red. Otherwise - if the Green time has not expired - the DEMAND

LED’s will flash.

4. Once the Green time has expired, the DEMAND LEDs will extinguish and the Master

and Slave will cycle to Yellow and then Red.

The REMOTE ACTIVE indicator lights up on both the Master and Slave controllers when a

button is pressed on the PTL Remote.

REMOTE

ACTIVE

PTL Remote Screen

Master / Slave Controller

For display use only

DATA SIGNS AUSTRALIA PTY LTD

10

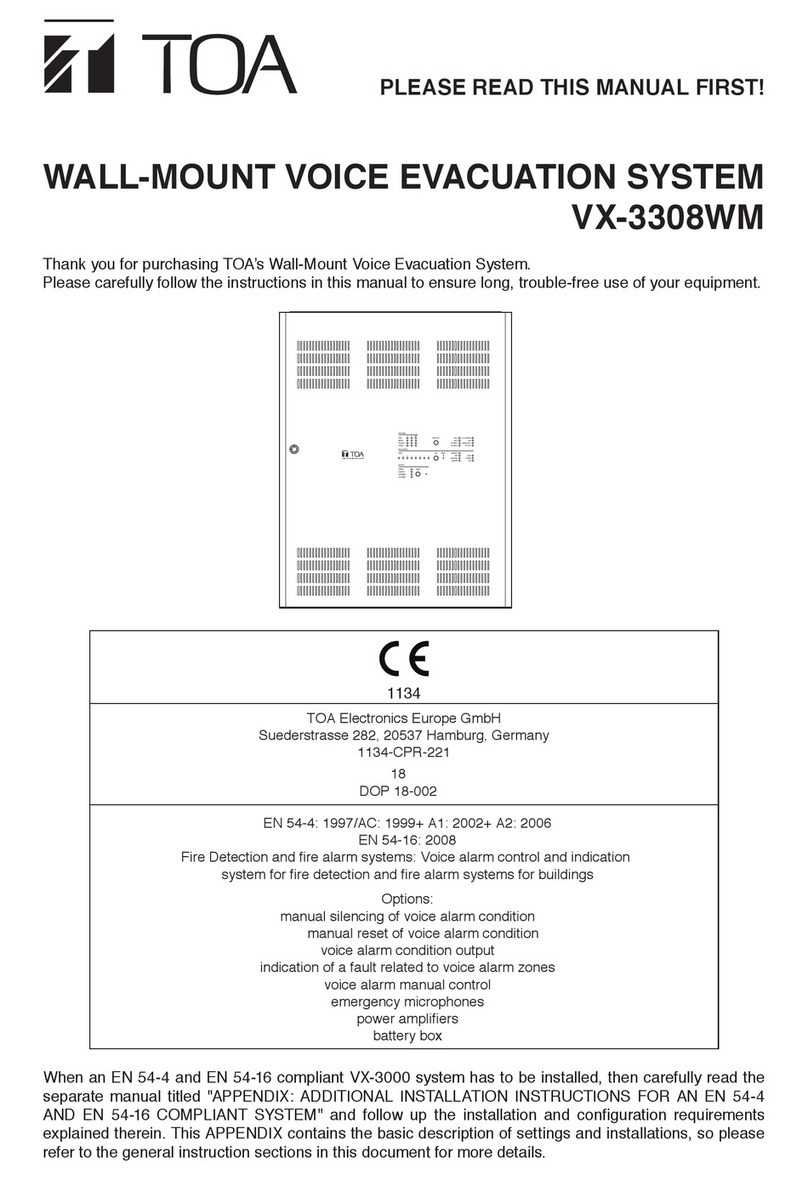

SLAVE SIGNAL DISPLAY

MASTER PHASE

MASTER SIGNAL DISPLAY

GREEN RED

MASTER FLASHING BEACON

SLAVE FLASHING BEACON

SLAVE PHASE

GREEN RED

SLAVE SIGNAL DISPLAY

GREEN PHASE

MASTER SIGNAL DISPLAY

GREEN

MASTER FLASHING BEACON

SLAVE FLASHING BEACON

RED PHASE

RED

LEGEND:

