Batco 2500 Series User manual

Part Number: P1511025 R0

Revised: Jun/11

Read this manual before using product. Failure

to follow instructions and safety precautions can

result in serious injury, death, or property

damage. Keep manual for future reference.

PITSTOP

2500 SERIES

OPERATION MANUAL

This product has been designed and constructed according to general engineering

standardsa. Other local regulations may apply and must be followed by the operator.

We strongly recommend that all personnel associated with this equipment be trained

in the correct operational and safety procedures required for this product. Periodic

reviews of this manual with all employees should be standard practice. For your

convenience, we include this sign-off sheet so you can record your periodic reviews.

a. Standards include organizations such as the American Society of Agricultural and Biological Engineers,

American National Standards Institute, Canadian Standards Association, International Organization for

Standardization, and/or others.

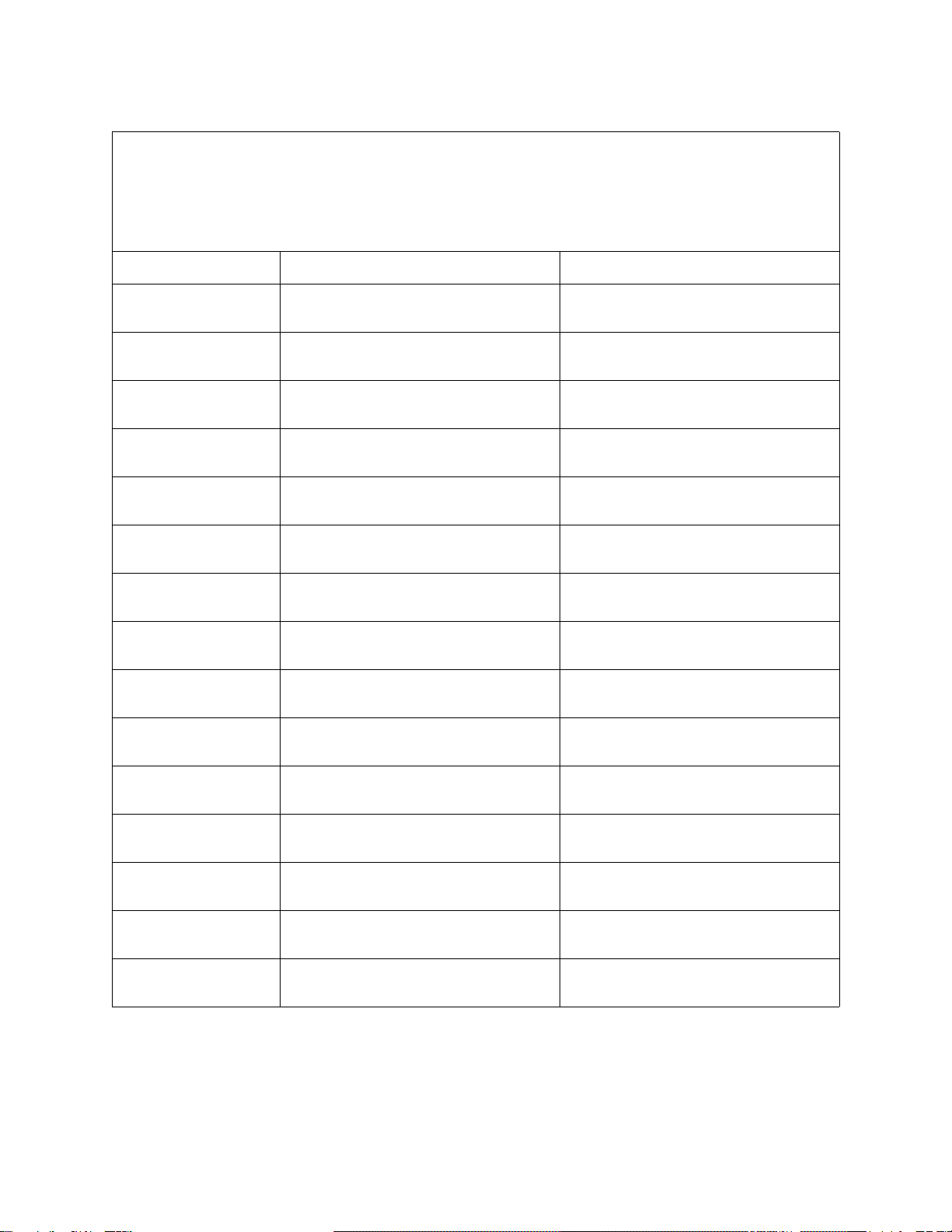

Date Employee Signature Employer Signature

TABLE OF CONTENTS

BATCO - PITSTOP

2500 SERIES

P1511025 R0 3

1. Introduction .......................................................................................................................... 5

2. Safety First............................................................................................................................ 7

2.1. General Safety ......................................................................................................... 8

2.2. Assembly Safety....................................................................................................... 9

2.3. Operational Safety.................................................................................................... 9

2.4. Transport Safety....................................................................................................... 9

2.5. Storage Safety........................................................................................................ 10

2.6. Maintenance Safety............................................................................................... 10

