BASHLIN Lineman's User manual

Important Safety

Information for Users of

Bashlin Lineman’s

Climbing Equipment

- WARNING -

For your personal safety, this booklet must be

completely read and all of the information under-

stood completely before using these products.

No. BLCE-405-A Rev. 11-11

119 WEST PINE ST., P. O. BOX 867, GROVE CITY, PA 16127-0867

(724) 458-8340 FAX (724) 458-8342 www.bashlin.com

BASHLIN INDUSTRIES INC.

Table of Contents

Important Safety Information ................................................... 3

General Information for Bashlin Climbing Equipment ..................... 3

Lineman’s Climbing Belts .......................................................... 4

Sizing ................................................................................................ 4

To determine Your “D” Size .............................................................. 4

Stock and Special Belts ................................................................... 4

Tips for Using Bashlin Tool Belts ..................................................... 5

Inspecting Your Bashlin Tool Belt..................................................... 6

Cleaning and Maintaining Your Bashlin Tool Belt ............................ 7

Lineman’s Climbing Harnesses ............................................... 7

Sizing Bashlin Lineman’s Climbing Harnesses ................................ 7

Styles of Bashlin Lineman’s Climbing Harnesses............................ 8

Tips for Using Bashlin Lineman’s Climbing Harnesses ................... 8

Inspecting Bashlin Lineman’s Climbing Harness............................. 9

Maintaining Bashlin Lineman’s Climbing Harness......................... 10

Styles of Bashlin Lineman’s Climbing Harness.............................. 10

Donning Bashlin Harnesses ........................................................... 10

Buckles on Bashlin Harnesses....................................................... 11

Proper Use of Bashlin’s Hook and Loop

Body Harness Chest Closure ......................................................... 12

Pole Straps and Adjustable Positioning Lanyards......... 12

Tips for Using Bashlin’s Pole Straps and Adjustable

Positioning Lanyards ...................................................................... 12

Inspecting Bashlin Pole Straps and Adjustable

Positioning Lanyards ...................................................................... 13

Maintaining Your Bashlin Pole Straps and Adjustable

Positioning Lanyard........................................................................ 14

Climbers ......................................................................................... 15

Sizing Your Bashlin Climbers.......................................................... 16

Climber Pads .................................................................................. 16

Strap Climber Pad Attachment ...................................................... 16

Hook-n-Loop Pad Attachment ....................................................... 17

Wearing Hook-Loop Pads .............................................................. 18

Tips for Using Bashlin Climbers ..................................................... 18

Inspecting Your Bashlin Climbers and Pads.................................. 19

Using the Bashlin Gaff Guage ........................................................ 21

Maintenance of Bashlin Climbers .................................................. 22

Sharpening the Gaffs on Your Bashlin Climbers............................ 22

Shaping the Gaffs on Your Bashlin Climbers ................................. 23

Before Returning Your Climbers to Service ................................... 23

Pole Cut Out Test............................................................................ 23

Replacing Bashlin Gaffs ................................................................. 24

Installing the New Bashlin Gaff ...................................................... 24

Replacing Bottom Straps on Bashlin Climbers ............................. 25

Installing 89N Bottom Straps ......................................................... 25

Installing 87N Bottom Straps ......................................................... 25

Inspection Record ...................................................................... 27

Se hable Espanol, (Para una versió espanola de este folleto de la

seguridad, contacta las Industrias de Bashlin S.a. por favor.)

Nous parlons Français (Pour une version française de ce livret

de sûreté, contacter les Industries de Bashlin Inc s’il vous plaît.)

Other languages upon request

This information is intended for the user of the products indicated. It must

be included with the product, read and understood by the user prior to

placing this product into service. This equipment is to be used by prop-

erly trained, professional workers. The information in this booklet, manu-

facturer’s demonstrations, sales seminars, catalog information or other

promotional materials may be a part of but does not constitute proper or

complete training in the use of these products.

The user must inspect this equipment before each use. Any equipment

found to be worn out, damaged, subject to shock loading or in any way

questionable, must immediately be removed from service or accident,

injury and even death could result. Specific guidelines for inspection are

included in this information booklet.

General Information for Bashlin Climbing Equipment

These products are fabricated from leather and synthetic woven materials

and rated metal hardware. They are assembled by riveting and/or sew-

ing. The thread used in assembly is of a contrasting color to permit easy

inspection.

These products are manufactured in accordance with OSHA,ANSI, ASTM

F887, and/or CSA standards and are labeled as such. Please contact us

for information regarding specific applicable standards for each product.

Important Safety Information

- WARNING -

Bashlin equipment must not be altered. Altering or modifying these

products voids all warranties, may affect performance, and could

cause accident, injury or death to the user.

- WARNING -

Lack of proper training or the incorrect use and/or abuse of these

products may cause accidents, injury or death.

- WARNING -

Shock loading is extremely damaging to climbing equipment. Any

belt, harness pole strap, APL or climber that has been shock loaded

must be removed from service.

3

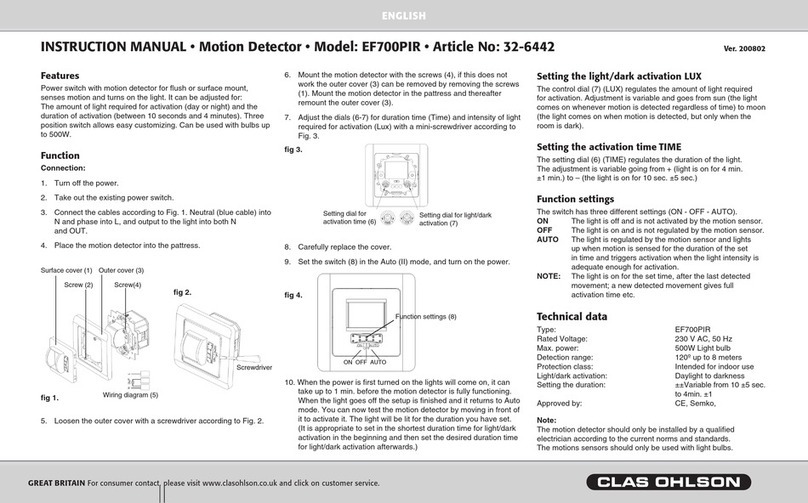

Sizing

Proper sizing is one of the most important considerations in the purchase

of a lineman’s tool belt. An improperly sized belt is uncomfortable and

may cause an accident or injury.

