BE1-BPR General Information 1-1

SECTION 1 • GENERAL INFORMATION

DESCRIPTION

BE1-BPR Breaker Protection Relays are three-phase and neutral, microprocessor based relays designed

to provide power systems with protection and security against monitored breaker failure or to initiate multiple

shot breaker reclosings.

Theserelaysincorporateapowerfulmeansof programminginternalrelaylogic to satisfy awiderangeofuser

requirements without makingany relay hardware changes. Microprocessor based design provides the basic

features of a programmable logic controller (PLC) combined with an instantaneous overcurrent module.

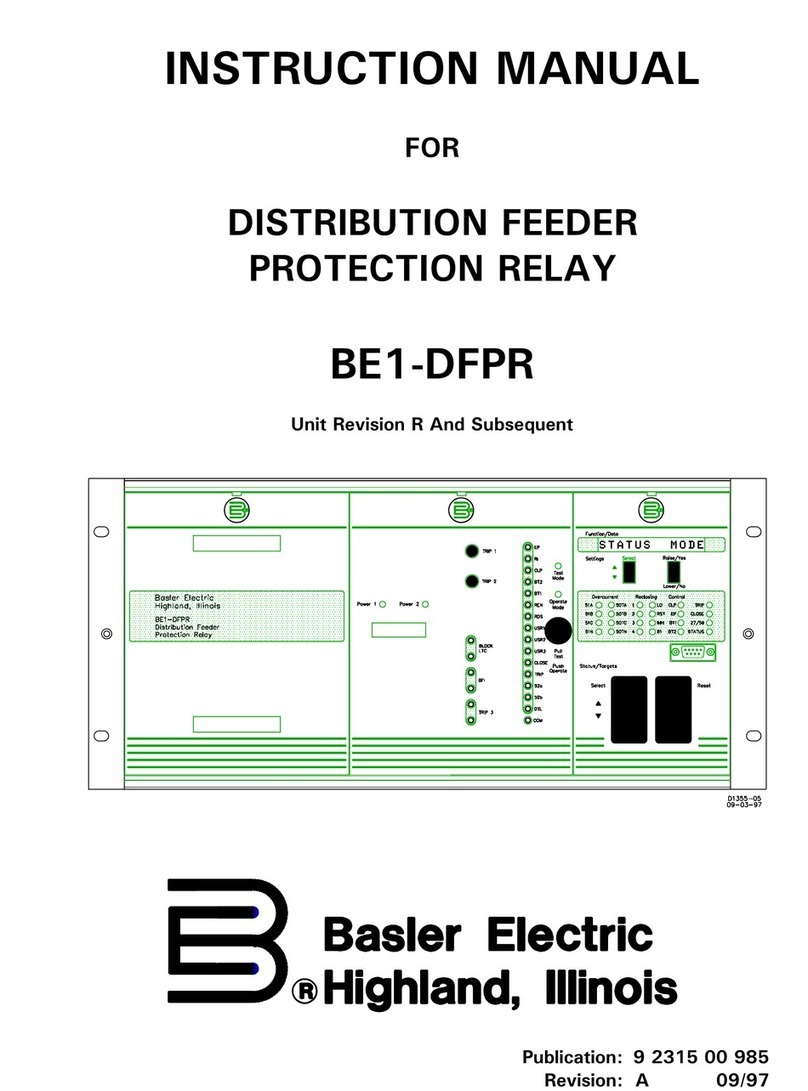

Cased in either a 19inchrack-mount or avertical panelmount , the relay offers installation versatility. A wide

temperature, 2 line by 16 character display provides diagnostic and setup information. Two RS-232 serial

ports (one each front and rear) and one RS-485 serial port (rear) provide remote communication and relay

control.

Built-in diagnostics andmonitoring features provideinformation for both thehealth of the relay and the health

of the breaker being monitored. Relay diagnostics include continuous background monitoring of the power

supplies, analog-to-digital (A/D) converter, random-access memory (RAM), read-only memory (ROM), and

electrically-erasableprogrammableROM(EEPROM). Adedicatedalarm(ALM)relay output providespower

supply, microprocessor, and software alarm status. Breaker diagnostics include a timing diagnostic log,

breaker contact duty monitoring, breaker resistor protection, and breaker arc detection. Other monitoring

features include oscillographic fault records and fault summary logs. BE1-BPR relays use the Inter-Range

Instrumentation Group (IRIG), Format B for high timing accuracy and resolution.

APPLICATION - STANDARD MODELS

Breaker Failure

BE1-BPR relays are intended to provide a preprogrammed solution for most breaker failure relaying

applications. Breaker failure relaying is the use of a current monitoring relay to determine whether or not

current continues to flow into a faulted circuit after a breaker has been instructed to interrupt the circuit. If

current continues to flow into the faulted circuit after a defined period of time has elapsed (sufficient for the

breaker to have interrupted the current), the circuit breaker is considered to have failed. Steps must then

be taken to trip the next set of breakers in the power system to prevent system damage. Breaker failure

schemes must be designed to isolate both the faulted circuit and the failed breaker.

Several reasons why a breaker fails to clear a fault are:

&

Trip circuit is open (broken wire, blown fuse, open trip coil).

&

Interrupting mechanism stuck, leaving a single phase of a three-phase circuit connected.

&

Interrupter flash-over due to the loss of dielectric strength through contamination or damage.

&

Operating mechanism failed to operate.

Breaker failure relays detect these conditions and initiate backup procedures.

Breaker failure relays are applied on a per breaker basis. That is, one breaker failure relay for each breaker

in the substation. BE1-BPR relay outputs must be arranged to initiate the tripping of all the circuit breakers

necessary to isolate the fault if the protected circuit breaker fails to operate. The relay may also need to

initiate transfer tripping of remote breakers to accomplish this task. Transfer tripping of the remote line end

for a breaker failure should also block reclosing of the remote circuit breakers. External lockout relays are

typically used to trip and block reclosing of the backup breakers because they normally require a positive

operator action to reset them.

Typically, breaker failure protection is applied to transmission and subtransmission systems. However,

breaker failureprotectionmay be applied to any portion of the power system where failureof a circuitbreaker

to operate properly could result in severe system damage or instability. Breaker failure protection can also

be used to selectively clear a failed breaker inastation with multiple buses without clearing the entire station.