BASF 6106 User manual

1,

REVISION

RECORD

OF

REVISION

REMARKS

'

01

VS

II Valid

for

SN

0000

-!-

0400

l

02

VS

III

Valid for

SN

0500

-/-

1300

03

VS

IV

Valid for

SN

2100

-/-

i

04

Corrections

05

Add.

Model

6108

Valid for Drives

with

PCB':\¥

88366

)

II

L I S T 0 F C 0 N T E N T S

SECTION

PAGE

SECT!

ON

PAGE

1.

INTRODUCTION

1-1

1.1 General 1-1

2.2.8

Type

of

Heads

2-20

1.2 Related Documentation 1-1

2.2.8.l

Read/Write

Head

2-20

l.J

Description 1-1

2.2.8.2

Side Select

Logic

2-21

1.4 Specification

Sulllllary

1-2

2.2.9

Write

Circuits

2-22

1.5

Opt

ions

Sulllllary

1-4

2.2.9.1

Write

Initiate

2-22

1. 5.1 Factory

Installed

Option 1-4

2.2.9.2

Write Logic 2-22

1.

5.

2

Jumper

Options 1-4

2.2.9.3

Erase

Delay

Logic

2-24

1.6 Recording

Media

1-5

2.2.lo

Read

Circuits

2-2

5

1.

7

Recording Formats 1-5

2.2.lo.1

Read

Initiate

and

Read

Block

2-2 5

1.

7.1

FM

Encoding

1-5

Diagram

1.

7.

2

MFM

Encoding

1-5

2.2.lo.2

Read/Write Select 2-2 6

1.8

Track

Format

1-6

2.2.lo.3

Read

Amplifiers

and

Filter

2-26

Network

1.8.1 Soft Sectored

Track

Formats 1-6

2.2.lo.4

Active

Differentiator

and

2-2 7

1.8.1.1

Soft Sectored

Track

Format

1-6 Comparator

for Single Density with

2.2.lo.5

Time

Domain

Filter

and

Crossover 2-27

16

Sectors/Track

a

128

Bytes Detector

1.8.1.2

Soft Sectored

Track

Format

1-9

2.2.lo.6

Timing

Diagram

Read

Circuits

2-28

for Single Density

(9

Sectors per

Track

a

256

Bytes) 2.2.11

DC-Control

and

Power

On

2-2 9

1.8.1.3

Soft Sectored

Track

Format

1-lo

Reset Logic

for

Double

Density 2.2.11.1

DC-Control

2-2 9

(16

Sectors per

Track

a

256

Bytes) 2.2.11.2

Power

On

Reset

Logic

2-2

9

2.

THEORY

OF

OPERATION

2-1

2.1 Functional Description

2-1

2.1.1 Drive

Mechanism

2-2

2

.1.2

Spindle

and

Front

Door

Mechanism

2-2

2.1.3

Positioning

Mechanism

2-3

2.1.4

Head

Load

Mechanism

2-4

2.2

Logic

Description 2-5

2.2.1

Interface

Logic

2-5

2.2.1.1

Input

Interface

2-6

2.2.1.2

Output

Interface

2-6

2.2.1.3

Jumper

Options 2-7

2.2.2

Stepper

Motor

Control 2-12

2.2.3

Drive

Motor

Control

2-14

2.2.4

Head

Load

Logic

2-15

2.2.5

Track

Zero

Detector 2-16

2.2.6

Write Protect Detector 2-17

2.2.7 Index/Sector-

and

Ready

Detector 2-18

2.2.7.1

Index/Sector Detection 2-18

2.2.7.2

Ready

Detection 2-19

III

t

L I S T 0 F C 0 NT E NT S

)

SECTION

PAGE

SECTION

PAGE

3.

INSTALLATION

AND

OPERATION

3-1

4.3.2.l

Drive

Motor

and

Drive Belt

4-2

3.1

Installation

3-1

Checks

3.1.1

General

3-1

4.3.2.2 Drive Belt Tension

Check

4-2

3.1.2

Unpacking

and

Inspection

3-1

4.3.2.3

Drive

Belt

Replacement

and

4-3

Tension

Adjustment

3.1.3 Connecting Cables 3-2 4.3.2.4 Drive

Motor

Speed

Check

4-3

3.1.4 Connectors

3-2

4.3.2.5 Drive

Motor

Speed

Adjustment

4-3

3.1.4.l

DC-Connector

3-2 4.3.2.6

Drive

Motor

Speed

Adjustment

4-4

3.1.4.2 Signal Connector

3-2

using a

Frequency

Counter

3.1.4.3

Frame

Connector

3-2

4.3.2.7 Drive

Motor

Replacement

4-4

3.1.4.4 Interconnecting

Diagram

3-2

4.3.3 Positioning

System

4-5

3.1.5

Logic

Levels

and

Termination 3-4 4.3.3.1

Track

Adjustment

Check

4-5

3.1.6 Connecting Configuration 3-4 4.3.3.2

Track

Adjustment

Procedure

4-6

3.1.6.l

Single

Drive

Configuration 3-4 4.3.3.3 Adjustment

Check

for Optical

4-7

3.1.6.2 Multiple

Drive

Configuration 3-4

Track

Zero

Switch

3.1.7 Selection of the Desired

Option

3-6 4.3.3.5

Track

Zero

Switch

Replacement

4-8

3.1.7.1 Selection Options 3-6 4.3.3.6

Head

Carriage

Replacement

4-9

3.1.7.2

Head

Load

Options 3-6 4.3.3.7

Head

Load

Pad

Replacement

(6106)

4-9

3.1.7.3

In

Use

I

Disk

Change

Option

3-6

4.3.4

Head

Load

Mechanism

4-10

3.1.7.4

Door

Lock

Options 3-6 4.3.4.1

Head

Load

Solenoid

Replacement

4-10

3.1.7.5 Activity

LED

Options

3-7

4.3.4.2

Head

Load

Actuator

Check

4-10

3.1.7.6

Write

Protect

Option

3-7

4.3.5 Read/Write Electronics

4-11

3.1.7.7 Stepper

Motor

Switching

3-7

4.3.5.l

Jitter

Check

and

Adjustment

4-11

3.1.7.8

Jumper

Matrix 3-8 4.3.5.2

Read

Amplitude

Check

4-11

3.1.8

Drive

Mounting

3-10 4.3.6

Photo

Transistors

and

LED's

4-12

3.1.8.1

Mounting

Positions 3-10

4.3.6.l

Photo

Transistor

Replacement

4-12

3.1.8.2

Mounting

Dimensions

3-10

4.3.6.2

LED-Replacement

4-12

3.2 Operation

3-11

4.3.6.3

Index

Detector

Adjustment

Check

4-12

3.2.1

General

3-11

4.3.6.4

Index

Detector

Adjustment

4-13

3.2.2

Mini

Disk

Storage

and

Handling

3-11

4.4 Location of Testpoints, IC's,

4-14

Potentiomenters

and

Connectors

3.2.3 Write Protect

3-12

3.2.3.l

Write Protect

if

notch

open

3-12

(optional)

3.2.3.2

Write

Protect

if

notch covered

3-12

5. Spare Parts

I

(ECMA)

5.1

Attachment

1,

Spare

Parts for

BASF

6106

5.2

Attachment

2, Spare Parts for

BASF

6108

4.