Bashlin tool belts are measured by

the “D” size, which is the distance be-

tween the heels of the D-rings. On 4

D-Ring belts (GD, GXD, GXDMP, G4D,

GX4D, and GX4DMP) this is the lower

belt assembly.

All linemen’s tool belts must be or-

dered according to the “D” size.

To Determine Your “D” Size

1. Locate the point where the heel

of the “D” ring should rest. As the

photo illustrates, this is approxi-

mately 4” down from the top of the

hip bone.

2. Begin to measure from this point. Measure

around the buttocks to the same point on

the opposite side.

When a properly sized tool belt is worn, the

D-rings will point nearly straight ahead and

the tongue adjustment will be in the center holes as shown in photo 3.

For the Padded Rest-A-Back (ex. 88BP) or Hip-Grip (ex. 88GP) tool belts,

add 2” to your standard “D” measurement.

Stock and Special Belts

Bashlin stocks right handed belts, in sizes D-18 to D-28 of the most pop-

ular belts. Belt sizes may vary on different style belts. Larger belts, up to

D-32, may be ordered. There is an additional cost for sizes D-29 to D-32.

Belts and holsters with left hand design are available at no additional

cost. Add “LH” to the part number.

Lineman’s Climbing Belts

4

Sizing Range for Bashlin

2 D-Ring Tool Belts - Per ASTM F887

D Size Center Tool

In. Minimum Hole Maximum Loops

D18 32 36 40 3

D19 33 37 41 3

D20 34 38 42 3

D21 36 40 44 4

D22 37 41 45 4

D23 38 42 46 4

D24 40 44 48 4

D25 41 45 49 4

D26 42 46 50 4

D27 44 48 52 4

D28 45 49 53 4

Sizing Range for Back Support

and 4 D-Ring Tool Belts

D Size Upper Tongue

In. B-Series G-Series/4D

D18 29-36 33-39

D19 30-37 35-41

D20 31-38 35-41

D21 32-39 37-43

D22 33-40 37-43

D23 34-41 39-45

D24 35-42 39-45

D25 36-43 41-47

D26 37-44 41-47

D27 38-45 43-49

D28 39-46 45-51

Tips for Using Bashlin Tool Belts

• Neverclimborworkwhileengagingbothendsofyourpolestrap

into one “D-Ring” of your tool belt.

• Alwaysvisuallyverifythesnap-hooksorcarabinersareengagedand

the gates fully closed and locked before allowing the equipment to

support your weight. Don’t rely on the “click”…for more than a few

guys that was the last thing they heard before they heard the sound

of the ambulance.

• Neverstorebelts,harnessstraps,orpadsnearstoves,steamcoils,

radiators, truck exhaust, etc...this will dry and weaken the materials.

Store your belt in a clean, dry location.

• Neverconnectatwistedstraporlanyardtothe“D-Rings”

• Alwaysclimbwiththesnapkeepersfacingoutwardandthepole

strap flat, with no twists, against the pole with the buckle side out.

• When“free”climbingneverletgoofthepoleorstructurewhile

repositioning your strap or lanyard.

• Nevercarryanywire,tools,orotheraccessoriesonthe“D-Rings”of

your tool belt. Any foreign objects carried on the “D” could interfere

with the operation of the snap-hook, or carabiner, causing an ac-

cidental disengagement resulting in a fall.

• Neverattachyourhand-linedirectlytoyourtoolbelt.Useahand-

linecarriersuchastheNo.33.WhenMrs.Smithaccidentally

catches your hand-line on the bumper of her car, she won’t drag you

off the pole.

5

- WARNING -

Bashlin’s 80 Suspenders, 81 Gut Straps, and 83 Detachable

Rest-a-Back are designed only to carry the weight of the tools and

belt you are wearing. They are not tested for or designed to support

your body weight. Incorrect use, such as using these products in

combination with a tool belt to fashion a saddle and loosening the

tool belt is very dangerous. The components of the 80, 81 and 83

could break under these circumstances. The result will be your belt

sliding off of your hips and your falling to the ground.

- WARNING -

Bashlin tool belts must be worn tightly and on, but not below the

hips. Incorrectly wearing a tool belt may cause accident, injury or

death.

• Onlylineman’sholstersaretobeattachedtoandusedontheclimb-

ing belt. Attach it to the belt correctly with the screwdriver pocket

toward your back. This will keep the tools in your holster separated

from the “D-ring” and reduce the chance of accidentally hooking

your snap or carabiner into a tool.

• Neverpuncturethecushionsectionofthebelttohangtoolsonthe

belt.

6

- WARNING -

A Lineman’s tool belt, even one with 4 D-Rings is not a saddle and

must not be worn as one. The belt should be worn snugly with the

lower D’s on, not below the hips. The upper belts on the wide (B

and G) series belts as well as the upper straps on the 4 D-Ring belts

are not to be worn on the hips. Wearing the belt incorrectly may

cause you to be ejected from the belt, causing injury or death.

Inspecting Your Bashlin Tool Belt

This equipment should be inspected

before each use. Your tool belt must be

inspected for the following;

• Electricalburns,cracks,or

deformation of the “D-rings” or

buckles.

• Looserivetsorbroken

stitching on the hardware

attachment points, and other

primary strength members.

(A)

• Degradedortornnylon

strength members, as well as

other physical, chemical, heat

or age related damage.

• Brokenorloosetoolloops,snapsor

a worn holster attachment point. (B)

• Dryrottedleather.(C)

• Elongatedholesinthetongue.

