Bartington MS2 User manual

Operation Manual for

MS2 Magnetic Susceptibility System

BARTINGTON INSTRUMENTS

Page 2 of 82 OM0408/49

Table of Contents

List of figures 6

1. About this Manual 7

1.1. Symbols Glossary 7

2. Safe Use 7

3. Introduction 8

4. General Information 9

4.1. Measuring Magnetic Susceptibility 9

4.2. The Sensors 9

4.3. Operating Environment Considerations 10

4.4. Software 11

4.5. SI and CGS units 12

4.6. Range Selection 12

4.7. Calibration 12

5. MS2 Meter 13

5.1. Front Panel Controls 13

5.2 MS2 Meter Rear Panel 14

5.3. Rear Panel 14

5.4. Connecting a Sensor 14

5.5. Taking Measurements 15

5.6. Serial Interface 16

5.7. Internal Batteries 17

5.8. Data Transmission 20

5.9. Power Supply Accessories 21

6. MS2B Dual Frequency Sensor 22

6.1. General Description 22

6.2. Dual Frequency Measurements 23

6.3. Single Frequency Measurements 23

BARTINGTON INSTRUMENTS

Page 3 of 82 OM0408/49

6.4. Setting up the Sensor 23

6.5. Preparation of Samples 25

6.6. Sample Holder Effects 25

6.7. Mass and Volume Specific Measurements 26

6.8. Taking Measurements 26

6.9. Calibration Notes 27

7. MS2C Core Scanning Sensor 28

7.1. General Description 28

7.2. Operating Instructions 29

8. MS2E High Resolution Surface Scanning Sensor 30

8.1. General Description 30

8.2. Characteristics 30

8.3. Operating Instructions 33

8.4. Care of Sensor 34

9. MS2 Probe Handle for Use with Probes Type MS2D and MS2F 35

9.1. General Description 35

10. MS2D Probe 36

10.1. General Description 36

10.2. Calibration Notes 37

11. MS2F Probe 37

11.1 General Description 37

11.2. Operating Instructions 38

12. MS2G Single Frequency Sensor 39

12.1. General Description 39

12.2. Setting Up 40

12.3. Sample Height Adjustment 40

12.4. Calibration 40

12.5. Taking Measurements 41

BARTINGTON INSTRUMENTS

Page 4 of 82 OM0408/49

13. MS2H Down-Hole Probe 42

13.1. General Description 42

13.2. MS2H Equipment List 43

13.3. Operating Procedure 43

13.4. Checking Calibration 46

13.5. Scaling Factors 47

14. MS2K High Stability Surface Scanning Sensor 47

14.1. General Description 48

