BE1-951

2

FEATURES

PROTECTION

• Phase, Neutral, and Negative Sequence Instantaneous

Overcurrent elements with settable time delay: 50TP,

150TP, 50TN, 150TN, 50TQ, 150TQ

• Phase, Neutral, and Negative Sequence Time

Overcurrent elements: 51P, 51N, 151N, 51Q

(51P elements can have voltage restraint)

• Each overcurrent element can be set for forward,

reverse, or nondirectional control (67P, 67N, 67Q).

Directional control is by Positive (671), Negative (672),

Zero Sequence Voltage (670V) and Zero Sequence

Current (670I) polarized directional units.

• All U.S. and IEC timing curves plus user program-

mable curve

• Minimizes transient overreach and overtravel on

overcurrent elements

• Optional separate ground current input provides zero

sequence current polarization and/or ground

overcurrent protection for a separate ground CT.

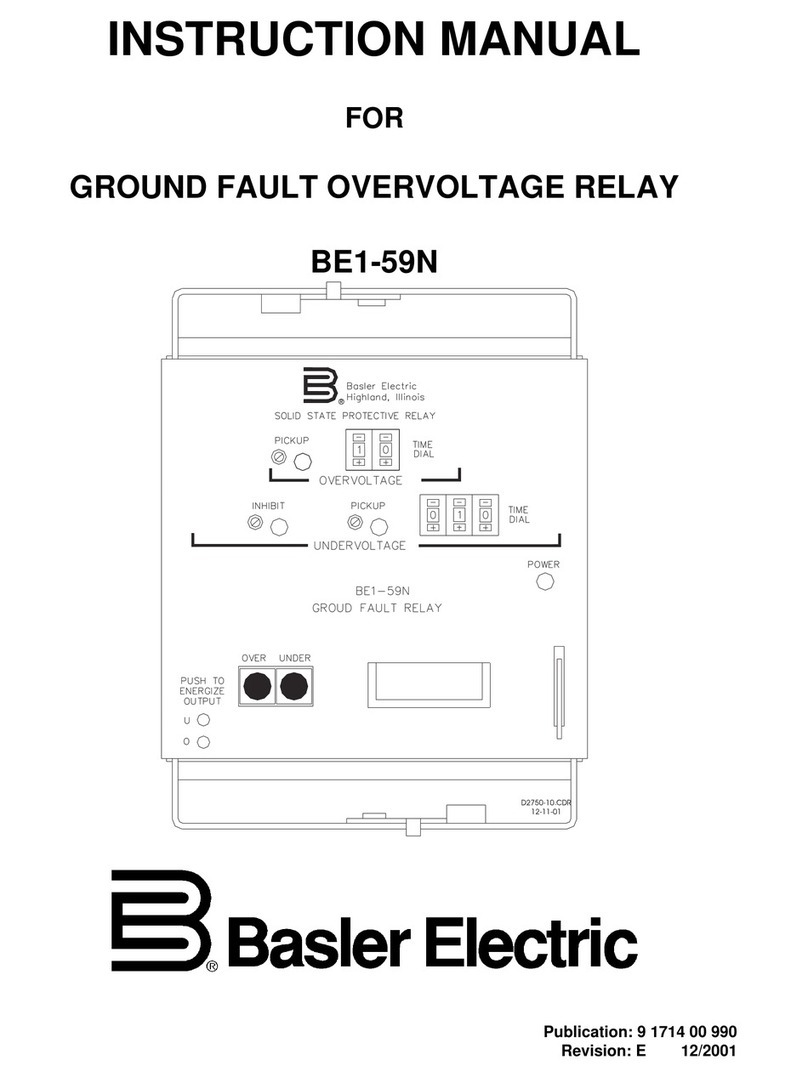

• Phase Undervoltage and Overvoltage elements:

27P, 59P. Elements use a 1 of 3, 2 of 3, or 3 of 3 logic,

and monitor either line-line or line-ground voltages.

• Auxiliary Undervoltage and Overvoltage elements:

27X, 59X, 159X. Elements monitor either fundamental or

third harmonic on the optional auxiliary 4th VT input, or

fundamental phase residual, 3V0, of the phase inputs.