- WARNING -

Any belt displaying evidence of any one of these conditions must

be removed from service. The average useful life of a tool belt is

5-8 years of normal usage.

7

Cleaning and Maintaining your Bashlin Tool Belt

Regularly cleaning your climbing belt will improve its appearance, make

it last longer, and keep your clothes cleaner. Dirt can get into the leather

and nylon fibers actually breaking them down. The cleaning process

will also help you to spot any worn components that could cause future

trouble.

These belts consist primarily of leather and nylon components. The

leather should be cleaned using a saddle soap, while the nylon is

cleaned better with mild soap and water. Avoid any petroleum based

cleaners that may damage nylon. After the dirt is removed, oil the leather

using a commercial leather preserver such as mink, Neatsfoot or bee

oil. The belt should be cleaned and leather oiled at least every 90 days,

more if the work conditions require it. After cleaning and oiling the belt,

let it dry overnight. Take a moment to wipe off the excess oil from the

leather, as it will stain your clothing and attract dirt. If the leather is

kept moist, it will last a long time. However, once the leather begins to

dry, no amount of oil will repair the damage. Preserve you belt and your

investment by regularly maintaining your belt.

Lineman’s Climbing Harnesses

Bashlin’s Lineman’s Climbing Harnesses merge a line belt with a full

body harness. They provide an extra level of comfort and security when

working on a pole, especially when using wood pole fall restricting

devices(WPFRD).TheseproductsmeettherequirementsoftheASTM

F887 for electric arc performance.

Sizing Bashlin Lineman’s

Climbing Harness

Proper sizing is essential for comfort

and performance in the event of a

fall. An improperly sized harness just

doesn’t feel good. In the event of an

incident requiring the equipment to

arrest a workers fall, the individual could fall out of an

improperly sized harness. To size the belt portion of the

harness, see page 4 of this booklet.

The Bashlin harnesses are sized in accordance with

the torso of the worker. For the wearer, this involves

measuring their height and chest size to determine the harness size

based on those measurements. For most individuals, their overall height

will determine the correct size. However, if the chest measurement is too

large for the corresponding height, move to the larger size. If the chest

See our catalog or www.bashlin.com for leather care and cleaning products.

Need more information? Contact our customer service and

ask about our video “Donning Bashlin Harnesses”.

8

size is too small for the height, use the individual’s height to determine

the size. For 99% of the individuals, this method will determine the

proper size. For the other 1% of you, kindly contact us.

Sizing Bashlin Lineman’s Climbing Harnesses

H Style Harnesses-662R and 662A

Size Height Chest

O One Size Fits Most 5’ 4” - 6’ 3” 34 in. - 48 in.

X X-Large 6’ 3” - 6” 6” 48 in. - 54 in.

2X Double X-Large 6’ 6” - 6’ 10” 54 in. - 60 in.

X-Style 683 Saddle Style 647/649 H-Style 662V

Size Height Chest

S Small 5’ 4” - 5’ 7” 34 in. - 36 in.

M Medium 5’ 8” - 5’ 11” 36 in. - 40 in.

L Large 6’ 0” - 6’ 3” 40 in. - 44 in.

X X-Large 6’ 3” - 6’ 6” 44 in. - 48 in.

2XL XX-Large 6’ 6” + 48 in. - 52 in.

3XL XXX-Large 6’ 6” + 52 in. - 56 in.

After determining the proper harness size, find the tool belt size by

using the directions on page 4 of this booklet.

Tips for Using Bashlin Lineman’s Climbing Harnesses

• Wearyourharnessassnuglyor,ifyouprefer,astightaspossible.

This will reduce strap slippage and help keep you in the harness in

the event of an arrested fall.

• Donotuseanimproperlysizedharness.

• Onlyuseaharnessmadefortheworkbeing

performed.

• Keepthebackattachmentpointpositioned

between the shoulder blades. This will allow

peak performance of the harness should it be

used to arrest a fall. It will also help keep the

straps on the shoulders during day to day use.

• Avoidexposingtheharnesstoexcessiveheat,

chemicals and prolonged sunlight that degrade

the material.

9

• Storetheharnessinaventilatedarea,andcleanitwithsoapand

waterregularly.Wesuggestacanvasornylonbagforstorageand

to carry as well as to protect the harness at the work-site.

• Don’tviolatesafetyrules.

Inspecting Bashlin Lineman’s Climbing Harness

The user must inspect the harness prior to each use. In addition, a

competent person, as defined by the ANSI Z359, other than the user must

inspect the equipment annually. This inspection must be documented,

and a record of the inspection kept as long as the equipment is in service.

Werecommendthattheequipmentbetaggedwithaserialnumber,and

the same number noted on the enclosed inspection record (page 27).

These products must be inspected for the following;

• Hardware-Lookforcracks,deformation,electrical

burns and secure attachment points. Inspect

the snap hooks for easy and smooth operation,

and gates that close completely. If using a quick

release buckle, make sure it won’t open if only 1

tab is depressed.

• Nylonorpolyesterstrengthmembers-burns,

cuts, chemical or ultraviolet degradation,

worn fibers, abrasion.

• Splices-Broken or cut stitches, fraying,

burns or worn fibers.

• Rivets-Loose,bentorcorrodedrivets

• Evidence of shock loading - including deployed

tags on shock absorbers, broken stitches,

elongated grommets, bent hardware, or even

witnessing an incident that doesn’t appear to affect

the equipment.

• Inspectthetoolbeltpertheinformationfoundon

page 6 of this booklet.

- WARNING -

Any equipment with evidence of any one

of these conditions must be removed from

service immediately.

The average useful life of harnesses products

is 1-4 years, from the date of manufacture

depending on work conditions, care and

usage.

See the inspection record on the back cover

of this booklet.

