TMI Products TQC Sheen 32-76e Series User manual

32-76-00-0002

1

Rev. 6/06/18

TESTING MACHINES, INC.

Measuring up to your standards

32-76e SERIES FRICTION/PEEL TESTER

$UWQU$%

Coefficient of Friction - Peel Tester-10262018-ab5700-m44.pdf 1Coefficient of Friction - Peel Tester-10262018-ab5700-m44.pdf 1 15-6-2020 13:40:3715-6-2020 13:40:37

32-76-00-0002

2

Rev. 6/06/18

TESTING MACHINES, INC.

Measuring up to your standards

Worldwide Headquarters

Sales and Service

40 McCullough Drive

New Castle, DE 19720 USA

Phone: 302-613-5600

Toll Free: 800-678-3221

Fax: 302-613-5619

www.testingmachines.com

Dear Valued Customer:

You are now the proud new owner of quality physical testing equipment

manufactured by Testing Machines Inc., the industry’s leader for over 80 years.

TMI has a long-standing commitment to quality products and customer

satisfaction.

To aid in setup, calibration, and operation of all Testing Machines Inc. equipment,

we offer telephone assistance by our Technical Support Department, available

Monday through Friday from 8:30 AM to 5:00 PM EST. TMI also offers on-site

Preventative Maintenance and Calibration service.

Please contact us at (302) 613-5600 if additional information is required.

Sincerely,

Testing Machines, Inc.

Coefficient of Friction - Peel Tester-10262018-ab5700-m44.pdf 2Coefficient of Friction - Peel Tester-10262018-ab5700-m44.pdf 2 15-6-2020 13:40:4915-6-2020 13:40:49

32-76-00-0002

3

Rev. 6/06/18

1 TABLE OF CONTENTS

1 TABLE OF CONTENTS ……………………………………………………….…………………………… 3

2 IMPORTANT SAFETY INSTRUCTIONS ……………………………………………………………….. 4

3 INTRODUCTION …………………………………………………………………………………………… 6

4 SPECIFICATIONS …………………………………………………………………...…………………….. 7

5 ACCESSORIES …………………………………………….……………………………………………….. 7

6 UNPACKING THE INSTRUMENT ………………………………………………………………………. 8

7 LIST OF EQUIPMENT …………………………..………………………………………….……………... 8

8 FEATURES ………………………………………………………………………………………………….. 8

9 GETTING TO KNOW THE INSTRUMENT …………………………………………………………….. 8

10 SET-UP ………………………………………………………………………………………………………. 9

11 OPERATION

a. RUN TESTS MENU ……………………………………………………………………………….. 11

b. TEST SETTINGS MENU .…………………………………………………………………………. 13

c. MACHINE OPTIONS MENU .……………………………………………………….……………. 15

d. MAINTENANCE MENU …………….……………………………………………………………. 16

12 RUNNING COF TESTS …………………………………………………………………………………. 17

13 HEATED TEST PLATEN ………………………………………………………………………………... 21

14 PEEL TESTING ………………………...…………………………………………………………………. 22

a. TEST SETTINGS MENU …………………………………………………………………………………… 22

b. STATISTICS …………………………………………………………………………………………………. 29

c. RUN TESTS MENU …………………………………………………………………………………………..31

15 CALIBRATING THE LOAD CELL ……………………………………………………………………... 33

16 INSTRUMENT MAINTENANCE …………………………………………………………….………….. 39

17 ANNEX – HEATED PLATEN TEMPERATURE UNITS ……………………………………………… 40

Coefficient of Friction - Peel Tester-10262018-ab5700-m44.pdf 3Coefficient of Friction - Peel Tester-10262018-ab5700-m44.pdf 3 15-6-2020 13:40:5015-6-2020 13:40:50

32-76-00-0002

4

Rev. 6/06/18

2 IMPORTANT SAFETY INSTRUCTIONS

Read all of these instructions carefully before operating the instrument.

1. Save these instructions for future reference.

2. Follow all warnings and instructions that are marked on the instrument.

3. Unplug the instrument from the wall outlet before cleaning. Wipe the outside surfaces with a dry soft

cloth only.

4. Do not use this instrument near water.

5. Do not place the instrument on an unstable cart, stand, or table.

6. Only operate the instrument from the type of power source indicated on the label.

7. For safety, this product is equipped with a three-wire grounding type plug. This plug will only fit into a

grounding type power outlet. If you are unable to insert the plug into the outlet, contact your electrician

to replace the outlet with the proper type. Do not defeat the purpose of the grounding-type plug.

8. Do not allow anything to rest on the power cord. Do not locate this product where persons will walk on

the cord.

9. If an extension cord is used with this product, make sure that the total ampere ratings of the product(s)

plugged into the extension cord do not exceed the extension cord ampere rating. Extension cords must

have a minimum insulation rating of 600v.

10. Do not remove any panels from the tester. Never push objects of any kind into any openings in the

instrument’s covers. Failure to heed this warning could result in fire or electric shock. Never spill liquid

of any kind on the instrument.