14.2. Characteristics 48

14.3. Operating Instructions 49

15. MS2/MS3 Susceptibility/Temperature System 51

15.1 MS2/MS3 Susceptibility Temperature System Cables 51

16. MS2W Water Jacketed Sensor 52

16.1. Calibration Note 53

17. MS2WF Furnace Sensor 53

17.1. Operation 54

17.2. Construction 55

17.3. Pt/Pt.Rh type ‘S’ thermocouple 55

18. Maintenance of MS2WF Furnace 56

18.1. Preparation of Plugs 56

18.2. Furnace Outer Insulation 56

18.3. Thermocouple Installation 57

19. MS2WFP Power Supply/Temperature Controller 58

19.1. Internal Power Distribution 59

19.2. Temperature Control 59

19.3. RS-232 Buffer 59

19.4. Data Format 60

20. Operating Instructions for Susceptibility/Temperature System 60

20.1. Setting Up the Equipment 61

BARTINGTON INSTRUMENTS

Page 5 of 82 OM0408/49

20.2. Connection to a Computer (GeoLab for Windows Software) 65

20.3. Sensor Orientation 66

20.4 Sample Insertion 67

20.5. High Temperature Measurements 67

20.6. Thermal Gradients 69

20.7. Low Temperature Measurements 70

20.8. GeoLab 70

21. Troubleshooting 71

21.1. No Push-Button Operation 71

21.2. Large Variations in Measured Values 71

21.3. Serial Communications Problems 71

22. Storage and Transport 72

23. Disposal 73

23.1. Waste Electrical and Electronic Equipment (WEEE) Regulations 73

Appendix 1. Magnetic Susceptibility of Common Rocks 74

Appendix 2. Calibration Graphs for MS2C Sensor 75

Appendix 3. Anisotropy of Magnetic Susceptibility Measurements (AMS) 77

A3.1. Installation of the AMS Adapter 77

Appendix 4. Adjusting MS2B the platen height. 79

Appendix 5. Calculating Magnetic Susceptibility 80

Notes 81

BARTINGTON INSTRUMENTS

Page 6 of 82 OM0408/49

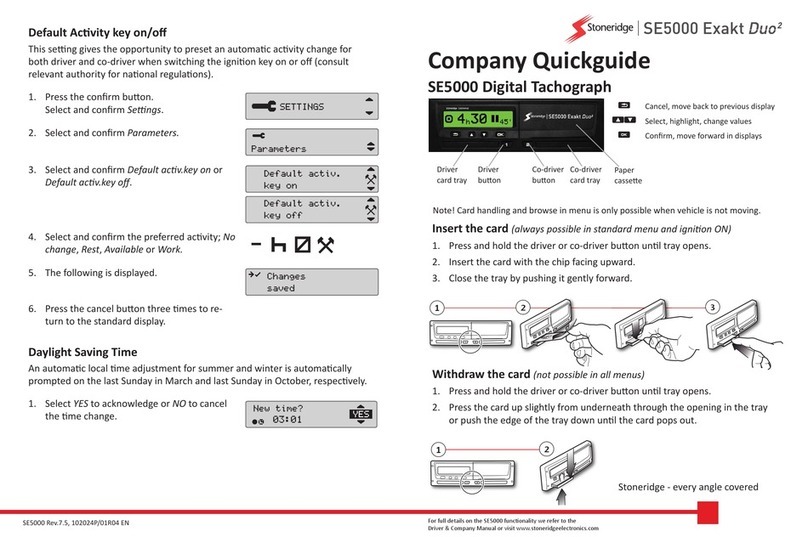

Figure 1a. MS2 meter, front panel. 16

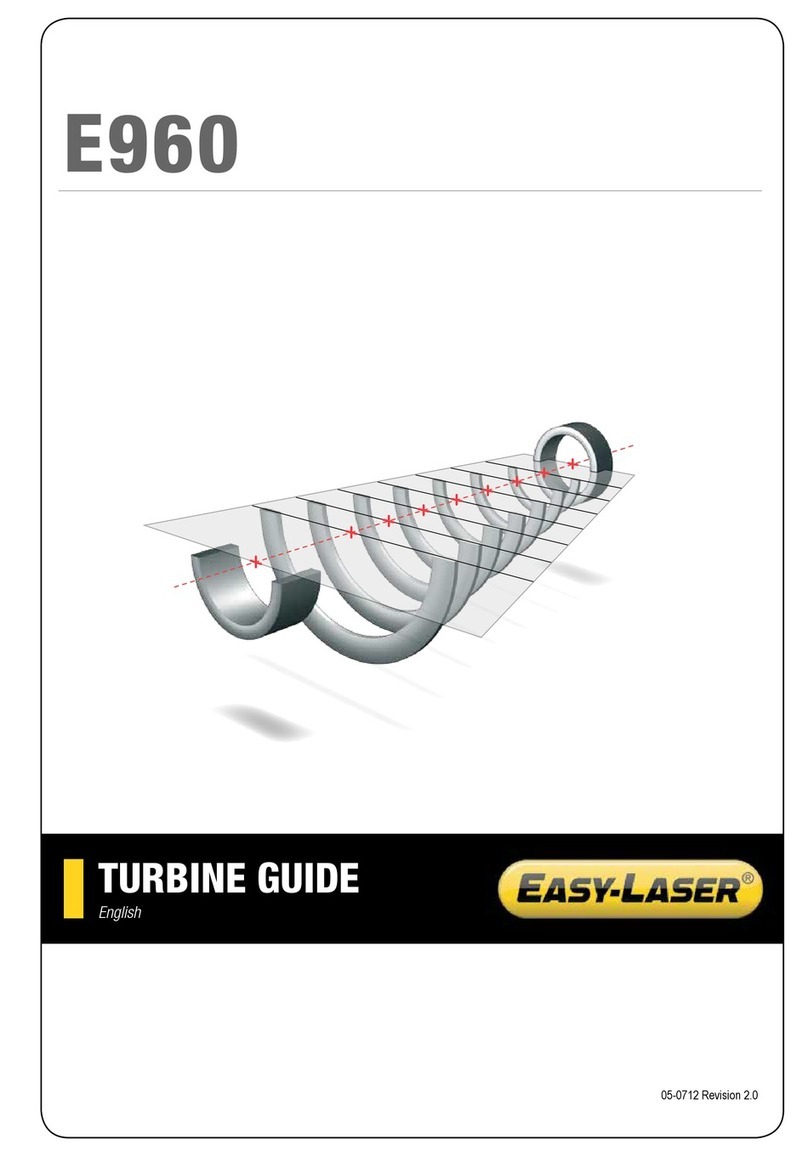

Figure 1b. MS2 meter, rear panel 17

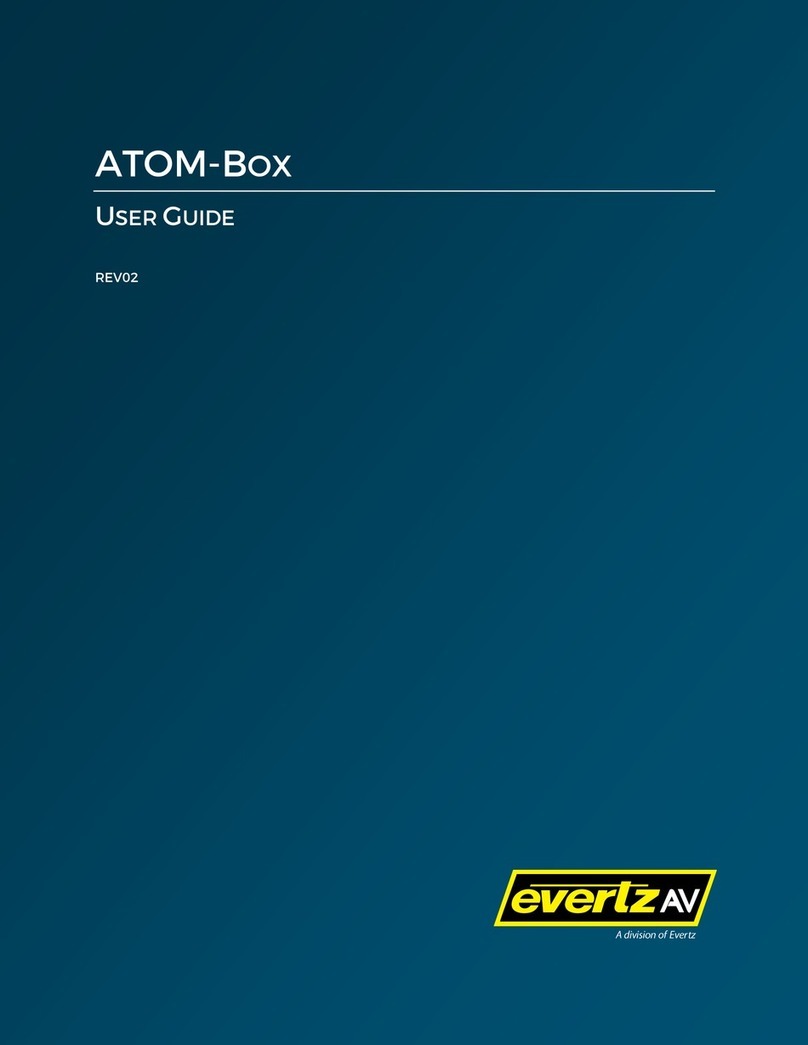

Figure 2. Replacing the MS2 battery. 20

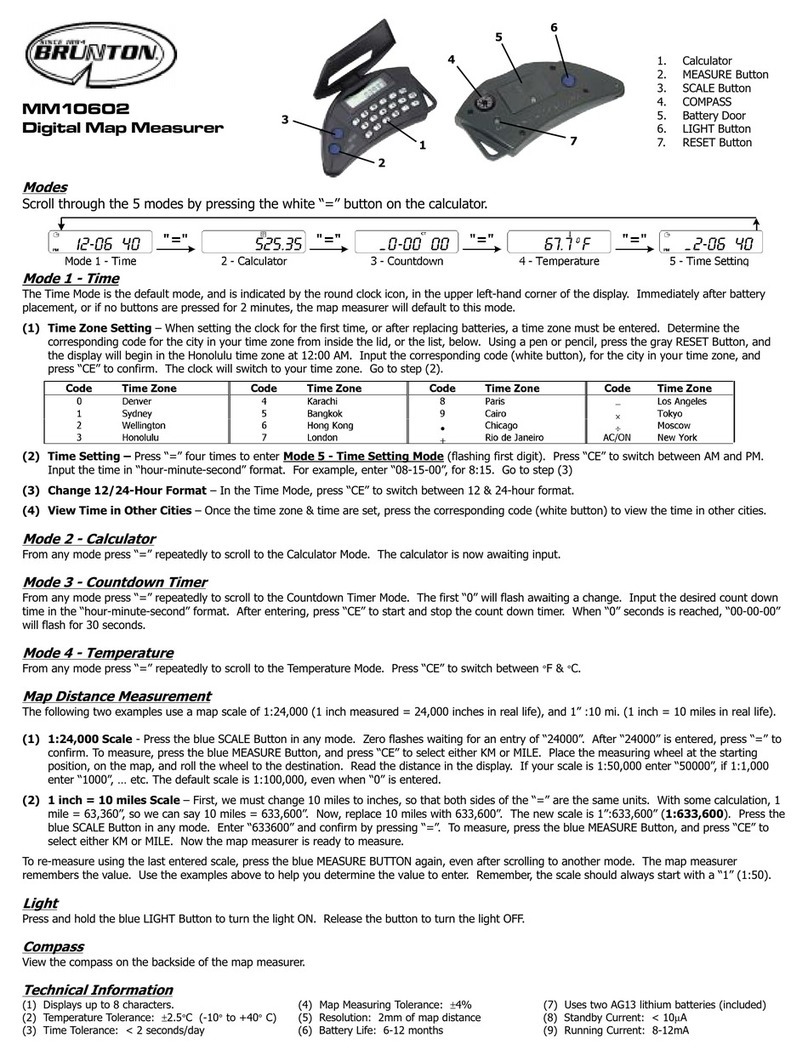

Figure 3. Screws in the base of the MS2 meter. 21

Figure 4. Double-sided insulation foam. 22

Figure 5. MS2B dual frequency sensor. 24

