BE1-79M Introduction v

CONTENTS

SECTION 1 INFORMATION.......................................................................................................... 1-1

Purpose.....................................................................................................................1-1

Application ................................................................................................................1-1

Model and Style Number..........................................................................................1-2

Style Number Example......................................................................................1-2

Style Number Change.......................................................................................1-2

Compatibility.......................................................................................................1-2

Style Number Identification Chart......................................................................1-3

Specifications............................................................................................................1-4

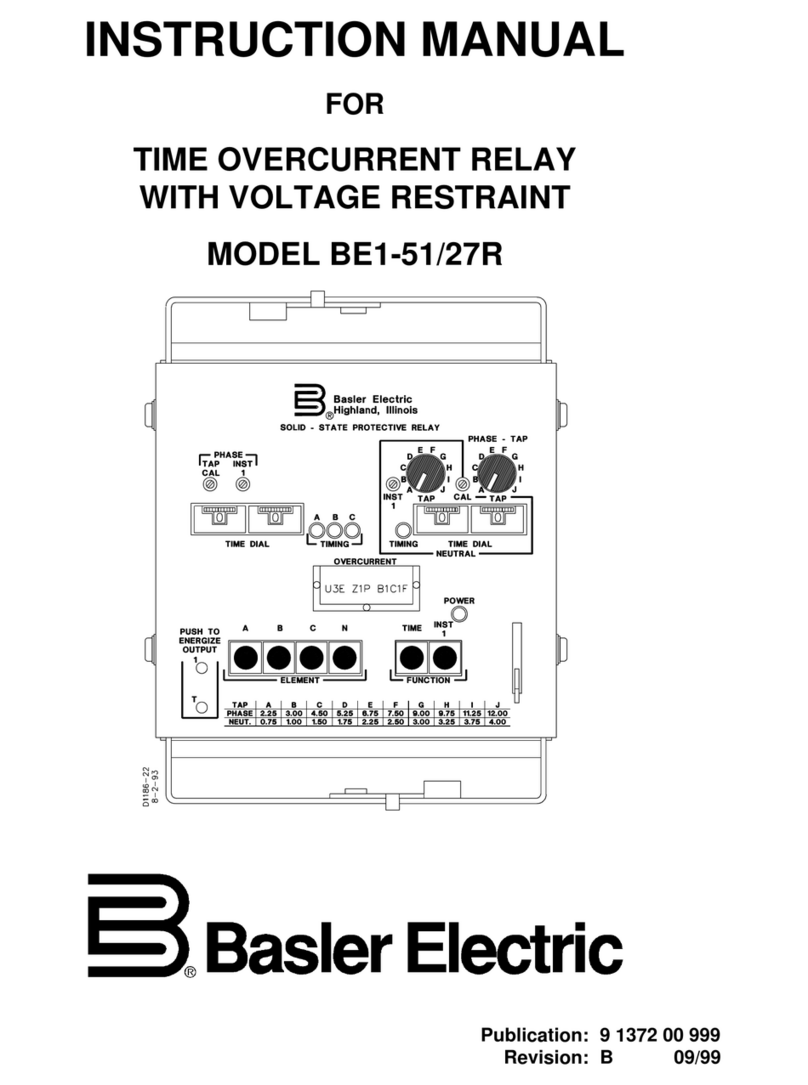

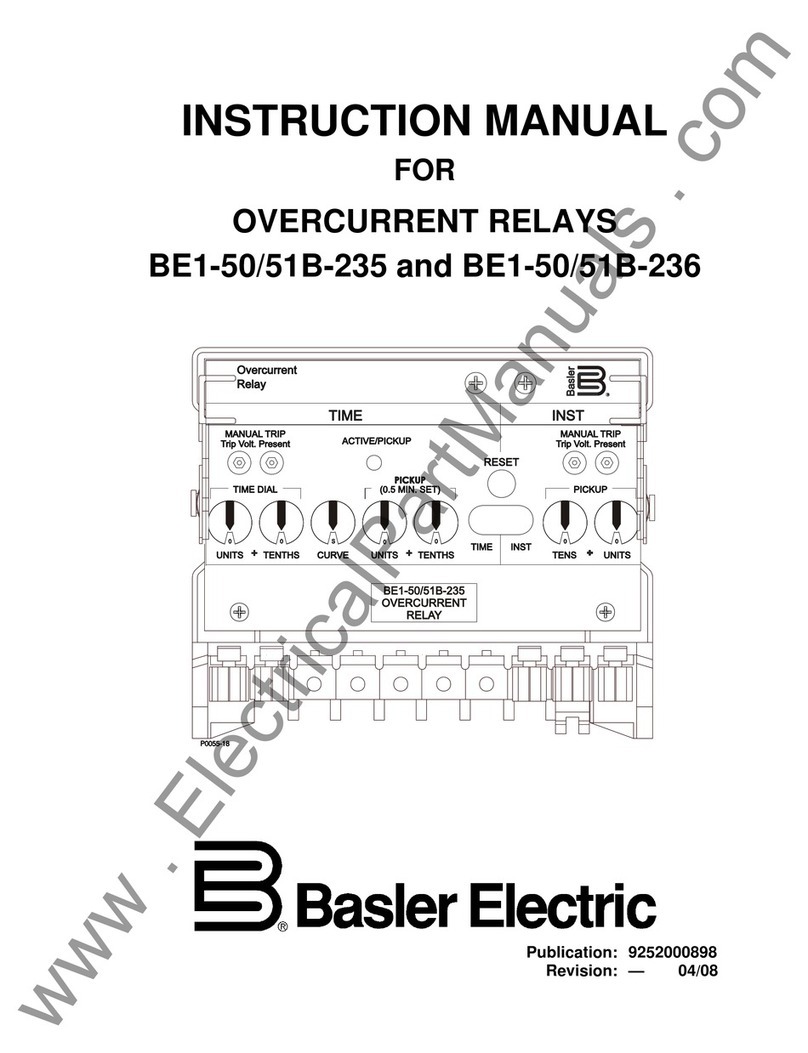

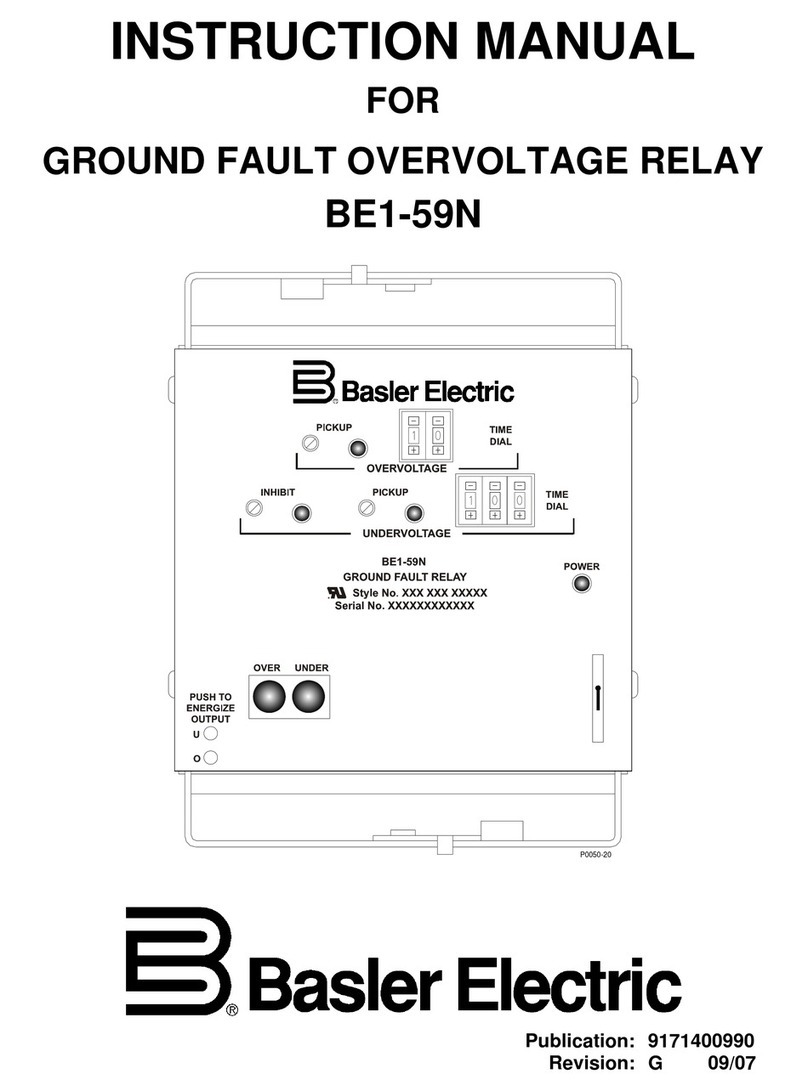

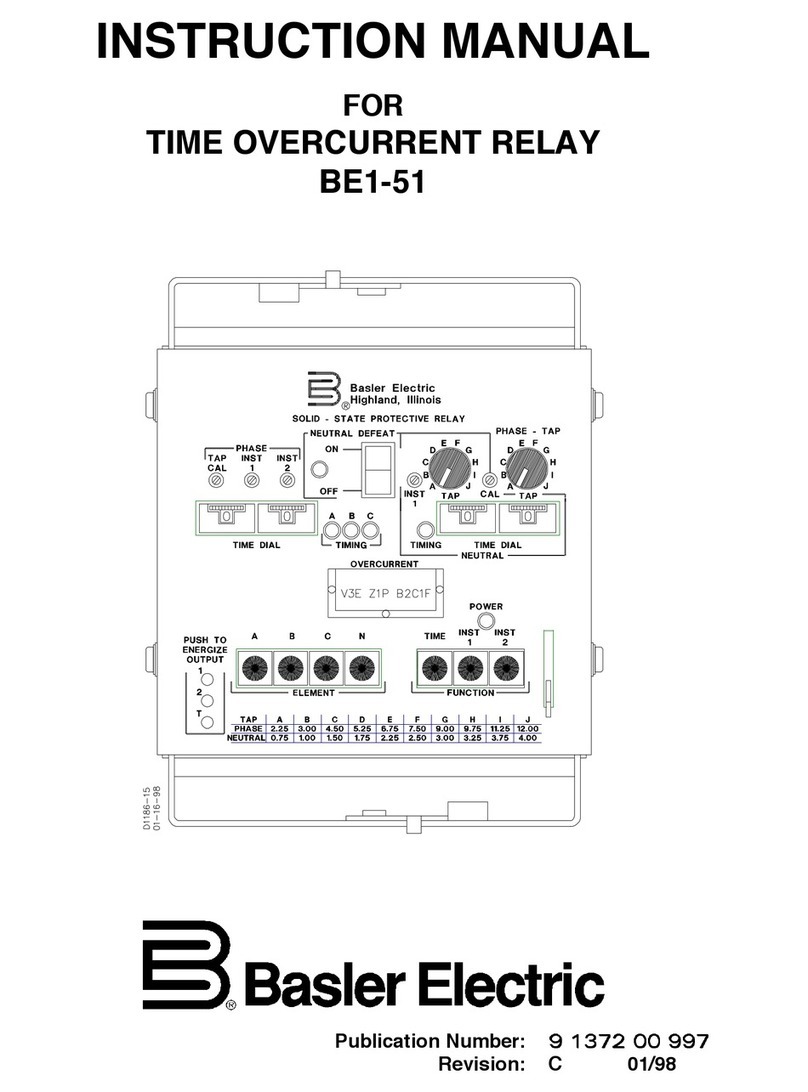

SECTION 2 HUMAN-MACHINE INTERFACE............................................................................. 2-1

SECTION 3 FUNCTIONAL DESCRIPTION ................................................................................. 3-1

General .....................................................................................................................3-1

Functional Description..............................................................................................3-1

Contact Sensing.................................................................................................3-1