MAINTENANCE

4-1

4.1

General

4-1

>

------

4.2 Tools

and

Test

Equipment

4-1

4.3

Checks,

Adjustment

and

4-2

Replacements

4.3.l

PCB

Replacement

4-2

4.3.2 Spindle Drive

System

4-2

IV

FIGURE

1 - 1

1 - 2

1 - 3

1 - 4

1 - 5

l - 6

1 - 7

1 - 8

1 - 9

2 - 1

2 - 2

2 - 3

2 - 4

a

2 - 4 b

2 - 5 a

2 - 5 b

2 - 6

2 - 7

2 - 8

2 - 9

2 -

lo

2 -

11

2 -

12

2 -

13

2 -

14

2 -

15

2 -

16

2 -

17

2 -

18

2 -

19

2 -

2o

2 -

21

2 -

22

2 -

23

2 -

24

2 -

25

2 -

26

2 -

27

2 -

28

2 -

29

L I S T

0 F

I L L

U

S T R A T I

0

N S

Model

BASF

6106/6108

Mini-Disk-Drive

Flexible

Disk

Construction

and

Dimensions

FM-Encoding

MFM-Enrodi

ng

Address

Mark

Patterns

Soft Sectored

Track

Format

with

16

Sectors per

Track

Simplified

EDC

Shift

Register

Soft Sectored

Track

Format

with 9 Sectors per

Track

Soft Sectored

Track

Format

for

Double

Density

(MFM)

PAGE

1-1

1-5

1-5

1-5

1-6

1-7

1-8

1-9

1-lo

Block

Diagram

BASF

6lo6/6lo8 2-1

Drive

Mechanism

2-2

Spindle

and

Front

Door

Mechanism

2-2

Positioning

Mechanism

6106

Positioning

Mechanism

6108

Head

Load

Mechanism

6106

Head

Load

Mechanism

6108

Interface

Logic

Auto

Select

Option

Radial Select Option

Auto

Head

Load

Option

Selected

Head

Load

Option

Radial

Head

Load

Option

Door

Lock

Latch Option

Timing

Diagram

Door

Lock

Latch Option

Disk

Change

Logic

Timing

Diagram

Disk

Change

Logic

Stepper

Motor

Control

Stepper

Motor

Timing

Diagram

Drive

Motor

Control

Head

Load

Circuit

Door

Lock

Solenoid

and

Activity

LED

Driver

Head

Load

Timing

Diagram

Track

Zero

Detector

Track

Zero

Timing

Diagram

Write

Protect

Detector

Index

Detector

Ready

Detector

Ready

Timing

Track

Geometry

Electrical

Connection of the

Read/Write

Head

Side Select Logic

2-3

2-3

2-4

2-4

2-5

2-7

2-7

2-8

2-8

2-8

2-9

2-9

2-11

2-11

2-13

2-13

2-14

2-15

2-15

2-16

2-16

2-17

2-18

2-lg

2-19

2-20

2-20

2-21

v

FIGURE

2 -

3o

Write

Initiate

Timing

2 -

31

a Simplified Write Circuits

6106/6108

2 -

31

b

Timing

Diagram

Write Operation

(Simplified)

2 -

32

2 -

33

2 -

34

2 -

35

2 -

36

2 -

37

2 -

38

Erase

Delay

Logic

Erase

Delay

Timing

Read

Circuits 6106/6108

(Simplified)

Read

Initiate

Timing

Read/Write

Select

Logic

Read

Amplifiers

and

Filter

Network

Active

Differentiator

and

Comparator

PAGE

2-22

2-22

2-2

3

2-2

3

2-24

2-2 4

2-2

5

2-2

~

2-26

2-2

7

2 -

39

Time

Domain

Filter

and

Crossover 2-28

Detector

2 -

4o

2 -

41

2 -

42

2 -

43

3 - 1

3 - 2

3 - 3

3 - 4

3 - 5

3 - 6

3 - 7

3 - 8

3 - 9

3 -

lo

3 -

11

3 -

12

3 -

13

5 - 1

5 - 2

Timing

Diagram

Read

Circuits

2-28

DC-Control

Logic

2-29

Power

On

Reset

Logic

Timing

Diagram

Power

On

Reset

Shipping Configuration

DC-Connector

Interconnecting

Diagram

Interface

Logic Levels

Recommended

Driver/Receiver

Circuit

Single Drive Configuration

Radial Select Configuration

Daisy

Chain

Select Configuration

Part Locations {Principal)

Mounting

Specification

Flexy

Disk

Loading

Write Protect Feature

(ECMA)

Write Protect Feature (optionJI)

