9282300990 Rev L BE1-87B General Information i

SECTION 1 • GENERAL INFORMATION

TABLE OF CONTENTS

SECTION 1 • GENERAL INFORMATION................................................................................................1-1

GENERAL............................................................................................................................................1-1

FEATURES..........................................................................................................................................1-1

Standard Features..........................................................................................................................1-1

MODEL AND STYLE NUMBER..........................................................................................................1-1

Style Number Example...................................................................................................................1-2

SPECIFICATIONS...............................................................................................................................1-2

Current and Voltage Settings..........................................................................................................1-3

Frequency.......................................................................................................................................1-3

Pickup Accuracy .............................................................................................................................1-3

Current Rating ................................................................................................................................1-3

Voltage Rating ................................................................................................................................1-3

Targets............................................................................................................................................1-3

Isolation...........................................................................................................................................1-3

Surge Withstand Capability (SWC) ................................................................................................1-3

Impulse Test ...................................................................................................................................1-3

Radio Frequency Interference........................................................................................................1-3

Electrostatic Discharge (ESD)........................................................................................................1-4

UL Recognition ...............................................................................................................................1-4

GOST-R Certification......................................................................................................................1-4

Environment....................................................................................................................................1-4

Shock..............................................................................................................................................1-4

Vibration..........................................................................................................................................1-4

Weight.............................................................................................................................................1-4

Case Size........................................................................................................................................1-4

