Telefire TBD-8100 User manual

Initiating Devices

TBD-8100

Conventional

Beam Detector

Technical Manual

TELEFIRE FIRE &GAS DETECTORS LTD

PO Box 7036

Petach Tikva 49250

Israel

Tel: 972 3 970 0400

Fax: 972 3 921 1816

Web: www.telefire.co.il

TBD-8100En100.pdf

Revision 1.00

November 2017

i

Note

The terms “Trouble” as used in NFPA 72 guideline and UL standards and

“Fault” as used in EN 54 standards are used interchangeably throughout this

manual.

i

Note

Do not install, operate, and maintain this product before fully reading this

manual.

© 2017 –Telefire Fire & Gas Detectors Ltd.

TBD-8100

© 2017 –Telefire Fire & Gas Detectors Ltd Revision 1.00 November 2017

–Page 1 of 10 –

1 Introduction

The TBD-8100 Beam Detector is comprised of an optical transmitter and a receiver

within the same device.

The transmitter sends out an invisible infrared beam, which is reflected by a prism

mirror; the mirror is placed on the opposite wall, facing the transmitter in a manner that

nothing blocks the beam’s path from one side to the other. The optical receiver monitors

the intensity of the reflected beam.

The detector can detect up to 9 meters on each side, 18 meters altogether.

The TDB-8100 detectors can be installed at three distance ranges:

8 to 50 meters (one prism)

50 to 75 meters (two prisms)

75 to 100 meters (four prisms)

2 Compatibility

The TBD-8100 is compatible with the following control panels:

All TSA-1000 models and TSA-1000X

TSA-200, TSA-240, TSA-200XT, TSA-240 XT, and TSA-200X

ADR-7000, SAVER-7000, GUARD-7, and ADR-3000 Analog Addressable Control

Panel when used with an ADR-712, ADR-718, or ADR-812A Input module.

3 Installation

Planning of quantity and location of detectors shall be done according to the local codes

and regulations and in accordance to the planning consultant's requirements.

i

Note

Notify the operator or the security personnel that the system will be temporary

disconnected before adding devices to the control panel.

All connections shall be done when power sources are disconnected.

3.1 Pre-installation planning

3.1.1 Cabling Planning –Wire Characteristics' Effect

Cable type selection and wiring shall be done according to local regulations.

System connections shall be done when power sources are disconnected.

Changing/installing electric activation modules shall be done after the system is in

quiescence state (push buttons and detectors in normal state).

The following table shows the effect of wiring characteristics on system performance:

Characteristic

Effect on Input Lines

Electric Resistance

Minimal

Capacitance

No affect

Inductance

Minimal

Mechanical Strength

High

TBD-8100

© 2017 –Telefire Fire & Gas Detectors Ltd Revision 1.00 November 2017

–Page 2 of 10 –

Table 1 Wiring Characteristics’ influence on System Performance

Use a two-wire cable –it is recommended to use a twisted pair cable of 18 –12 AWG.

Refer to the following table for maximum branch length per gives cable cross-section.

Use a shielded twisted-pair when connecting between buildings.

3.1.2 Cabling Planning –control panel zone or input module IDC

Use a standard two-conductor cable with each conductor having a cross section of 0.8 to

3.3 mm2. Maximum loop resistance: 50Ω.

Table 2 specifies the maximum allowable length of cable, based on the cable’s cross

section

Cable Type

Cross Section

(mm2)

Detection Line Maximum Length for a

given Cross Section

AWG 18

0.8 mm2

1,200 m

AWG 16

1.3 mm2

1,900 m

AWG 14

2.1 mm2

3,000 m

AWG 12

3.3 mm2

4,800 m

Table 2 Maximum Length for an Input Line

3.1.3 Cabling Planning –24Vdc Supply

The module requires 24Vdc from the addressable control panel or an auxiliary power

supply such as the TPS-74A OR TPS-34A.

Use an auxiliary power supply whenever the module is installed a long distance from the

addressable control panel or whenever the total current consumption of all NACs

exceeds the capability of the addressable control panel's 24Vdc output.

3.1.4 Cabling planning –shielded cables

It is recommended to avoid wiring outside buildings due to a risk of lightning strikes. If

required, it is mandatory to use shielded cables. The shielding must be grounded via the

control panel grounding terminals.

3.2 Installation –Prior to Detector Positioning

3.2.1 Control Panel Detector Configuration –Addressable Control

Panels

Configure the input addresses of the ADR-712, ADR-718, or ADR-812A as Input Circuit.