Parts

Breakdown

6106

Parts

Breakdown

61o8

2-2 g

2-2

9

3-1

3-2

3-3

3-4

3-4

3-4

3-5

3-5

3-9

3-lo

3-11

3;;ll2

3-12

5-2

5-3

L I S T 0 F T AB L E S

TABLE

PAGE

1 -

1 Specification

SulllTiary

1-2

1 -

2 Factory

Installed

Option 1-4

l - 3

Jumper

Selectable Options 1-4

2 - 1 Input Signals 2-6

2 - 2 Output Signals 2-6

2 - 3 Write Protect Jumpering 2-9

2 - 4

Sequence

of the Stepper

Motor

2-12

Signals

3 - 1

DC-Power

Requirements 3-2

3 - 2

Reconmended

Jl

Mating

Connectors 3-2

3 - 3 Select Options Jumpering 3-6

3 -

4

Head

Load

Option Jumpering 3-6

3 - 5

In

Use

Disk

Change

Option 3-6

Jumpering

3 - 6

Door

Lock

Options Jumpering 3-6

3 - 7 Activity

LEO-Option

Jumpering 3-7

3 - 8 Write Protect Option Jumpering 3-7

3 - 9 Stepper

Motor

Switching Option 3-7

Jumpering

3 - lo Option

Jumper

Matrix 3-8

3 -

11

Flexy

Disk

Loading

3-11

3 -

12

Flexy

Disk

Unloading

3-11

4 - 1 Standard Tools

and

Test 4-1

Equipment

4 -

2 Special Tools

and

Test 4-1

Equipment

5 - l Spare Parts

BASF

6106

5-4

5 - 2 Spare Parts

BASF

6108

5-7

5

-3

R/W

PCB-88356

5-10

5 - 4

R/W

PCB-88366

5-13

VI

(

SECTION

1

INTRODUCTION

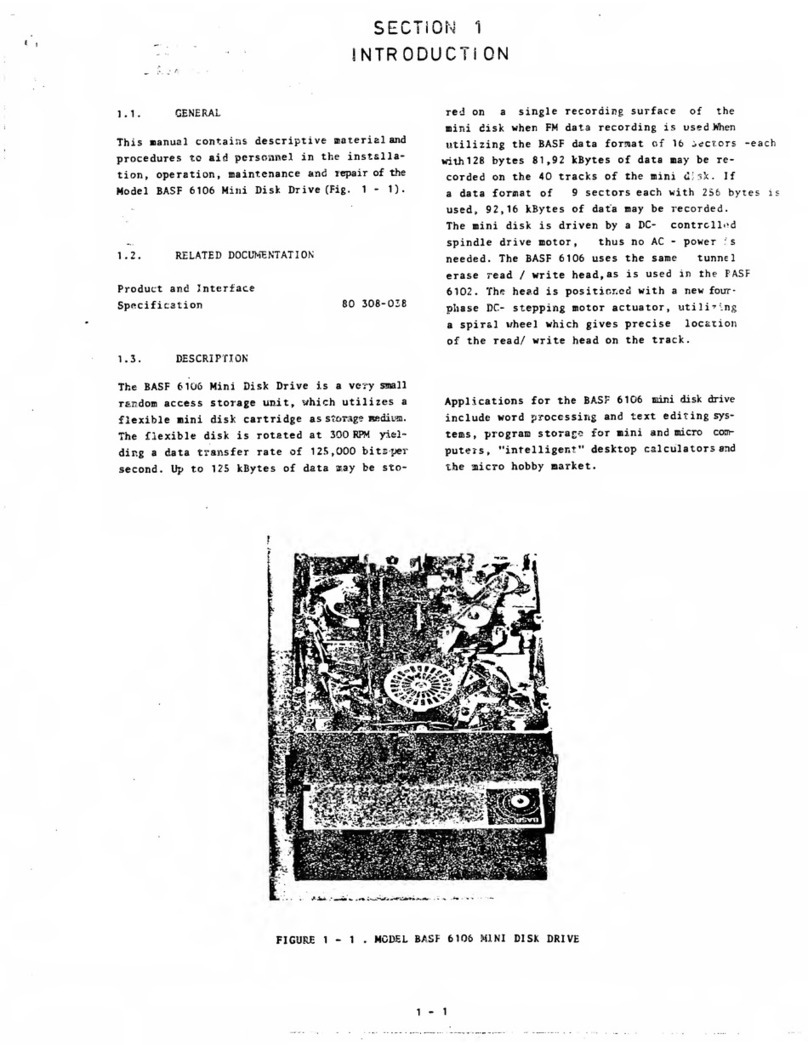

1.1

GENERAL

This

manual

contains descriptive material

and

procedures useful in

installation,

operation,

maintenance

and

repair of the

BASF

Mini

Disk

Drive

Models

BASF

6106

and

BASF

6108.

1.2

RELATED

DOCUMENTATION

Product-

and

Interface Specification

BASF

6106/6108

So

3o7-o46

1.3

DESCRIPTION

The

models

BASF

6106

and

BASF

6108

are

very

compact

random

access data storage units.

which

utilize

a

5.

25"

Flexy

Disk

as

storage

medium.

The

BASF

6106

stores data

on

one

side of the

Flexy

Disk,

the

BASF

6108

on

both

sides.

The

Flexy

Disk

is

rotated

at

300

RPM

yielding

a data

transfer

rate

of

125~000

bits

per

second

in single density.

Up

to

125

kbytes

of

raw

data

may

be

stored

on

a single recording surface in

single density,

and

twice

as

much

in

double

density.

Data

capacity

on

all

4o

tracks varies

from

81.92 kbytes

(BASF

6106,

16

sectors

at

128

bytes)

to

368.64

kbytes,

so

increasing capacity

more

then four times

by

using the

BASF

6108

with

9 sectors of

512

bytes each.

The

mini

disk drives are

equipped

with a

DC-

controlled spindle drive

motor,

thus

no

AC-Power

is

needed.

Ceramic

read/write

heads

with

tunnel

erase are

used

with·in

the

BASF

6106/6108

to ensure

reliable

data recording.

The

heads

are positioned with a fourphase

DC-

stepper

motor

actuator.

utilizing

a spiral

wheel

which

provides precise location of the read/write

head

or

heads

on

the track.

Applications for

both

types of

mini

disk drives

comprise

word

processing

and

text

editing systems,

program

storage for

mini

and

micro

computers.

"intelligent"

desktop calculators

and

the

hobby

micro

computer

market.

FIGURE

l - 1

MODEL

';!ASF

61o6/6lo8

MINI

DISK

DRIVE

1 - 1

1.4

SPECIFICATION

SUMMARY

Acomprehensive

list

of principal specifications for

model

BASF

6106

and

model

BASF

6lo8

is

provided

in

table 1 -

1.

P E R F 0 R MA NC E S P E C I F I C AT I 0 NS

CAPACITY

BASF

6106

(single sided)

Unformatted

Single Density

per

Disk

125

kilobytes

per Surface

125

kilobytes

per

Track

J.125 kilobytes

Formatted

(16

Sectors/Track)

per

Disk

per Surf

ace

per

Track

per Sector

TRANSFER

RATE

LATENCY

Maximum

Average

ACCESS

TIME

81.920 kbytes

81.

920

kbytes

2.048 kbytes

128

bytes

125

kilobits/s

200

ms

loo

ms

Track

to

track positioning

12

ms

Average

Settling

Time

Head

Load

Time

240

ms

max.

48

ms

max.

35

ms

Drive

Motor

Start

Time

max.65o

ms

Double

Density

250

kilobytes

250

kilobytes

6.250 kilobytes

16J.84o kbytes

16J.84o kbytes

4.o96 kbytes

256

bytes

250

kilobits/s

F·U

tt

C T I 0 NAL S P E C I F I C AT I 0 NS

BASF

6108

(double sided)

Single Density

Double

Density

250

kilobytes

500

kilobytes

125

kilobytes

250

kilobytes

J.125 kilobytes

6.