GREEN

1 to 99 seconds

YELLOW

4 seconds

RED

5 to 99 seconds

FLASHING

Beacon

RADIO OR WIRED LINK

RADIO OR WIRED LINK

CYCLE

PLANT CROSSING OPERATION

SHUTTLE OPERATION

Cycle and Phase Intervals for Shuttle

and Plant Crossing Modes

Roadworks

Site

One-Way Road

PTL OPERATIONS MANUAL 11

SLAVE SIGNAL DISPLAY

MASTER PHASE

MASTER SIGNAL DISPLAY

GREEN RED

MASTER FLASHING BEACON

SLAVE FLASHING BEACON

SLAVE PHASE

GREEN RED

SLAVE SIGNAL DISPLAY

GREEN PHASE

MASTER SIGNAL DISPLAY

GREEN

MASTER FLASHING BEACON

SLAVE FLASHING BEACON

RED PHASE

RED

LEGEND:

GREEN

1 to 99 seconds

YELLOW

4 seconds

RED

5 to 99 seconds

FLASHING

Beacon

RADIO OR WIRED LINK

RADIO OR WIRED LINK

CYCLE

PLANT CROSSING OPERATION

SHUTTLE OPERATION

Gating Control Mode

Single PTL unit use only.

Gating Control is used to control the flow of traffic from a single traffic flow direction only.

Note: The Gating Operation Mode can only be selected on a controller set up as a

MASTER, to activate this mode:

1. Switch the left key to PROGRAM MODE.

2. Use the button to Select GATING CONTROL and select ON.

3. Switch the Key Switch back to SHUTTLE position.

To switch off Gating Operation Mode, follow the same process as above, selecting OFF in

step 2.

Gating control can also be used with 2 PTL units operating independently by two traffic

operators using a Walky-Talky to communicate with each other.

GATING CONTROL

OFF

* O N

M A I N M E N U [ T Y P E 1 ]

QUICK START

U N I T S E T T I N G S

* GATING CONTROL

Note: If using 2 PTL Compact in Gating Mode, each PTL must be set on its own unique

channel number as there in NO radio-link communication between each unit and also to

eliminate risk of possible interference between the two units.

In this mode, the line of sight or distance limit does not apply.

Note: Two independent PTL Remotes are required for this operation.

Roadworks

Site

One-Way Road

Normal line-of-sight operation not used

in this setup configuration.

Two-way radios used between traffic

management operators.

DATA SIGNS AUSTRALIA PTY LTD

12

Use the PTL Remote to control, set the Red and Green times,

test or power off (blank) the Lights.

Only the PTL Remote can be used for these functions.

The top of the screen shows the battery level of the PTL

Remote. The signal strength between the Master and the PTL

Remote is also indicated.

The status box shows current operational type and the

countdown timer for the currently displaying Lights.

The main section of the screen shows the state of the

connected devices.

Press the Green or Red Light buttons on the main section of

the screen to change the lights being displayed.

Use the MENU button on the bottom of the screen to open the

SETTINGS menu screen.

From the menu screen, the operator can Power On/Off the

connected PTL Compact units, change the pre-set times,

and request a PTL Compact self-test to be performed on the

connected PTL Compact units.

The RF Channel as well as the STATUS is also selected from

this menu.

Press BACK to return to normal operating mode.

Type 1 PTSS — PTL Remote Usage

PTL OPERATIONS MANUAL 13

Select Type 1 Power On/Off from the menu.

To startup from shut down state, press the button on the

screen for 5 seconds. Alternatively, to startup from an inactive

state, use the same button and press for 5 seconds.

In shutdown state, the lights are disabled and the LCD’s on the

PTL Controllers are turned off.

When the SELF TEST button is pressed, the following

sequence is run on the PTL Compact to test the aspects, on

any connected units:

Green signal, yellow signal, red signal and blank for 0.2

seconds.

Note: the Red and Green Times are reset to the default times

of Green = 1 Seconds, Red = 5 Seconds.

Type 1 PTSS — Startup and Shutdown

using the PTL Remote

Type 1 PTSS — Self-Test using the

PTL Remote

It is advisable that the self-test not be carried

out while the PTL Compact are setup on the

roadway.

SETTING THE RF CHANNEL ON THE REMOTE CONTROL.

To set the RF Channel on the Remote Control, follow these instructions.

1. Press the MENU button on the bottom of the screen to go to settings.

2. Press the RF Channel option.

3. Enter the new channel number.

4. To re-start normal operation, press the BACK button.

DATA SIGNS AUSTRALIA PTY LTD

14

MAIN MENU

On Master or Slave Controllers.

While the Controller is in the PROGRAM setting, use the Up or Down buttons to

navigate forward and back through the MENU’s to select all other programming functions.