Please refer to the control panel’s technical instructions for further details concerning

device programming.

3.2.2 Input configuration in a control panel (TSA-1000 only)

Ensure that the input, to which the detector is connected, is configured at the panel as a

type D input (regular detectors zone). Please refer to the TSA-1000 technical manual for

a detailed explanation concerning the mode of configuring the various types of inputs.

3.3 Installation –Placing the Detector

The TBD-8100 is designed to protect indoor fire risk areas, except environments where

smoke, steam, dust, or corrosive gasses are present under normal conditions.

Observe NFPA 72 guidelines and local fire codes when installing the detectors.

TBD-8100

© 2017 –Telefire Fire & Gas Detectors Ltd Revision 1.00 November 2017

–Page 3 of 10 –

In order to decrease detection time, a proper positioning of the detector is most

important.

Based on experience, it is well known that smoke rising from a fire does not go straight

upwards, but tends to flow sideways; as a result of air flows and the effect of

temperature gradients among the various air layers, the smoke creates a "mushroom"

shape at a certain elevation.

The time interval between the actual time that the fire started and the time that the

smoke detector alarm sets off depends upon the location and elevation of the beam

detector, the detection zone, the amount of smoke emitted, the ceiling's shape and the

ventilation.

The detection coverage on each side of the beam is 9 meters maximum. Place the

detector up to 9 meters from the wall, or 18 meters from the next, similar, parallel

detector, under a flat ceiling.

i

Note

Install the detector horizontally with the red light down on the right side.

Figure 1 Placing the Detectors

Commonly, rising smoke tends to spread sideways before it reaches the ceiling because

a layer of hot air near the ceiling prevents the smoke’s further rise. Therefore, the

detector should be installed on the building’s wall, at least 50 cm but no more than 1

meter below the ceiling in order to comply with the UL 268 / NFPA 72 and the SI 1220-3

2014 edition.

i

Note

Measure the wiring to ensure there are no shorts before connecting the wiring

to the control panel.

Connecting or adding inputs, outputs, and extinguishing devices shall be

done when all power to the control power is disconnected (AC and batteries

disconnected).

TBD-8100

© 2017 –Telefire Fire & Gas Detectors Ltd Revision 1.00 November 2017

–Page 4 of 10 –

Figure 2 Detector Inner Structure

3.3.1 Connecting the detector's relays to an input or zone module

When connecting the alarm and fault outputs to the zone input in the control panel or to

the addressable input assembly, use a model TRA-1B adapter (see Figure 3).

Figure 3 Connecting to the zone input in a control panel or to an addressable

assembly input using a model TRA-1B adapter

3.3.2 Connection of an Optional TBD-8100R Indicator Module

Position the TBD-8100R assembly at eye level.

The TBD-8100R assembly is intended for receiving alarm or fault warnings from the

detector.

TBD-8100

© 2017 –Telefire Fire & Gas Detectors Ltd Revision 1.00 November 2017

–Page 5 of 10 –

The assembly also enables checking the detector’s functioning: If a magnet is positioned

near the indicator’s LED indication light, the detector enters an alarm mode.

Additionally, using the TBD-8100C instrument of the TBD-8100R assembly, you can

assess the detector’s signal strength, amplification and type of fault (the letter F appears

in one of the screen’s locations):

a. More than 50% dust accumulation on the detector

b. More than 90% dust accumulation on the detector

c. Signal level is very low or it does not exist

d. Alarm

The most recent alarm of the detector (in case there are several detectors connected

within the same zone).

Figure 4 Information displayed in the TBD-8100C instrument

To receive information, bring the TBD-8100C –on the photo-diode side –near the red

LED of the TBD-8100R.

TBD-8100

© 2017 –Telefire Fire & Gas Detectors Ltd Revision 1.00 November 2017

–Page 6 of 10 –

Figure 5 Receiving information from the TBD-8100R assembly

The assembly connects to the detector via two conductors. Connect the optional

indicator module to the detector, as described in the drawing.

Figure 6 Connection of an Optional TBD-8100R Indicator Assembly to the Detector

3.4 Aligning the Detector

The detector can be aligned in a few ways:

a. Using the 4 LEDs in the detector card or a power or a voltmeter

b. Using an external monitor

TBD-8100

© 2017 –Telefire Fire & Gas Detectors Ltd Revision 1.00 November 2017

–Page 7 of 10 –

i

Note

In some cases (usually when the distance between the detector and the

prism is less than 10 m), there is a need to attach the black patch, supplied

with the detector, onto the transmitter’s lenses.