Figure 6. MS2C core scanning sensor. 30

Figure 7. MS2E high resolution surface scanning sensor. 32

Figure 8. MS2E response characteristics. 33

Figure 9. MS2E calibration sample: correct orientation 34

Figure 10. Using a non-magnetic ruler with MS2E sensor. 36

Figure 11. MS2 probe handle for use with probes type MS2D and MS2F. 37

Figure 12. MS2D probe. 38

Figure 13. MS2F probe. 39

Figure 14. Relative variation in sensitivity around the MS2F probe 40

Figure 15. MS2G single frequency sensor. 41

Figure 16. MS2H down-hole probe. 44

Figure 17. MS2K high stability surface scanning sensor. 49

Figure 18. MS2K Depth Response. 51

Figure 19. MS2W water jacketed sensor. 54

Figure 20. MS2WF furnace sensor. 55

Figure 21. MS2WFP power supply/temperature controller. 60

Figure 22. Susceptibility/temperature system. 62

Figure 23. X/T Equipment 63

Figure 24. MS2WFP Connections. 63

Figure 25. MS2WFP outline drawing and mains voltage selection. 64

Figure 26. MS2WFP Mains Voltage Selector Switch. 65

Figure 27. Water Supply Connections. 65

Figure 28. Water cooling system for susceptibility/temperature system. 66

Figure 29. Setting MS3 to Mode B in Bartsoft. 67

Figure 30. Mounting the MS2W on the MS2WF. 68

Figure 31. Using Tweezers to insert crucible into MS2W. 69

Figure 32. Plug inserted above crucible. 69

Figure 33. Thermocouple Selection Switch. 70

Figure 34. MS2WFP Control Panel. 70

Figure 35. Connection for T type Thermocouple. 72

Figure A1.1 Magnetic susceptibility of common rocks. 76

Figure A2.1. Relative response to varying core diameter within MS2C sensor. 77

Figure A2.2. Thin section response of MS2C sensor. 78

Figure A3.1. Changing the MS2B platen. 79-83

BARTINGTON INSTRUMENTS

Page 7 of 82 OM0408/49

This manual describes the operation of the MS2 range of magnetic susceptibility measurement

instruments.

It should be read in conjunction with the magnetic susceptibility product brochure DS0020 and

operation manual OM1131 (Multisus for Windows), both of which are available on the MS2/MS3

product page on the Bartington Instruments at www.bartington.com/ms3.html.