10

Maintaining Bashlin Lineman’s Climbing Harness

Clean the tool belt per page 7 of this book. Your harness should be cleaned

as needed to remove dirt that will break down nylon fibers and to remove

sweat and other chemicals that may degrade the webbing. Cleaning is

best done by hand washing with mild laundry

soap and water, rinsing the soap out completely,

and hang drying. If the tool belt can be removed

from the harness it may be machine washed on

the gentle cycle by placing it in a nylon mesh

bag. Do not machine dry these products.

The equipment is best stored in a ventilated

canvas or nylon bag. It will be protected from

mechanical and chemical damage as well as the

sunlight that will severely degrade webbings.

The ventilation is needed to reduce the chance

of mold and mildew, especially in humid cli-

mates. Do not store next to excessive heat.

Styles of Bashlin Lineman’s Climbing Harnesses

Bashlin offers several different styles of Lineman’s climbing harnesses.

They offer unique methods of connecting the harness and belt together,

to accommodate different climbing styles. For specific information

regarding your harness, please see the data sheet included with your

product. If none is included with your harness, contact customer

service.

Donning Bashlin Harnesses

• Grasptheharnessbytheback

attachment point, remove all twists

from the material and open the chest

closure, or as on the 683 style one side

of the chest assembly. (1)

• Placetheharnessontheshouldersand

fasten the chest closure. (2)

• Bucklethelegstraps.

• Adjusttheshoulderstrapssotheseat

strap is snugly underneath the buttocks.

• Thebackattachmentmustbesquarelybetween

the shoulder blades. (3)

• Tightentheleg,chestandshoulderstraps.

• Ifyourharnesshas2piecebuckles,replacethe

1

2

3

11

plastic keepers an inch or so away from the

buckles. This is done by placing the keeper

under the strap, pinching the webbing and

sliding the material into the slots of the

keeper. This will greatly reduce any slippage

of the 2-piece buckle. Then simply slide the

remaining material into the elastic keepers.

Withgrommetstylebuckles,simplyplace

any excess webbing under the elastic keepers. (4)

• Makeanalcheckofallbucklesandstrapsbeforebeginningthe

work.

• Securethetoolbeltinthenormalmanner.Thebeltmustbeworn

correctly, per the instructions in this booklet. See pages 4-5.

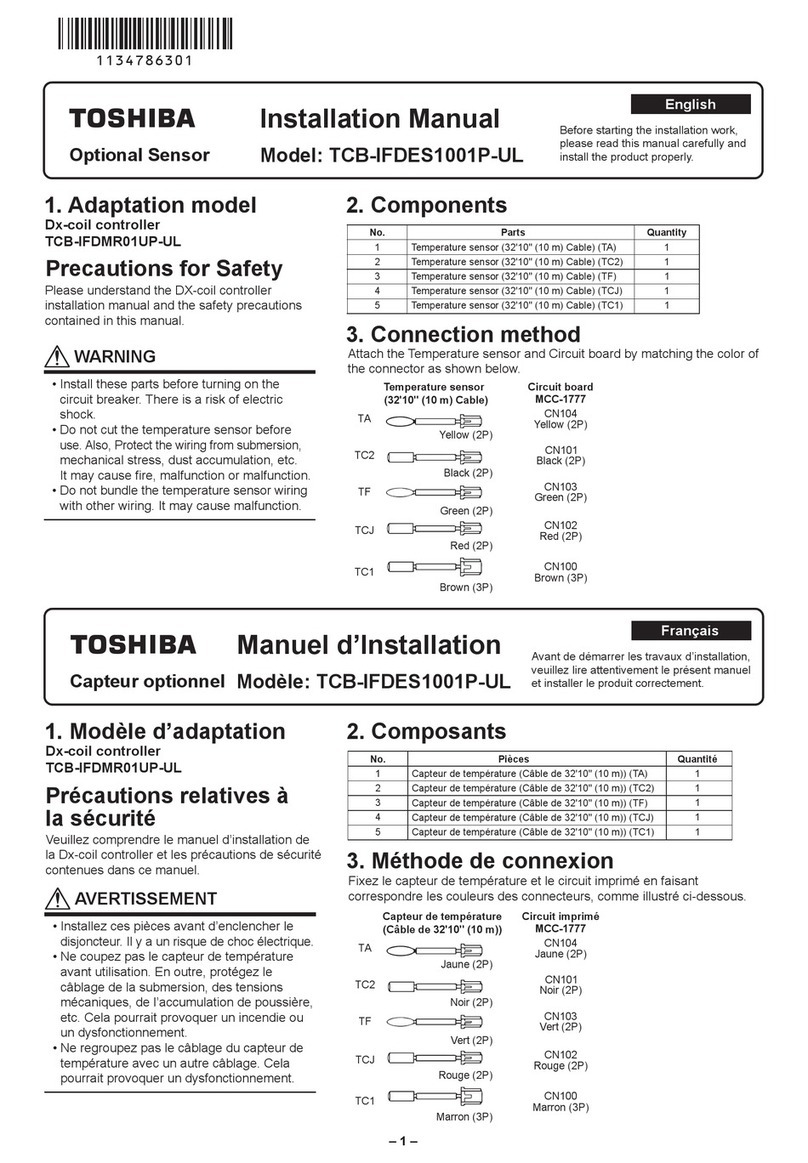

Buckles on Bashlin Harnesses

• Interlocking Pass-Thru Buckles – Connect these buckles by

sliding the smaller adjuster through the slot on the frame attached

to the harness. (1) Note it will slide

through much easier if the printing

on the top of the adjuster is turned

toward the attachment point of the

frame. (2) Be certain the free end of

the strapping is captured by the frame. After the buckle is secured

and the strap adjusted, tuck the webbing into the keeper to restrict

the strap movement. (3)

• Grommet Tongue Buckles – Slide the end of

the billet through the buckle frames and adjust

the strap to the correct length. Place the

tongue of the buckle frame through the billet

grommet that will make the strap the correct

length, (4) then secure the end of the billet in the keeper. (5)

• Quick Release Buckles – Connect the buckles by sliding the male

end in the female section until both of the tabs

“click” and the buckle is locked. (6-7) The buckle

is released by depressing both tabs until the

male end can be removed. (8) Both tabs must

be moved to release the buckle. If it releases

when only one tab is moved, the harness should

be removed from service. Adjust the strap after

the buckle is connected, then tuck the excess

webbing into the strap keeper to maintain the

adjustment.

