BASEWEST TS-453 Use and care manual

BASEWEST

Operating & Calibration

Instructions

Model TS-453 Test Set

A380 Escape Slide

Lighting Systems

September 29, 2016

BASEWEST INC.

4240 116th Terrace N • Clearwater FL 33762

Tel: 727/573-2700 • Fax: 727/573-4307

E-mail: [email protected]

www.basewest.com

25-60-74

BASEWEST

Operating & Calibration Instructions

Model TS-453 Test Set

Page 2 of 12 25-60-74

29 September 2016

1.0 GENERAL

This manual covers the operation and calibration of the Model TS-453 Test Set for the

Airbus A380 escape slide lighting system. The Model TS-453 is designed to test for

short circuit conditions and/or electrical cross-talk in escape slide lighting circuits and

aircraft interface harnesses.

This device is a GO/NO-GO tester that does not provide parametric electrical readings.

2.0 THEORY OF OPERATION

2.1 The Model TS-453 Test Set detects short circuits and/or electrical cross-talk conditions

in A380 escape slide lighting systems and electrical interface harnesses by verifying

each of the ten different circuits against all other circuits connected via the interface.

Testing is conducted relative to nominal threshold values of 2 Mand 6.7Kdepending

on particular circuit at test. Circuit selection, sequencing, and testing are controlled by a

microprocessor in the device.

2.2 After proper hook-up and activation per the operating instructions, the TS-453 conducts

a self-test to confirm readiness for test. When the self-test is complete, testing of the

connected interface harness and systems will commence automatically. The test set

cycles automatically through each of the ten circuit tests (described in Appendix A),

illuminating each of the indicator LEDs, in order, left to right, top to bottom as the circuit

test is completed. The following indications are provided:

BASEWEST

Operating & Calibration Instructions

Model TS-453 Test Set

Page 3 of 12 25-60-74

29 September 2016

If all ten indicator LEDs in the top panel illuminate and remain ON, a proper

test has been accomplished. Otherwise, there is a fault in the instrument and

it must be checked and repaired before proceeding.

If all ten indicator LEDs in the top panel illuminate and remain GREEN, the

interface harness and attached system is “GO” and has tested good for

release to service.

If one or more of the ten indicator LEDs in the top panel illuminates RED, the

interface harness and attached system is “NO GO” and may not be released

to service. The RED-illuminated indicator LED will indicate the particular

circuit that either a short circuit or cross-talk condition has been detected.

2.4 Power is provided by a non-rechargeable 9V battery located in a compartment

accessible from the bottom of the instrument case. If the “LOW BATT” indicator light on

the main panel illuminates, the battery should be replaced before testing is conducted.

3.0 OPERATING INSTRUCTIONS

3.1 Connect the A380 interface harness and system to be tested to the TS-453 test set via

the 26-pin connector at the top of the instrument.

3.2 Slide the Door Test Selector switch to proper position for the interface harness under

test, as indicated:

LEFT Position = M1, M2, M4, or M5 doors

RIGHT Position = M3 or Upper Deck (UD) doors

3.3 Turn the test set ON via the rocker switch on the instrument panel. All LEDs on the top

indicator light panel will activate and perform a self-test in the following sequence:

Three RED flashes with increasing intensity

Three GREEN flashes with increasing intensity

NOTE: if any LED fails to flash in this sequence, the test unit must be removed

from service and repaired prior to any testing.

3.4 Immediately after the self-test, the TS-453 will commence automatic testing of the

connected system via the interface harness. The progress of this test can be confirmed

by observing that each indicator LED turns ON, in sequence left to right, top to bottom,

as the individual circuits are tested. The LEDs remain ON until the test is complete and

the test set is turned OFF. The following are the test indications:

All LEDs illuminate GREEN and remain ON – This indicates that no short

circuit or cross-talk conditions have been detected in any of the circuits (e.g.,

there is an open circuit condition with a resistance of nominally 2 Mand for

some special cases 6.7K), and that the interface harness under test is “GO”

and released for service.

One or more LEDs illuminate RED – This indicates that there is an electrical

closed/short circuit or cross-talk condition below the threshold resistance of

BASEWEST

Operating & Calibration Instructions

Model TS-453 Test Set

Page 4 of 12 25-60-74

29 September 2016

nominally 2 Mor 6.7Kin the circuit under test and the interface harness

and connected system under test is “NO GO” and may not be released to

service.