25

kilobytes

16J.84o kbytes J27.68o kbytes

81.920 kbytes

163.840

kbytes

2.o48 kbytes 4.o96 kbytes

128

bytes

256

bytes

125

k

ilobits/s

250

kilobits/s

BASF

6106

BASF

6108

Single Density

Rotational

Speed

300

RPM!

2,5 %

Recording Density

( inside Track)

3979

BPRAD

(2768

BPI)

Flux

Density

7958

FTPRAD

(5536

FCI)

Track

Density

48

TPI

Track

Radius

Track

00

57,15

nm

Track

39

36.5125

nm

Encoding

Method

FM

Media

Requirements

BASF

Flexy

Disk

5.25"-l

+)

On

Side

l,

Side 0 see

6106

Track

radius 1 is

2.

1167

nm

smaller then track radius

O.

Double

Density Single Density

Double

Density

Joo

RPM

! 2,5 %

Joo

RPM

! 2,5 %

Joo

RPM!

2,5 %

7958

BPRAD

3979

BPRAD

7958

BPRAD

(5536

BPI)

(2768

BPI)

(5536

BPI)

7958

FTPRAD

7958

FTRAD

7958

FTPRAD

(5536

FCI)

(5536

FCI)

(5536

FCI)

48

TPI

48

TPI

48

TPI

+) +)

57,15

nm

55,o3

11111

+)

55,o3

11111

+)

J6.5125

nm

34.3958

nm

34.3958

nm

MFM

FM

MFM

BASF

Flexy

Disk

BASF

Flexy

Disk

BASF

Flexy

Disk

5.25"-lD 5.25"-2 5.25"-20

lABLE

1 - 1

SPECIFICATION

SUMMARY

(continued)

1 - 2

(

P HY S I C A L S P E C I F I C AT I 0 NS

Environmental limits

Ambient

temperature

on

disk surface (operation)

Relative humidity

Maximum

wet

bulb

DC-voltage

requirements

Power

dissipation

Mechanical

dimensions:

Width

Height

Depth

Weight

R E L I AB I L I T Y

MTBF

Unit

life

time

MTTR

Error

rates:

Soft read errors

Hard

read errors

Seek

errors

S P E C I F I C AT I 0 NS

ME DI A S P E C I F I CAT I 0 NS

10°

to

So

0c

(So°F

to

12o°F)

2o

%to

Bo

%

29°c

(B4°F)

+

12

voe

.:!:.

s

,;

max.

loo

mVpp

ripple

+ s

voe

+ s

,;

o,S A

max.

So

mVpp

ripple

+)

motor

starting

current

max.

o.65 Afor

max.

So

msec

head

load

start

current

o.7 Afor

So

msec

lo.o

Watts

operating

4.o

Watts

stand

by

(motor

off)

7.5

Watts

motor

on

and

deselected

146.1

11111

(S.75 inch)

S3.S

11111

(2.11 inch)

190.0

11111

(7.48 inch)

1.4

kg

10000

POH

under

typical

usage+)

S years

3o

minutes

1 per

10

8

bits

read

1 per

loll

bits

read

1 per

106

seeks

+)

Duty

cycle of Spindle

Drive

Motor:

£0%

of

POH

Jacket 133.3

11111

(5.25 inch) square

Disk

l3o.2

11111

(5.125 inch) diameter

Center hole 28.57

11111

(1.125 inch) diameter

TABLE

1 - 1

SPECIFICATION

SUMMARY

1 - 3

1.5

OPTIONS

SUlltlARY

The

following tables

list

the options of the

BASF

6106

and.

BASF

6108

Mini

Disk

Drives.

1.5.1

FACTORY

INSTALLED

OPTION

Option

Function

Door

Lock

Locks

the font

door

under

Solenoid control of the users

soft-

ware.

TABLE

1 - 2

FACTORY

INSTALLED

OPTION

1.5.2

JUMPER

OPTIONS

The

following options are selectable

by

jumpers

on

the

PCB.

Refer to Table 3 - lo for

jumper

option matrix.

Option

RADIAL

SELECT

AUTO

SELECT

HEAD

LOAD

IN

USE

Function

Allows

the connection of

three

mini

disk drives to

the host system.

Each

drive

has

its

own

address (0,1,2)

selectable

by

jumper.

The

interface

is

always

enabled (drive

is

always

selected).

The

SELECT-lines

are not

used.

Loading

of the

head

can

be

accomplished

in

three

modes:

• Selected

Head

Load

(INT.SELECT•

HEAD

LOAD)

•

Auto

Head

Load

(INT.

SELECT)

• Radial

Head

Load

(HEAD

LOAD)

The

head

will

be

loaded only

if

the inserted

mini

disk

rotates.

Pin

34

of the interface

is

used

as

IN

USE

input signal

and

controls the

door

lock

solenoid

and

the

activity

indicator.

If

this

option

is

used

the

disk

change

option

must

be

disabled.

Option

DOOR

LOCK

LATCH

DISK

CHANGE

ODOR

LOCK

ACTIVITY

INDICATOR

OPTIONS

WRITE

PROTECT

OPTION

STEPPER

MOTOR

SWITCHING

Function

Allows

locking of the

door

withoui maintaining the

IN

USE

signal activated

by

storing the

state

of the

IN

USE-signal

into the

IN

USE-

flipflop.

To

use

this

option

the

IN

USE-option

must

be

jumpered.

Notifies the host system

that the

mini

disk

has

been

changed.

If

this

option is

used, the

IN

USE-option

must

be

disabled.

Locking

of the

door

can

be

accomplished

as

follows:

1.

by

the

IN

USE-signal

2.

by

the

IN

USE-FF

(DOOR

LOCK

LATCH)

3.

if

the drive

is

selected

(I/D

ENA

activ)

4.

if

the

head

will

be

loaded

(HDLOADENA

activ)

5.

if

1. or 3.

is

true

6.

if

1.

or 2. or 3.

is

true

7.

if

1. or 4.

is

true

8.

if

1. or

2.

or 4.

is

true

The

lighting of the

activity

LED

is

selectable

by

jumper

to

one

of the following

conditions :

• the

head

is

loaded

and

the

drive

is

ready

• the

door

is

locked

and

the

drive

is

ready

Allows

protection of the

mini

disk against overwrite

if

the write protect notch

is

closed

(ECMA,

Shugart).

The

stepper

motor

is

switched

on

and

oft

together with the

drive

motor

if

a

jumper

is

in-

serted.

If

the

jumper

is

not

inserted, the stepper

motor

will

be

enabled

as

long

as

power

is

supplied.