1

4

2 3

4 5

6

7

8

12

Proper Use of Bashlin’s Hook and Loop Body Harness

Chest Closure

• Adjustcheststraptotheproperverticalpositionontheshoulder

straps. It should cross at the mid-point of a chest pocket.

• Wrapthestrapunderandovertherightshoulderstrap.Firmlypress

the hook and loop material together across the length of the strap.

• Tuckthefreeendofthestrapbehindtheleftshoulderstrap.

Pole Straps and Adjustable

Positioning Lanyards (APL)

Bashlin’s Pole Straps and Adjustable Positioning Lanyards (APL) are

made from woven nylon, 6 ply nylon, nylon reinforced leather or braided

rope with a red center. These straps are designed to be used with the

climbing belt as a positioning strap. They are not lanyards for fall arrest,

nor are they to be used for pulling the line truck out of a ditch.

Bashlin pole straps and adjustable positioning lanyards use double

action locking snaps, or carabiners.

Tips for Using Bashlin’s Pole Straps and Adjustable

Positioning Lanyards

• Never climb or work while engaging both ends of your pole strap

into one “D-Ring” of your tool belt.

• Alwaysvisuallyverifythesnap-hooksorcarabinerareengagedand

- WARNING -

For the chest strap closure of the harness to be secure, at least 2”

of the strap must extend beyond the inside edge of the left shoul-

der strap. The hook and loop must be secure at all times during

use. Keep the material free from foreign matter that could keep

the hook and loop sections from securely mating. If there are any

indications of wear, remove the harness from service.

13

the gates fully closed and locked before allowing the equipment to

support your weight. Don’t rely on the “click”…for more than a few

guys that was the last thing they heard before they heard the sound

of the ambulance.

• Neverstorebelts,straps,orpadsnearstoves,steamcoils,

radiators, truck exhaust, etc...this will dry and weaken the leather.

Store in a clean, dry location.

• Neverconnectatwistedstraporlanyardtothe“D-Rings”

• Alwaysclimbwiththesnapkeepersfacingoutwardandthepole

strap flat, with no twists, against the pole with the buckle side out.

• When“free”climbingneverletgoofthepoleorstructurewhile

repositioning your strap.

• DisablingthelockingdevicesontheAPLorPoleStrapHooksisnot

very intelligent and can be dangerous. The locking snap-hooks and

carabiners are not sized in proportion to the “D-ring”. If the lock is

disabled, they will be prone to accidental disengagement or roll-out.

• Theleatherkeeperonthepolestrapisanintegralpartofthestrap

as designated by the ASTM F887 standard. Removing this piece

of leather not only makes the strap not compliant (Important at the

Lineman’s Rodeo or in case of an accident), it also makes it harder

for you to maintain control of the length of your strap.

Inspecting Bashlin Pole Straps and Adjustable

Positioning Lanyards

These straps and lanyards must be inspected prior to each use. They

should be inspected for the following;

• Electricalburns,cracks,or

deformation of the snap-hooks,

buckle or adjustable carabiner.

• Looserivetsorbrokenstitchingon

the hardware attachment points, sewn

splices or compression fittings, and

other primary strength members.

• Degradedortornnylonstrength

members, as well as other physical,

chemical, heat or age related damage.

• Dryrottedleather.

• Exposedredwearindicator (A) (A1)

• Elongatedholes,orbrokenstitches

on the strap material or rope.

14

• Improperlyfunctioningordamaged

snap hooks or carabiners including;

- A sticking gate or locking

mechanism (B)

- Gages that don’t close completely

- A malfunctioning locking

mechanism

- Weakormissingsprings

• ForAdjustable Positioning Lanyard

(APL), inspect the friction adjuster

for freedom of movement. There

must be no debris in the unit. Inspect

cables and set screws for condition

and proper engagement. (A) The nut

on the through bolt must be secure.

(B) Do not oil the mechanical adjustors as they will accumulate dust

and dirt, which could cause them to stick.

Maintaining your Bashlin Pole Strap and/or Adjustable

Positioning Lanyard

Regularly cleaning your strap or lanyard will make it last longer. Dirt will

get into the leather and nylon fibers actually breaking them down. Dirt

and debris will also diminish the performance of the friction adjuster.

The cleaning process will also help you to spot any worn components

that could cause future trouble.

These products consist of leather and synthetic components. The

leather should be cleaned using a saddle soap, while the nylon is

cleaned better with mild soap and water. Avoid any petroleum based

cleaners that may damage nylon. Hang the nylon strap or lanyard to dry

overnight. For leather straps, after the dirt is removed, oil the leather

using a commercial leather preserver such as mink, Neatsfoot or bee

oil. The leather strap should be cleaned every 90 days, more if the

work conditions require it. After cleaning and oiling, let it dry overnight.

Then take a moment to wipe off the excess oil from the leather, as the

B

A

- WARNING -

Any pole strap or lanyard displaying evidence of any one of these

conditions must be removed from service. The average useful life of

Bashlin straps and lanyards is 1-4 years of normal usage.

15

excess will attract dirt. If the leather is kept moist, it will last a long time.

However, once the leather begins to dry, no amount of oil will repair

the damage. Preserve your strap and your investment by regularly

maintaining your strap.

For information regarding Wood Pole Fall Restricting products,

see the information included with the product.

See our catalog or www.bashlin.com for leather care and cleaning products.

