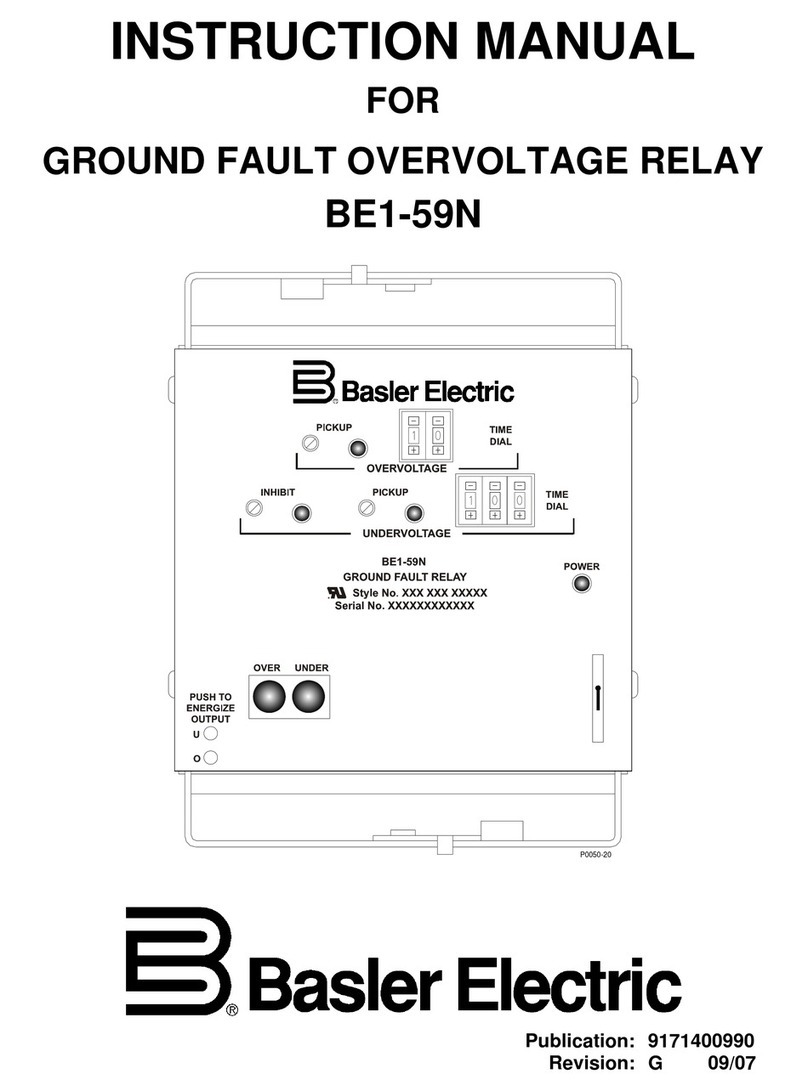

BE1-59N

APPLICATION

2

PURPOSE

The available fault current for single-phase-to-ground

Faults is very limited for ungrounded systems and

systems that are grounded through a high resistance.

This current limiting reduces the possibility of extensive

equipment damage, and eliminates the need for a

neutral breaker by reducing the fault current below the

level required to sustain an arc.

But it remains important to detect and isolate single-

phase- to-ground faults in order to prevent their evolu-

tion into more dangerous faults such as phase-to-

phase-to-ground and three-phase-to-ground faults.

Sensitive voltage relays can be used to detect ground

faults where the fault current is very small. The

BE1-59N is especially suited to the task.

HIGH RESISTANCE GROUNDING

A common method of grounding an ac generator is to

connect a distribution transformer between the neutral

of the generator and the station ground. The distribu-

tion transformer’s primary voltage rating is equal to, or

greater than, the generator’s rated line-to-neutral

voltage. The distribution transformer secondary is rated

at 200/240 Vac or 100/120 Vac, and a resistor is con-

nected across the secondary winding. When reflected

through the transformer, the resistor is effectively a

high resistance.

RP= RS X N2

where RP is the effective primary resistance

RS is the actual value of the secondary resistor

N is the turns ratio of the distribution transformer

Available single-phase-to-ground fault current at the

generator terminals is greatly reduced by the high

effective resistance of the distribution transformer and

secondary resistor. The distribution transformer pro-

vides isolation for the protection scheme and reduces

the voltage to a convenient level.

The BEl-59N ground fault overvoltage relay is con-

nected across the secondary resistor to detect the

increase in voltage across the distribution transformer

caused by a ground fault in the generator stator

windings. A ground fault at the generator terminals will

result in rated line-to-neutral voltage across the trans-

former primary, while ground faults near the neutral will

result in lower voltages. The overvoltage relay set point

must be higher than any neutral voltage caused by

normal unbalances in order to avoid nuisance trips.

This will allow a certain percentage of the stator

windings to go unprotected by the overvoltage relay.

The overvoltage relay function typically protects 90 to

95% of the generator stator windings.

The BEl-59N ground fault overvoltage relay monitors

the fundamental frequency (50 or 60 Hz) voltage that

accompanies a ground fault, and is insensitive to the

third harmonic voltage present during normal opera-

tion.

One hundred percent protection of the generator stator

windings is obtainable with the optional overlapping

undervoltage element. The undervoltage element is

tuned to measure the third harmonic voltage, which is

present in the generator neutral under normal operat-

ing conditions. The undervoltage element detects the

reduction of the normal third harmonic voltage that

accompanies a ground fault near the neutral point of

the generator.

An undervoltage inhibit feature is included with the

third harmonic undervoltage element. This feature

supervises the operation of the ground fault relay to

prevent operation during startup and shutdown by

monitoring the generator terminal voltage.

UNGROUNDED SYSTEMS

The BEl-59N ground fault overvoltage relay is used to

detect ground faults on ungrounded three-phase-three-

wire systems. The relay is connected as shown in

Figure 1. A set of voltage transformers is wired with a

grounded wye primary and a broken delta secondary.

The BEl-59N is connected across the broken delta. It is

often necessary to connect a resistor across the

broken delta to avoid ferroresonance.

Figure 1 - Ungrounded 3-Phase, 3-Wire System