iii

CONTENTS

SECTION 1 GENERAL INFORMATION 1-1

Purpose ...................................................... 1-1

Description .................................................... 1-1

Definite Time Option ......................................... 1-1

Inverse Time Option .......................................... 1-1

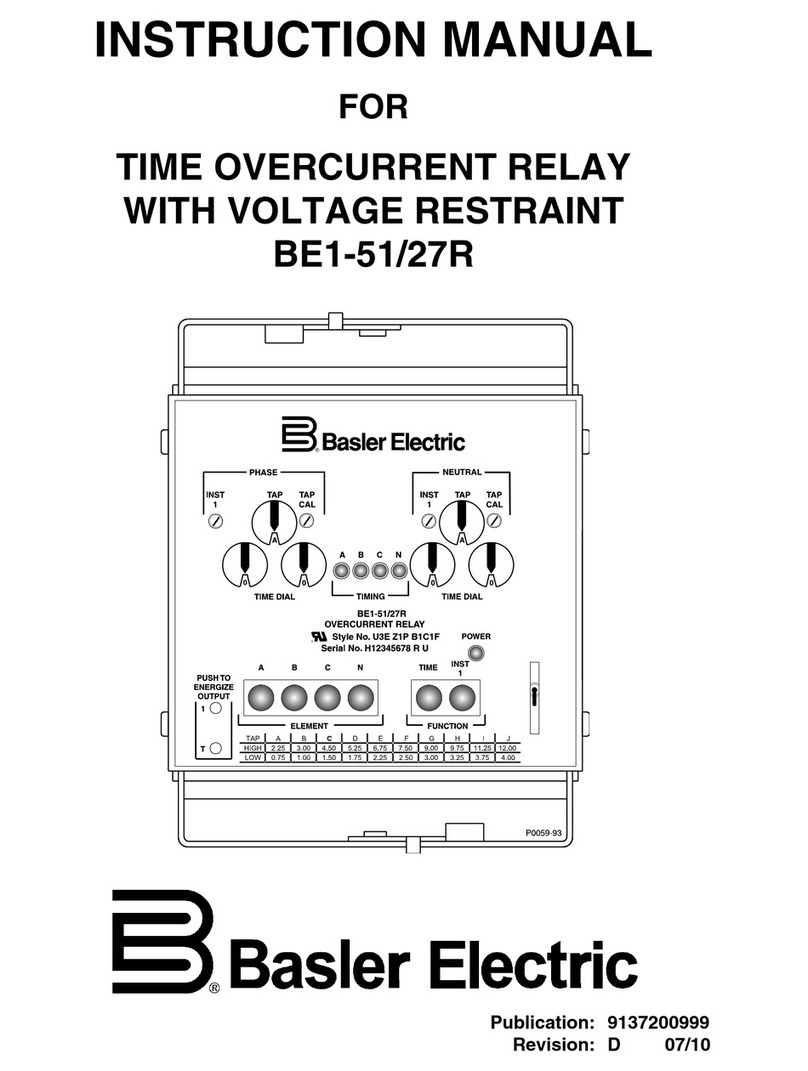

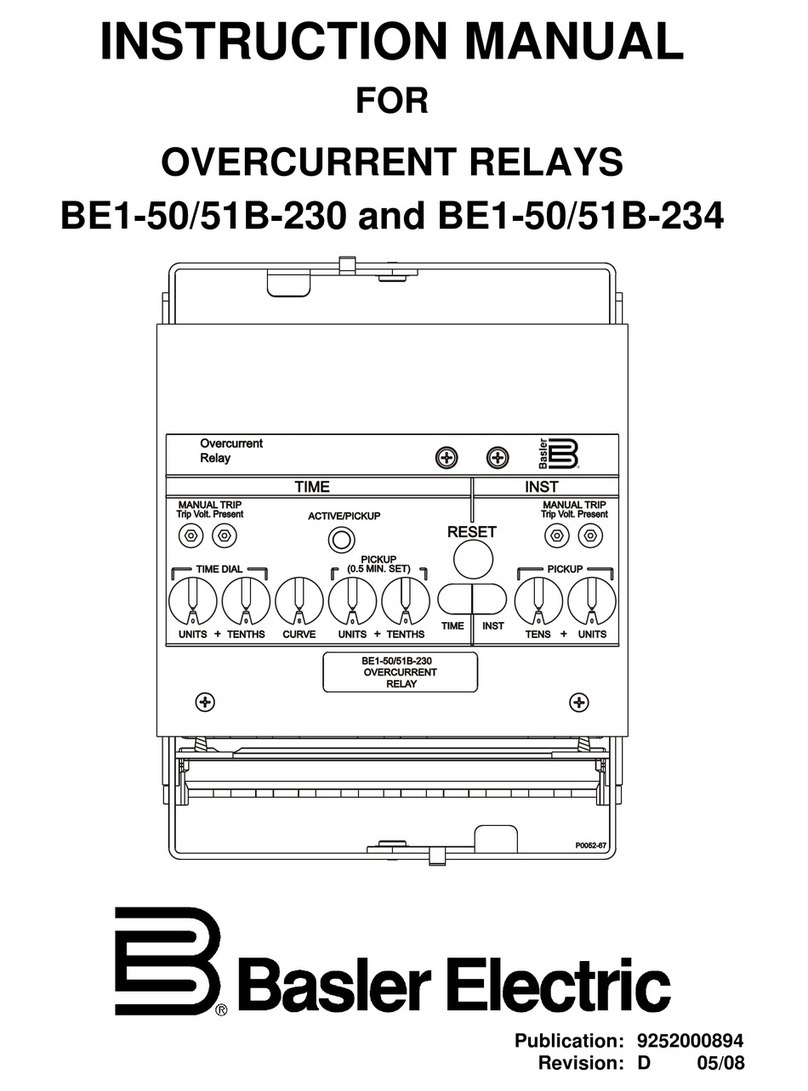

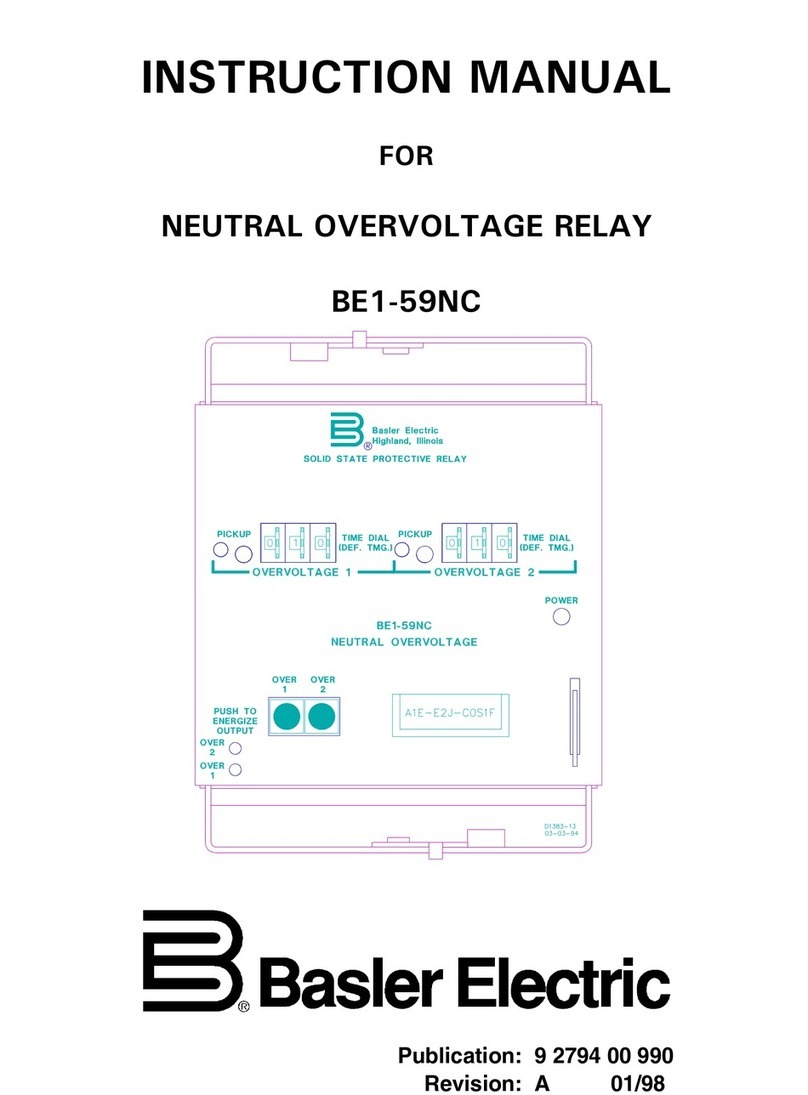

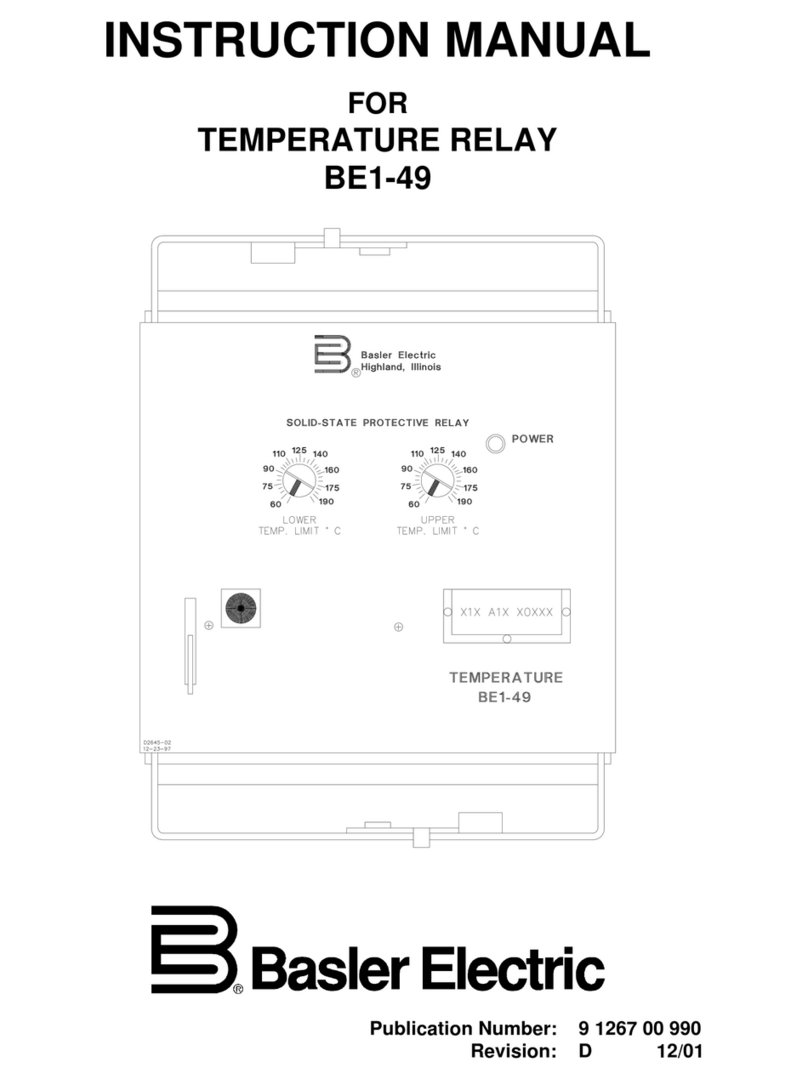

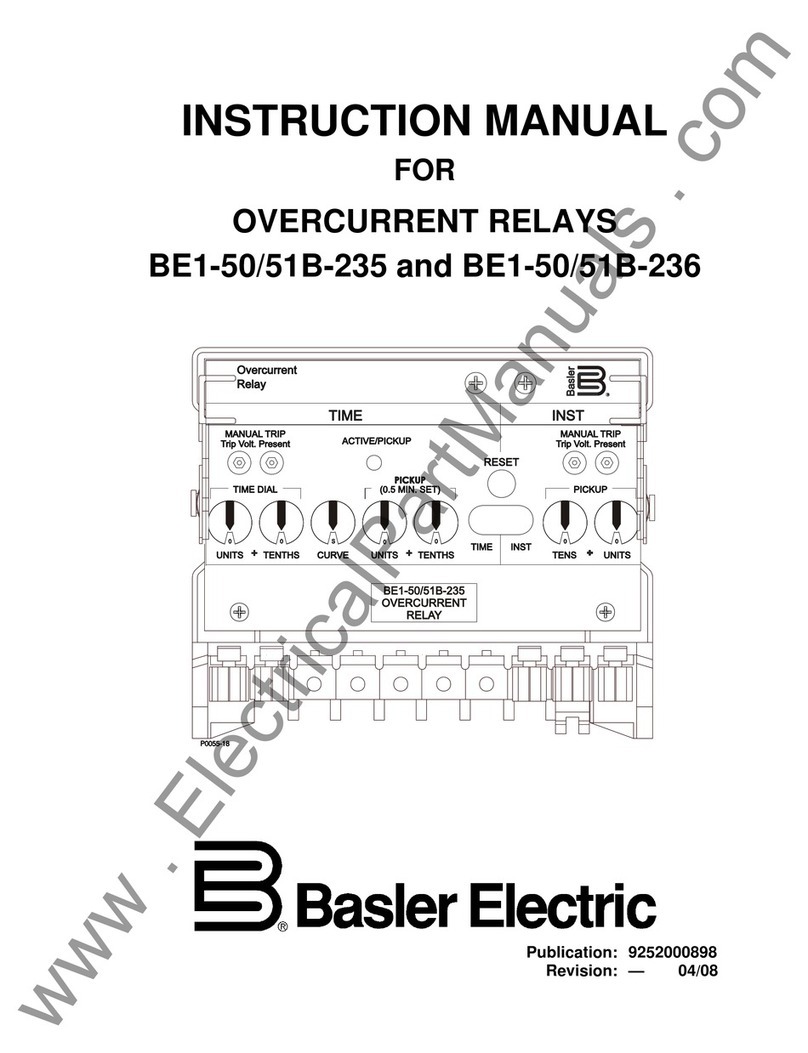