NOTE: Any deviation from these indications, including flickering of LED indicator

lights requires that the test set, the interface harness, and/or the connected

systems are suspected of a fault and must be checked and re-tested before

returned to service.

3.5 After the test is completed, turn the TS-453 OFF via the rocker switch. All LED’s will

revert to OFF, and the device is automatically re-set for the next test.

4.0 CALIBRATION PROCEDURE

4.1 Calibration may be performed by the user, a third party calibration facility, or BaseWest,

at the user’s option. Calibration is recommended to be performed on an annual basis,

but user experience and calibration requirements may indicate a different calibration

schedule.

4.2 Remove all connections to the connector interface.

4.3 Turn the unit face down and remove the four screws attaching the back of the case.

Note: opening the unit will void any existing calibration.

4.4 Turn the unit face up and slightly separate the front of the case enough to have access

to Trimpot R1 located on the bottom left side of the main PCB which is attached to the

back cover.

4.5 Set the Door Test selector to M1,M2,M4,M5 and turn the unit on.

4.6 Allow the TS-453 to remain ON for at least 20 seconds after a test sequence has

completed. At that time, the test set will automatically cycle to a calibration mode. While

in this mode, the TS-453 can be calibrated in the following manner:

Connect an ammeter between Pins Y(-) and Z(+)

Read 2.40 +/- 0.05 A (microamps). If the reading is not in that range, Adjust

Trimpot R1 at Main PCB until reading is under limits.

4.7 Turn the unit OFF and turn back ON, allow the TS-453 to remain ON for at least 20

seconds after the test sequence has completed. At that time verify Ammeter reading of

2.40 +/- 0.05 uA between Pins Y(-) and Z(+).

4.8 Properly position the back and front of the case, close the unit and replace the four

screws. Note that attention should be taken not to pinch any internal wires or disconnect

the Ribbon cable.

BASEWEST

Operating & Calibration Instructions

Model TS-453 Test Set

Page 5 of 12 25-60-74

29 September 2016

5.0 TEST SET GO/NO-GO CHECK HIGH RESISTANCE

5.1 The following GO/NO-GO check procedure can be performed on the TS-453, with

reference to Chart 1, below. This is the same procedure used for final inspection at the

factory. This check requires the BaseWest P/N 7-6045 test load.

