basic coatings B0626 Instruction manual

OVER STAINS AND GAME LINE PAINTS

For Stains: Allow stains to dry per manufacturer’s

directions or longer depending on

environmental conditions. Apply 2 coats of

a Basic Coatings’ Quick Dry Sealer and 2

coats Basic Coatings’ finish.

For Game Line Paints: Please refer to Basic Coatings Technical

Bulletin, Approved Game Line Paints and

Procedure, for proper application and a

current list of approved paints.

Note: A TEST BOARD IS RECOMMENDED WITH ANY STAIN/GAME

LINE PAINT TO INSURE COMPATIBILITY AND COLOR ACCEPTANCE.

Technical Data

©Basic Coatings • All Rights Reserved. • 1001 Brown Avenue • Toledo, Ohio 43607-0127

800-441-1934 • bcinfo@basiccoatings.com • www.basiccoatings.com Quick Dry Sealer • 01.2015 • Page 1

QUICK DRY SEALER

Technical Data

Basic Coatings’ Quick Dry Sealers are oil-modified urethanes designed to penetrate and seal bare wood surfaces quickly before

finishing. Quick Dry Sealers leave a clear high film build layer that is typically ready to sand in four to six hours.

Polyurethane Quick Dry Sealer for Wood Floors

FEATURES

• Excellent Penetration into Bare Wood

• Easy Application

• Light in Color

• Contains No Stearates

• Available in 5 gallon pails

RECOMMENDED USES

• Basketball, Volleyball and Racquetball Courts

• Multipurpose Rooms, Stages and other Recreational Wood Floors

• Ideal for Enhancing the Natural Beauty of Wood Floors

RECOMMENDED SYSTEMS

New Installations/Newly Sanded Floors

..........2 coats BasicCoatings’

Quick Dry Sealer and 2 coats of a Basic Coatings’ finish

B0626, B0628

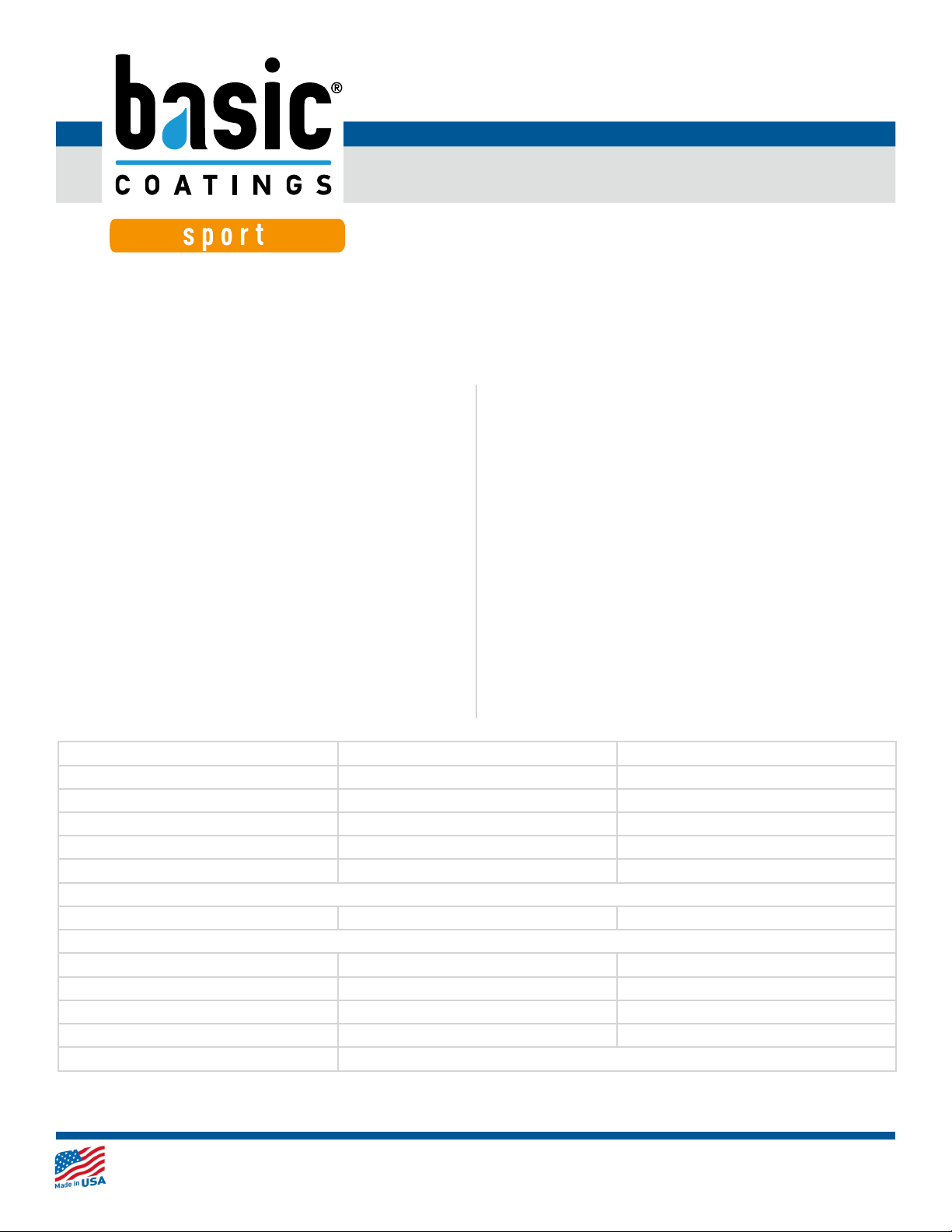

PROPERTIES Quick Dry Sealer Quick Dry Sealer 350

Color Slight Amber Slight Amber

Solid Content 35% 30%

Viscosity (cps) 15 15

VOC <550 g/L <350 g/L

Flash Point 100°F 57°F

Dry Time - Recoat 4 - 6 hours 4 - 6 hours

Coverage 300 - 600 sq. ft. / Gal (8 - 15 sq. M/L) 300 - 600 sq. ft. / Gal (8 - 15 sq. M/L)