11. Do not attempt to service this product yourself. Opening or

removing covers may expose you to dangerous high voltages.

12. At the end of its service life, dispose of the product according to the relevant statutory regulations.

13. Refer all servicing to Testing Machines’ Technical Support Staff:

Testing Machines Inc.

Customer Service Department

40 McCullough Drive

New Castle, DE 19720 USA

Phone: (800) 678-3221 or (302) 613-5600

Fax: (302) 613-5619

Email: response[email protected]om

Web: www.testingmachines.com

14. Unplug the unit from the wall outlet and refer servicing to qualified service personnel under the following

conditions:

i When the power cord or plug is damaged or frayed.

i If liquid has been spilled into the product.

i If the product has been exposed to rain or water.

15. Adjust only those controls that are covered by the operating instructions. Improper adjustments of other

controls may result in damage to the instrument and will often require extensive work by a technician to

restore the unit to normal operation.

Coefficient of Friction - Peel Tester-10262018-ab5700-m44.pdf 4Coefficient of Friction - Peel Tester-10262018-ab5700-m44.pdf 4 15-6-2020 13:40:5015-6-2020 13:40:50

32-76-00-0002

5

Rev. 6/06/18

16. Back-up Battery:

Inside the Instrument tester a CR2032 type coin battery is used on the microcontroller

PCB to provide the necessary power to the timekeeping memory chip of the instrument during the power

off period. This to maintain the clock, calendar and setup information.

When the battery is worn out it may only be replaced by a trained service engineer!

When the battery is worn out dispose it under the ordinance of each local government or the law issued by

relating government.

The battery contains organic electrolyte.

In case of electrolyte leakage from the battery, and an eventual contact with this electrolyte to the operator

the actions described below are required.

In case of eye contact:

Flush the eyes with plenty of clean water for at least 15 minutes immediately, without rubbing. Take a

medical treatment. If appropriate procedures are not taken, this may cause an eye irritation.

In case of skin contact:

Wash the contact areas off immediately with plenty of water and soap. If appropriate procedures are not

taken, this may cause sores on the skin.

In case of inhalation:

Remove to fresh air immediately. Take a medical treatment

In case of electrolyte leakage, take it up with absorbent cloth.

This may only be done by a trained service engineer!

17. Instrument Labels:

The following labels can be found on the instrument.

Earth (Ground)

Electrical Shock Warning

Consult the Operator’s Manual

18.

Coefficient of Friction - Peel Tester-10262018-ab5700-m44.pdf 5Coefficient of Friction - Peel Tester-10262018-ab5700-m44.pdf 5 15-6-2020 13:40:5015-6-2020 13:40:50

32-76-00-0002

6

Rev. 6/06/18

3 INTRODUCTION

The 32-76 Series Friction/Peel Tester is a state-of-the-art precision laboratory instrument

for measuring the static and kinetic friction between two specimens or between a

specimen and a substrate. The instructions in this manual will guide the operator, step by

step, through the first test.

Throughout this manual the expected touch screen icons are displayed. These icons show

the user vital information pertaining to the function of the tester.

The following figures show different views of the Tester.

32-76e Series Friction/Peel Tester – Front View

32-76e Series Friction/Peel Tester – Side Panel 32-76e Series Friction/Peel Tester – Back

Panel

Start/Stop Button

Touchscreen Display

Power Switch

USB Drive

or Printer

GraphMaster

Output

Circuit

Breaker

Power

Jack

Coefficient of Friction - Peel Tester-10262018-ab5700-m44.pdf 6Coefficient of Friction - Peel Tester-10262018-ab5700-m44.pdf 6 15-6-2020 13:40:5015-6-2020 13:40:50

32-76-00-0002

7

Rev. 6/06/18

4 SPECIFICATIONS

Power: 120/240VAC 50/60 Hz (24VDC wall adapter)

Output: USB flash drive, USB ESC/POS printer, RS232 over a USB COM port, GraphMaster™

software (optional)

Dimensions: 515 mm x 495 mm x 508 mm (20.3 in x 19.5 in x 20 in)

Weight (approx.): 25 kg. (55 lbs.)

Load Cells Available: 5N, 10N, 20N, 50N, 100N (10N load cell is standard)

Speed Range: 10 to 50 cm per minute (4 to 20 inches per minute)

Travel Distance: 2.5 to 25.4 cm (1 to 10 in)

Standards: ASTM D 1894, ISO 8295, TAPPI 5816, TAPPI T 549

Warning:

If the supplied power cord needs to be adapted to the local power requirements this must be done by

a qualified electrical engineer. The plug must be equipped with a safety earth terminal.

Please Note:

Power cord wire colors:

Brown or Black = Line

Blue or White = Neutral

Yel/Grn or Green = Earth/Ground

Note:

Due to the weight of the instrument a two person lift is required.