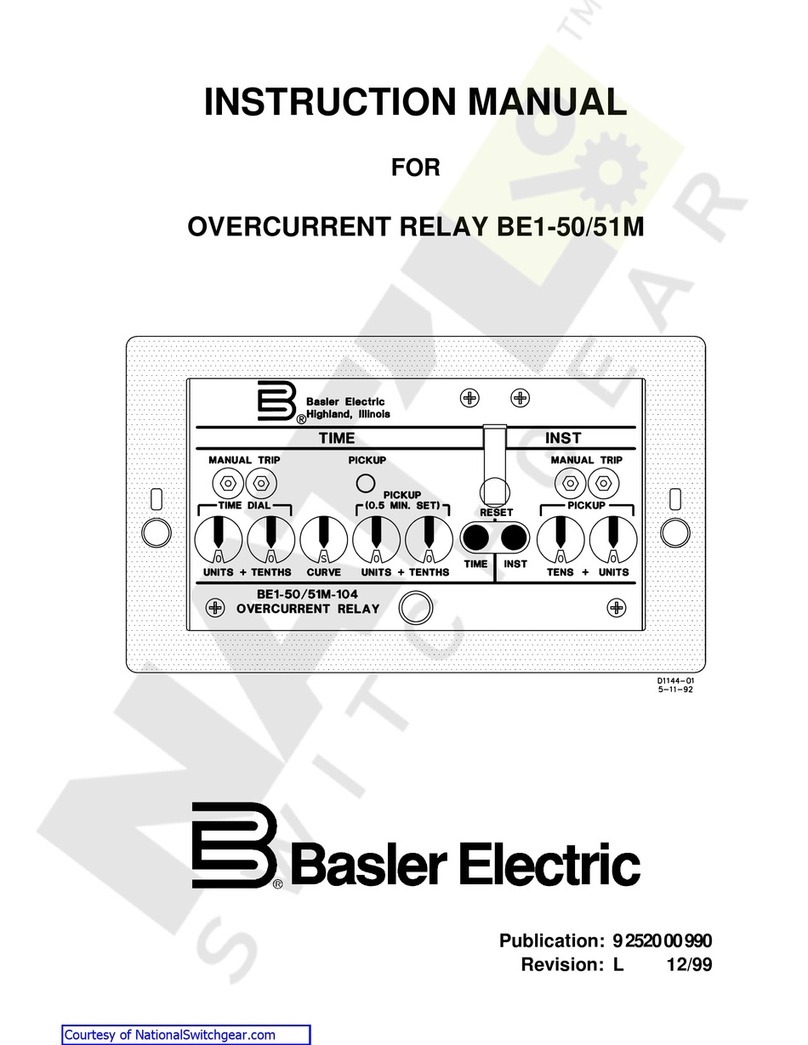

Relay Assembly ............................................. 1-1

Model and Style Number Description ................................ 1-1

Sample Style Number ........................................ 1-4

Style Number Identification Chart ............................... 1-4

Specifications .................................................. 1-5

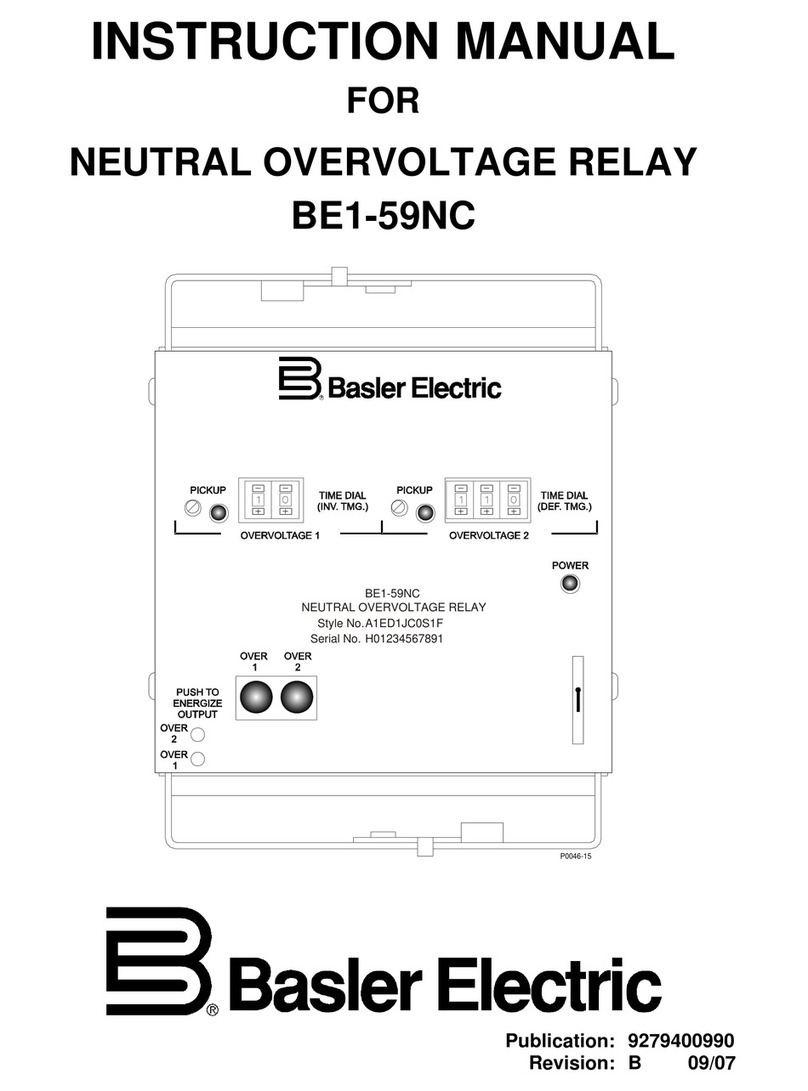

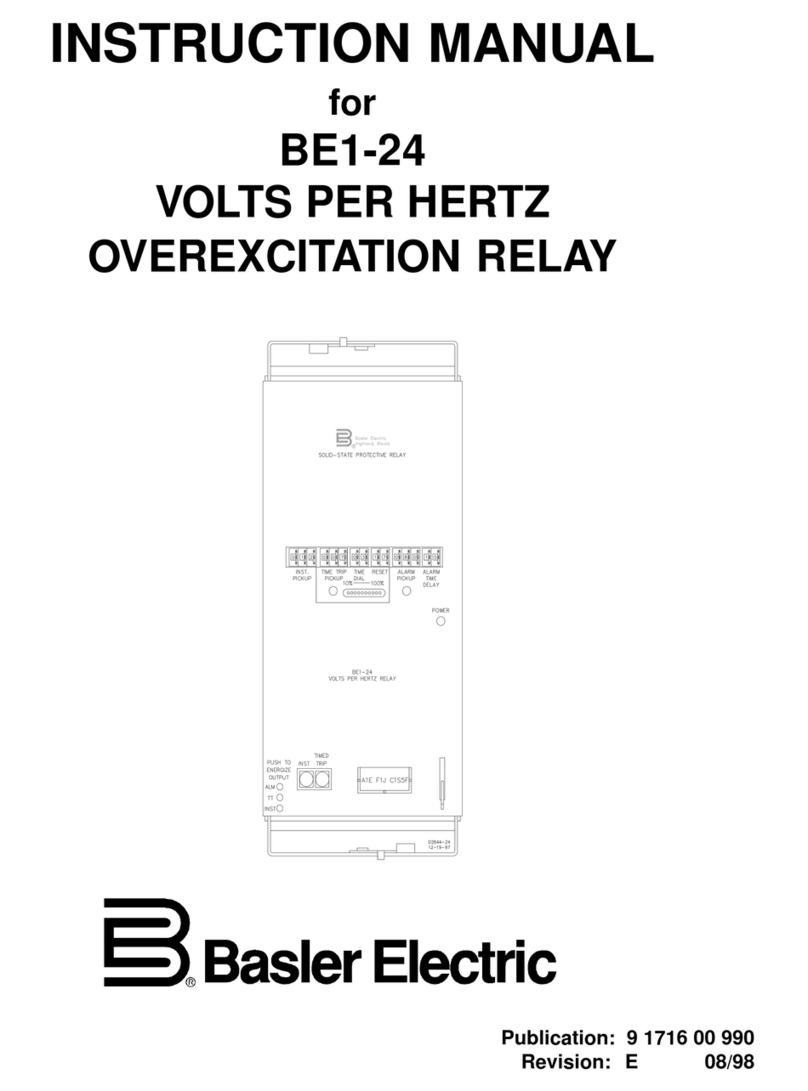

SECTION 2 CONTROLS AND INDICATORS 2-1

SECTION 3 FUNCTIONAL DESCRIPTION 3-1