Contact Interface................................................................................................3-3

Logic Switch.......................................................................................................3-3

Thumbwheels.....................................................................................................3-4

Instantaneous Trip Enable (Optional) ...............................................................3-4

Microprocessor ..................................................................................................3-4

Program Monitor................................................................................................3-4

Power Loss Detector.........................................................................................3-4

Outputs...............................................................................................................3-5

Power Supply.....................................................................................................3-5

Operational Characteristics......................................................................................3-6

Power-up............................................................................................................3-6

Reset.........................................................................................................................3-7

Lockout......................................................................................................................3-7

Reclosing Sequences........................................................................................3-8

Reclose Fail .......................................................................................................3-8

Maximum Cycle .................................................................................................3-8

Block Load Tap Changer...................................................................................3-8

Control Outputs and Special Contact Assignments ...................................... 3-11

Reclosing Event Memory ...................................................................................... 3-11

Purpose........................................................................................................... 3-11

Data Retrieval................................................................................................. 3-12

Data Retention................................................................................................ 3-12

Clearing Stored Data...................................................................................... 3-13

SECTION 4 INSTALLATION.........................................................................................................4-1

General .....................................................................................................................4-1

Relay Operating Precautions...................................................................................4-1

Dielectric Test...........................................................................................................4-1

Mounting...................................................................................................................4-1

Connections..............................................................................................................4-1

SECTION 5 TESTS AND ADJUSTMENTS ................................................................................5-1

General .....................................................................................................................5-1

Required Test Equipment.........................................................................................5-1

Operational Test Procedure.....................................................................................5-1