TABLE

1 - 3

JUMPER

SELECTABLE

OPTIONS

1 - 4

)

1.6

RECORDING

MEDIA

The

BASF

mini

disk drives

use

a removable

130

11111

(5.25 inch) diameter

flexible

disk

as

storage media. Fig. 1-2

shows

·construction

and

dimensions of a

typical

5.25" Flexy Disk.

The

rec011111ended

recording

media

is:

for

model

BASF

6106

mini

disk drives:

single

density:

double density: 5.25"-1

5.25"-l

D

for

model

BASF

6108

mini

disk

drives:

single

density:

double density: 5.25"-2

5.25"-2 D

The

Flexy

Disk

is

an

oxide coated

flexible

disk enclosed in a

protective

plastic

envelope.

The

protective

envelope contains

apertures

for

head

contact,

index

detection,

write

protect

detection

and

drive spindle

loading.

The

write

protect

notch

is

used

to

protect

the

written

data

on

the Flexy

Disk

(see

2.2.6

Write Protect Detector).

St:ALEll

t'Kon;cT1

Vt:

.IACKE'I'

MYLAR

DlSK

TRACK

00

FIG.

1 - 2

SI' I

NOLE./

111111

,\cn:ss

---

.......

........

O

/\..;

------;.~-lNDE.X/

SECTOR

llOLE

-

LINER

/

/

FLEXIBLE

DISK

CONSTRUCTION

AND

DIMENSIONS

lNDEX

HOLE

TRACK

39

1 - 5

1.7

RECORDING

FORMATS

The

format of the data recorded

on

the

diskette

depends

on

the host system. There are

two

encoding

schemes

used:

•

FM

(Frequency

Modu

1

ation)

for

single

density

•

MFM

(Modified Frequency Modulation)

for double density.

1.7.1

FM-ENCODING

This

scheme

utilizes

clocks

to

define

bit

cell

times.

The

presence of a flux reversal

between

clock pulses

is

defined

as

a

"one"

bit.

The

absence of a flux reversal

between

clocks

is

defined

as

a "zero"

bit.

On

the write data

and

read data

interface

lines

between

disk drive

and

host system every pulse represents a flux

re-

versal

on

the

diskette.

8µsec

Bl

TC

ELL

~-r-

' i

DATA

I,,,

11

I

0 I,I0 I0 I0 I,I

I I I

I

I I I I I I

I I I

-jSµst-

I I

I

I

I

1

j4µ~1

I I I I I I I

I

1if:

I I I I I I

WRITE

DATA·······

••••

I

•••

CDCDCDC

CDC C C CDC

FIG.

1 - 3

FM-ENCODING

1.7.2

MFM-ENCODING

Aflux

transition

is

always

recorded

at

the center

of the

bitcell

for

each "one" data

bit.

No

flux

transition

is

recorded for a "zero"

bit

unless

it

is

not followed

by

another "zero"

bit.

In

this

case the flux

transition

is

provided

at

the

end

of the

first

bit

cell.

4

µsec

BITCELL

DATAl \h

tj

0

I]

I

0 I

0 I

0 I\ I

I I I I I I

I I I

f'

5

~iJS~

I I

I I I I I

-tl.J-151--

I

WRITE

DATA

I ' '

I '

ODD

OCCD

FIG.

1 - 4

MFM-ENCODING

1.8

TRACK

FORMAT

The

tracks of the Flexy

Disk

may

be

formatted

in

numerous

ways,

depending

on

the formatter

of the host system used.

The

BASF

mini

disk

drives write

and

read hard or

soft

sectored

track formats.

1.8.1

SOFT

SECTORED

TRACK

FORMATS

In

a

soft

sectored track format the user

may

record

one

long

record or several smaller

records

on

a track.

The

most

common

soft

sectored track formats are described in the

following chapters.

(The

designer should also consider national

and

international standards for data

inter-

change).

1.8.1.1

SOFT

SECTORED

TRACK

FORMAT

FOR

SINGLE

DENSITY

(16

sectors/track

a

12B

bytes)

This format

is

shown

in

Fig. 1-6.

It

is

similar

to

the

IBM-format.

The

beginr.ing of a track

is

indicated

by

a

physical

index

pulse.

Every

record

is

pre-

ceded

by

a unique record

identifier.

Record

identifiers

and

data

fields

are separated

by

gaps.

The

gaps

are necessary to allow updating

of a data

field

without disturbing adjacent

fields.

INDEX

GAP

This

gap

starts

with the index pulse

and

is

16

bytes in length.

It

is

not affected

by

any

update write process.

IDENTIFIER

GAP

This

gap

consists of

11

bytes

FF

and

may

vary

slightly

in

length

after

the data

field

has

been

updated.

DATA

GAP

This

gap

separates the data

field

from

the

following ID-field

and

is

nominally

27

bytes

in length.

It

will vary

slightly

in

length

after

the data

field

has

been

updated.

TRACK

GAP

The

gap

between

the

last

data

field

and

the

index

pulse

is

defined

as

Track

Gap.

It

varies

slightly

in length,

due

to

write frequency

and

disk speed

tolerances.

It

is

nominally

101

bytes in length.

ADDRESS

MARK

(AM)-BYTE

The

soft

sectored track

format

needs unique

bit

patterns to identify the beginning of

ID

and

Data

Fields for synchronizing the

deserializer

circuit

in the host system.

The

unique

bit

pattern

is

called

Address

Mark

(AM).

AM-patterns

do

not

contain clock

bits

in

all

bit

cells

(all

other

data bytes

must

have

clock

bits

in every

bit

cell!).

There

are three

different

AM-patterns

used:

e

ID-AM

e

DATA-AM

e

DELETED

DATA-AM

in front of

an

ID-Field

in front of a

Data

Field

in front of a Deleted

Data

Field

I

BYTE

ID

-

AM:

~c

6

cs

C4

s s

cl

·~s

I I

i1

...

" I I I I

SEP

CLOCK

(C7)

..

"

••

11

rn

07

1)6

05 04

03

n.i

8

SEP

DATA

(R)

I I I I I I I

DATA

-

AM:

I

Ir

C7

c6

C5

C4

C3

r,2

c,

f"

8

,

·e

I I

...

...

r1 I I I

I

SEP

CLOCK

(C7)

II

ti

,,

II

II

oa

07

06

05

I\

02

o,:

SEP

DATA

(FB)

••

I I I I I

1:

I

I

I

DELETED

DATA

-

At!:

I

t11

C7 ~

C5

G.

C3

~

Cl

1c

8

•

I

,,

,.,

n

I I I

•

S!P

CLOCK

(C7)

II

"

..

le

D9

n 7 D6

D5

D4

!IEP

DATA

(r8)

I

I I

I

I

FIG.

l - 5

ADDRESS

MARK

PATTERNS

1 - 6

)

(

SECTOR

IDENTIFIER

The

sector

identifier

consists of the

identifier

mark,

the address

identifier

and

the

EDC

pattern.