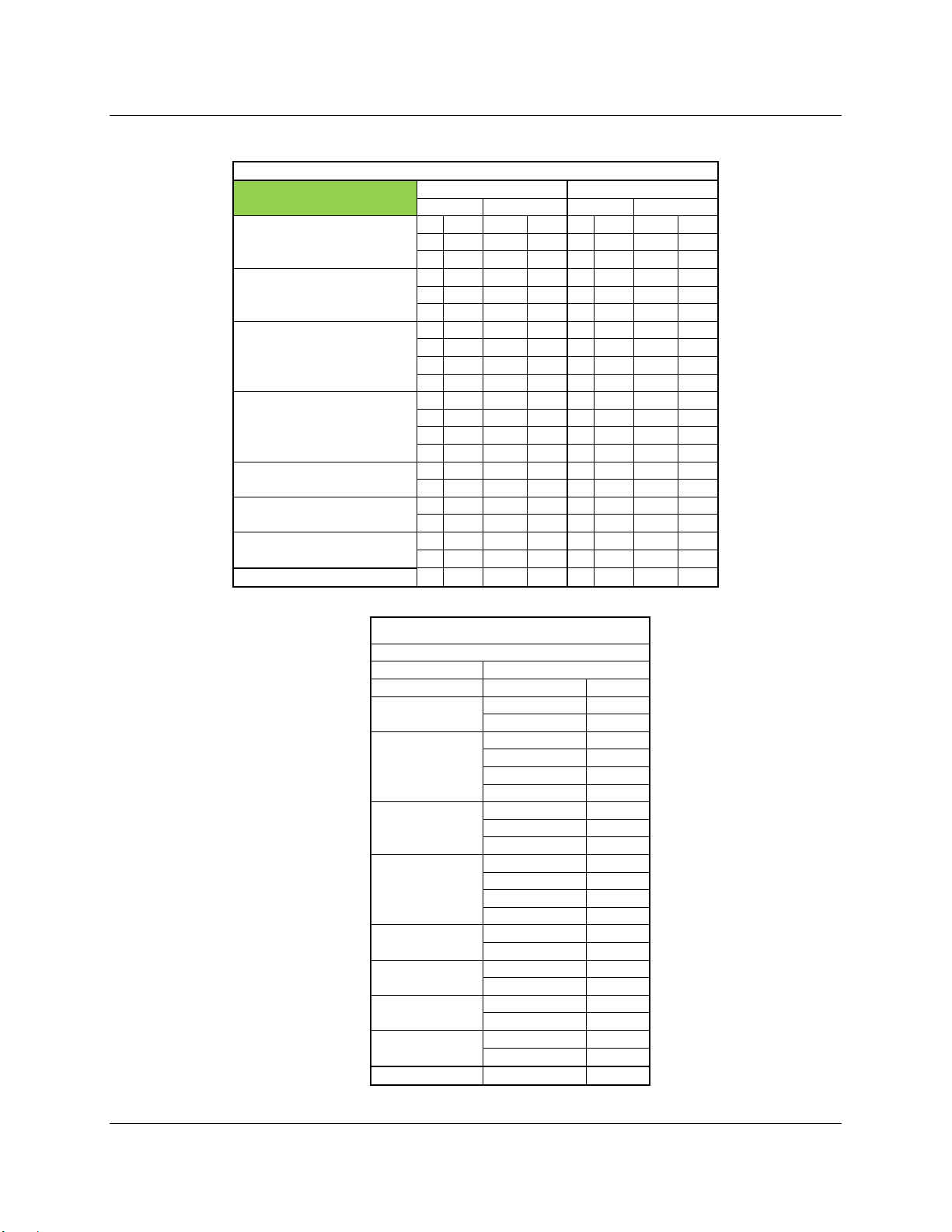

Chart 1 - TS-453 Test Set GO/NO-GO High Resistance Check

Circuit to

be Tested Door Selector

Test Switch

7-6045 Test Load: Install BLUE and WHITE Wire Pins

into the indicated TS-453 Connector Contact(s)

BLUE PIN WHITE PIN

MainGND M1, M2, M4, M5 X P,R,A,B,C,D,T,U,E,F,b,V,S,a,c,W

MainGND M3, UD G P,R,A,B,C,D,T,U,E,F,S,a,c,W

Lights M1, M2, M4, M5 M, K, or L P,R,A,B,C,D,T,U,E,F,b,V,S,a,c,W

CV M1, M2, M4, M5 P, R, A, or B M,L,K,J,G,H,C,D,T,U,E,F,b,V,S,a,c,W

RI M1, M2, M4, M5 J, or H P,R,A,B,C,D,T,U,E,F,b,V,S,a,c,W

GG M1, M2, M4, M5 C, D, T, or U M,L,K,J,G,H,P,R,A,B,E,F,b,V,S,a,c,W

SES M1, M2, M4, M5 E or F P,R,A,B,M,L,K,J,G,H,C,D,T,U,b,V,S,a,c,W

PGRV M1, M2, M4, M5 b or V P,R,A,B,M,L,K,J,G,H,C,D,T,U,E,F,S,a,c,W

CC M1, M2, M4, M5 S or a P,R,A,B,M,L,K,J,G,H,C,D,T,U,E,F,b,V,c,W

SDS M1, M2, M4, M5 c or W P,R,A,B,M,L,K,J,G,H,C,D,T,U,E,F,b,V,S,a

5.2 With the unit turned OFF, place the Door Selector Test switch into the position indicated

for the circuit to be tested per Chart 1.

5.3 Place the BLUE wire pin contact on the 7-6045 test load into any of the TS-453

connector contacts listed under “BLUE Pin” in Chart 1 for the circuit to be tested.

5.4 Place the WHITE wire pin contact on the 7-6045 test load into any of the TS-453

connector contacts listed under “WHITE Pin” in Chart 1 for the circuit to be tested.

5.5 Select the “2.5 M(GREEN)” setting on the 7-6045.

5.6 Turn the TS-453 ON via the rocker switch. Wait for the unit to complete its automatic

self-test and circuit test procedures.