Outline drawings of the MS2 meter and sensors are also available on the product page.

Following the instructions in this manual will enable the optimum operation for which your

equipment is designed. Failure to follow these instructions may invalidate your warranty.

The following symbols used within this manual call your attention to specific types of

information:

WARNING: Indicates a situation in which serious bodily injury or death could result if the

warning is ignored.

Caution: Indicates a situation in which bodily injury or damage to your instrument, or both,

could result if the caution is ignored.

Identifies items that must be disposed of safely to prevent unnecessary damage to the

environment.

Note: Provides useful supporting information on how to make better use of your purchase.

2. Safe Use

WARNING: While the MS2 meter usually runs off internal batteries, it can also be powered

by mains electricity. Ensure that the unit is properly earthed at all times. When using

the mains power supply, ensure that the mains adaptor is correct for the local AC mains

voltage (110V or 240V). Do not open the casing or have contact with any internal parts.

WARNING: In addition to the above, ensure that the mains selector on the MS2WFP sensor

is set to the local AC mains voltage (110V or 240V).

WARNING: These products are not qualified for use in explosive atmospheres or life

support systems. Consult Bartington Instruments for advice.

BARTINGTON INSTRUMENTS

Page 8 of 82 OM0408/49

The MS2 Magnetic Susceptibility System comprises a variety of sensors together with a field

portable measuring instrument, either the MS2 meter or the MS3 meter.

The MS3 meter is a more compact instrument than the MS2 meter, of higher range and lower

noise, with a primarily USB interface for use in conjunction with a Windows computer or PDA. It

can be used with all of the MS2 sensors in place of the MS2 meter. As it is the subject of its own

operation manual (OM3227), available from the product page, it will not be discussed further

here.