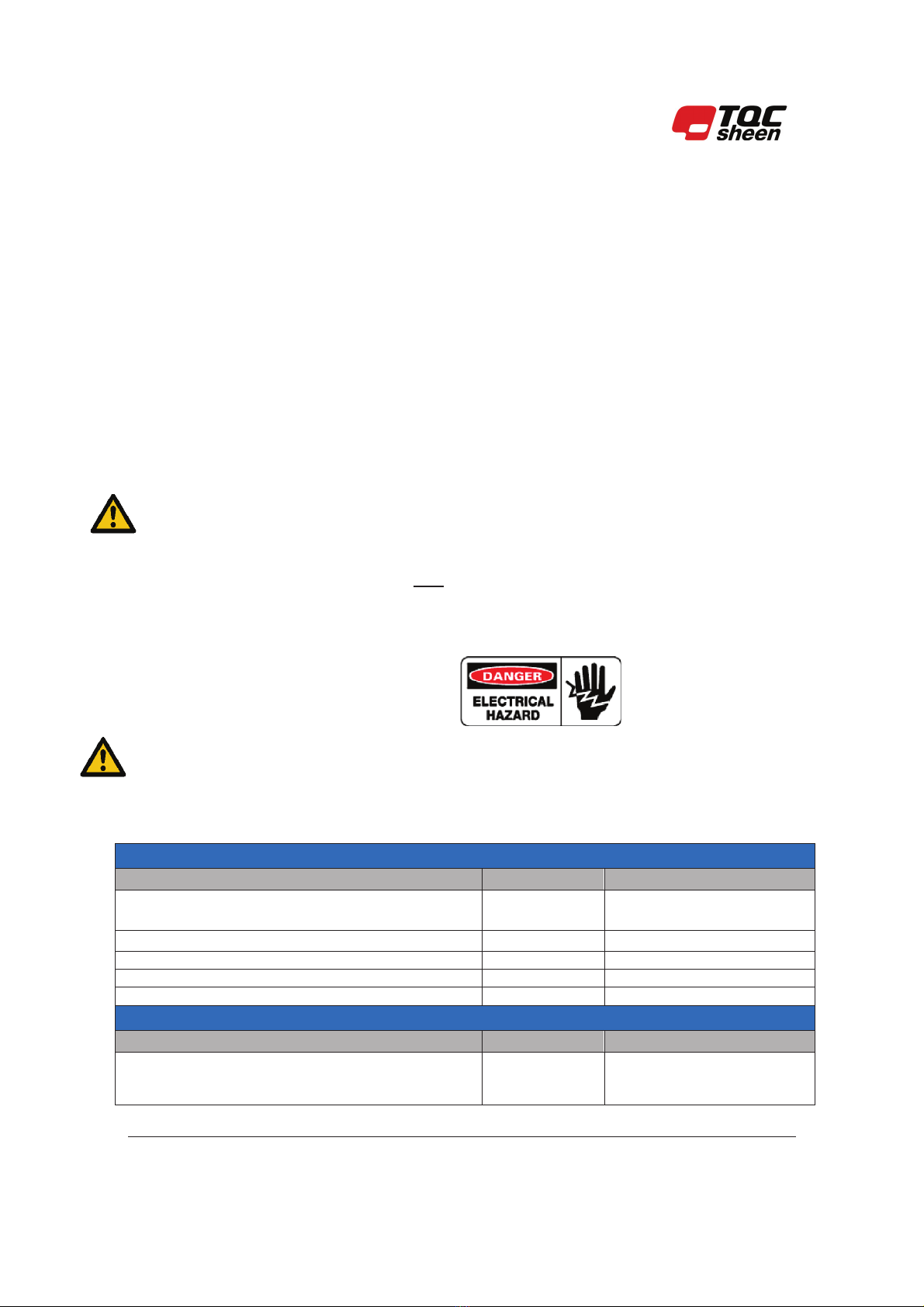

5 AVAILABLE ACCESSORIES

Hardware

Description

Part #

Installation

Available Sleds -100 Gm - 1816 Gm (System software

accepts variable sled weights)

Please Specify

Sled

Field Installation (by customer)

Hook Weight Set 10-1000g

32-07-10

For field calibration

Heated Test Platen

32-76-08

Factory Installation

T Peel Fixture

32-76-03

Field Installation (by customer)

180 Degree Peel Fixture

32-76-04

Field Installation (by customer)

Software

Description

Part #

Installation

GraphMaster Software

03-84-00-

0001

CD with USB Dongle

Coefficient of Friction - Peel Tester-10262018-ab5700-m44.pdf 7Coefficient of Friction - Peel Tester-10262018-ab5700-m44.pdf 7 15-6-2020 13:40:5115-6-2020 13:40:51

32-76-00-0002

8

Rev. 6/06/18

6 UNPACKING THE INSTRUMENT

SAVE THE BOX

Please save all the original packing material in the event that the tester must be returned. Prior to

returning any item, the customer MUST obtain a Return Material Authorization Number (RA #) from

the TMI Customer Service Department.