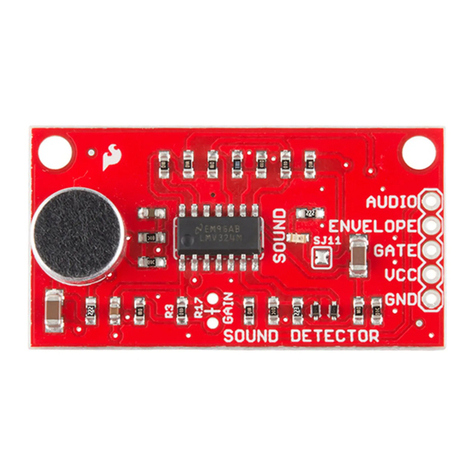

Climbers

Your Bashlin climbers are known the world over for their comfort and

superiorperformance.WhetheryourchoiceisthepopularBD14,

or one of the rugged steel climbers, BD12 or BD16, you have the

proven Bashlin 17° angle gaff, roomy

comfortable stirrup and innovative

offset design.

All Bashlin pole climbers come with

the following items standard; (A)

- 1 pair of shanks with the bottom

nylon straps installed

- 1 pair of gaff guards

- 1 pair of top slides with 4 screws

in a small packet

- 1 gaff gauge (Pole Climbers Only)

If any of these listed items are

not in your box, please contact us

immediately.

In addition, these climbers are sold

as sets and include the

following items designated

by part number

- Climbers with bottom

straps (ex. BD14-1N)

- Add 85 N top straps

(ex. BD14-2N) (A)

- Add 110D climber pad

(ex. BD14-3N)

- Replace 110D climber pad with 130D (ex. BD14-4N) (B)

- Replace 130D with 140DS climber pad (ex. BD14-5N) (C)

A

B

C

16

Sizing Your Bashlin Climbers

For maximum comfort and performance,

the climber shank must be adjusted to

fit your leg. This is done by performing

the following steps;

• Placetheadjustabletopslideonthe

shank.

• Putyourfootinthestirrupand

move the top of the adjuster to a

point two fingers below the bottom

of the knee bone. (D)

• Holdingthetopslideinplace,install

one of the screws, recheck the

position, then install the second

screw.

• Adjustthesecondshanktothesamesize.

- The shank should be low enough to keep the pad from rubbing

your knee bone. If you are experiencing excessive rubbing on the

knee bone, lower the top slide.

- The standard adjustment for Bashlin climbers per ASTM F887 is

14 3/4 to 18 inches. If by adjusting your climbers to the proper

height, the top slide is in the last hole, or if the climbers are simply

too short, you must use the longer top slides, number 14ATS, for

aluminum climbers or 16ATS for steel. Using the longer adjusters

gives you a better fit and reduces the flexing of the shank section

of the climber, especially in the critical section 4-8 inches above

the gaff.(See Climber Inspection).

Climber Pads

Bashlin climber pads reduce the shin

discomfort caused by standing on

climbers for extended periods of time.

Strap Climber Pad Attachment

(110, 130, 140, 145 or 150 series

pads)

Strap pads are held on your Bashlin

climbers with a 1 inch nylon strap that

has a tongue buckle closure. The strap

is normally oriented with the buckle

close to the front of the pad. The pad

should wrap around the front of your

leg and inside of the shank.

B

17

A

Hook-n-Loop Pad Attachment

(145-V or 150V series pads)

• Withthetopslidesecuredtotheclimber,inserttheshankintothe

tunnel of the pad until the top slide loop is seated in the tunnel slot

or steel insert. Squeezing the tunnel will allow the climber to slide in

easier. (A)

• (B, C) Feed the climber pad retaining strap through the top slide

loop and/or the steel insert and pull tight to secure the shank to the

pad. To assist in sliding the strap through the loop, place a piece of

paper or other thin material over the end of the strap while sliding

through the top slide loop. A pair of pliers can be used to pull the

strap.

C

18

Wearing Hook-Loop Pads

• Stepintotheclimberand

attach the bottom strap

securely to your boot. (A)

• Feedthefreeendofthepad

with the hook through the

steel loop. (B)

• Pullthroughuntilthepadis

snug on your leg. (C)

• Securethefreeend

around the pad, mating

the hook to the loop on

the body of the pad.

• Checkthesecurityof

the climber and pad

by taking a step or two

on the structure you

are climbing before

ascending in them.

Tips for Using Bashlin Climbers

• OnlyuseaBashlinGaffGaugeonBashlinPole

Climbers.

• Removefromserviceanyclimbersthathave

come in contact with an electric arc.

• Neveretchorscratchthecriticalsectionof

the climber shank, 4-8 inches above the gaff.

Points of stress will be created, and flexing

of the shank will cause a fracture and finally

premature failure of the climber shank. (F)

• Forgedaluminumalloyclimbersare30%

lighter than steel, yet compare quite

favorably with the strength of shanks made

A, B

C

- WARNING -

BECERTAINYOUHAVEPULLEDTHEMINIMUMWRAPWARNING

LABEL THROUGH THE STEEL LOOP. This will ensure that you have

at least the minimum amount of hook/loop interface to properly

secure the pad/climber to your leg. Failure to achieve this minimum

wrap may result in release causing SERIOUS INJURY OR DEATH (D)

D

F

19

of either steel or titanium. Aluminum yields a better performing

climber than steel or titanium. However, the aluminum is softer than

either material, will wear faster, and requires regular inspection and

maintenance.

• Donotusealuminumalloyclimberswithclimbingbootsthathavea

steel heel guard. The heel guard wears deeply into the stirrup of the

climber and will require premature replacement of the shanks.

• Bashlinrequiresthatanyothermanufacturer’sequipmentused

with our products be made in accordance with the ASTM F887

Standards.

• Don’tviolatesafetyrules.

• Keepdirtanddebrisclearedfromthehookandloopmaterialwith

a soft brush. Debris can compromise the performance of the hook

and loop material, even causing the strap to release.

Inspecting your Bashlin Climbers and Pads

Your climbers must be inspected prior to each use. Your climbers should

be removed from service until repaired or replaced if you find any of the

following:

• Climber straps that

are worn, cut, burned,

have elongated holes,

or loose buckles.