The range of equipment described in this manual in addition to the MS2 Meter is as follows:

• MS2B dual frequency sensor

• MS2C core scanning sensor

• MS2E high resolution surface scanning sensor

• MS2 handle for use with probes type MS2D and MS2F

• MS2D probe

• MS2F probe

• MS2G single frequency sensor

• MS2H down-hole probe

• MS2K high stability surface scanning sensor

• MS2W water jacketed sensor

• MS2WF furnace sensor

• MS2WFP power supply/temperature controller

All sensors are described in the product brochure.

Each MS2 sensor is designed for a specific application and sample type, and is connected to

the MS2 meter via a simple TNC-TNC coaxial cable that is supplied with the order. The meter

displays the magnetic susceptibility value of materials when these are brought within the

influence of the sensor.

An RS-232 serial interface allows the instrument to operate in conjunction with custom software,

Multisus or Bartsoft, running on a portable data logger or PC. Interfacing commands are

provided should there be requirement for an alternate interface.

The MS2 meter is powered by internal rechargeable batteries.

BARTINGTON INSTRUMENTS

Page 9 of 82 OM0408/49

The circuitry within the MS2 meter powers the sensors and processes the measurement

information produced by them. The measurements are obtained digitally using a time dependent

method. This results in precise and repeatable measurements. The sensors are independently

calibrated and are therefore fully interchangeable between MS2 meters.

Magnetic susceptibility corresponds to the ability of a material to be magnetised in an external

field. Bulk (volume) susceptibility χvol can be directly related to the relative permeability (μr ) of a

material: χvol = μr - 1 and where μr is the ratio of permeability of material/permeability of vacuum.

The MS2/3 instruments rely on the change of inductance in an inductor when the permeability of

its core is changed.

The reference state is measured when the sensor contains only air (the permeability of air is

approximated as the permeability of a vacuum). Taking a reading with a sample will then give the

permeability of the material.

Any thermally induced sensor drift needs to be eliminated by occasionally obtaining a new ‘air’

value, to re-establish the zero reference. This is done by pressing the ‘Z’ button on the MS2

meter (see Front Panel Controls).

The magnetic susceptibility value is displayed digitally and output via a serial interface.

For further information on calculating the magnetic susceptibility and how it is related to

magnetic permeability, see Appendix 5. Calculating Magnetic Susceptibility.

Each sensor subjects the sample to a non-saturating field that has the advantage of measuring

initial susceptibility without destroying any sample magnetic remanence. When measuring non-

metallic samples, the sensors are particularly insensitive to sample conductivity.

BARTINGTON INSTRUMENTS

Page 10 of 82 OM0408/49

The sensors can be broadly divided into laboratory and field survey sensors:

Type Sensor Purpose

Laboratory

sensors

MS2B Measurement of magnetic susceptibility of soil, rock and

sediment samples.

MS2C High resolution volume susceptibility measurements on

whole cores.

MS2E Measurements with high spatial resolution along split cores

or suitably prepared geological specimens.

MS2G Measurements of powder or liquid samples.

MS2W Measuring temperature dependency of magnetic

susceptibility.

Field

survey

equipment

MS2D Assessment of the concentration of ferromagnetic materials

in the top 100mm of the land surface.

MS2F Stratigraphic study of exposed geological and

archaeological sections.

MS2H Down-hole sensor for sub-surface measurements of

volume magnetic susceptibility of strata.

MS2K Highly repeatable measurements of the volume magnetic

susceptibility of moderately smooth surfaces.

The full range, specifications and functions of the sensors available for use with the MS2 meter

are given in the product brochure.

The following environmental factors should be taken into account when using the MS2 system.

4.4.1. Temperature Induced Drift

The MS2 sensors operate on the principle of comparison between the magnetic permeability

of air and the relative permeablility obtained with the contribution of the sample magnetic

permeability. In order to do this the sensors are required to measure the magnetic permeability

to a high resolution. This can be a very demanding requirement as any change in temperature

can lead to a slight distortion of the coil shape, causing an apparent change in permeability, and

therefore in susceptibility.

Each sensor employs its own technique for temperature compensation to minimise any

temperature induced drift. A facility for automatic correction of temperature drift at the end of a

measurement sequence is also provided by the Multisus and Bartsoft software packages. This

drift correction is worked out by taking a zero (or blank) reading at the start, and then taking a

second blank reading (not a zero) after the sample measurement.

BARTINGTON INSTRUMENTS

Page 11 of 82 OM0408/49

The best precaution is to ensure that the operating temperature is constant during

measurements, and preferably cool, and that sensor and samples have time to reach an

equilibrium temperature. This may be more difficult when operating in the field.

4.4.2. Wet Conditions

Caution: These instruments are protected against the ingress of moisture but operation in

very wet conditions should be avoided.

Note: Some sensors can be operated while submerged in water: see product brochure for

further information.