7 LIST OF EQUIPMENT

Included in the packaging of your Slip and Friction/Peel Tester will be the following components:

1 Instruction Manual with Calibration Documents

1 Universal Power Supply

1 Line Cord

1 Stylus

1 Calibration Fixture Assembly (TMI# 32-06-05-006)

8 FEATURES

x 7” full-color digital touchscreen display

x High speed data collection and analysis for precise measurement of static COF with 500 readings

during the first second

x Selectable units (COF or grams for COF; N gf, kgf, ozf, lbf for peel tests)

x Interchangeable load cells 5N, 10N, 20N, 50N and 100N (purchased separately)

x Automatically reports static and kinetic friction results after measurement

x Settable distance and time for Static and Kinetic

x Test storage including individual results up to 100 readings, average and standard deviation

x Direct drive arm with unique skid control

x Sled-connecting mechanism ensures level pulling action

x Software accepts variable sled weights

x Peel testing with optional T peel and 180 degree peel fixtures

x Direct output to PC based GraphMaster software providing friction curve analysis and storage

x Mini USB output for PC connection and printer (GraphMaster compatible)Multiple Data Export

options: USB flash drive, USB

9 GETTING TO KNOW THE INSTRUMENT

The Coefficient of Friction/Peel Tester incorporates high-tech capabilities with user-friendly, menu

driven software to ease use and speed testing. The part names, functions, and descriptions of the parts

are listed below.

On/Off Switch – main power switch for the unit.

Touchscreen – a 7” touchscreen for machine control

Test Button – hardware button that controls starting and stopping of a test

Coefficient of Friction - Peel Tester-10262018-ab5700-m44.pdf 8Coefficient of Friction - Peel Tester-10262018-ab5700-m44.pdf 8 15-6-2020 13:40:5115-6-2020 13:40:51

32-76-00-0002

9

Rev. 6/06/18

Level – located on the top of the upright of the unit, the level is used to ensure the front and rear feet of

the machine are aligned properly on the table or benchtop.

Leveling Pads – four feet located on the bottom of the unit, used in conjunction with the level to align

the tester on the table or benchtop.

Load Cell – a measuring device used to determine the force required to move the sample and sled.

USB Connector – output port to a USB receipt printer or thumb drive

RS-232 Connector – RS232 output via Mini USB connection

Power Supply Connector – connects power supply to tester.

Power Supply – an AC adapter whose input is an AC outlet and outputs to the power supply connector

on the rear of the unit.

NOTE: You should only use a power supply provided by TMI specifically for your instrument.

The supply tested for this application is the Mean Well GST60A24-P1J (60W, 24V, 2.5A).

Your instrument may require that the supply be modified for fit; contact TMI for details.

10 SET-UP

MACHINE

1. Place the tester in an environment that is free from shock and vibration, on a flat level surface that

is strong enough to support the load of the tester. Use the four adjustable legs on the tester and

turn them until level.

2. Plug power source into a filtered or clean AC outlet.

Coefficient of Friction - Peel Tester-10262018-ab5700-m44.pdf 9Coefficient of Friction - Peel Tester-10262018-ab5700-m44.pdf 9 15-6-2020 13:40:5115-6-2020 13:40:51

32-76-00-0002

10

Rev. 6/06/18

11 OPERATION

STARTUP

Upon initial power-up, you will be in the Run Tests menu.

The following is a detailed look at each menu and their functions.

INSTRUMENT CONTROLS

The Instrument controls are broken down into four main menus:

1 Run Tests Menu

2 Test Settings Menu

3 Machine Options Menu

4 Maintenance Menu

They can be selected by pressing one of the four large buttons to the left side of the screen shown

below.

1

2

3

4

Coefficient of Friction - Peel Tester-10262018-ab5700-m44.pdf 10Coefficient of Friction - Peel Tester-10262018-ab5700-m44.pdf 10 15-6-2020 13:40:5215-6-2020 13:40:52