MENU: VIEW PTL STATUS

When this menu item is selected, all the current settings and status of the PTL controller

are shown.

Use the Up or Down buttons to navigate forward and back through the list.

MENU: QUICK START

Use the Quick Start Menu item, this will guide you through the process to set the Master

or Slave.

MENU: UNIT SETTINGS

Use this menu to set the Unit ID and Communications settings.

SUBMENU: ID

For the PTL-Type-1 this is the same function as QUICK START.

MENU: OPERATING SETTINGS [Master only]

WIRELESS LINK (RF)

Enter the RF channel then press the button.

Note: you will also need to change this value to match on the other unit(s) communicating with a

Master unit.

MENU: FAULT LOG

Sub-menu: VIEW LOGS

Select this menu item to scroll through the fault log file.

More information regarding the fault log file is provided in the Fault Conditions section of this manual.

Sub-menu: ERASE ALL

Selecting this menu item deletes the fault log file that is stored on the SD memory card

MENU: ASPECT TEST

Press Master Red, Yellow, Green or Slave Yellow for Beacon Lights. Press button to exit.

MENU: FACTORY SETTING

This menu item is restricted to Data Signs internal factory use.

For GATING CONTROL see section on page 11.

PTL OPERATIONS MANUAL 15

Controller display screens for Master

and Slave

Master ID=0 The following values will be shown on the display panel during normal

operation

1 4 . 2 V S I G : 5

TYPE 1 PTSS MASTER

NORMAL ALL RED

C H N : 2 0 0 0 S e c

First line: Master Battery Voltage. Right side, Slave Battery Voltage. & Signal Strength

Second line: Shows TYPE 1 PTSS.

Third line: Control Type (i.e. NORMAL). Right side, Current light sequence

Fourth line: Current RF Channel. Right side, Current state remaining time

Slave ID=1. The following values will be shown during normal operation:

U N I T I D : 1 1 3 . 3 V

CHN : 2 SLAVE

CONNECTED TO : PTLD2

T I M E O U T I N : 0 2 S e c

First line: The ID of this unit. Right side, current Battery Voltage.

Second line: RF Channel set on this unit.

Third line: The Serial Number of the Master Controller this unit is connected to.

Fourth line: The current RF timeout value. If this starts to count down there are

interruptions to the RF communications.

DATA SIGNS AUSTRALIA PTY LTD

16

Each Traffic Light is fitted with an aerial located on the top of the control box. This will provide

Wireless Radio (RF) communication between the PTL units; however, the units still need to be

positioned in line-of-sight to each other.

The maximum distance is about 800m, depending on surrounding environment.

The radio link module fitted to the PTL unit communicates on one of eight channels. This

must be set to the same channel on each unit to maintain wireless communication. This

applies to the Master, Slave, and the Remote Control.

Radio Link Operation

If the radio link between the Master and a Slave unit is disrupted for a continuous 2 second

period (the default time) all units will revert to red lights and “CONTACTING SLAVE…” will be

shown on the display panel on the Master Controller.

Signal Strength

The Remote Control will display the signal strength of the Master Controller to the PTL

Remote as a Graphic symbol in the top right corner on the display. The Master and Slave

Controllers display the Signal Strength and the Battery Level on the display. The RF Signal

Strength is a value out of 5, where 5 is the strongest value.

Wireless Link (RF) Explained

PTL OPERATIONS MANUAL 17

If any fault conditions occur as discussed throughout this document, the Portable Traffic

Lights will go to Red.

The faults logged are outlined below. Reference back to the Australian Standard is provided

in the table.

Fault ID Description

0Yellow

1Red

2 Green

3 Beacon

6 Excessive Link

7 Conflicting Link

8 Link Timeout

10 Low Battery

11 Tilt

To view the current fault log file, select FAULT LOG VIEW LOGS from the

Mode menu. Use the and arrow buttons to move through the fault log entries.

The last fault logged is shown first.

A sample fault log entry may be:

F A U L T L O G ( 1 / 1 )

XX/XX

/

X X X X 0 0 : 0 0 : 1 4

0 0 - M A S T E R

Y e l l o

w

( O p e n )

The time shown with each fault log entry is the time that this fault occurred since the Master

Controller was powered up. The second part is the Portable Traffic Light unit affected (i.e.

Slave#2 or Master). The last part of the entry is the fault description.

Note: The XX/XX/XXXX is not used for PTL Type-1.