Functional Description ........................................... 3-1

Sensing ................................................... 3-1

Power Supply ............................................... 3-2

Power Supply Status Contacts .................................. 3-2

Voltage Inhibit Circuit ......................................... 3-2

Input Conditioning Circuit ...................................... 3-2

Crystal Reference Oscillator ................................... 3-2

Synchronizer Circuit .......................................... 3-3

Reference Circuit ............................................ 3-3

Period Difference Circuit ...................................... 3-3

Period Difference To Frequency Difference Circuit .................. 3-3

Threshold Setting Comparator .................................. 3-3

Definite Time Delay Circuit (Timing Option E1) ..................... 3-3

Inverse Time Delay Circuit (Timing Option D1) ..................... 3-3

Relay Output ............................................... 3-3

Internally Operated Target Driver ................................ 3-4

Current Operated Target Driver ................................. 3-4

Target Indicator ............................................. 3-4

SECTION 4 INSTALLATION 4-1

General ....................................................... 4-1

Relay Operating Precautions ...................................... 4-1

Dielectric Test .................................................. 4-1

Relay Mounting ................................................ 4-1

S1 Case, Panel Drilling Diagram, Semi-Flush Mounting .............. 4-2

S1 Case, Outline Dimensions, Front View ......................... 4-2

S1 Case, Single-Ended, Semi-Flush Mounting, Side View ............ 4-3

S1 Case, Single-Ended, Semi-Flush Mounting, Outline Dimensions ..... 4-4

S1 Case, Single-Ended, Projection Mounting, Panel Drilling Diagram .... 4-5

S1 Case, Single-Ended, Projection Mounting, Rear View ............. 4-6

S1 Case, Single-Ended, Projection Mounting, Side View ............. 4-7

S1 Case, Double-Ended, Semi-Flush Mounting, Side View ............ 4-8

S1 Case, Double-Ended, Semi-Flush Mounting, Outline Dimensions .... 4-9