The detector would signal during the initial detector direction, by

lighting up the 4 green LEDs, that the black patch must be attached.

3.4.1 Using detector card 4 LEDs or a voltmeter

1. Move the alignment switch (DIP SW 6) to the calibration position (ON).

2. Power on the detector.

3. Slowly turn one of the alignment wheels in one direction while watching the HL1-

HL5 LEDs. As the detector approaches optimum calibration, the number of lit green

LEDs increases from left to right.

Each LED that lights up, indicates that the beam’s signal strength is increasing. You

should aim to reach a maximum number of lit LEDs.

If only the red LED lights up, the beam is not being reflected by the prism.

Additionally, the signal strength can be measured by connecting a voltmeter to

points +RM- in the XT1 adapter.

The voltage should approach the voltage supplied to the detector.

4. If the number of lit LEDs starts decreasing, you are moving away from the optimum

direction –Retract until you reach a maximum number of lit LEDs.

5. Measure the voltage between points 3 and 4 (RM) in the XT1 connector. Maximize

the voltage so that it approaches 24Vdc, as near as possible (at a small operating

range of the detector, when the patch is attached to the lens, the actual voltage

measured during calibration is only about one half of the input voltage).

6. Repeat the procedure with the other wheel.

7. Verify that the detector faces the prism and does not receive reflections from other

sources. Cover the prism and check if the voltmeter’s voltage drops to around 0V.

8. Return calibration switch 6 to the OFF position and you have about 50 seconds to

put back the detector’s cover. After a minute and a half the red LED starts flashing

once every 5 seconds, approximately.

3.4.2 Adjusting the detector using an external monitor

1. Connect a monitor to a TRA-1B adapter at the TV In +/- terminals

2. Power on the monitor

3. Turn the alignment switch (DIP SW 6) to the calibration position (ON)

i

Note

Do not power on the detector before the DIP SW 6 has been switched to the

calibration position (ON).

4. Turn the detector power ON. Attention –During calibration, the detector is in a fault

mode

TBD-8100

© 2017 –Telefire Fire & Gas Detectors Ltd Revision 1.00 November 2017

–Page 8 of 10 –

5. Turn switch 3 to the OFF position. In this position, the detector’s data is displayed

on the monitor

Figure 7 The Monitor’s Display

6. Using the detector’s adjustment wheels, swivel it around the horizontal and vertical

axes until the prism’s image reaches the center of the monitor; then, by fine tuning,

reach a maximum signal strength

In certain cases, the maximum signal strength center might be reached when the

prism is not at the monitor’s center

Additionally, the RM voltage can be measured at points 3(+) and 4(-). The voltage

should approach 24Vdc

7. Slowly turn one of the adjustment wheels in one direction while watching the HL1-

HL5 LEDs. As the detector approaches optimum calibration, the number of lit green

LEDs increases from left to right

i

Note

In some cases (usually when the distance between the detector and the

prism is less than 10 m), there is a need to attach the black patch, supplied

with the detector, onto the transmitter’s lenses

The detector would signal, by lighting up the red led, during the initial

adjustment, that the patch must be attached.

8. If the number of lit LEDs starts decreasing, it means that you are moving away from

the optimum direction –Retract until you reach a maximum number of lit LEDs

9. Measure the voltage between points 3 and 4 (RM) in the XT1 adapter

10. Maximize the voltage so that it approaches 24Vdc, as near as possible (at a small

operating range of the detector, when the patch is attached to the lens, the actual

voltage measured during calibration is only about one half of the input voltage)

11. Repeat the procedure with the other wheel

12. Verify that the detector faces the prism and does not receive reflections from other

sources. Cover the prism and verify that the voltmeter’s voltage drops to around 0V

13. Revert calibration switch 6 to the OFF position, and you have about 50 sec to return

detector’s cover. After a minute and a half, the red LED starts flashing once every

four seconds, approximately

TBD-8100

© 2017 –Telefire Fire & Gas Detectors Ltd Revision 1.00 November 2017

–Page 9 of 10 –

3.5 Testing the Detectors in the Field after Installation

i

Note

Ensure that the control panel is in walk test mode before testing the

detectors.

1. Execute the detector field-test:

2. Cover the prism with a non-transparent material (cardboard)

3. Ensure that the detector does not enter a fault status for a period of 5 seconds, and

after 20 seconds the control panel indicates a fault

4. Verify that the detector’s red LED flashes every 1 second

5. Once the cardboard has been removed from the prism, verify, that the detector

returns to normal operation and the red LED flashes once every 5 seconds

6. Cover 70% of the prism, and induce an alarm

This action can also be carried out by bringing a magnet near the display LED in the

optional TBD-8100R module, provided the LED is connected to the detector

7. Ensure that the detector is programmed in the appropriate matrices as specified by

the planning consultant.