Figures

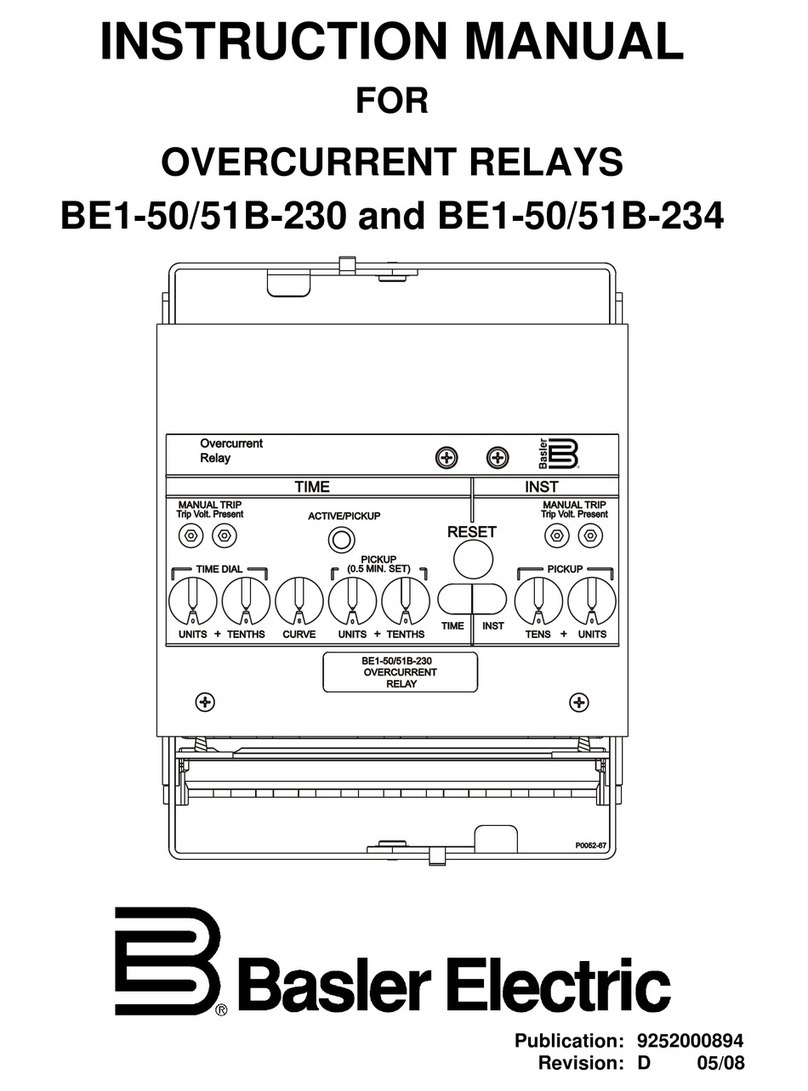

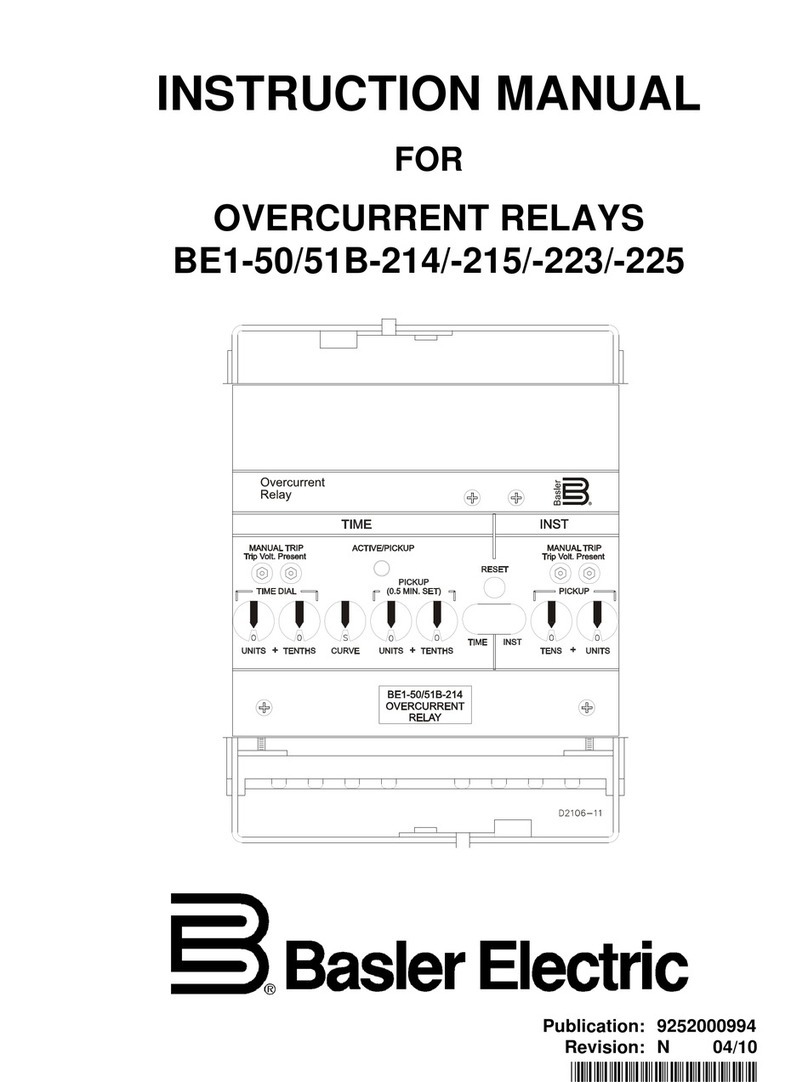

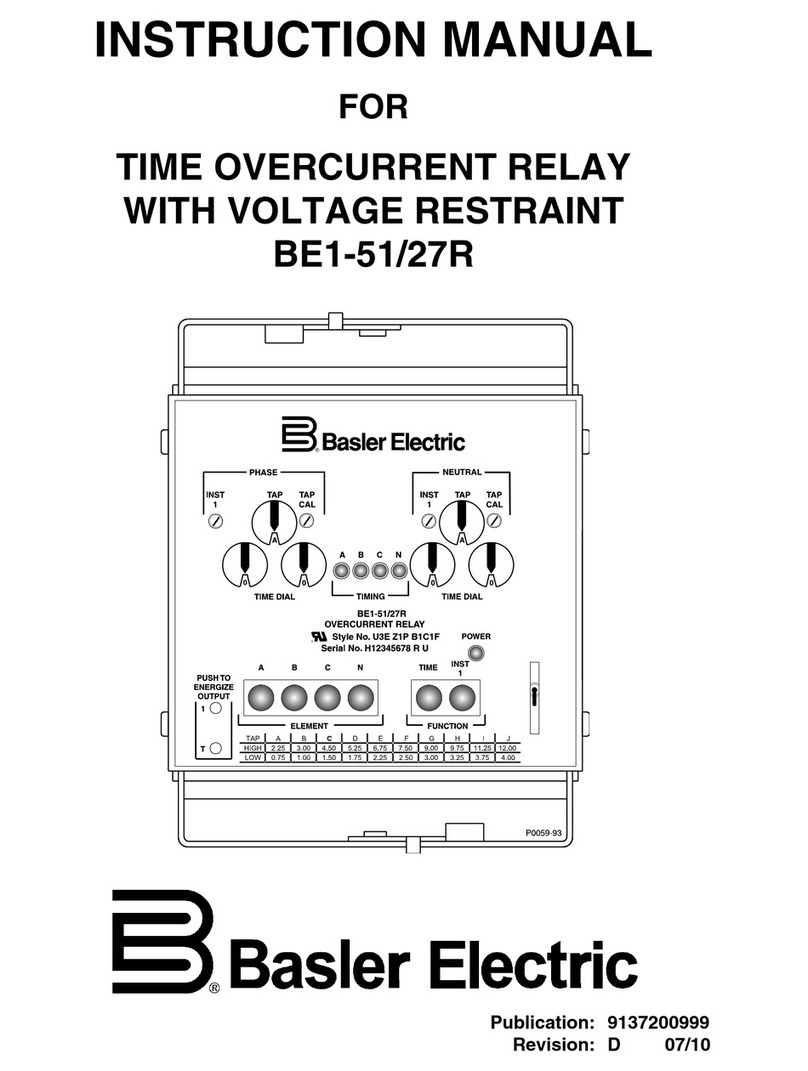

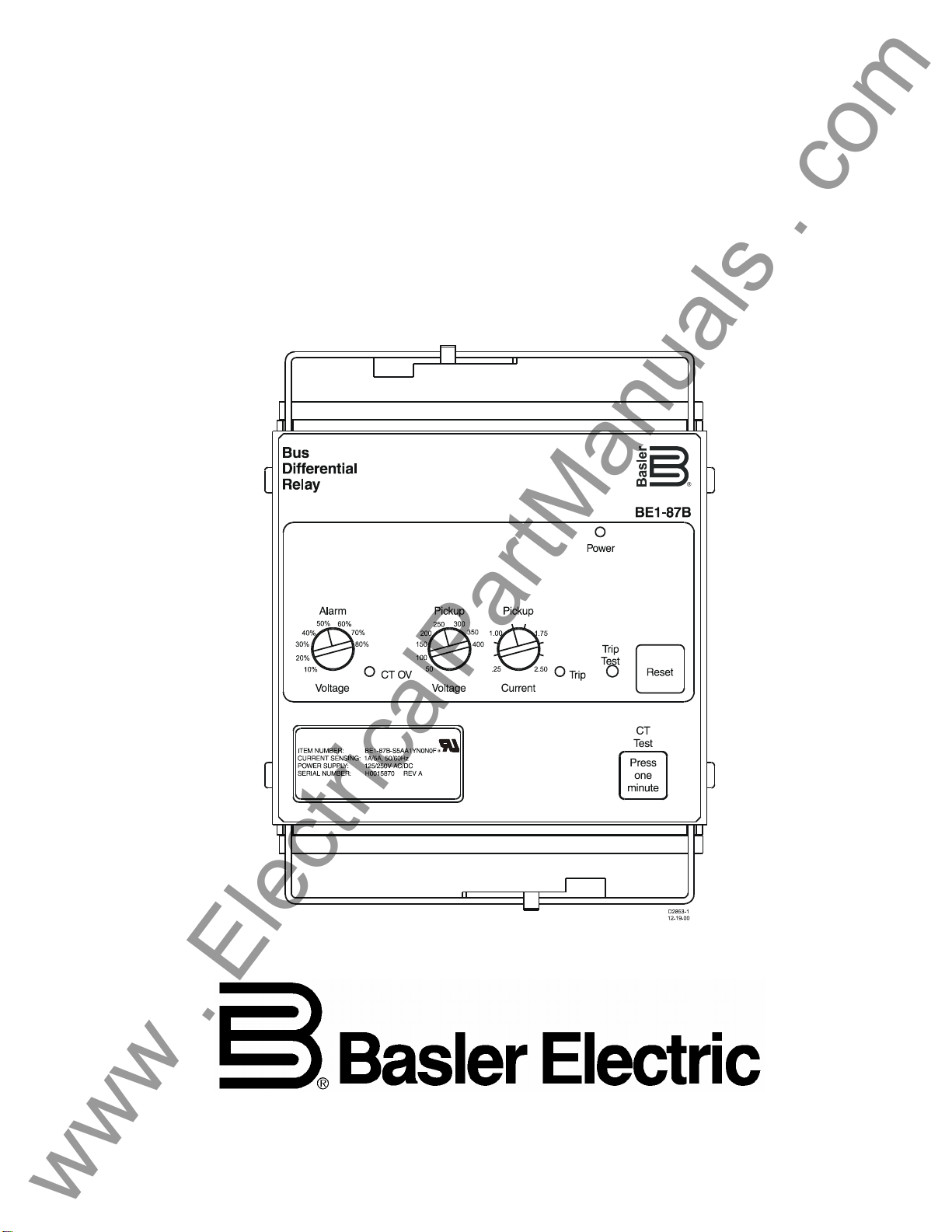

Figure 1-1. BE1-87B Style Chart...............................................................................................................1-1

Figure 1-2. Typical Pickup Current Response Time without a Trip Delay ................................................1-2

Tables

Table 1-1. BE1-87B Power Supply Specifications....................................................................................1-2

www . ElectricalPartManuals . com