2.7. Hydraulic Safety..................................................................................................... 10

2.8. Electric Motor Safety.............................................................................................. 10

2.9. Tire Safety.............................................................................................................. 11

2.10. Safety Decal Locations......................................................................................... 11

2.10.1. Decal Installation.................................................................................... 11

2.10.2. Decal Locations...................................................................................... 11

3. Machine Components........................................................................................................ 15

3.1. Controls.................................................................................................................. 16

3.2. Matching Equipment............................................................................................... 17

4. Assembly ............................................................................................................................ 19

4.1. Electric Top Drive Assembly ................................................................................. 19

4.2. Hydraulic Drive Kit.................................................................................................. 21

4.3. Electric Wet Kit....................................................................................................... 22

5. Transport............................................................................................................................. 25

5.1. Pre-Transport Checklist.......................................................................................... 25

5.2. Transport Procedure .............................................................................................. 25

6. Placement ........................................................................................................................... 29

6.1. Set-Up Conversions............................................................................................... 29

7. Operation ............................................................................................................................ 31

7.1. Pre-Operation Checklist......................................................................................... 31

7.2. Machine Break-In And Operation.......................................................................... 31

7.2.1. Starting Conveyor:.................................................................................... 32

7.2.2. Conveyor Shutdown:................................................................................ 33

7.2.3. Truck Positioning:..................................................................................... 33

7.2.4. Emergency Shutdown: ............................................................................. 34

7.2.5. Re-Starting (Full Tube):........................................................................... 34

7.2.6. Grain Removal.......................................................................................... 34

7.2.7. Optional Self-Contained Hydraulics:......................................................... 34

7.2.8. Operating Tips:......................................................................................... 34

8. Storage................................................................................................................................ 35

TABLE OF CONTENTS

BATCO - PITSTOP

2500 SERIES

4P1511025 R0

9. Maintenance........................................................................................................................ 37

9.1. Maintenance Schedule........................................................................................... 37

9.1.1. Initial start-up servicing............................................................................. 37

9.1.2. 40 Hours or Weekly:................................................................................. 37

9.1.3. Every 100 Hours or Annually:................................................................... 37

9.2. Maintenance Checklist ........................................................................................... 38

9.3. Service & Maintenance Procedures....................................................................... 38

9.3.1. Fluids and Lubricants................................................................................ 38

9.3.2. Greasing................................................................................................... 39

9.3.3. Conveyor Belt Tension ............................................................................. 39

9.3.4. Conveyor Belt Alignment.......................................................................... 40

9.3.5. Belt Relacing............................................................................................. 42

9.3.6. Electric Drive Belt Tension & Alignment................................................... 43

9.3.7. Hydraulic Oil Level.................................................................................... 44

10. Troubleshooting ............................................................................................................... 47

11. Appendix .......................................................................................................................... 49

11.1. Mechanical Specs ................................................................................................ 49

New Equipment Warranty ....................................................................................................... 51

BATCO - PITSTOP 1. INTRODUCTION

2500 SERIES

P1511025 R0 5

1.Introduction

Congratulations on your choice of a Batco PitStop to complement your agricul-

tural operation. This equipment has been designed and manufactured to meet

the needs of the discriminating buyer for the efficient movement of grain, pulse

crops, fertilizer, and other granular materials.

Safe, efficient, and trouble-free operation of your PitStop requires that you, and

anyone else who will be operating or maintaining the conveyor, read and under-

stand the safety, operation, maintenance, and troubleshooting information

contained within this manual.

Equipment is available in various combinations. In most cases, the following

instructions will apply to all machines. Where the assembly information varies,

additional instructions will be included and will be indicated with an arrow.

Keep this manual handy for frequent reference and to pass on to new operators

or owners. Call your Batco distributor or dealer if you need assistance, infor-

mation, or additional copies of the manual.

Always give your dealer the serial number of your Batco PitStop Conveyor when

ordering parts or requesting service or other information.

The serial number plate is located where indicated. Please mark the number in

the space provided for easy reference.

Model #

Serial #

Production Year

1. INTRODUCTION BATCO - PITSTOP

2500 SERIES

6P1511025 R0

BATCO - PITSTOP 2. SAFETY FIRST

2500 SERIES

P1511025 R0 7

2.Safety First

The Safety Alert symbol to the left identifies important safety messages on the

product and in the manual. When you see this symbol, be alert to the possibil-

ity of personal injury or death. Follow the instructions in the safety messages.

Why is SAFETY important to you?

Three big reasons:

• Accidents disable and kill.

• Accidents cost.

• Accidents can be avoided.

SIGNAL WORDS

Note the use of the signal words DANGER, WARNING, CAUTION, and NOTICE

with the safety messages. The appropriate signal word for each message has

been selected using the definitions below as a guideline.

The Safety Alert symbol means: “ATTENTION, BE ALERT! YOUR SAFETY IS

INVOLVED”.

DANGER

Indicates an imminently hazardous situation

that, if not avoided, will result in serious injury

or death.

WARNING

Indicates a hazardous situation that, if not

avoided, could result in serious injury or

death.