3.6 Troubleshooting

Fault

Possible cause

Action

The red LED flashes every

second.

The voltage supplied to the

detector is not in the

allowed range (8-28V).

Check and correct the

voltage feeding the

detector.

All green LEDs are flashing

(see Figure 2).

The signal emitted by the

transmitter is too strong

Attach the black round

patch (supplied with the

detector) to the transmitter.

The red LED is lit

continuously.

The transmitter does not

emit a signal.

Adjust the detector per

section 3.4

The green LEDs are not on.

No power to the detector.

Check the voltage at points

1-2 (24Vdc) in the detector.

TBD-8100

© 2017 –Telefire Fire & Gas Detectors Ltd Revision 1.00 November 2017

–Page 10 of 10 –

4 Specification

Operating Range

One prism.............................................................. 8 to 50 meters

Two prisms ............................................................ 50 to 75 meters

Four prisms............................................................ 75 to 100 meters

Maximum detection area............................................... 1,800 m2

Prism

Dimensions (W / H / D) .......................................... 100 / 100 / 10 mm

Weight ................................................................... 75 g

Detector dimensions (W / H / D).................................... 76 / 99 / 144 mm

Detector weight............................................................. 450 gr.

Operating Temperature range....................................... -25°C –+55°C

Relative Humidity Range .............................................. 10% –93% non-condensing

Nominal voltage supply................................................. 24Vdc

Maximum current consumption (24Vdc)

Quiescence or Alarm State.................................... 20mA

during calibration.................................................... 50mA

Local Indication

normal status: HL4 LED flashes for 0.3 seconds once every 4 seconds

Alarm: HL4 LED constantly lit

Fault: The HL4 LED flashes every second

Error Message:

You can Figure out the type of fault by watching the combination of the HL1, HL2

and HL3 LED flashes, while the DIP SW 5 switch is raised.

Outputs......................................................................... 2

Alarm output: Activated during each alarm situation until “Return” is implemented

Fault output: activated during a fault until it is repaired

All values are nominal. Specifications are subject to change without prior notice

5 Certification

Telefire’s TBD-8100 Conventional Beam Detector has the following approvals:

