2© Atlas Copco Industrial Technique AB - 9839 0880 01

Table of Contents

General Data Protection Regulation (GDPR)........................................................4

Legend of symbols .................................................................................................5

Introduction .............................................................................................................6

General Information ..........................................................................................6

About Operation Manual...................................................................................6

Revision history ................................................................................................7

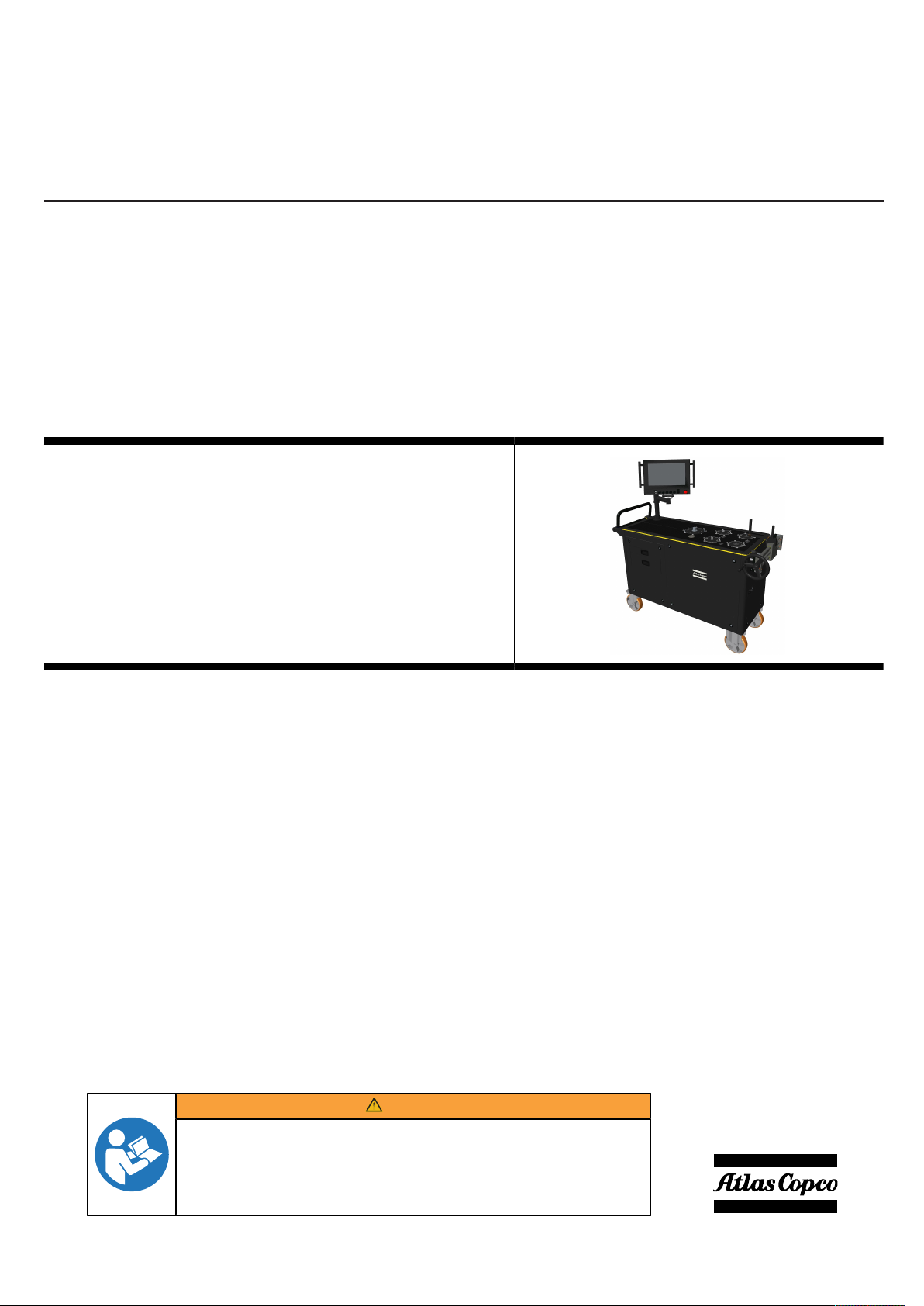

Operation Overview ..............................................................................................16

User interfaces................................................................................................16