• Worn climber pads

that have broken rivets

or loops. (A)

• Hook-n-Loop pads

sleeve retaining strap is

damaged or missing.

Hook and loop on pad

will not stay secured, or

broken stitches. Steel

- CAUTION -

The average useful life of Bashlin Climbing Equipment based on

normal usage:

Tool Belts 5 - 8 years

Climbers 2nd set of gaffs

Pole Straps 1 - 4 years

A

Table of contents

Popular Security Sensor manuals by other brands

Renkforce

Renkforce 1362990 operating instructions

MRC

MRC FC-2601 Operation manual

Infinite

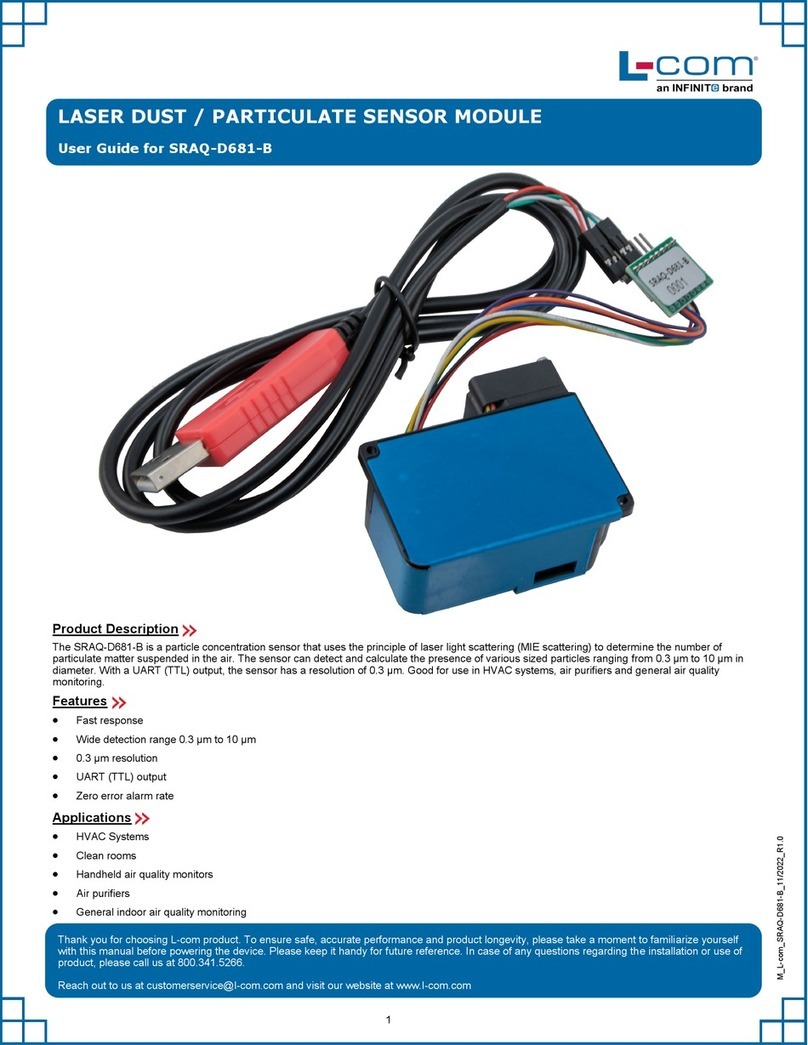

Infinite L-com SRAQ-D681-B user guide

Elkron

Elkron DC500 quick start guide