SI 1220 Approved

GOST Approved

Table of contents

Other Telefire Security Sensor manuals

Popular Security Sensor manuals by other brands

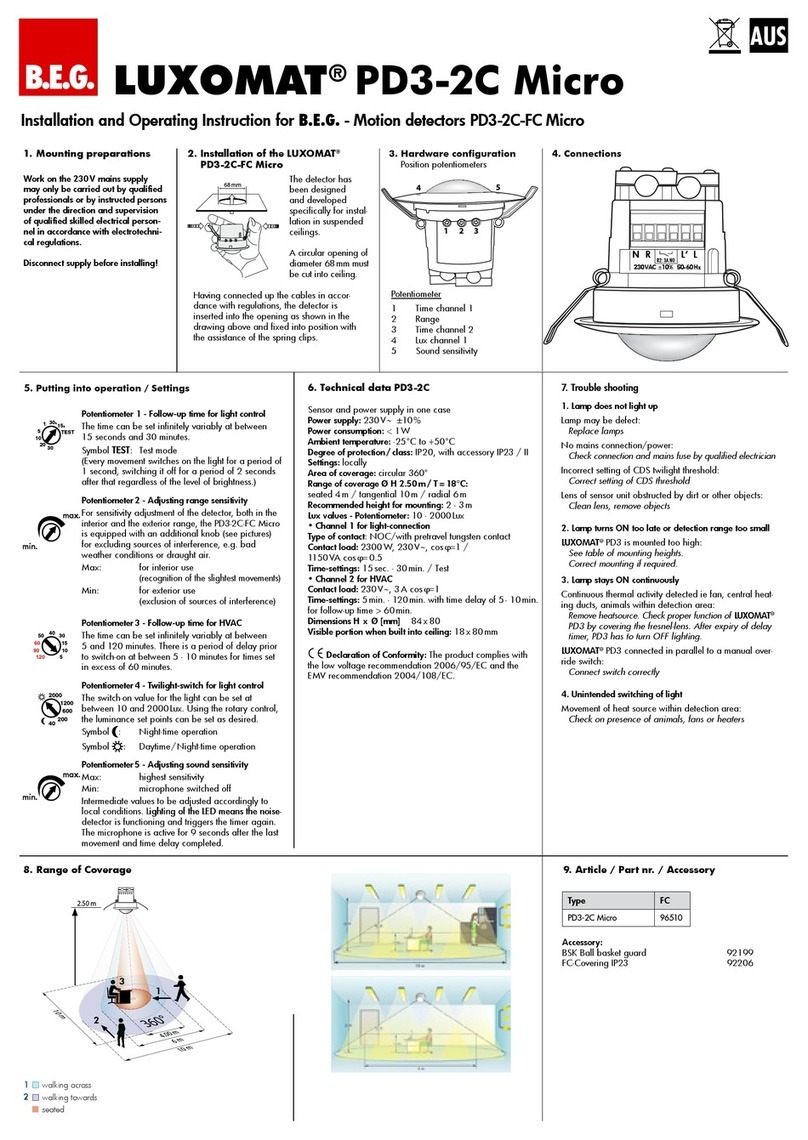

LUXOMAT

LUXOMAT PD3-2C-FC Micro Installation and operating instruction

Saxby Lighting

Saxby Lighting 90978 instruction manual

Endress+Hauser

Endress+Hauser USR30 technical information

PCB Piezotronics

PCB Piezotronics IMI Sensors M641B12 Installation and operating manual

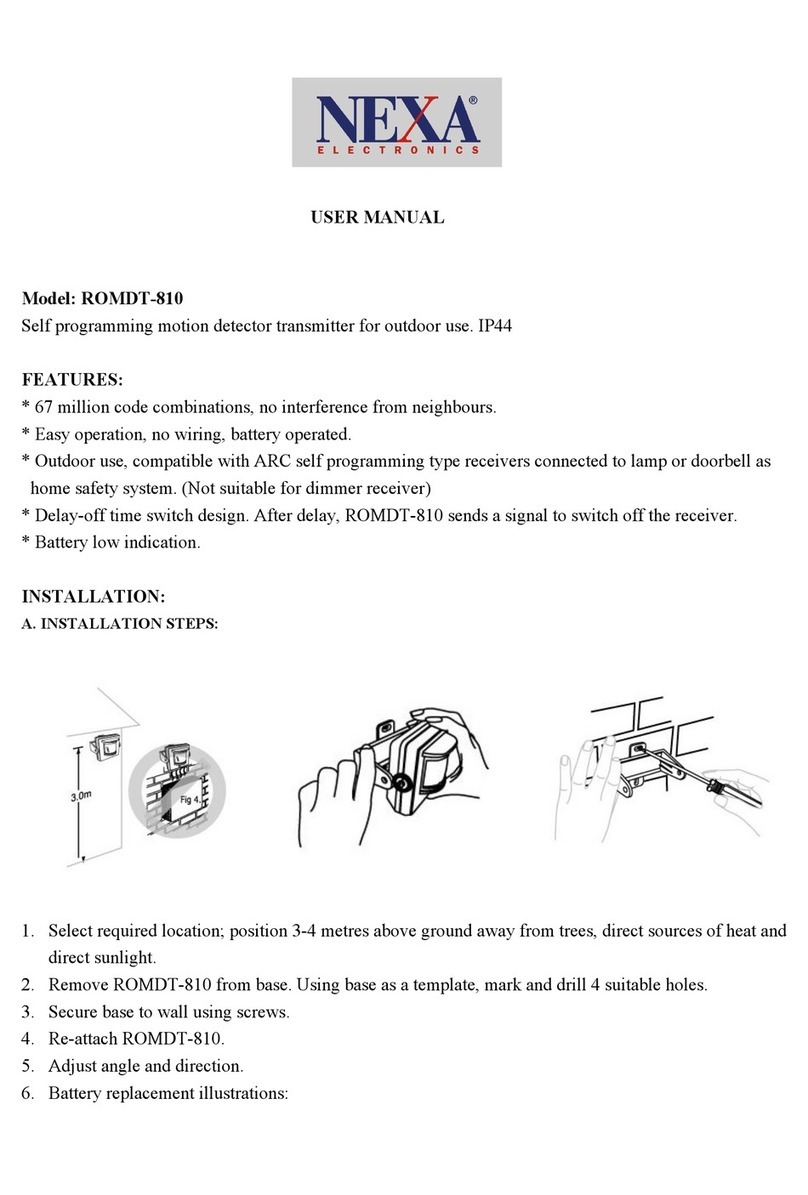

Nexa

Nexa ROMDT-810 user manual

MSA

MSA ALTAIR 4XR quick start guide