Clean Up Mineral Spirits Mineral Spirits

Storage Do not store above 120°F (49°C) Do not store above 120°F (49°C)

Packaging 5 US gal (18.9 L) 5 US gal (18.9 L)

Application Basic Coatings’ T-bar applicator, lamb’s wool applicator, or brush

©Basic Coatings • All Rights Reserved. • 1001 Brown Avenue • Toledo, Ohio 43607-0127

800-441-1934 • bcinfo@basiccoatings.com • www.basiccoatings.com

SURFACE PREPARATION

1. For new installations, refer to NWFA/MFMA specifications

and accepted procedures for acclimation of the wood, floor

preparation, and sanding.

2. Before sanding, clean the floor using Basic Coatings’ Squeaky

Cleaner following label instructions. Cleaning should be done to

remove contaminants from the floor.

3. Sand floors using accepted NFWA/MFMA procedures. All old

finish must be removed. A NIOSH dust mask should be worn

during sanding.

4. Finish sanding with new 120-grit screens is recommended.

5. Vacuum. Tack the floor with 3-4 clean terry cloth tack towels

dampened with mineral spirits to remove all dust caused by the

sanding and screening process. Tack until no residue collects on

the towels. Allow the floor to dry with good ventilation.

FINISH APPLICATION

Always maintain adequate ventilation during all phases of the coating

and drying process.

1. Stir product well before application.

2. Using Basic Coatings’ Applicator or lamb’s wool applicator,

apply

Quick Dry Sealer at the recommended coverage rate. Apply

with the grain.

3. Allow to dry, times will vary depending on conditions, usually

4 to 6 hours. Use air blowers to dry corners and dead air spots

thoroughly.

4. Abrade floor with new 100 to 120 grit screens is recommended.

5. Vacuum. Tack with 3 - 4 clean terry cloth tack towels dampened

with virgin mineral spirits to remove dust. Tack until no dust

residue collects on the towels. Allow the floor to dry with good

ventilation.

6. Apply second coat or finish coat in the same manner or following

manufacturers recommended instructions.

DRY TIME

Typical dry time is 4 to 6 hours depending on environmental

conditions. Allow longer dry times in low temperature or high

humidity environments.

PRECAUTIONS

KEEP OUT OF REACH OF CHILDREN. FOR PROFESSIONAL USE

ONLY.

CAUTION! COMBUSTIBLE. VAPOR AND SPRAY MIST HARMFUL.

CONTAINS MINERAL SPIRITS. MAY CAUSE DIZZINESS,

HEADACHE OR NAUSEA. CAUSES IRRITATION.

NOTICE: Reports have associated repeated and prolonged

occupational overexposure to solvents with permanent brain

and nervous system damage. Intentional misuse by deliberately

concentrating and inhaling the contents may be harmful or

fatal. Harmful or fatal if swallowed. Keep away from heat,

sparks and flame. Do not smoke. Extinguish all pilot lights and

turn off heaters, non-explosion-proof electrical equipment

and all other sources of ignition until vapors are gone.

Prevent build-up of vapors. Use with adequate ventilation. Do

not breathe vapors, dust or spray mist. Wear an appropriate,

properly fitted respirator (NIOSH approved) during and

after application unless air monitoring demonstrates vapor

mist levels are below applicable limits. Follow respirator

manufacturer’s directions for respirator use. Provide fresh

air ventilation during and after application. Wear protective

clothing. Close container after each use. Avoid contact with

eyes, skin and clothing. Wash thoroughly after handling. In case

of spillage, absorb and dispose of in accordance with federal,

state and local applicable regulations. To avoid spontaneous

combustion, soak oil rags and waste daily in water-filled metal

containers. Do not store above 100°F (38°C).

FIRST AID: If swallowed, call a physician immediately. Do NOT induce

vomiting. If affected by inhalation of vapor, remove to fresh air. If

breathing is difficult, get medical attention immediately. In case of

eye contact, flush immediately with plenty of water for 15 minutes

and call a physician. For skin, wash thoroughly with soap and water.

OBLIGATION OF MANUFACTURER

The following is made in lieu of all warranties, expressed or implied:

Seller’s and manufacturer’s only obligation shall be to replace such

quantity of the product proved to be defective. Neither seller nor

manufacturer shall be liable for any injury, loss or damage, direct

or consequential, arising out of the use of or the inability to use the

product. Before using, the user shall determine the suitability of the

product for the intended use and user assumes all risk and liability

whatsoever in connection therewith. The foregoing may not be altered

except by an agreement signed by officers of seller and manufacturer.

QUICK DRY SEALER

Quick Dry Sealer • 01.2015 • Page 2

This manual suits for next models

1

Other basic coatings Food Saver manuals