32-76-00-0002

11

Rev. 6/06/18

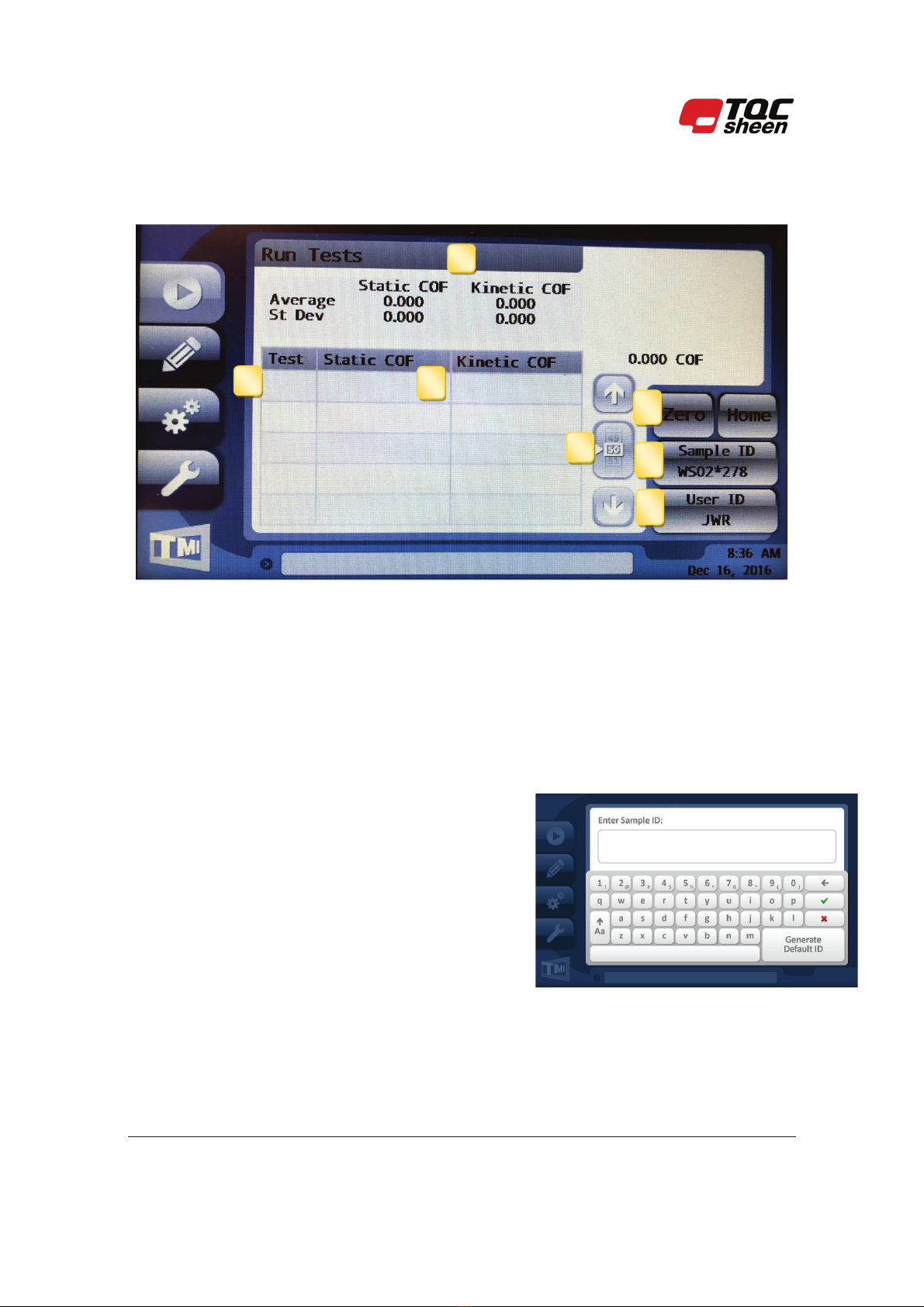

11.1 RUN TESTS MENU

This is the menu where the user will initiate tests and view all test results data.

1. STATISTICS

Statistics are calculated for the current group of samples and displayed in the table.

2. TEST #

An automatically incremented identifier for each test.

3. TEST RESULTS

This can be set up for coefficient of friction or force (see Test Settings).

4. ZERO

The zero button is used to zero the currently displayed force value.

5. SEARCH

Allows the user to search for specific test

data.

6. SAMPLE ID

A user-defined sample identifier. Clicking

on this button will open a full keyboard

(shown right) where the user can enter a

Sample ID.

NOTE: Special characters (@#$%*&^, etc.)

and spaces cannot be used in the Sample ID field.

Changing the Sample ID deletes all test results currently store in the instrument memory.

Press the check mark without entering an ID for a Generated ID based on the instrument

time and date.

2

3

4

6

7

5

1

Coefficient of Friction - Peel Tester-10262018-ab5700-m44.pdf 11Coefficient of Friction - Peel Tester-10262018-ab5700-m44.pdf 11 15-6-2020 13:40:5215-6-2020 13:40:52

32-76-00-0002

12

Rev. 6/06/18

7. USER ID

A user-defined user identifier. Clicking on this button will open a full keyboard (shown

right) where the user can enter a User ID.

USB COMMUNICATION

The USB-A port on the right-hand side of the instrument may be used to save

data to either a FAT formatted USB thumb drive or printed to a Point of Sale

printer. The port will automatically recognize the device that is attached and the

Report button will appear in the upper right-hand corner of the display. To save

or print data, touch the Report button.

Point of Sale Printer screen

USB drive screen

Coefficient of Friction - Peel Tester-10262018-ab5700-m44.pdf 12Coefficient of Friction - Peel Tester-10262018-ab5700-m44.pdf 12 15-6-2020 13:40:5215-6-2020 13:40:52