Mittelmann

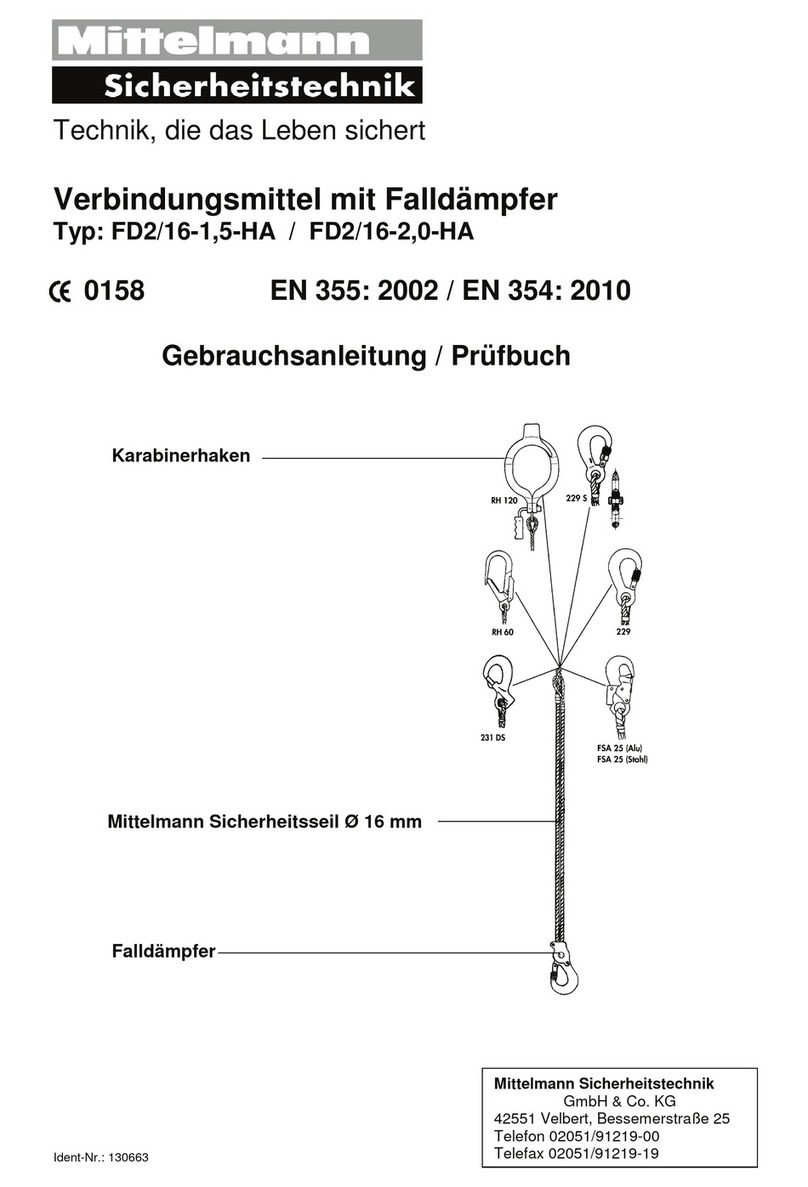

Mittelmann FD2/16-1,5-HA use instructions

Critical Environment Technologies

Critical Environment Technologies CGAS-A installation manual

Telefire

Telefire TBD-8100 Technical manual

BW Technologies

BW Technologies GasAlert Extreme Quick reference guide

Honeywell

Honeywell Notifier NRX-TFIX58 Installation and maintenance instructions

Conrad

Conrad FAZ 3000-TF-2 operating instructions

Siemens

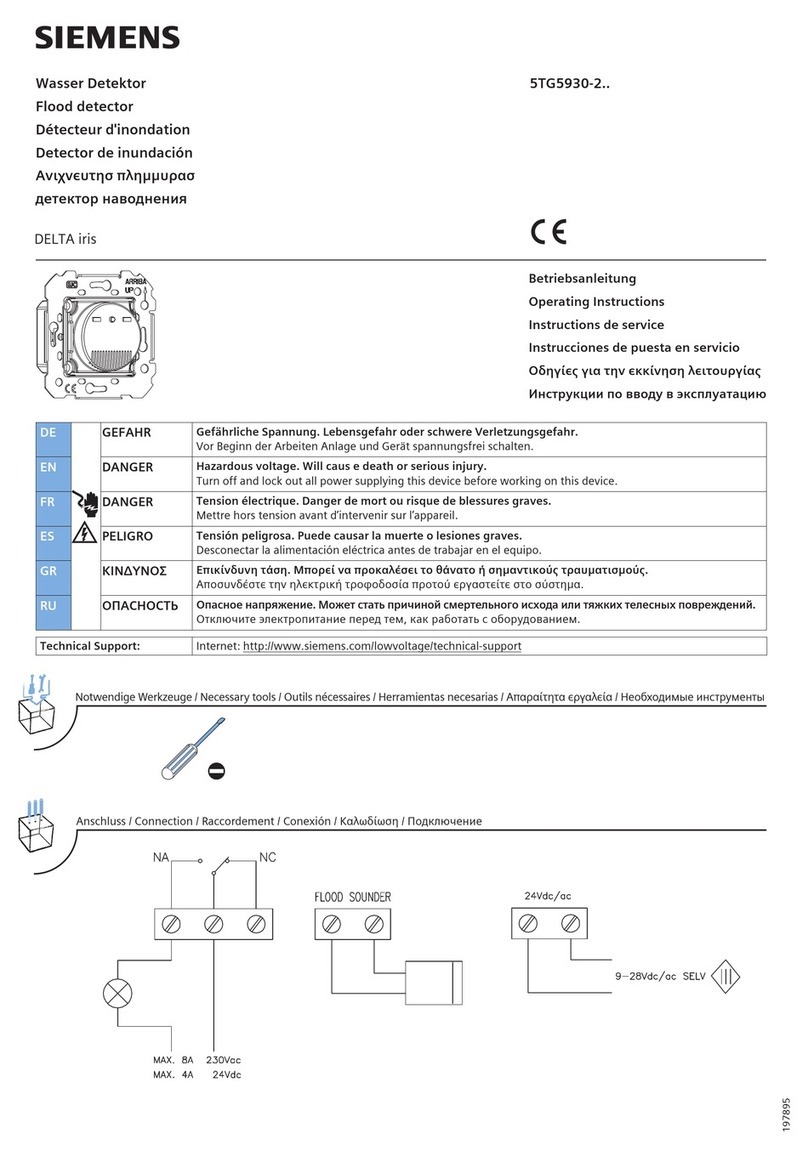

Siemens DELTA iris 5TG5930-2 Series operating instructions

Hugo Müller

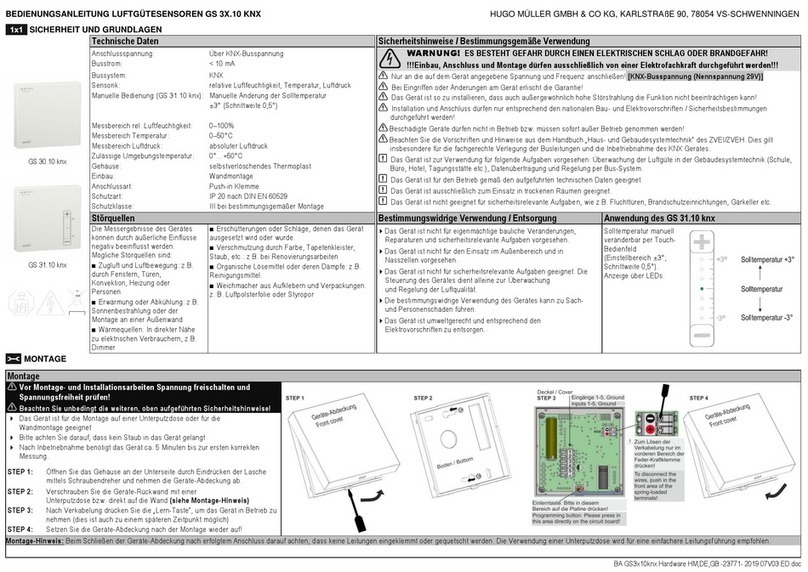

Hugo Müller GS 30.10 knx instruction manual