The LED indicator light for the circuit under test should illuminate GREEN, along

with all of the other indicator LEDs on the top panel.

5.7 Turn the TS-453 OFF via the rocker switch.

5.8 Select the “1.8 M(RED)” setting on the 7-6045.

BASEWEST

Operating & Calibration Instructions

Model TS-453 Test Set

Page 6 of 12 25-60-74

29 September 2016

5.9 Turn the TS-453 ON again via the rocker switch. Wait for the unit to complete its

automatic self-test and circuit test procedures.

The LED indicator light for the circuit under test should illuminate RED; all other

indicator LEDs on the top panel should illuminate GREEN.

5.10 Repeat steps 5.2 through 5.9 for any number of combinations of circuits and/or pin-outs,

as required by the user use Appendix A for reference.

6.0 TEST SET GO/NO-GO CHECK LOW RESISTANCE

6.1 The following GO/NO-GO check procedure can be performed on the TS-453, with

reference to Chart 2, below. This check requires the two resistor loads of: a) 4.12 K

ohms for RED (NO-GO) and b) 28.0 K ohms for GREEN (GO) indication. (Resistor load

should be placed across test circuit contacts)

Chart 2 - TS-453 Test Set GO/NO-GO Low Resistance Check

Circuit to

be Tested Door Selector

Test Switch

7-6045 Test Load: Install BLUE and WHITE Wire Pins

into the indicated TS-453 Connector Contact(s)

BLUE PIN WHITE PIN

MainGND M1, M2, M4, M5 X M, or L

MainGND M3, UD G K, or L

Lights M1, M2, M4, M5 M, K, or L J, or H, or X

Lights M3, UD M, K, or L J, or H, or X

RI M1, M2, M4, M5 J, or H M, or K, or L

RI M3, UD J, or H M, or K, or L

6.2 With the unit turned OFF, place the Door Selector Test switch into the position indicated

for the circuit to be tested per Chart 2.

6.3 Place the blue wire pin of the 7-6045 into any of the TS-453 connector contacts listed

under “BLUE PIN” in Chart 2 for the circuit to be tested.

6.4 Place the white wire pin of the 7-6045 into any of the TS-453 connector contacts listed

under “WHITE PIN” in Chart 2 for the circuit to be tested.

6.5 “GO” Check: Select the 28.0 K(GREEN) Load.

6.6 Turn the TS-453 ON via the rocker switch. Wait for the unit to complete its automatic

self-test and circuit test procedures.

The LED indicator light for the circuit under test should illuminate GREEN, along

with all off the other indicator LEDs on the top panel.

BASEWEST

Operating & Calibration Instructions

Model TS-453 Test Set

Page 7 of 12 25-60-74

29 September 2016

6.7 Turn the TS-453 OFF via the rocker switch.

6.8 “NO-GO” Check: Select the less than 4.12 K(RED) Load. Reconnect it to the same

contacts on the TS-453 that were previously selected in 6.3 and 6.4.

6.9 Turn the TS-453 ON again via the rocker switch. Wait for the unit to complete its

automatic self-test and circuit test procedures.

The LED indicator light for the circuit under test should illuminate RED; all other

indicator LEDs on the top panel should illuminate GREEN.

6.10 Repeat steps 6.2 through 6.9 for any number of combinations of circuits and/or pin-outs,

as required by the user, use Appendix A for reference.

7.0 CARE & MAINTENANCE

7.1 The TS-453 test set is a sensitive electronic instrument; it should be treated and

protected with appropriate care.

•

Do not drop or crush the instrument

• Do not apply external electrical inputs

• Keep instrument away from all fluids

• Protect from extreme temperatures, weather/rain

7.2 The device is designed for handheld use in a shop environment and is not designed to

withstand a drop to the ground or to survive excessive compression loads.

7.3 The device is not water or fluid resistant; do not allow the device to sit in standing fluids or

subject to splash or rain.

7.4 Surface cleaning only with a slightly damped cloth (water or alcohol) is recommended.

DO NOT use other solvents or cleaners.

