BE1-46N Introduction iii

CONTENTS

SECTION 1 GENERAL INFORMATION 1-1

Description ................................................1-1

Principles of Symmetrical Operation ............................1-1

Model and Style Number .....................................1-1

Style Number Example ...................................1-2

Style Number Identification Chart ...........................1-2

Specifications ..............................................1-3

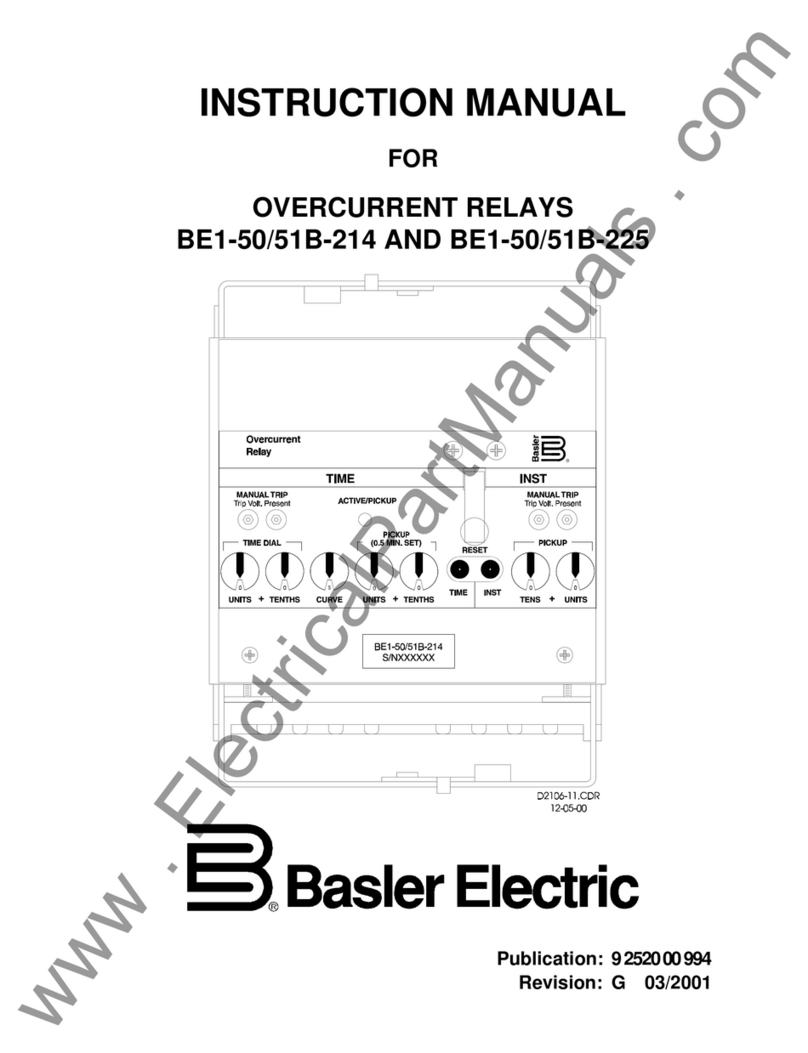

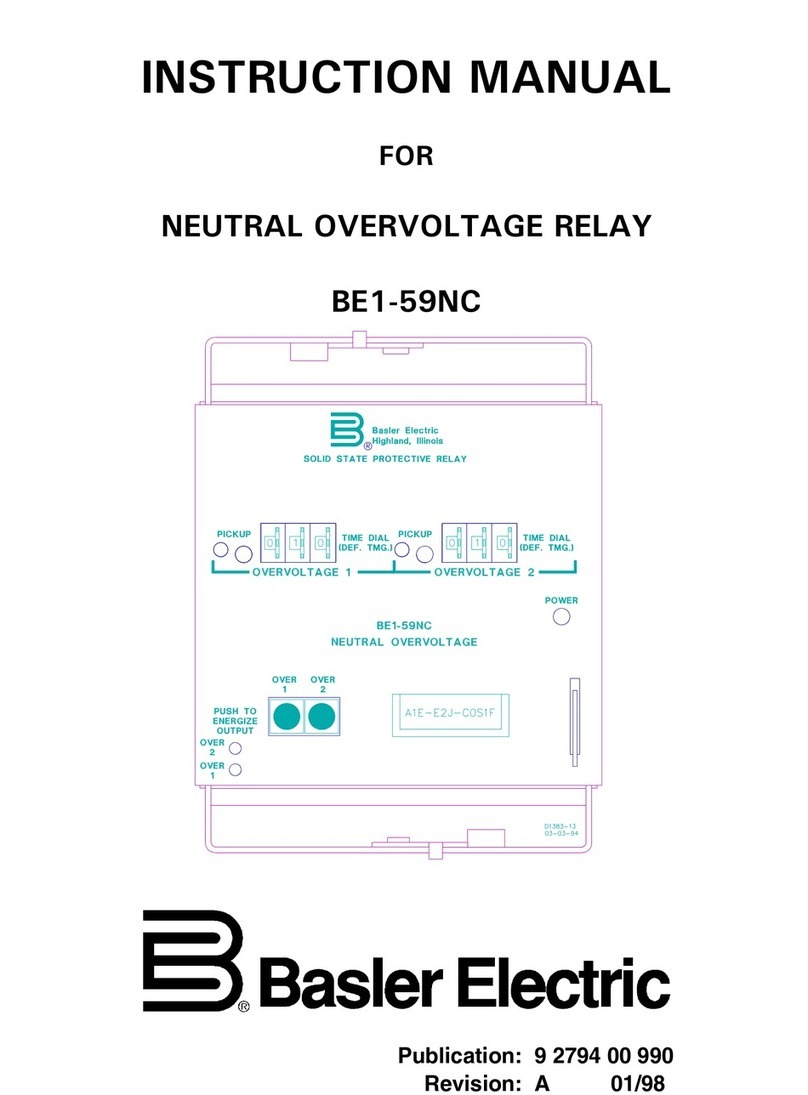

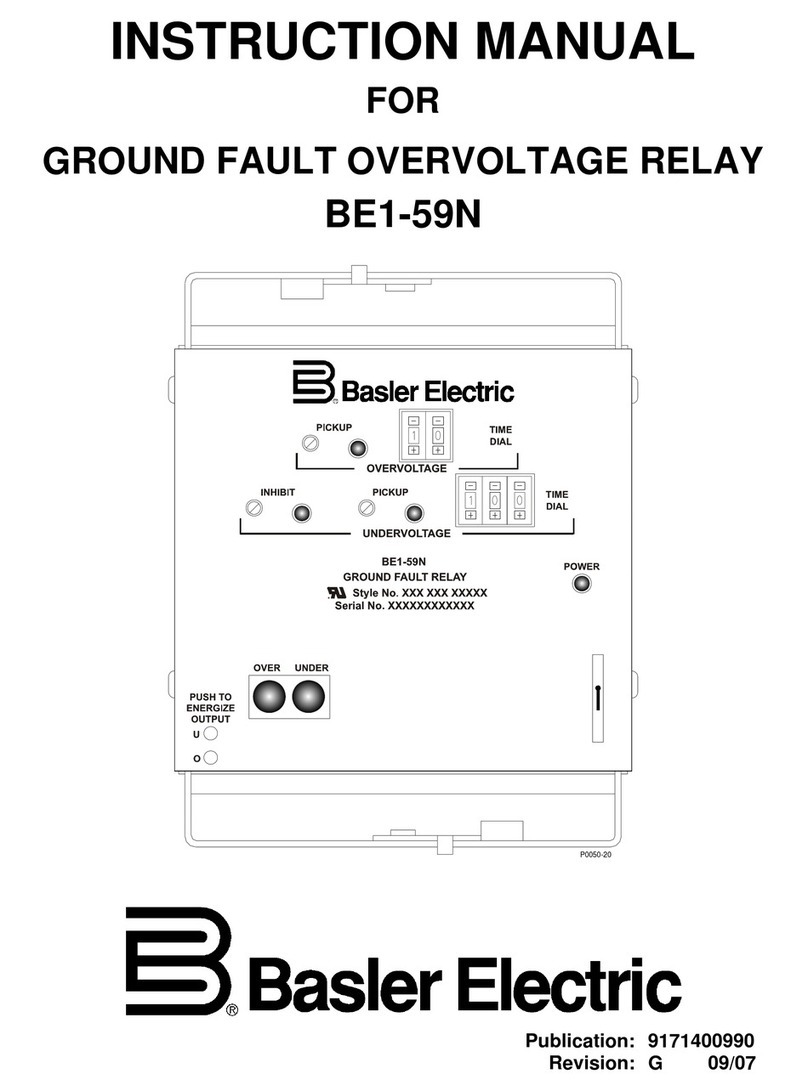

SECTION 2 HUMAN-MACHINE INTERFACE 2-1

Controls and Indicators ......................................2-1

SECTION 3 FUNCTIONAL DESCRIPTION 3-1

General ...................................................3-1

Input Sensing ..............................................3-1

Measuring I2...............................................3-1

Microprocessor .............................................3-2

Program Monitor ............................................3-2

Outputs ...................................................3-2

Power Supply ..............................................3-2

Power Supply Status Output ..................................3-3

Setting Consideration ........................................3-3

I nReference Level (Tap Value) ............................3-4

Alarm and Pickup ........................................3-4

K Setting ..............................................3-4

MAX TIME .............................................3-4

Calculation Example ........................................3-5

Setting Tap Adjust ..........................................3-5

Method 1, Single-Phase ..................................3-5

Method 2, Three-Phase ...................................3-6

Further Considerations .......................................3-7

Characteristic Curves ........................................3-8

SECTION 4 INSTALLATION 4-1

General ...................................................4-1

Relay Operating Precautions ..................................4-1

Dielectric Test ..............................................4-1

Mounting ..................................................4-1

S1 Case, Outline Dimensions, Front View ....................4-2

S1 Case, Panel Drilling Diagram, Semi-Flush Mounting .........4-3

S1 Case, Outline Dimensions, Rear View .....................4-4

S1 Case, Semi-Flush Mounting, Side View ...................4-5

S1 Case, Panel Drilling Diagram, Projection Mounting ..........4-6

S1 Case, Projection Mounting, Side View .....................4-7

Remote Meter Dimensions and Drilling Diagram ...............4-8

Connections ...............................................4-8

Typical DC Control Connections ............................4-9

Typical AC Sensing Connections ..........................4-10

Typical Internal Connections ..............................4-11

www . ElectricalPartManuals . com