You can also use an SD card reader on a laptop/PC to read the fault log files from the SD

card. The file will be in the LOGS directory on the SD card.

Fault Conditions

All critical faults are logged to a file on the SD card fitted to the Master Controller.

Turn the Master Controller OFF and remove the SD card from its slot, leave the power

OFF while re-inserting the SD card.

DATA SIGNS AUSTRALIA PTY LTD

18

This section contains some tips on handling some of the issues that may arise when using

the Traffic Lights. If you cannot resolve the issue you are experiencing using the information

below, please contact Data Signs on the Help Desk Via the Web site. As discussed above, the

Fault Log stored on the SD card in the Master Controller may assist in issue diagnosis.

Turning the Controller On

If the POWER light does not come on when the key-switch is turned to ON:

• Check that the controller connector is inserted properly.

• Check the fuse inside the Controller and on the battery fuse board.

• Check that the battery voltage is above 10.5 Volts.

Radio Wireless Link failure

If the radio wireless link fails regularly, try changing the Channel set on all Controllers, as

some interference may be occurring on the operating channel. Power-cycle each unit after

the Channel has been set correctly

SD Card Failure

In the case of SD card failure, you will be notified on the display. Default values will be used if

the SD card fails. All parameters can be changed, however they will not be saved, so you will

need to enter your desired parameters each time the Master Controller is turned on, until the

SD card is replaced.

Lights Not Working

Check the connections on the controller or the lights.

If you need to ship the Controller or parts back to Data Signs for repair, contact the

Help-Desk at datasigns.com.au/ServiceSupport/HelpDesk

Troubleshooting Guide

Never insert or remove the SD-Card with the power on, switch key

to OFF first.

Note: If shipping Controllers it is recommended to ship as a set, i.e. Master, Slave and

Remote. It will benefit to ship all these items as this will enable our service department to

perform a full operational test and diagnosis.

PTL OPERATIONS MANUAL 19

This manual complies with the Specification MRTS264 Type-1 Portable Traffic Signals and

where relevant AS4191-2015 Portable Traffic Signals.

Each state or territory has its own guidelines and training or accreditation requirements for

the use of the DataSign-PTL-COMPACT on public roads, particularly for road works usage.

The usage and training requirements are outside the scope of documentation provided by

Data Signs. The list below serves as a guide only; please contact the road traffic authority in

your state or territory for more information.

• In New South Wales, refer to the Traffic Control at Work sites document released by

the RTA/RMS. Note the training requirements in section 2.4.

• In Victoria, refer to the Road Management Act 2004 – Worksite Safety – Traffic

Management, Code of Practice for guidance on the use of the DataSign-PTL on roads

in Victoria. Note the training requirements.

• In Queensland, see the Traffic and Road Use Management (TRUM) manual that

is issued under the authority of Section 166 of the Transport Operations (Road

Use Management) Act 1995. Also see the Manual of Uniform Traffic Control Devices

(Queensland), which within the meaning of the Transport Operations (Road Use

Management) Act 1995, contains the design of, and the methods, standards and

procedures in relation to every sign, signal, marking, light or device, installed on a

road. Training requirements are available from the Main Roads QLD website.

• In Western Australia, see the Traffic Management for Works on Roads - Code of

Practice. Note the accreditation requirements. Also see the Traffic Controllers’

Handbook.

• In South Australia, there is a Work zone Traffic Management course.

• Generally, the Australian Standard AS 1742.3–2002: Manual of Uniform Traffic Control

Devices, Part 3: Traffic Control Devices for Works on Roads should also be consulted.

Suggestions & Improvements

Data Signs develops its products with the end users in mind. As such, we are always open

to suggestions for product improvement. Contact Data Signs, Head Office in Australia at:

datasigns.com.au

Disclaimer

The information contained in this document is proprietary information of Data Signs Pty Ltd

unless otherwise indicated. Data Signs Pty Ltd make every effort to ensure the quality of the

information it makes available. Notwithstanding the foregoing, Data Signs Pty Ltd does not

make any warranty as to the information contained herein and does not accept any liability

for any injury, loss or damage of any kind incurred by use of or reliance upon the information.

Data Signs Pty Ltd reserves the right to make modifications, additions and deletions to this

document at any time and without notice.

The Data Signs logo is a registered trademark of Data Signs Pty Ltd in Australia, New Zealand,

United Kingdom, India and United States of America, and a trademark in other countries.

This manual suits for next models

2

Table of contents

Other Data Signs Safety Equipment manuals