IDENTIFIER

MARK

This

field

comprises 7 bytes (see Fig. 1-6).

The

6 bytes of zeros in front of the address

mark

byte are for synchronisation of the data

separator

in

the host system.

The

ID-AM-byte

contains a data pattern of

FE

where

the clock

bits

C6,

CS

and

C4

are missing as explained

before.

ADDRESS

IDENTIFIER

The

address

identifier

comprises the following

6 bytes:

TRACK

ADDRESS

(TRK)

This byte represents in binary notation the

track address

from

00

for the outermost track

to

39

for the innermost track.

SIDE

ADDRESS

(SID)

Represents in binary notation the sioe address

(OO

or

01)

of the

mini

disk.

SECTOR

ADDRESS

(SEC)

Represents in binary notation the sector address

from

01

for the

1st

sector to

16

for the

last

sector

of

a track.

SECTOR

LENGTH

(LEN)

This byte

identifies

the length of the data

field

as

follows:

00:

128

bytes

01:

2S6

bytes

02:

S12

bytes

03:

lo24 bytes

EDC-BYTES

(EDC)

These

two

bytes are hardware generated

from

the

host system

by

shifting

serially

the

bits

of the

sector

identifier

starting

with the

ID-AM

and

ending

with the 4th byte of the sector

identifier

through

a 16-bit

shift

register

described

by

the generator

polynominal:

xl6 + xl2 +

XS+

l.

(For

more

details

read chapter EDC-implementation!)

NDEX

GAP

SECTOR

IDENTIYIER

IDENTIFIER

GAP

FIRST

DATA

BLOCK

DATA

BLOCK

GAP

LAST

DATA

BLOCK

DATA

BLOCK

GAP

TRACK

GAP

16

X

FF

13

BYTES

11

X

FF

137

BYTES

27

X

FF

137

BYTES

27

X

FF

IOI

X

FF

1st

:>ec:tor

.r--L

I!llDEX

PULSE

SECTOR

IDE~TIFIER:

ADDRESS

IDENTIFIER

E D C

TRK

SI

0

SEC

LEN

2

BYTES

'-v----'

ID-AH

DATA

BLOCK:

...__...._...,

DATA-AM

I)

DATA

PATTERN

2)

CLOCK

PATTERN

•

DELETED

AM

DATA

FIELD

I 2 8 II Y T E S

P8

ID

-

AM:

SEP

CLOCK

(C7)

SEP

DATA

(FE)

DATA -AM:

E D C

SEP

CLOCK

(C7)

2

llYTES

S!P

DATA

(PB)

DELETED DATA -

SEP

CLOCK

(C7)

SEP

DATA

(F8)

r,sc6

I

BYTE

cs

c•

s

I I n " " I

"

..

••

II

rD

0,

D6

DS

D4

8

I I I I I

I

le

,e

C7

c6

Cs

C4

C3

I I

,..

" " I

11

..

u

II

De

D7 D6

Ds

~

I I I I I

I

AH:

fa

C7

Cri

C5

Cti

C3

I I " " n I

..

!I

le

D9

D7

D6

Ds

D4

I I I I I

FIGURE

1 - 6

SOFT

SECTORED

TRACK

FORMAT

WITH

lE

SECTORS/TRACK

FOR

SINGLE

DENSITY

(FM)

1 - 7

s

r,

ls

I I I

D)

Di

I I

I

I

I

Cz

c,

~

8

I I I

Dz

D1:

I

1:

I

I

I

I

I

I

'"2

c,

•Cs

I I •

DATA

BLOCK

The

data block contains the data

mark,

the data

field

and

the

EDC-bytes.

DATA

MARK

This

field

comprises 7 bytes (see Fig. 1-6).

The

6 bytes of zeros in front of the data

address

mark

are for synchronisation of the

data separator

circuit

in the host system.

The

data address

mark

byte contains

FB

in front of

a

normal

data

field.

When

a deleted data

field

follows,

F8

must

be

written.

The

clock pattern

of the data address

mark

is

C7

(C6,

CS

and

C4

missing).

DATA

FIELD

This

field

comprises

128

bytes.

If

it

comprises

less

than

128

bytes, the remaining positions

shall

be

filled

with zeros.

EDC-BYTES

These

two

bytes are hardware generated

by

the

host system

by

shifting

serially

the

bits

of

the data block

starting

with the

Data-AM

and

ending with the

last

byte of the data

field

through a 16-bit

shift

register

described

by

the

following generator polynominal:

xl6

+

xl2

+

xs

+

1

EDC-IMPLEMENTATION

Fig. 1-7

is

a simplified logic of a

shift

register,

which

may

be

used

to generate the

EDC

bytes.

Prior to the operation,

all

positions of the

shift

register

are

set

to

ONE.

Input data are

added

(exclusive

OR)

to

the contents of position

c

1S of

the

register

to

form

a feedback. This feedback

in

turn

is

added

(exclusive

OR)

to

the contents of

position

c

4

and

position

c

11

.

On

shifting,

the outputs of the exclusive

OR

gates

are entered into positions

c

0,

Cs

and

c

12

respec-

tively.

After the

last

data

bit

was

added, the

register

is

shifted

once

more

as

specified above.

The

register

then contains the

EDC

bytes.

When

further

shifting

is

to take place during the writing

of the

EDC

bytes, the control signal

inhibits

ex-

clusive

OR

operations.

To

check

for

errors

when

reading, the data

bits

are

added

into the

shift

register

in exactly the

same

manner

as

they

were

during writing. After the

data the

EDC

bytes are also entered into the

shift

register

as

if

they

were

data. After the final

shift,

the

register

contents will

be

all

ZERO

if

the record

does

not contain

errors.

CONTROL

OUTPUT

for

EDC

writing

INPUT

FIGURE

l - 7

SIMPLIFIED

EDC

SHIFT

REGISTER

l - 8

)

I

(

1.8.1.2

SOFT

SECTORED

TRACK

FORMAT

FOR

SINGLE

DENSITY

(9

SECTORS/TRACK

i

256

BYTES)

In

this

format,

which

is

shown

in

Fig. 1-8,

each

sector contains

256

bytes.

I

1---------

lst

SECTOR

r--L

X + Y +Z • 204

BYTES

INDEX PULSE

SECTOR

IDESTIFIER:

ADDRESS

IDENTIFIER

E D C

TRK

SID

SEC

01 2

BYTES

DATA

BLOCK:

.....__,.......