BASEWEST

Operating & Calibration Instructions

Model TS-453 Test Set

Page 8 of 12 25-60-74

29 September 2016

APPENDIX A – CIRCUIT TEST PROTOCOLS

The charts provided in this appendix detail the specific circuits that are tested during each automated test

cycle. This is provided as a reference only, but may be used to select specific circuits for the GO/NO-GO

check in Sections 5.0 and 6.0 (Highlighted cells are for 6.7Kthreshold see section 6.0 TEST SET

GO/NO-GO CHECK LOW RESISTANCE for details). If there are any questions, please contact

BaseWest.

Chart 3 - Lights Circuit Test

Lights Test M1, M2, M4, M5 M3, UD

vs vs vs vs vs vs

CV

M P K P L P M P K P L P

M R K R L R M R K R L R

M A K A L A M A K A L A

M B K B L B M B K B L B

RI

M J K J L J M J K J L J

- - - - - - - - - - - -

M H K H L H M H K H L H

GG

M C K C L C M C K C L C

M D K D L D M D K D L D

M T K T L T M T K T L T

M U K U L U M U K U L U

SES M E K E L E M E K E L E

M F K F L F M F K F L F

PGRV M b K b L b - - - - - -

M V K V L V - - - - - -

CC M S K S L S M b K b L b

M a K a L a M V K V L V

SDS M c K c L c M c K c L c

M W K W L W M W K W L W

Main GND M X K X L X - - K G L G

Chart 2 - Main Ground Circuit Test

M1, M2, M4,

M5 M3, UD

vs vs

Lights X M G K

X L G L

CV

X P G P

X R G R

X A G A

X B G B

RI - - - -

- - - -

- - - -

GG

X C G C

X D G D

X T G T

X U G U

SES X E G E

X F G F

PGRV X b - -

X V - -

CC X S G b

X a G V

SDS X c G c

X W G W

BASEWEST

Operating & Calibration Instructions

Model TS-453 Test Set

Page 9 of 12 25-60-74

29 September 2016

Chart 4 - CV Circuit Test

CV Test M1, M2,M3, M4, M5 UD M3, UD

vs vs vs vs vs vs vs vs

Lights

P M R M A M B M P M R M A M B M

P L R L A L B L P L R L A L B L

P K R K A K B K P K R K A K B K

RI

P J R J A J B J P J R J A J B J

P G R G A G B G - - - - - - - -

P H R H A H B H P H R H A H B H

GG

P C R C A C B C P C R C A C B C

P D R D A D B D P D R D A D B D

P T R T A T B T P T R T A T B T

P U R U A U B U P U R U A U B U

SES P E R E A E B E P E R E A E B E

P F R F A F B F P F R F A F B F

PGRV P b R b A b B b - - - - - - - -

P V R V A V B V - - - - - - - -

CC P S R S A S B S P b R b A b B b

P a R a A a B a P V R V A V B V

SDS P c R c A c B c P c R c A c B c

P W R W A W B W P W R W A W B W

Main GND P X R X A X B X P G R G A G B G

Chart 5 - RI Circuit Test

RI Test M1, M2, M4, M5 M3, UD

vs vs vs vs

Lights

J M H M - - J M H M

J K H K - - J K H K

J L H L - - J L H L

CV

J P H P - - J P H P

J R H R - - J R H R

J A H A - - J A H A

J B H B - - J B H B

GG

J C H C - - J C H C

J D H D - - J D H D

J T H T - - J T H T

J U H U - - J U H U

SES J E H E - - J E H E

J F H F - - J F H F

PGRV J b H b - - - - - -

J V H V - - - - - -

CC J S H S - - J b H b

J a H a - - J V H V

SDS J c H c - - J c H c

J W H W - - J W H W

Main GND - - - - - - - - - -

BASEWEST

Operating & Calibration Instructions

Model TS-453 Test Set

Page 10 of 12 25-60-74

29 September 2016

Chart 6 - GG Circuit Test

GG Test M1, M2,M3, M4, M5 UD M3, UD

vs vs vs vs vs vs vs vs

Lights

C M D M T M U M C M D M T M U M

C L D L T L U L C L D L T L U L

C K D K T K U K C K D K T K U K

RI

C J D J T J U J C J D J T J U J

C G D G T G U G - - - - - - - -

C H D H T H U H C H D H T H U H

CV

C P D P T P U P C P D P T P U P