4.4.3. Noise and Interference Check

Caution: These instruments should not be operated close to high power radio transmitters,

heavy electrical machinery, computers, or other electrical or magnetic equipment.

Note: The unit is unlikely to be affected by interference from other equipment in the

normal operating environment. However, by their nature the sensors are susceptible

to electromagnetic interference and operation close to a radio frequency source with a

frequency close to the operating frequency of the sensor should be avoided. It is important

to position the sensor to minimise interference and obtain the best performance.

Select the normal sensitivity, x1.0 range. With no sample present, first press the ‘Z’ button and

then select continuous measurements on the ‘M’ toggle switch. If fluctuations of greater than ±1

least significant digit per reading appear on the display then external electrical noise should be

suspected. In this case the only solution is to re-site the equipment.

Before using the laboratory sensors, first check the selected area for freedom from large ferrous

objects by moving the sensor and watching for any changes on the display.

4.4.4. Electromagnetic Compatibility

The MS2 meter and sensors contain no high frequency electronics likely to cause emissions

that could affect other apparatus. Emissions are minimised by the use of a rechargeable

battery charged from a mains adaptor and decoupling of the internal switched mode power

supply. The sensors generate a small magnetic field so very sensitive equipment such as SQUID

magnetometers will be affected if placed in close proximity.

The available software is described in the product brochure and is supplied with individual

operation manuals. Bartsoft is the most up to date software package and can be used to operate

both the MS2 and MS3 meters. Multisoft is an older software package that is only compatible

with the MS2 meter. The Geolabsoft software is intended for use only with the MS2 X/T

Temperature Susceptibility System.

BARTINGTON INSTRUMENTS

Page 12 of 82 OM0408/49

The instrument may be pre-set to display the susceptibility value directly in either SI or CGS

units. The table below shows the basic mass or volume specific unit thus produced.

Mass and volume in SI and CGS units

Mass (cmass ) Volume (cvol)

SI 10-8 (m3/kg) 10-5

CGS 10-6 (cm3/g) 10-6

Numerical conversion from SI to CGS units is accomplished by dividing the SI value by 4π, i.e. cCGS

= cSI/4π. The MS2 meter performs this function internally but by using the constant 0.4π to keep

the numbers in a similar range of magnitude.

The instrument may be pre-set to display the susceptibility value in either the 1.0 or 0.1 range.

The table below shows the the exponent value of the least significant digit (i.e. the last digit on

the LCD) for each range. The units in the table below for volume susceptibility.

Exponent values for least significant digit in 1.0 and 0.1 ranges

SI CGS

1.0 10-5 10-6

0.1 10-6 10-7

On the 0.1 range a decimal point will be displayed, effectively moving all the digits on the LCD to

the left when compared with the 1.0 range. It should also be noted that one measurement in the

0.1 range will be an average of multiple readings taken over a period of 10 seconds.

All sensors are calibrated either directly or indirectly to the diamagnetism of water (H2O), where

density r(rho) = 1.

cmass (mass susceptibility of H2O) is -0.72 x 10-6 CGS

Therefore, for H2O, cvol = rx cmass

= 1 x -0.72 x 10-6 CGS.

Precise mass specific measurements are only possible using the MS2B sensor where the

sample volume is accurately defined.

BARTINGTON INSTRUMENTS

Page 13 of 82 OM0408/49

Figure 1a. MS2 meter, front panel.

Key to Figure 1a

1. ‘Measure’ (‘M’) push button

2. Toggle switch

3. ‘Zero’ (‘Z’) push button

4. On/Off Switch

5. Range multiplier switch

6. Socket for coaxial cable connection to sensor

There are five front panel controls.

1. ‘Measure’ push button, labelled ‘M’: permits sample readings to be taken.

2. Toggle switch: performs the same function as the push button but permits continuous

measurements.

3. ‘Zero’ push button, labelled ‘Z’: permits ‘air’ readings to be taken. By performing

a measurement to ‘air’ this control re-sets the instrument and brings subsequent

measurements within the range of the display.

4. On/Off Switch: controls the internal battery supply and also permits the selection of either SI

or CGS units.

5. Range multiplier switch: allows selection of either x1 or x0.1 sensitivity range. In the second

case the result is shown to the first place of decimal and a 10-fold increase in measurement

time provides additional noise filtering. The switch also activates the battery indicator.

531 24

6

BARTINGTON INSTRUMENTS

Page 14 of 82 OM0408/49

Figure 1b. MS2 meter, rear panel.

Key to Figure 1b

1. Power supply connector

2. RS-232 serial interface

3. Three-way rotary switch

4. Charging light

The rear panel contains the following features:

1. Power supply connector: the power adaptor plug should be inserted here. For more

information see Internal Batteries.

2. RS-232 serial interface: an MS2 RS-232 cable can be inserted here and connected to a

computer to allow control and communication using Bartsoft or Multisus software. For more

information see Serial Interface.