32-76-00-0002

13

Rev. 6/06/18

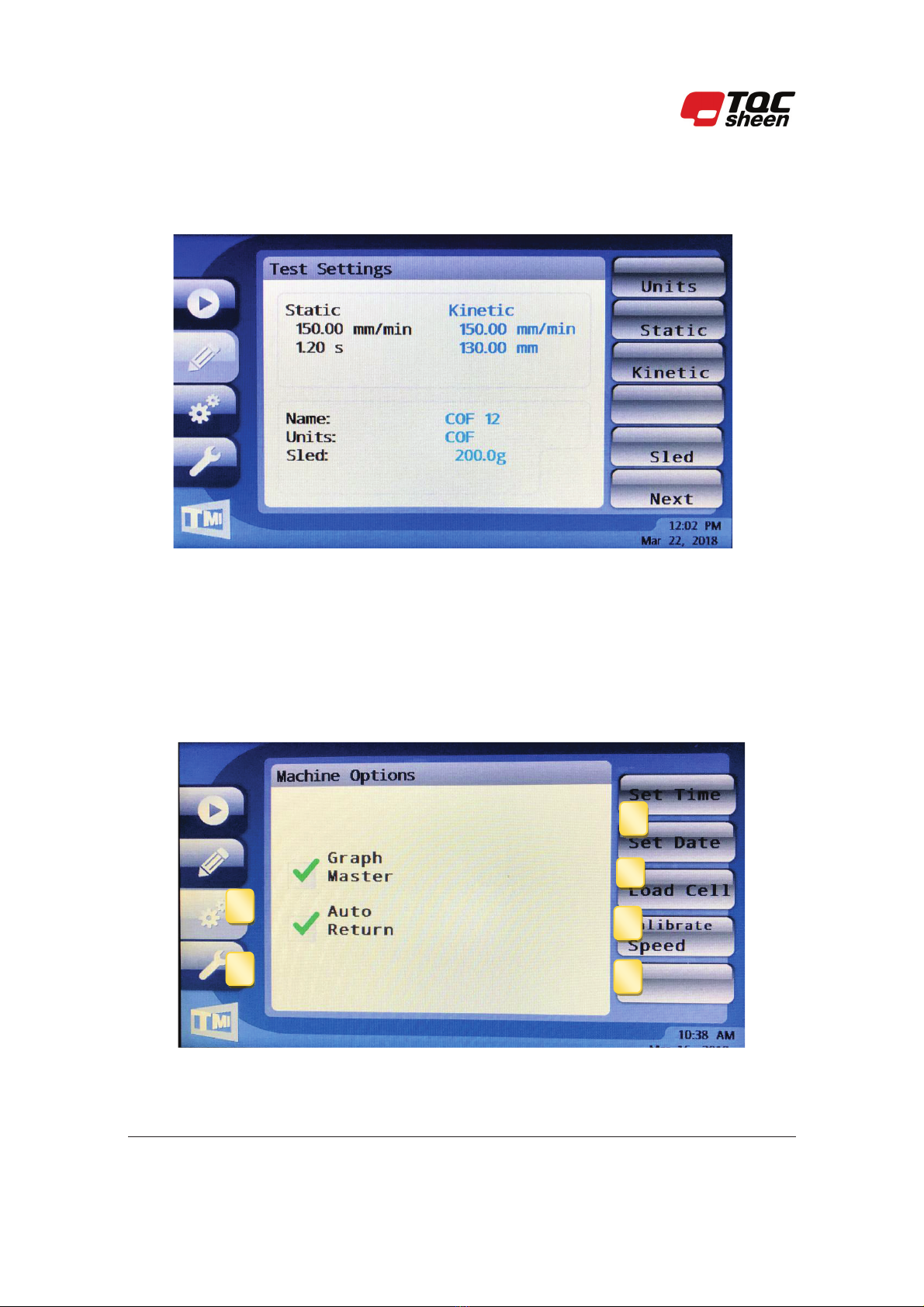

11.2 TEST SETTINGS MENU

This is the menu where all of the test-specific settings are selected.

1. LOAD

Load the currently selected test so it may be run as indicated by “Active”. The “->”

means the indicated test is temporarily selected for other functions, i.e. Load, New, Edit,

and Delete.

2. NEW

Create a new test. This will ask the user to name the test before taking you to the test

setup menu. Then the user must choose the test type.

1

2

3

4

5

6

Coefficient of Friction - Peel Tester-10262018-ab5700-m44.pdf 13Coefficient of Friction - Peel Tester-10262018-ab5700-m44.pdf 13 15-6-2020 13:40:5315-6-2020 13:40:53

32-76-00-0002

14

Rev. 6/06/18

3. EDIT

Edit the currently selected test. This menu allows you to edit a current test or setup new

test parameters. Units, sled weight, static and kinetic test parameters, and the name can

be edited from this menu. This menu is also part of the new test setup.

4. DELETE

Delete the currently selected test.

5. BACK

Navigate back to the previous menu.

11.3 MACHINE OPTIONS MENU

1

2

3

4

5

6

Coefficient of Friction - Peel Tester-10262018-ab5700-m44.pdf 14Coefficient of Friction - Peel Tester-10262018-ab5700-m44.pdf 14 15-6-2020 13:40:5415-6-2020 13:40:54

32-76-00-0002

15

Rev. 6/06/18

1, 2 SET TIME AND SET DATE

Select the current date and time for the instrument.

3 LOAD CELL

This allows the user to view, add, delete, or edit load cell information. The user can also select

between stored load cell options.

4 CALIBRATE SPEED

Allows the user, with the aid of a tachometer (not included with unit), calibrate the speed of the

sled.