DATA-AM

I)

DATA

PATTERN

2)

CLOCK

PATTERN

•

DELETED

AM

DATA

FIELD

E D C

2 5 6 B Y T E S 2

BYTES

Fe

256

YTES

(32+Y)

X

FF

9th

SECTOR

--1

ID

-

AM:

SEP

CLOCK

(C7)

SEP

DATA

(FE)

DATA

-

AM:

SEP

CLOCK

(C7)

SEP

DATA

(FB)

I

I

I

I I

I I

I

le

I e

C7

c6

C5

C4

I I

...

..

,,

1:

..

,,

If

Ir

De

D7 Db

Ds

I I I I

I

C3

I

rt.

I

Cz

I

Dz

I

c,

I

I

~e

I

DELETED

DATA

-

AM:

I

I

I

;a

C7

ct,

C5

Ct.

C3

0i

I I n n n I I

SEP

CLOCK

(

C7)

Cl

ICe

I •

De D 7

D6

D5

D4

SEP

DATA

(Fe)

I I I I I

FIGURE

1 - 8

SOFT

SECTORED

TRACK

FORMAT

WITH

9

SECTORS/TRACK

1 - 9

1.8.l.3

SOFT

SECTORED

FORMAT

FOR

DOUBLE

DENSITY

(16

Sectors a

256

bytes)

On

double sided

diskettes

for double density

track 0

on

side 0

is

recorded in

FM.

For

this

track only the previous described track

format for single density

is

valid.

All

other

tracks

on

the

diskette

are recorded in

MFM.

For

these tracks the following track format

will

be

valid (see Fig. 1-9).

The

content of the data blocks

is

doubled to

256

bytes.

In

MFM

recording the

bit

density

is

also doubled, the

sector

count will

be

the

same

as

in

single

density format (1.B.1.1).

The

meaning

of the

different

fields

arMl

the generation of the

EDC-bytes

are the

same

as

in single density re-

cording.

Only

the address

mark

pattern

is

changed

as

shown

in Fig. 1-9.

INDEX

GAP

SECTOR

IDENTIFIER IDENTIFIER

GAP

FIRST

DATA

BLOCK

DATA

BLOCK

GAP

LAST

DATA

BLOCK

DATA

BLOCK

GAP

TRACK

GAP

146BYTES

22

BYTES

22

• 4E

271.

BYTES 54

x

l.E

262 BYTES 54

x4E

192x4E

r---,

L-------------

---

--·

---

1st

SECTOR------------1

)--26th

SECTOR

_j

...J

l__

Ii

JDEX

-PULSE

INDEX

GAP

BO

x

l.E

12

•

oo

3 •

c2

11

J

Fe

J5o

.LE

11M15s1NG

CLOCK

TRANSITIONS

BETWEEN

B1Ts

s

AND 1..

w---,::::_-·

__

-

I

---

--

1

--

------

1

---

---

i---1

BYTE

----1

'

---

-----

I C2

I

C2

C2

---

FC

----

I

1

I , I

0

I

0

I

0

I

0

I , I

0

I

1

I

1

I

0

I

0

I

0

I

0

I

1

I

0

I

1

I,

I

0

I

0

I

0

I

0

I ,

1-;i

1

I , I

1

11

I

1

I

1

I

0

I

ril

INDEX

-AM

Ds

07

C5

c,

C3

D2

De

07

C5

c,

C3

D2

De

D1

C5

C4

C3

02

De

~

C\:,

°'

D:i

02

c,

Cs

I I I

n

I I I I I

n

I I I I I

n

I I I I I I I I I I

SECTOR

IDENTIFIER

IDENTIFIER

MARK ADDRESS IDENTIFIER E D C

12

x

00

3

x

A1 2)

FE

CYL

SID

SEC 01

7

BYTES

7)

MISSING

Cl

OCK

TRANSITIONS BE TWEEN

BITS

4

AND

3

ID-AM·

I

---~~------=-----

1

----:::--------

'

Al

A1

A1

---

1-'E

---:i

l110111010101011l1101110101n1:.11l110111010101011l111111111111110.

Os

05

Ci.

C3 C2

0,

Ds

05

Ci.

C3

C2

D,

De

D:-,

c,.

C3

Cz

Di

Os

D1

Cf;

Ds

Di.

D3

02

Ca

I I

1n1

II

I

l!:I

II

I

1n1

111111111

DATA BLOCK

DATA MARK DATA

FIELD

EDC

2)

MISSING CLOCK TRANSITIONS

BETWEEN

BITS

4

AND

3.

1)

DELFTFO

RF

CORD

FB

12K00

3xA1

21

FBJ)

255

BY

rES

2

BYTES

DATA

-AM

I

-------

1

----.

______

_

--

--

--

1

----

-----

1

A1

A1

A1

--

FB

----

I

110

t1

IOI

O

IO

IOl1!11Q

I 1

IO

IOIO

IO

I

1111oi

1

IO

IU

IO

I

0~

1111111I1101111

l

I

jDs

D5

C1.

C3

C2

D,

Os

Dr;

c,,

C3

r.7

Di

llfl

Dr)

c,,

C3

C7

o,

lltt

ll·;

llr,

05

111.

07

D1

11

I

I::

I I I I

In

I I I I I n I I I I I I I I I

I

l

I

I

DELETED

DATA-AM.

Al

A1

A1

FB

l110111010101011l110111010101011!110111010101011!11111111110101ol

Ds

I

FIGURE

l - 9

SOFT

SECTORED

TRACK

FORMAT

FOR

DOUBLE

DENSITY

(MFM)

1 -

lo

(

2.1

FUNCTIONAL

DESCRIPTION

The

models

6106

and

6108

comprise

the following

mechanisms

and

functional

circuits

(see Fig. 2 - 1). Functional Circuits:

•

Interface

•

Drive

Motor

Control

Mechanisms:

•

HEAD

LOAD-.