3. Three-way rotary Switch: allows the user to select one of three RS-232 communication

settings options. For more information see Serial Interface.

4. Charging light: this LED will light up when power is connected and the MS2 battery is being

charged. For more information see Internal Batteries.

Connect the sensor to be used to the front panel socket of the MS2 meter with the supplied 50Ω

TNC-TNC cable, and switch on by selecting either SI or CGS units.

31 2

4

BARTINGTON INSTRUMENTS

Page 15 of 82 OM0408/49

Set the meter to the 1.0 range for the initial measurement of any sample, to establish the

approximate result, before switching to the more sensitive 0.1 range. If the value of a sample is

greater than 1000 then the most significant digit will not be seen if measured on the 0.1 range,

leading to an apparent gross error in the result.

Irrespective of the type of sensor being used, measurements are accomplished using the

following procedure.

1. Take an ‘air’ reading by pressing the ‘Z’ push button with the sample to be measured away

from the influence of the sensor. The display will appear blank and a colon will appear to

show the instrument is ‘busy’. The completion of a Z cycle will be announced by a bleep and

the display will show all zeros.

2. Place the sample within the influence of the sensor and press the ‘M’ button. The ‘busy’ colon

will appear and the display will show the previous reading until updated at the completion of

the current measurement period. This is announced with a beep. At this time serial data will

be transmitted.

3. If either push button is enabled at the completion of a cycle then a repeat measurement will

be taken.

4. To measure weakly magnetic material, select the more sensitive x0.1 range and compensate

for any thermally induced drift by making a series of measurements:

a) Zero to air by pressing ‘Z’ button = R0 ( = 0)

b) Measure samples = R1 , R2 ....

c) Measure ‘air’ = RFinal

The mean of an ‘air’ measurement before and after the sample is subtracted from the nth

sample measurement Rn:

Corrected value Rk= Rn- n x (RFinal- R0)/N

where N is the total number of measurements after the initial zero (including RFinal)

In the case that only one sample measurement is taken: Rk= R1- (RFinal- 0)/2

When taking manual measurements, attempt to keep the time between measurements as

consistent as possible. If recording values by hand then the previous value can be read whilst

the current measurement is taking place, thus saving time and improving precision.

The drift correction can be done automatically using Multisus or Bartsoft where the time of

each measurement is recorded, and the is drift applied linearly as a function of time.

BARTINGTON INSTRUMENTS

Page 16 of 82 OM0408/49

The magnetic susceptibility of common rocks is shown in Appendix 1.

An RS-232 compatible serial interface, which permits data logging in the field and data

processing in the laboratory, is included within this unit. The instrument produces a serial output

of each meter reading, whether triggered by a signal on the serial interface or by a manual push

button operation. A zeroing operation produces no serial output.

Via the four-way connector on the rear panel of the instrument, the RS-232 serial interface

allows data communication between the MS2 meter and a computer with custom designed

software. For reasons of economy of battery drain, the interface is restricted to operate over a

maximum cable length of 50 metres.

An RS-232 connecting cable is provided with the MS2 for connection to a computer via a 9-way

D-type connector. No hardware handshaking is provided.

The 'Z' and 'M' functions can be controlled externally by sending the ASCII character Z (Zero)

or M (Measure) to the MS2 from the computer. To zero the instrument once, therefore, it is

necessary to send Z followed by carriage return. Sending M followed by carriage return will

cause a single measurement to be made. To return the instrument to the IDLE mode, any other

character can be sent.

Data is only transmitted from the MS2 following the instruction to measure. The delay between

the instruction being received and the data being transmitted will be equal to the measuring

period, which depends on the sensor type (see relevant specification in the product brochure)

and the range selected. The time taken to reset the meter to zero is the same as that required

to take a measurement. Software should allow sufficient time for a response before issuing the

next command.

The RS-232 interface operates in one of three modes as set by the screwdriver-operated rotary

switch on the rear panel. The options are:

A. Standard operation 1200 baud with a 7 bit word (for use with Multisus software).

B. X/T system operation 1200 baud with an 8 bit word (for use with GeoLab software).

C. Operation at 9600 baud with an 8 bit word.

See Data Transmission for further information.

BARTINGTON INSTRUMENTS

Page 17 of 82 OM0408/49

The instrument is powered by internal maintenance-free rechargeable Ni-MH batteries.

Recharging can be carried out from either a mains electricity supply or a vehicle power socket.

WARNING: When using the mains power supply, ensure that you are using a mains adaptor

that is correct for local AC mains voltage (110V or 240V).

To recharge the batteries, connect either the 12V mains power supply adaptor or the vehicle

power socket cable to the 2.1mm connector on the rear panel of the instrument where a yellow

LED will indicate that charging is taking place. The rate of charge will depend on whether the

instrument is switched ON (trickle charge) or OFF (full charge).The charger input is polarity

protected and any DC source as specified in the product brochure can be used.