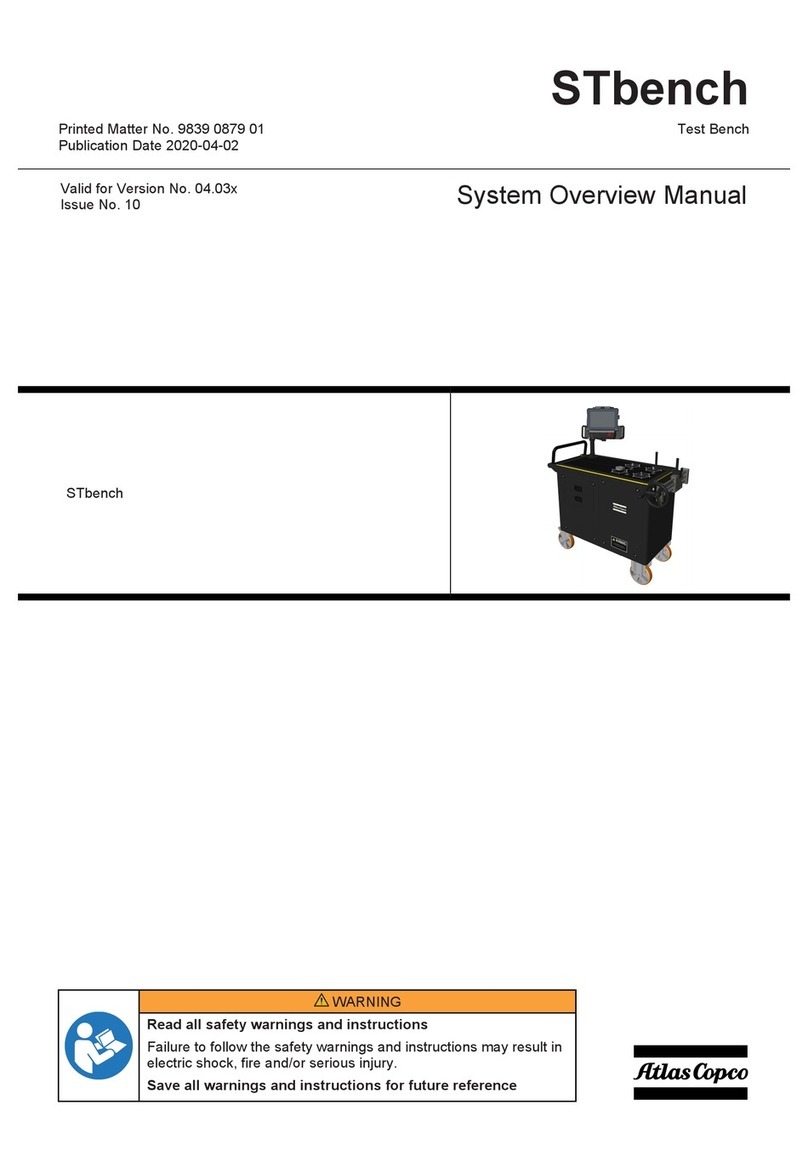

STbench PC / STbench Docking Station.............................................16

STbench top plate ...............................................................................17

Tilting top plate ....................................................................................18

Wrench rig ...........................................................................................19

Articulated arm ....................................................................................20

Motorized Cell......................................................................................20

Drawers ...............................................................................................27

Main panel ...........................................................................................27

Battery status indicators and Battery Charger switch..........................29

Ethernet Port .......................................................................................30

Serial cable port...................................................................................30

USB ports ............................................................................................30

External transducers sockets ..............................................................30

Start PC / Stop PC...............................................................................31

Power Supply socket ...........................................................................31

Keyboard .............................................................................................32

Handlebar ............................................................................................32

Printer support .....................................................................................32

Monitor support....................................................................................32

Flange for SRTT-B ..............................................................................33

Forklift..................................................................................................33

Getting Started ......................................................................................................34

General Information ........................................................................................34

Charging the battery .......................................................................................34

Powering On the STbench..............................................................................34

Power saving mode ........................................................................................34

Powering Off the STbench..............................................................................34

Powering Off the STbench with PC ................................................................34

Operation ...............................................................................................................35

General Safety Information.............................................................................35

Calibrating Power Focus - General Information..............................................35

Calibrating PowerMACS - General Information ..............................................36

Calibrating generic controllers - General Information .....................................36

Articulated arm - General information.............................................................37