5 GRAPHMASTER

Checking the GraphMaster box allows the instrument to communicate with the GraphMaster

software (sold separately). Leaving the GraphMaster box unchecked the instrument will out put a

header and data stream using RS-232 protocol as shown here. The serial port settings are 9600

baud, 8 data bits, no parity and 1 stop bit.

Test #,Static Maximum,Static Minimum,Static Average,Static St Dev,,Kinetic Maximum,Kinetic

Minimum,Kinetic Average,Kinetic St Dev,Static Speed,Static Distance,Static Duration,Kinetic

Speed,Kinetic Distance,Kinetic Duration,Force Units,Distance Units,Sample ID,User

ID,YYYY/MM/DD,HH:MM:SS,Sled grams,Width,Pre-Test Distance,Pre-Test Duration,Pre-Test

Force,Pre-Test Speed,Post Test Distance,Post Test Duration,Post Test Speed,Test Delay,%

drop,Return Speed,Test Complete Return

3, 0.117, 0.117, 0.117, 1.579, 3.345, 0.117, 2.499, 0.926, 8.333, 0.000,

0.000, 8.333, 260.000, 31.200,N ,mm,Edge lock,JR,2018/03/16,13:44:10, 0.000,

25.400, 0.000, 0.000, 0.000, 8.333, 0.000, 0.000, 8.333, 0.000, 0.000,

8.599,Enabled

6 AUTO RETURN

Checking the Auto Return box will enable the carriage to return to home automatically

after each test run. It is recommended that this feature not be used during COF testing.

Coefficient of Friction - Peel Tester-10262018-ab5700-m44.pdf 15Coefficient of Friction - Peel Tester-10262018-ab5700-m44.pdf 15 15-6-2020 13:40:5415-6-2020 13:40:54

32-76-00-0002

16

Rev. 6/06/18

11.4 MAINTENANCE MENU

1 MACHINE INFO displays the following:

MODEL NUMBER

SERIAL NUMBER

DATE OF MANUFACTURE

SOFTWARE VERSION

DATE OF LAST CALIBRATION

TESTS RAN- the total number of tests run on the instrument since its date of

manufacture.

2 FACTORY RESET will reset all parameters to factory defaults, delete all results, and

delete all saved test methods except the “D 1894” one.

3 DIAGNOSTICS

The diagnostics menu displays useful instrument feedback such as:

Raw ADC – gives the load cell counts.

Load cell – gives the force being applied to the load cell in grams-force.

Speed – gives the speed of the lead screw in rpm.

USB – displays whether a device is properly connected or not

This menu will also display the current state of the limit switches and button.

1

2

3

4

Coefficient of Friction - Peel Tester-10262018-ab5700-m44.pdf 16Coefficient of Friction - Peel Tester-10262018-ab5700-m44.pdf 16 15-6-2020 13:40:5415-6-2020 13:40:54

32-76-00-0002

17

Rev. 6/06/18

4 ADMIN

The Admin screen is intended to be used by the service engineers of the TMI Group

Companies. It shows the following data:

Bootload FW- This unit’s firmware is field upgradable by service technicians

Reset Cal Date- resets the date of the most recent calibration date to the current date

Note: All these routines are key/password protected and are intended for use by a

qualified service engineer.

Coefficient of Friction - Peel Tester-10262018-ab5700-m44.pdf 17Coefficient of Friction - Peel Tester-10262018-ab5700-m44.pdf 17 15-6-2020 13:40:5515-6-2020 13:40:55

32-76-00-0002

18

Rev. 6/06/18

12 RUNNING TESTS

1. Select and load the test to be used for testing the material from the TEST SETTINGS

menu. The user is able to create, view and modify the test in the TEST SETTINGS

menu as described in the previous section if needed.

2. Go to the RUN TESTS menu and enter the Sample ID and User ID.

3. Make certain that the load cell arm is in the home position. This can be done by pressing

the HOME button on the display.

WARNING: Remove sled before pressing home key or load cell

damage may occur.

4. At this point the user may zero the load cell if necessary by touching the ZERO button

on the display. Note: Before re-zeroing load cell , disconnect sled from load cell arm