Note: To maintain the full capacity of the batteries it is necessary to completely discharge

and recharge them not more than every six months.

5.6.1. Battery Charging: Laboratory Use

When the instrument is switched on and connected to the mains supply via the battery charger,

the batteries receive a trickle charge and therefore continuous use from the power supply is

permitted.

5.6.2. Battery Charging: Field Use

Note: For field use, the batteries will need to be charged overnight for use the following

day. A full recharge will take 16 hours with the instrument switched off and connected to an

external mains supply or vehicle power socket.

Caution: To prevent overcharging, do not continue charging for more than 16 hours.

5.6.3. Battery Check

The condition of the batteries can be checked by selecting ‘BATT’ on the range multiplier switch.

The battery indicator lamp will appear:

• Green: charge acceptable.

• Yellow: re-charge soon.

• Red: re-charge immediately.

Note: Use of the instrument when the battery voltage is low will cause excessive

measurement drift and serial communication may fail.

BARTINGTON INSTRUMENTS

Page 18 of 82 OM0408/49

5.6.4. Replacing the MS2 Meter Battery

Figure 2. Replacing the MS2 battery.

Key to Figure 2.

1. NiMH battery pack

2. Two-way connector

3. Earth lead to earth point in the upper enclosure

For MS2 meters purchased prior to 1st January 2006, scrape away the wax coating over the four

slotted nuts in the base of the unit and undo the nuts with a 6mm wide split screwdriver.

Figure 3. Screws in the base of the MS2 meter.

1 2

3

BARTINGTON INSTRUMENTS

Page 19 of 82 OM0408/49

For units purchased after 1st January 2006, the holes are no longer filled with wax. A small

Philips screwdriver must be used to release the enclosure halves. The top half of the enclosure

can now be carefully lifted away from the unit.

Caution: Before opening the enclosure, ensure that the instrument is turned off and not

connected to the mains power.

Caution: Take care not to disconnect the earth lead between the two halves of the

enclosure.

Note: It is recommended to disconnect and lift PC7 off (4 screws), and lift rear panel out

while assembling the new battery pack.

Disconnect and remove the battery. On later batteries the connection is via a two-way connector.

On older units the connection is via a terminal block with screw terminals. The terminal block

forms part of the battery assembly, and must be removed with the battery to avoid the possibility

of shorting the battery and creating a potential fire risk. Once the battery has been disconnected,

remove the terminal block: this will be used on the replacement battery.

Figure 4. Double-sided insulation foam.

Key to Figure 4

1. Double sided foam

Note: The double-sided adhesive foam that holds the battery in place should be replaced

when the battery is replaced. The old foam can be removed using isopropanol cleaning

solvent.

WARNING: On no account use acetone as this will dissolve the enclosure.

Once dry, apply new strips of double sided foam (supplied with the replacement battery).

Insert the replacement battery and reconnect.

1

BARTINGTON INSTRUMENTS

Page 20 of 82 OM0408/49

For older units, it will be necessary to remove the two-way plug from the replacement battery,

cutting each wire separately so as not to short the battery. Assemble the terminal block onto the

battery wires, then reconnect being careful to connect black to black and red to red.

Re-assemble top half of enclosure and secure with the appropriate screws or slotted nuts.

Dispose of the old battery in an approved disposal facility.

Two-way transmission of data may be accomplished over a screened cable up to 50 metres.

A 2-metre cable with a 9-way ‘D’ type connector is provided.

The baud rate and bit format are set by a rotary switch on the rear panel as follows:

A. Standard serial interface

Baud rate 1200

Bits per character 1 start, 7 data, 2 stop, no parity

Number of characters 5 + carriage return

Character format Sign, four digits, CR

Control lines Inactive

Code ASCII

B. Serial interface for κ/T system operation

(Used for compatibility with the temperature meter)

Baud rate 1200

Bits per character 1 start, 8 data, 2 stop, no parity

Number of characters 5 + carriage return

Character format Sign, four digits, CR

Control lines Inactive

Code ASCII

C. Serial interface for 9600 baud option

Baud rate 9600

Bits per character 1 start, 8 data, 2 stop, no parity

Number of characters 5 + carriage return

Character format Sign, four digits, CR

Control lines Inactive

Code ASCII

Table of contents

Other Bartington Measuring Instrument manuals

Bartington

Bartington MS3 User manual

Bartington

Bartington Grad-13 Series User manual

Bartington

Bartington Grad-13 Series User manual

Bartington

Bartington Mag-01 User manual

Bartington

Bartington Mag613 User manual

Bartington

Bartington Mag-01H User manual

Bartington

Bartington Mag-01 User manual

Bartington

Bartington Mag690 User manual

Bartington

Bartington Mag628 User manual

Bartington

Bartington Grad601 User manual