C R D R T R U R C R D R T R U R

C A D A T A U A C A D A T A U A

C B D B T B U B C B D B T B U B

SES C E D E T E U E C E D E T E U E

C F D F T F U F C F D F T F U F

PGRV C b D b T b U b - - - - - - - -

C V D V T V U V - - - - - - - -

CC C S D S T S U S C b D b T b U b

C a D a T a U a C V D V T V U V

SDS C c D c T c U c C c D c T c U c

C W D W T W U W C W D W T W U W

Main GND C X D X T X U X C G R G T G U G

Chart 7 - SES Circuit Test

SES Test M1, M2, M4, M5 M3, UD

vs vs vs vs

Lights

E M F M E M F M

E K F K E K F K

E L F L E L F L

RI

E J F J E J F J

E G F G - - - -

E H F H E H F H

CV

E P F P E P F P

E R F R E R F R

E A F A E A F A

E B F B E B F B

GG

E C F C E C F C

E D F D E D F D

E T F T E T F T

E U F U E U F U

PGRV E b F b - - - -

E V F V - - - -

CC E S F S E b F b

E a F a E V F V

SDS E c F c E c F c

E W F W E W F W

Main GND E X F X E G F G

BASEWEST

Operating & Calibration Instructions

Model TS-453 Test Set

Page 11 of 12 25-60-74

29 September 2016

Chart 8 - PGRV Circuit Test

PGRV Test M1, M2, M4, M5 M3, UD

vs vs

Lights

b M V M

In this mode

PGRV indicator

is set by default

to GREEN

since in M3/UD

mode there are

no pins

assigned for a

pin by pin

verification.

b K V K

b L V L

RI

b J V J

b G V G

b H V H

CV

b P V P

b R V R

b A V A

b B V B

GG

b C V C

b D V D

b T V T

b U V U

SES b E V E

b F V F

CC b S V S

b a V a

SDS b c V c

b W V W

MGND b X V X

Chart 9 - CC Circuit Test

CC Test M1, M2, M4, M5 M3, UD

vs vs vs vs

Lights

S M a M b M V M

S K a K b K V K

S L a L b L V L

RI

S J a J b J V J

S G a G - - - -

S H a H b H V H

CV

S P a P b P V P

S R a R b R V R

S A a A b A V A

S B a B b B V B

GG

S C a C b C V C

S D a D b D V D

S T a T b T V T

S U a U b U V U

SES S E a E b E V E

S F a F b F V F

PGRV S b a b - - - -

S V a V - - - -

SDS S c a c b c V c

S W a W b W V W

MGND S X a X b G V G

BASEWEST

Operating & Calibration Instructions

Model TS-453 Test Set

Page 12 of 12 25-60-74

29 September 2016

Chart 10 - SDS Circuit Test

SDS Test M1, M2, M4, M5 M3, UD

vs vs vs vs

Lights

c M W M c M W M

c K W K c K W K

c L W L c L W L

RI

c J W J c J W J

c G W G - - - -

c H W H c H W H

CV

c P W P c P W P

c R W R c R W R

c A W A c A W A

c B W B c B W B

GG

c C W C c C W C

c D W D c D W D

c T W T c T W T

c U W U c U W U

SES c E W E c E W E

c F W F c F W F

PGRV c b W b - - - -

c V W V - - - -

CC c S W S c b W b

c a W a c V W V

MGND c X W X c G W G

Chart 11 - Case Ground Circuit Test

M1, M2, M3, M4, M5, UD

Circuits vs

Case GND vs k Case GND K

Lights

Case GND M

Case GND L

CV

Case GND P

Case GND R

Case GND A

Case GND B

RI Case GND J

Case GND G

Case GND H

GG

Case GND C

Case GND D

Case GND T

Case GND U

SES Case GND E

Case GND F

PGRV Case GND b

Case GND V

CC Case GND S

Case GND a

SDS Case GND c

Case GND W

Case GND vs X Case GND X

Table of contents

Other BASEWEST Test Equipment manuals

Popular Test Equipment manuals by other brands

Uniks

Uniks EV CHECK manual

VOLTCRAFT

VOLTCRAFT MS-410 operating instructions

TMI Products

TMI Products TQC Sheen 32-76e Series manual

pico Technology

pico Technology PicoScope 6000A Series user guide

Tektronix

Tektronix TDS7054 Service manual

MONARCH INSTRUMENT

MONARCH INSTRUMENT Nova-Pro UV365 instruction manual