9171400990 Rev G BE1-59N Introduction v

CONTENTS

SECTION 1 •GENERAL INFORMATION................................................................................................ 1-1

PURPOSE........................................................................................................................................... 1-1

APPLICATION .................................................................................................................................... 1-1

High Resistance Grounding.......................................................................................................... 1-1

Ungrounded Systems................................................................................................................... 1-2

MODEL AND STYLE NUMBER.......................................................................................................... 1-2

Style Number Example................................................................................................................. 1-3

SPECIFICATIONS.............................................................................................................................. 1-4

Voltage Sensing Inputs................................................................................................................. 1-4

Undervoltage Sensing Input Range ............................................................................................. 1-4

Pickup Accuracy........................................................................................................................... 1-4

Dropout......................................................................................................................................... 1-4

Timing Characteristics.................................................................................................................. 1-4

Output Contacts............................................................................................................................ 1-4

Power Supply................................................................................................................................ 1-5

Target Indicators........................................................................................................................... 1-5

Type Tests.................................................................................................................................... 1-5

Physical ........................................................................................................................................ 1-6

Agency Recognition/Certification ................................................................................................. 1-6

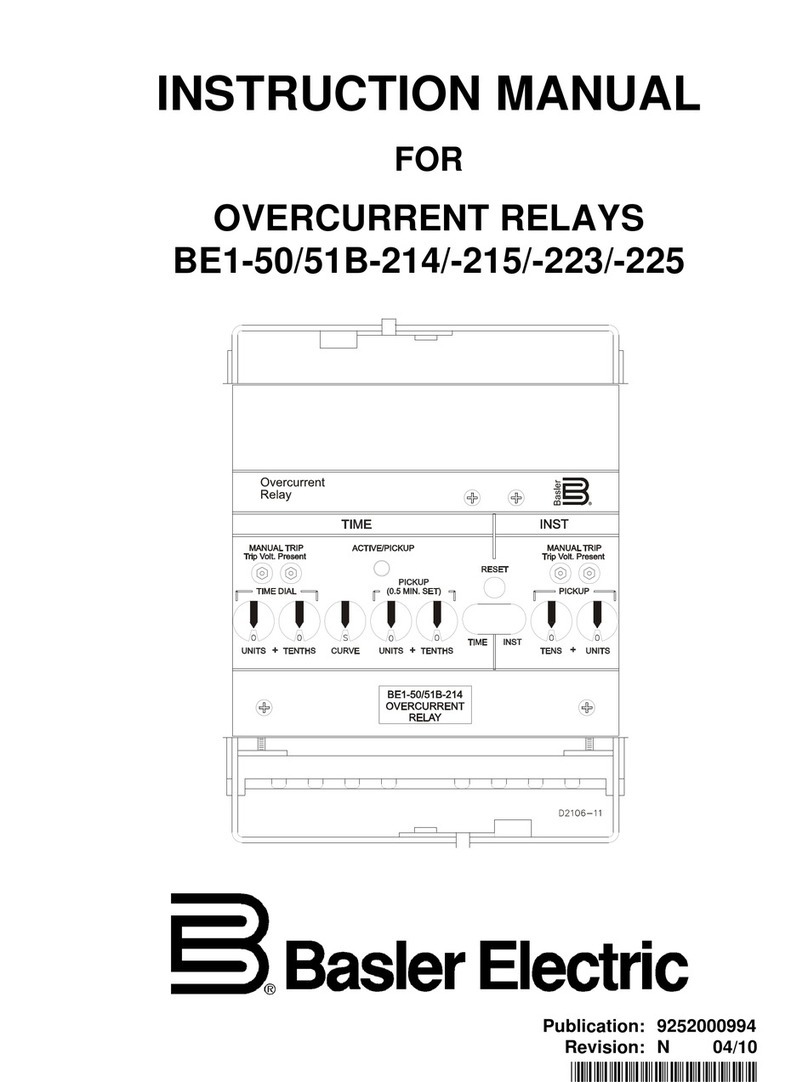

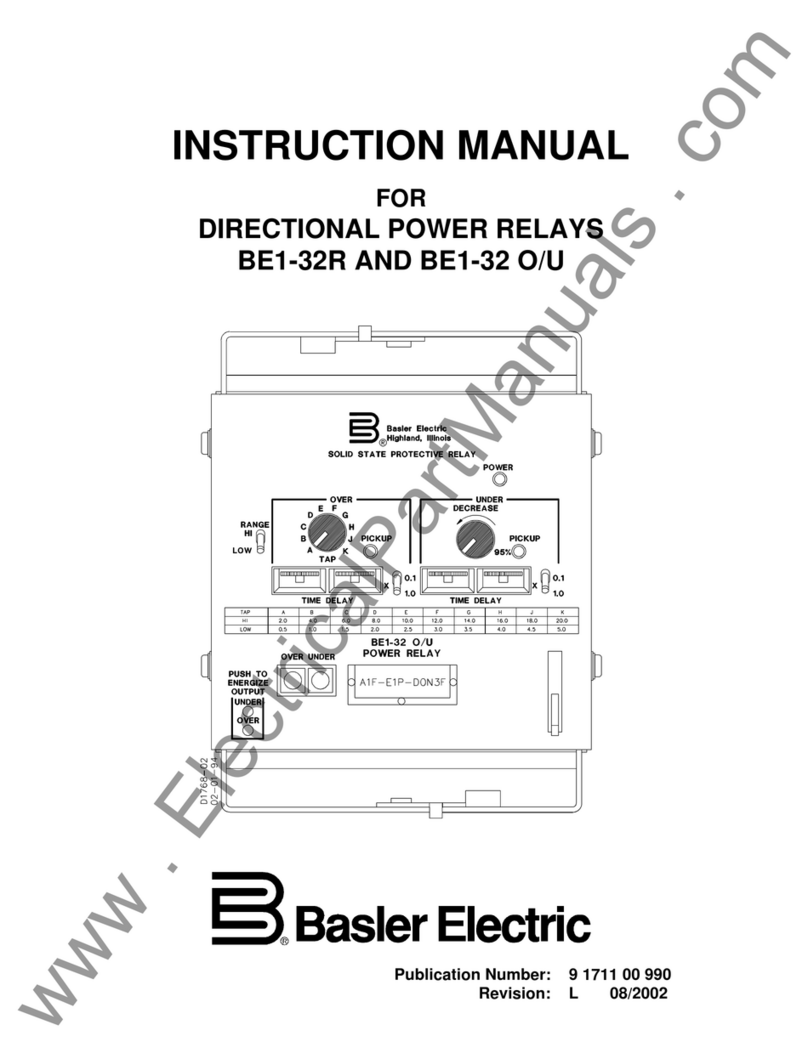

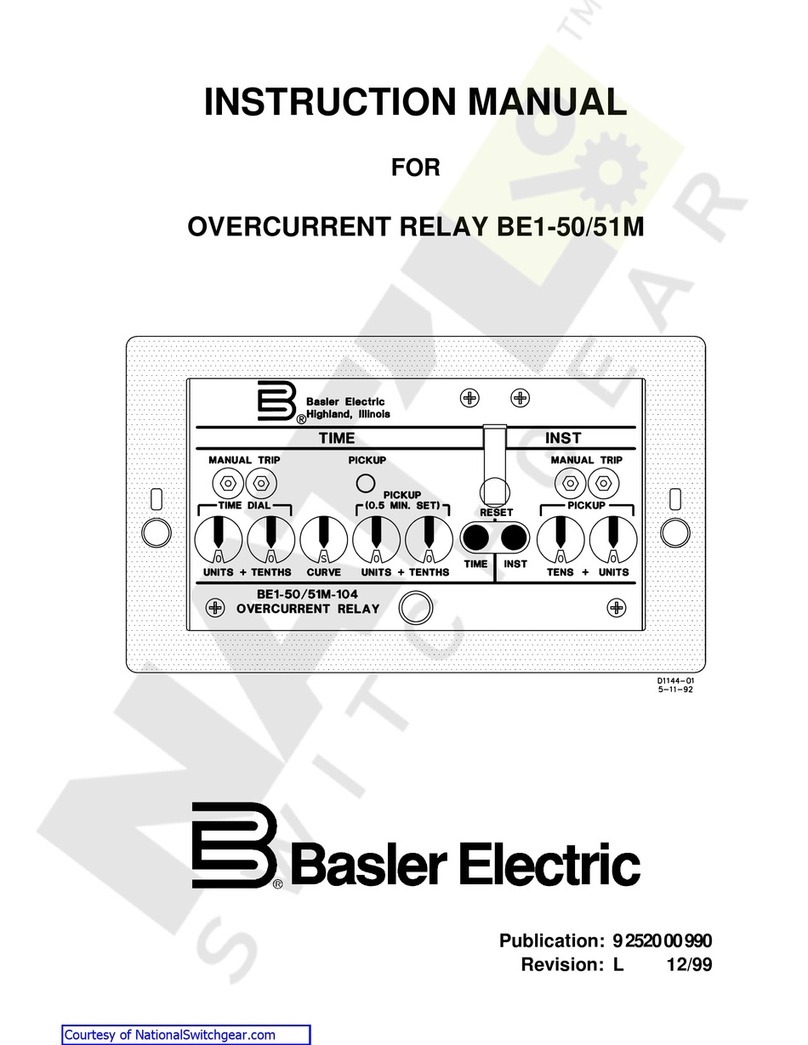

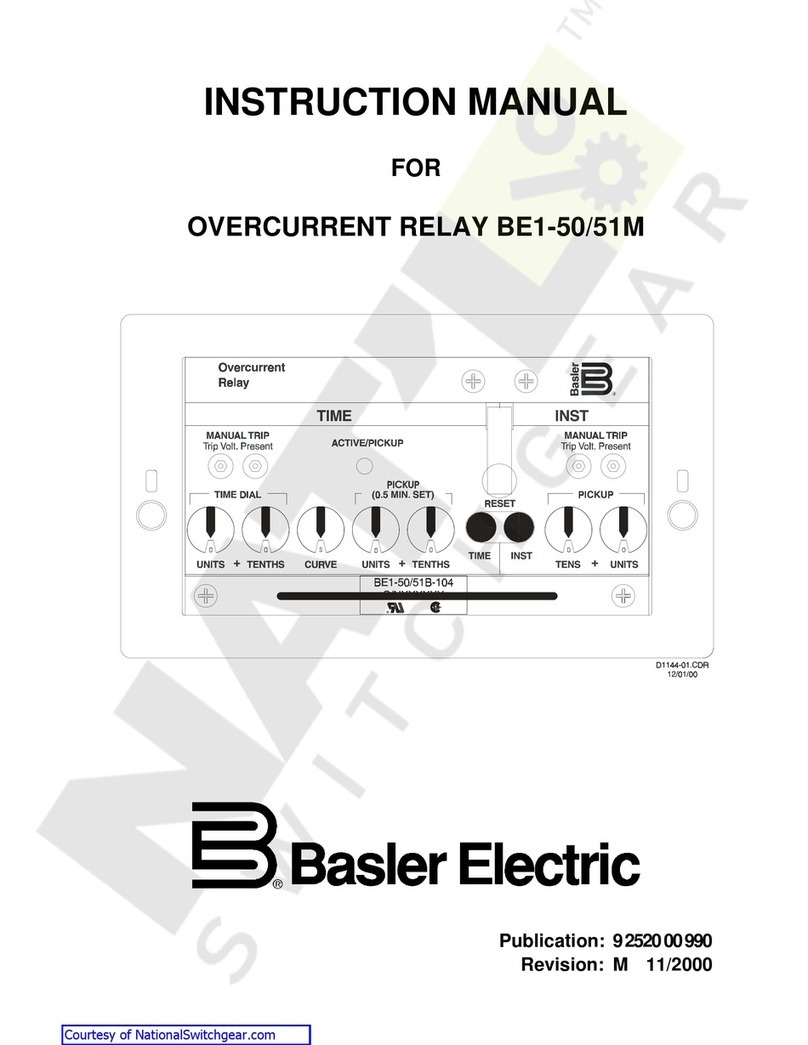

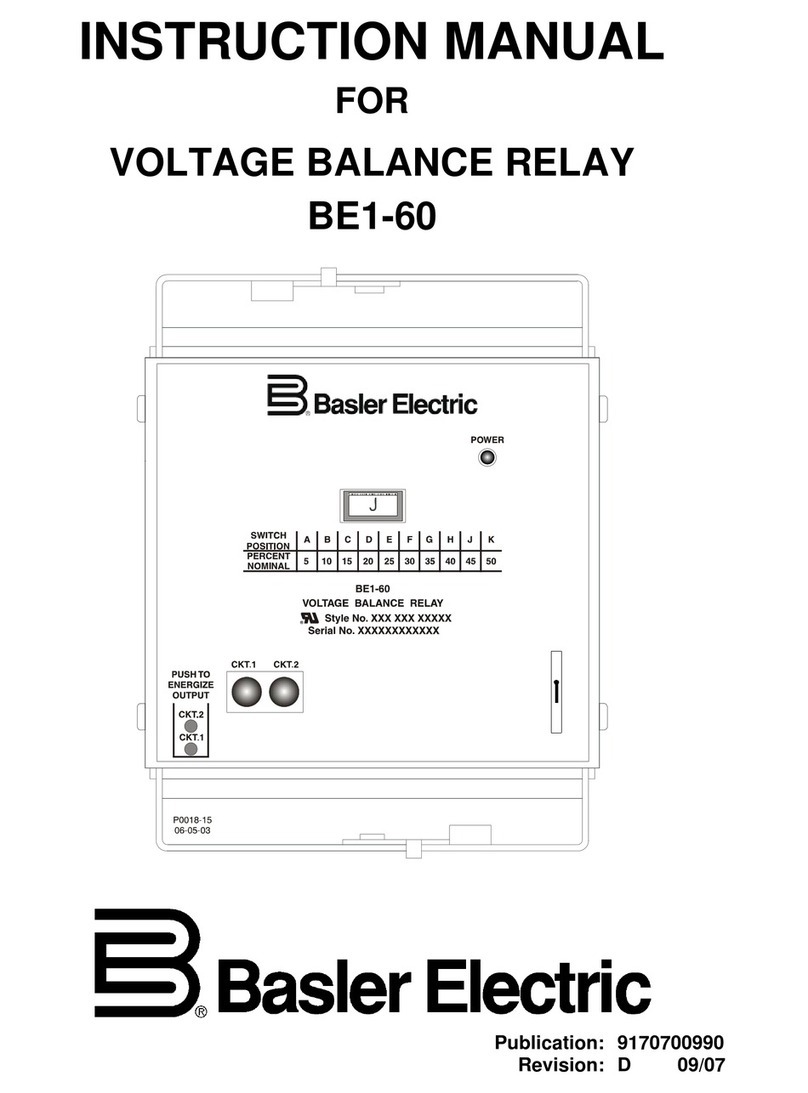

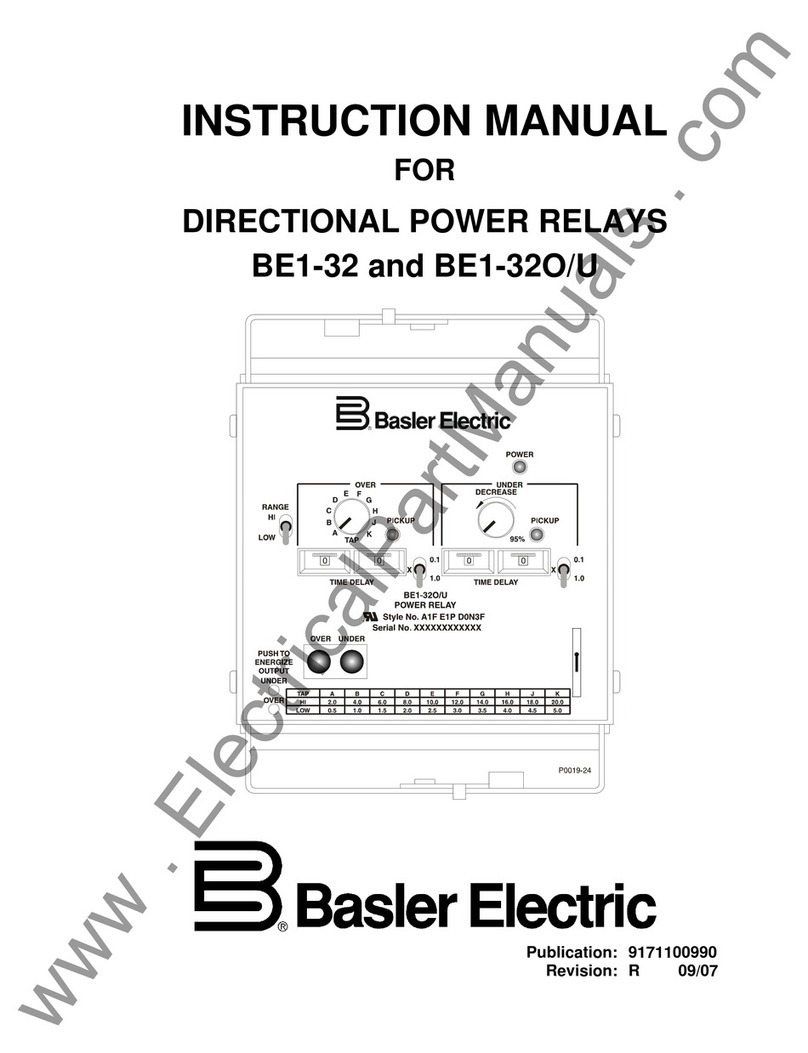

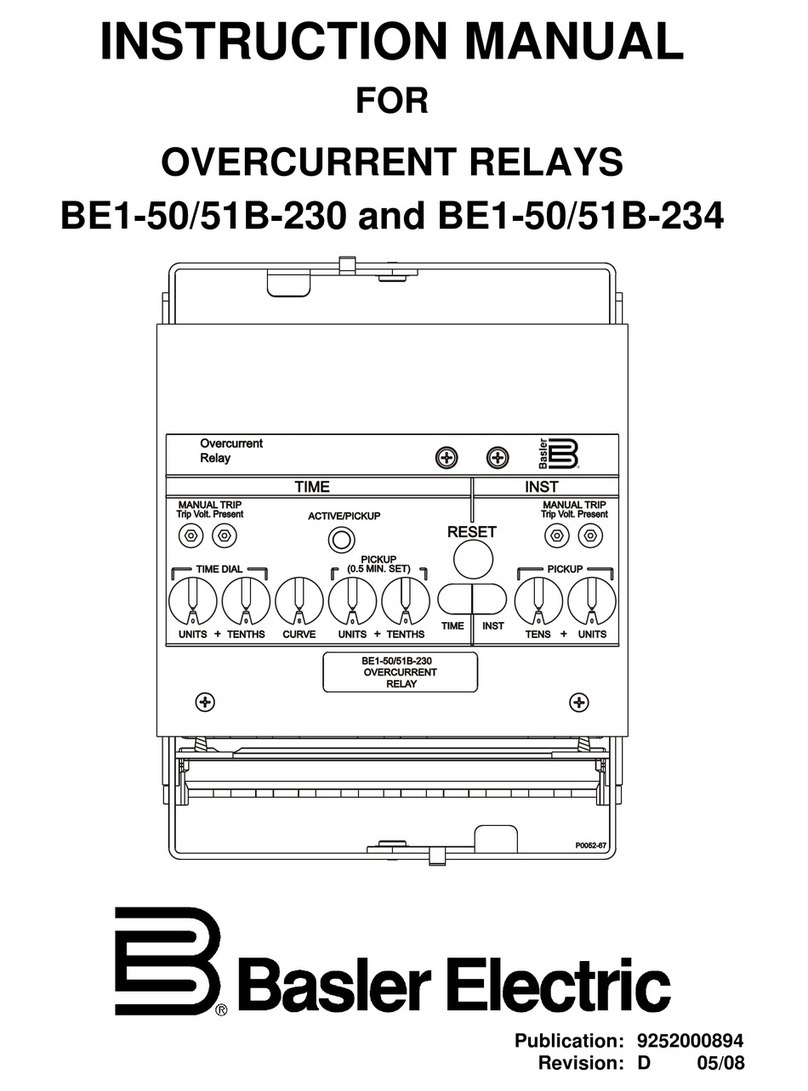

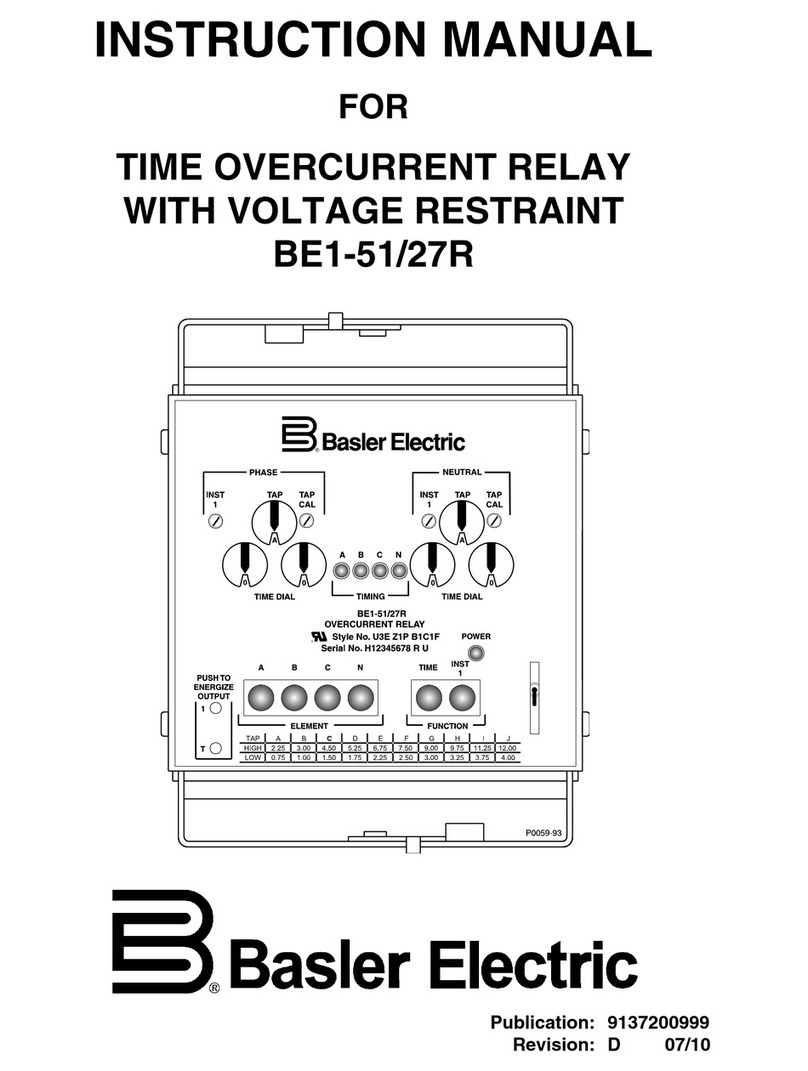

SECTION 2 •CONTROLS AND INDICATORS ....................................................................................... 2-1

INTRODUCTION................................................................................................................................. 2-1

SECTION 3 •FUNCTIONAL DESCRIPTION........................................................................................... 3-1

INTRODUCTION................................................................................................................................. 3-1