• Overexcitation, volts per Hertz element: 24

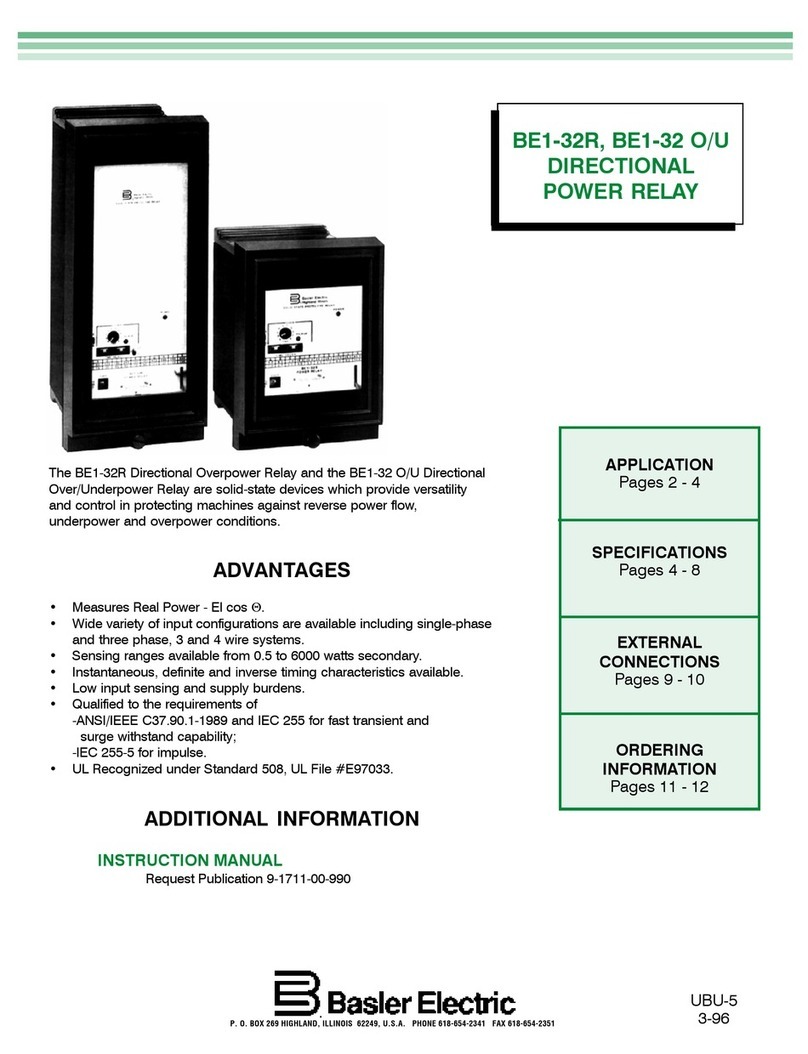

• Forward or Reverse Power: 32

• Negative Sequence Overvoltage element: 47

• Over/Under Frequency elements: 81, 181, 281, 381,

481, 581

• Each 81 element can be assigned to monitor 3 phase VT

input (VP) or Auxiliary voltage input (Vx).

• Breaker Failure protection function: BF

• Two general purpose logic timers: 62, 162

• Programmable Logic using BESTlogic

• Four protection setting groups with external or automatic

(cold load pickup, load, unbalance, recloser shot)

selection modes

• Sync check with dead line/dead bus voltage monitor

logic, 25, 25VM (Requires optional 4th VT sensing

circuit)

• Fuse loss detection protects against false trip due to loss

of voltage sensing: 60FL

CONTROL

• Four shot recloser with zone sequence coordination and

sequence controlled protective element blocking

functions

• Virtual breaker control switch—controllable from both

HMI and com. ports: 101

• Four virtual selector switches—controllable from both

HMI and com. ports: 43, 143, 243, 343

• Virtual lockout latches: 86, 186. Status is stored in

EEPROM.

• Communication port control of 101 and #43 switches

allows for SCADA control of relay and breaker

INSTRUMENTATION

• Real time A, B, C phase current, voltage, and frequency

and derived neutral and negative sequence current and

voltage

• Real Time per phase and 3 phase Watts, Vars, and

3 phase Power Factor

REPORTS

• Current demands for phase, neutral, and negative

sequence currents, and forward and reverse watts and

vars—magnitudes and time stamps are recorded for

today's peak, yesterday's peak, and peak since reset

• Optional 4000 point log of demand readings

• kWh and kvarh, forward and reverse

• Breaker operations counter and contact interruption duty

FAULT RECORDING

• 255 event sequence of events report with I/O and alarm

sub-reports

• Fault Reporting; 1 or 2 oscillography records per fault

report

• 16 fault summary reports; two most recent Fault

Summary Records saved to non-volatile memory

• Total number of oscillography records settable from 6 to

16

• Total of 240 cycles oscillography memory @ 12

samples/cycle

• COMTRADE format

• Load compensated distance to fault

COMMUNICATION PORTS

• Three independent general purpose communication

ports

- Front RS-232 ASCII communications

- Rear RS-232 ASCII communications

- Rear RS-485 ASCII, Modbus, DNP 3.0, and TNP

protocols

• IRIG time sync (unmodulated)

SELF TEST AND ALARM FUNCTIONS

• Relay fail, major alarm, and minor alarm LEDs, and

fail-safe alarm output contact (closed or open)

See style chart, page 12, for ordering information

• Extensive internal diagnostics monitor all internal

functions of the relay

• More than 20 additional alarm points—programmable

for major or minor priority

Including:

- Phase current, and forward and reverse watt and

var demand alarm

- Neutral and negative sequence unbalance demand

alarms

- Three breaker alarm points programmable for slow trip,

interruption duty threshold, or operations counter

- Trip circuit voltage and continuity monitor

- Close circuit monitor via BESTlogic

PROGRAMMABLE I/O

• Four programmable inputs

• Five programmable outputs and one dedicated

programmable alarm output

Courtesy of NationalSwitchgear.com