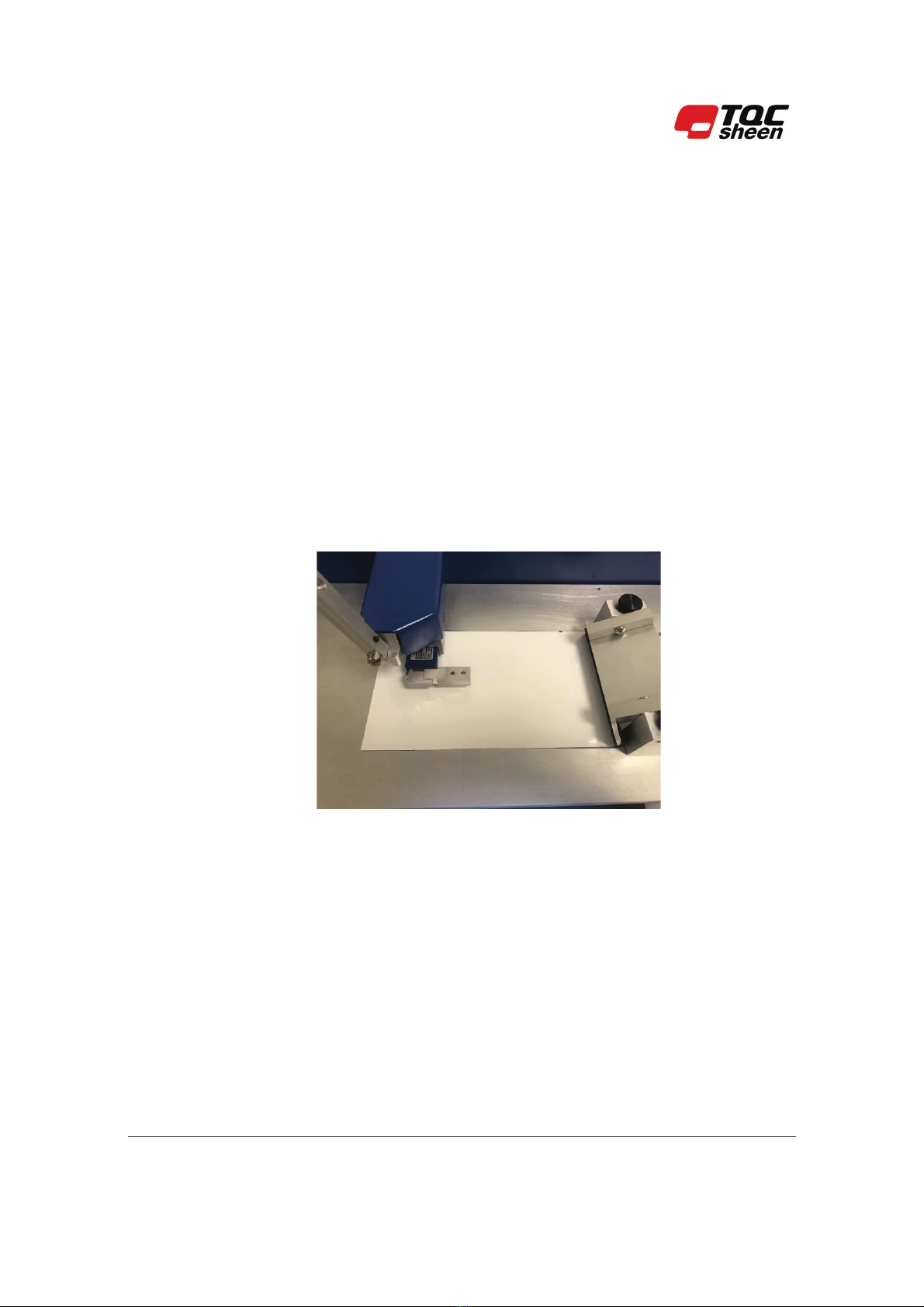

5. Place the sample to be tested on the platen. The sample should be at least 1 inch

(25.4mm) wider than the width of the sled being used for testing. The sample can be

taped to the platen or the platen clamp may be used.

6. Attach the sled sample to the sled and then place the sled on the platen sample with the

pin in the right side hole as shown.

7. Place the anti-drift arm down onto the sled. Make certain that there is some play between

the screws on the arm and the sled.

Coefficient of Friction - Peel Tester-10262018-ab5700-m44.pdf 18Coefficient of Friction - Peel Tester-10262018-ab5700-m44.pdf 18 15-6-2020 13:40:5515-6-2020 13:40:55

32-76-00-0002

19

Rev. 6/06/18

8. Press the GREEN button to the right of the display to start the test. The ring on the

button should be RED while the test is running. The user may interrupt the test by

pressing the button while the test is running.

9. When the test has completed the message below will appear on the display.

10. Remove the sled and the sample from the platen and press the button to return the load

cell arm to the home position. If the load cell detects a change in force, the arm will stop.

11. The instrument is now ready to perform the next test.

12. An unwanted result can be deleted by touching the value in the result grid. The following

screen will appear. Press the GREEN checkmark to delete the line from the test data.

Coefficient of Friction - Peel Tester-10262018-ab5700-m44.pdf 19Coefficient of Friction - Peel Tester-10262018-ab5700-m44.pdf 19 15-6-2020 13:40:5515-6-2020 13:40:55

32-76-00-0002

20

Rev. 6/06/18

13. After all the desired tests have been completed, the data can be exported to a point of sale

type printer, or a thumb drive through the USB-A port on the right hand side of the

instrument. The thumb drive must be formatted with an FAT partition. The thumb drive

data will be in a .txt file. Alternately, the data can be exported to a PC that has the TMI

GraphMastertm software installed for analysis.

Coefficient of Friction - Peel Tester-10262018-ab5700-m44.pdf 20Coefficient of Friction - Peel Tester-10262018-ab5700-m44.pdf 20 15-6-2020 13:40:5615-6-2020 13:40:56

This manual suits for next models

1

Table of contents

Other TMI Products Test Equipment manuals