DOOR

LOCK-

and

ACTIVITY

LED-

Driver

•

Drive

Mechanism

•

Track

Zero

Detector

e

Spindle

and

Front

Door

Mechanism

•

Write

Protect Detector

• Positioning

Mechanism

•

Index

I

Ready

Detector

•

Head

Load

Mechanism

•

Read

I

Write Circuits

•

DC-

Control

and

Power

On

Reset

LOGIC

•

SIDE

SELECT

LOGIC

SELECT

11

....--

110

ENA

-

SELECT

21

WRITE

INHIBIT

SELECT

31

' I

-

t •

READ

READ/

DATA

I

WRITE

DATA/

WRITE

WR

T

CURRENT

or

RO

PLAYBACK

WRITE

GATE

I

CIRCUITS

ERASE

-

_

CURRENT

I

SIDE

S

IOE

SHH

Tl

I

SIDE

1

SELECT

0

N

LOGIC

u

p

I T

u p

T

PHASE

1 u

DIRECTION

STEPPER

'

T

~I

MOTOR

1

STEP/

CONTROL

4

INDEX

I

~Jl!n

~·

STEPPER

DOOR

LOCK

SENSOR

1

MOTOR

I

N

SOLENOID

\

1

N

T

(opt1onal1

~

ACTIVITY

,"'

~

T

E

I

LED\

~

£

R

I~

I~

~""'

R

F I

~~

t'"ll.1il

~r;i;

)\

ZERO

4

TRACK

F

A I

~

:'\

•

LIGHT-

A

TRACK

00/

(

DOOR

LOCK

DOOR

LOCK

~

~

BARRIER

t.r

..._

ZERO

'-

~

IN

USE

I

ENA

AND

""""

~

-..,

11.1ETECTOR

(

E

~-MOTOR

(oplion;il I

ACTIVITY

I

E

IUD

LOAD

DRIVER

R/W

HEAD

LOAD/

_

ENA

~HEAD___

HEAD

~

LOAD

,

DRIVER

HEAD

LOAD

SOLENOID

DRIVE

MOTOR

ON/

MOTOR

CONTROL

INDEX/

INDEX

I

INDEX

REA.DY

H

1

ADY

READY/

DETECTOR

DISK

WRT

+ERASE

CURRENT

CHANGE

I

--

I

Iopt1onall

WRITE

WRITE

•

sv

DC

Ul·

CONTROL

PWR

ON

RESFT

PROTECT

PROTECT/

•

12V

DC

ANO

DETECTOR

POWER

ON

RESET

..__

FIGURE

2 - 1

BLOCK·

DIAGRAM

BASF

6106/6108

2 - 1

2.1.1

DRIVE

MECHANISM

The

spindle

is

rotated at

300

rpm

by

a

DC

drive

motor. Rotation of the spindle

is

provided

by

a

belt

and

pulley.

The

drive

motor

is

started

and

stopped

by

the interface signal

MOTOR

ON.

The

ratio

between

motor

and

spindle speed

is

approximately 7:1.

The

drive

mechanism

is

shown

in Fig.

2 - 2.

2.1.2

SPINDLE

AND

FRONT

DOOR

MECHANISM

The

main

parts of

this

mechanism

are the drive

hub. the centering cone. the centering

cone

expander

and

the front

door

with pressure

arm

and

door

latch (see Fig. 2 - 3).

For

loading,

a

diskette

is

inserted

and

the front

door

pressed.

The

pressure

arm

moves

down.

the

centering

cone

enters the Flexy Disk. Just

before the centering

cone

reaches the

full

down

position,

the centering

cone

expander

is

FRONT

DOOR

(closed)------41r

DOOR

LATCH

DRIVE

MOTOR

SPINDLE

DRIVE

PULLEY

FIGURE

2 - 2

SPINDLE

DRIVE

HUB

DRIVE

MECHANISM

activated

and

expands

the centering

cone

which

grips

the inner diameter of the Flexy

Disk

to ensure correct

alignment.

The

door

latch

is

activated

and

holds the

front

door

in a closed position.

For

un.loading

a disk,

the front

door

must

be

pressed again.

The

door

latch

opens

and

the pressure

arm

is

moved

upwards

by

a spring.

The

centering

cone

and

centering

cone

expander also

move

upwards

and

disengage the

mini

disk

from

the drive

hub.

CENTERING

CONE

EXPA.\DER

CO:\E

PRESSURE

ARM

DRIVE

Hl'B

? -2

2.1.4

HEAD

LOAD

MECHANISM

The

head

load

mechanism

comprises

(see Fig. 2 - 5):

•

Head

Load

Solenoid

•

Head

Load

Actuator

HEAD

LOAD

PRESSURE

ARM

R/W

HEAD

HE

AO

LOAD

PAO

HEAD

LOAD

ACTUATOR

HEAD

LOAD

SOLENOID

R/W

HEAD

0

R/W

HEAD

1

When

the

head

load solenoid

is

energized,the

head

load

actuator

releases

the

head

load pressure

arm

of the

carriage

assembly.

On

the

single

sided

mini

disk drive

(BASF

6106)

this

causes the

mini

disk to

be

pressed

against the

read/write

head

by

the

head

load pad.

On

the

double sided

mini

disk drive

(BASF

6108)

the

Flexy

Disk

is

pressed against the bottom

head

(HEAD

O)

by

the upper

head

(HEAD

1)

mounted

in the pressure

arm.

The

pressure

foam

on

the

head

load

actuator

stabilizes

the Flexy Disk.

When

the

head

load solenoid

is

deener -

gized,the

head

load actuator

is

lifted

by

a spring.

The

head

load pressure

arm

is

lifted

also.

FIGURE

2 -

Sa)

HEAD

LOAD

MECHANISM

BASF

6106

FIGURE

2 -

Sb)

HEAD

LOAD

MECHANISM

BASF

6108

2 - 4

\

(

(

2.1.3

POSITIONING

MECHANIS~

The

main

parts

of the positioning

mechanism

are (see Fig. 2 -4):

• Stepper

Motor

• Spiral

Wheel

• Carriage

Assembly

The

stepper motor

is

a four phase motor

and

is

rotated

15°

by

every step pulse.

The

spiral

wheel

directly

connected

to

the

shaft

of the stepper

motor

converts the

rotational

motion of the stepper motor

to

a

linear

motion of the read write

head

assent>ly.

GUIDE

BARS

R/W-HEAD

The

BASF

6106

carriage assembly (Fig. 2 - 4a)

consists

of the read/write head,

and

the

head

load pressure

arm.

The

read/write

head

is

inserted

in the carriage assembly,

which

rides

on

two

guide

bars.

The

Flexy

Disk

is

pressed against the read/

write

head

by

the

head

load pressure

arm.

The

head

load pressure

arm

is

released

by

the

head

load

mechanism.

In

the

BASF

6108

carriage

assembly (Fig. 2 -

4b)

the head load pressure

pad

is

replaced

by

the upper

read/write head.

HEAD LOAD PRESSURE

ARM

STEPPER

MOTOR

SHAFT

FIGURE

2 - 4

a)

POSI

fIONHIG

MECHANISM

BASF

6106

R/W-HEAO

0 (BUTTON

TYPEI

R/W

HEAD 1

I CATAMARAN

FIGURE

2 -

4b)

POSITIONING

MECHANISM

BASF

6108

2 - 3

Other manuals for 6106

2

This manual suits for next models

1

Table of contents

Other BASF Floppy Disk Drive manuals