INPUTS............................................................................................................................................... 3-1

FILTERS ............................................................................................................................................. 3-1

OVERVOLTAGE COMPARATOR...................................................................................................... 3-1

DEFINITE TIME DELAY (OPTIONAL)................................................................................................ 3-1

INVERSE TIME DELAY (OPTIONAL)................................................................................................ 3-2

REFERENCE VOLTAGE CIRCUIT.................................................................................................... 3-2

UNDERVOLTAGE ELEMENT (OPTIONAL)....................................................................................... 3-2

Undervoltage Operation ............................................................................................................... 3-2

Undervoltage Inhibit...................................................................................................................... 3-2

OUTPUTS........................................................................................................................................... 3-2

PUSH-TO-ENERGIZE

OUTPUT PUSHBUTTONS............................................................................ 3-2

POWER SUPPLY STATUS OUTPUT................................................................................................ 3-3

POWER SUPPLY ............................................................................................................................... 3-3

TARGET INDICATORS ...................................................................................................................... 3-3

Internally Operated Targets.......................................................................................................... 3-3

Current Operated Targets ............................................................................................................ 3-3

SECTION 4 •INSTALLATION.................................................................................................................. 4-1

INTRODUCTION................................................................................................................................. 4-1

RELAY OPERATING GUIDELINES AND PRECAUTIONS ............................................................... 4-1

MOUNTING......................................................................................................................................... 4-1

CONNECTIONS.................................................................................................................................. 4-9

MAINTENANCE................................................................................................................................ 4-12

STORAGE......................................................................................................................................... 4-12

SECTION 5 •TESTING ............................................................................................................................ 5-1

INTRODUCTION................................................................................................................................. 5-1

OPERATIONAL TEST ........................................................................................................................ 5-1