BE1-24 Introduction iii

CONTENTS

SECTION 1 GENERAL INFORMATION.....................................................................................1-1

Purpose....................................................................................................................1-1

Overexcitation..........................................................................................................1-1

Volts Per Hertz Principle..........................................................................................1-1

Relay Characteristics...............................................................................................1-2

Applications..............................................................................................................1-2

Model And Style Number.........................................................................................1-6

Sample Style Number........................................................................................1-6

Specifications...........................................................................................................1-8

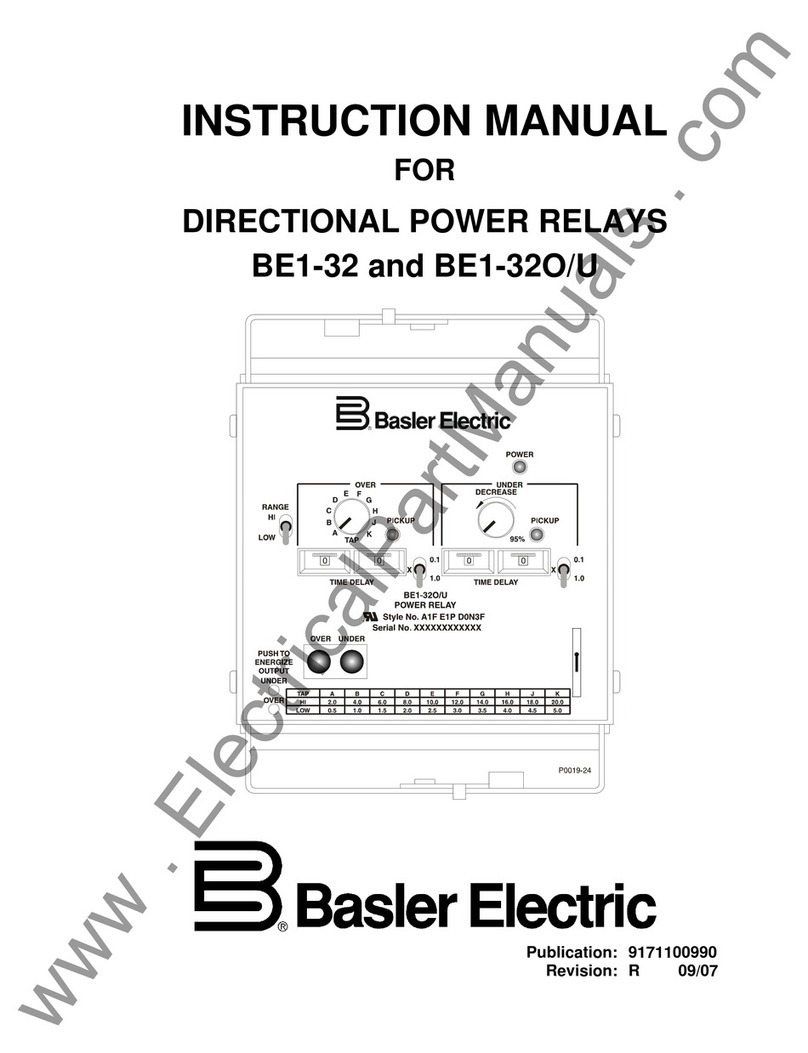

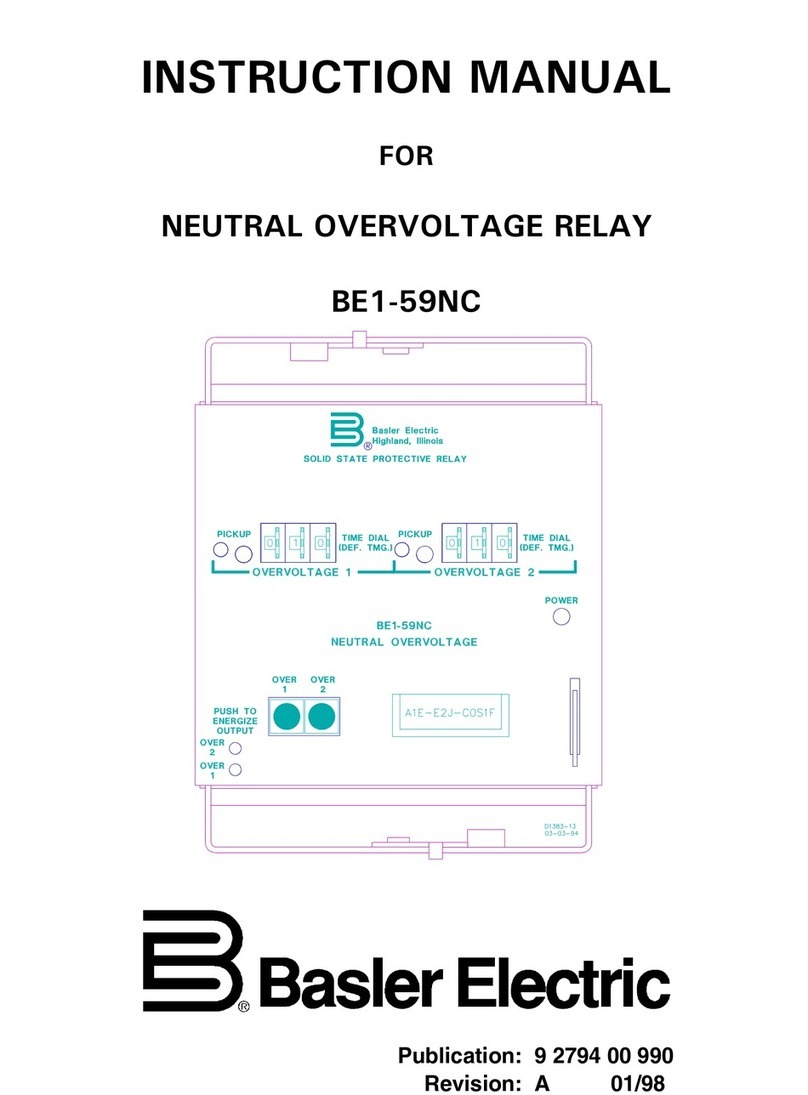

SECTION 2 HUMAN-MACHINE INTERFACE............................................................................2-1

Controls and Indicators............................................................................................2-1

SECTION 3 FUNCTIONAL DESCRIPTION................................................................................3-1

General....................................................................................................................3-1

Functional Description .............................................................................................3-1

Thumbwheel Switches ......................................................................................3-1

Input Sensing.....................................................................................................3-1

Third Harmonic Rejection Filter.........................................................................3-2

Microprocessor..................................................................................................3-2

Trip Level Detector............................................................................................3-2

Digital-to-Analog Converter...............................................................................3-2

Output Functions......................................................................................................3-3

Inverse Square Timing .....................................................................................3-3

Definite Time Alarm...........................................................................................3-4

Instantaneous Trip Output ................................................................................3-4

Outputs ....................................................................................................................3-4

Timing Status Display ..............................................................................................3-4

Watchdog Circuitry...................................................................................................3-5

Relay Fail Function..................................................................................................3-5

Targets.....................................................................................................................3-5

Built-In-Test..............................................................................................................3-5

Push-To-Energize-Output Pushbuttons...................................................................3-5

Power Supply...........................................................................................................3-5

SECTION 4 INSTALLATION.......................................................................................................4-1

General....................................................................................................................4-1

Relay Operating Precautions...................................................................................4-1

Dielectric Test..........................................................................................................4-1

Mounting..................................................................................................................4-1

Connections.............................................................................................................4-8

SECTION 5 OPERATIONAL TEST.............................................................................................5-1

General....................................................................................................................5-1

Relay Operating Precautions...................................................................................5-1

Built-In-Test..............................................................................................................5-1

Operational Test Procedures...................................................................................5-1

Pickup................................................................................................................5-2

Instantaneous Time Verification........................................................................5-3

Definite Time Delay Alarm.................................................................................5-3

Inverse Square Timing ......................................................................................5-4