CAUTION

Indicates a hazardous situation that, if not

avoided, may result in minor or moderate

injury.

NOTICE

Indicates a potentially hazardous situation that, if not

avoided, may result in property damage.

2. SAFETY FIRST BATCO - PITSTOP

2.1. GENERAL SAFETY 2500 SERIES

8P1511025 R0

2.1. GENERAL SAFETY

Important: The general safety section includes instructions that apply to all safety practices.

Any instructions specific to a certain safety practice (e.g., assembly safety), can

be found in the appropriate section. Always read the complete instructional

sections and not just these safety summaries before doing anything with the

equipment.

YOU are responsible for the SAFE use and maintenance of your equipment.

YOU must ensure that you and anyone else who is going to work around the

equipment understands all procedures and related SAFETY information

contained in this manual.

Remember, YOU are the key to safety. Good safety practices not only protect

you, but also the people around you. Make these practices a working part of your

safety program.

• It is the equipment owner and the operator's responsibility to read and under-

stand ALL safety instructions, safety decals, and manuals and follow them

before assembling, operating, or maintaining the equipment. All accidents

can be avoided.

•Equipment owners must give instructions and review the information initially

and anually with all personnel before allowing them to operate this product.

Untrained users/operators expose themselves and bystanders to possible

serious injury or death.

• Use this equipment for its intended purposes only.

• Do not modify the equipment in any way. Unauthorized modification may

impair the function and/or safety, and could affect the life of the equipment.

Any modification to the equipment voids the warranty.

• Do not allow children, spectators, or bystanders within the work area.

•Have a first-aid kit available for use should the need arise, and know how to

use it.

•Provide a fire extinguisher for use in case of an accident. Store in a highly vis-

ible place.

•Wear appropriate protective gear. This list includes, but

is not limited to:

• a hard hat

•gloves

• protective shoes with slip-resistant soles

• protective goggles

• hearing protection

• dust mask or respirator

• For Powered Equipment: before servicing, adjusting, or repairing powered

equipment, unplug, place all controls in neutral or off position, stop the engine

or motor, remove ignition key or lock out power source, and wait for all mov-

ing parts to stop.

BATCO - PITSTOP 2. SAFETY FIRST

2500 SERIES 2.2. ASSEMBLY SAFETY

P1511025 R0 9

•Follow good shop practices:

• keep service area clean and dry

• be sure electrical outlets and tools are properly

grounded

• use adequate light for the job at hand

• Think SAFETY! Work SAFELY!

2.2. ASSEMBLY SAFETY

• Read through the instructions to get to know the sub-assemblies and hard-

ware that make up the equipment.

• Do not take chances with safety. The components are large, heavy, and can

be hard to handle. Always use the proper tools, stands, jacks, and hoists for

the job.

• Always have 2 or more people assembling the equipment. Because of the

weight, do not attempt assembly alone.

2.3. OPERATIONAL SAFETY

• Before servicing, adjusting, repairing, or unplugging powered products

(including hydraulic and electric motor drives).

• Do not allow riders when transporting.

• Do not operate machine with any guards removed.

2.4. TRANSPORT SAFETY

• Check with local authorities regarding transport on public roads. Obey all

applicable laws and regulations.

• Always travel at a safe speed, never exceeding 20 mph (32 km/h). Reduce

speed on rough surfaces. Use caution when turning corners or meeting traf-

fic.

• Make sure the SMV (slow moving vehicle) emblem and all the lights and

reflectors that are required by local authorities are in place, are clean, and

can be seen by all over-taking and oncoming traffic. Always use hazard-warn-

ing flashers on tractor/towing vehicle when transporting unless prohibited by

law.

• Use the optional light package and highway tires when transporting with a

truck on the highway.

• Be sure that the unit is hitched securely to the towing vehicle. Always use a

retainer through the hitch, and a safety chain between the machine and the

towing unit.

• Keep to the right and yield the right of way to allow faster traffic to pass. Drive

on the road shoulder if permitted by law.

2. SAFETY FIRST BATCO - PITSTOP

2.5. STORAGE SAFETY 2500 SERIES

10 P1511025 R0

2.5. STORAGE SAFETY

• Store the unit in an area away from human activity.

• Do not permit children to play on or around the stored equipment.

2.6. MAINTENANCE SAFETY

• Before applying pressure to a hydraulic system, ensure all components are

tight and that hoses and couplings are in good condition.

• Relieve pressure from hydraulic circuit system before servicing or disconnect-

ing from tractor.

• Before resuming work, install and secure all guards when maintenance work

is complete.

2.7. HYDRAULIC SAFETY

• Always place all tractor hydraulic controls in neutral before disconnecting

from tractor or working on hydraulic system.

• Make sure that all components in the hydraulic system are kept in good con-

dition and are clean.

• Replace any worn, cut, abraded, flattened, or crimped hoses.

• Do not attempt any makeshift repairs to the hydraulic fittings or hoses by

using tape, clamps, or cements. The hydraulic system operates under

extremely high-pressure. Such repairs create a hazardous and unsafe condi-

tion because they will fail suddenly.

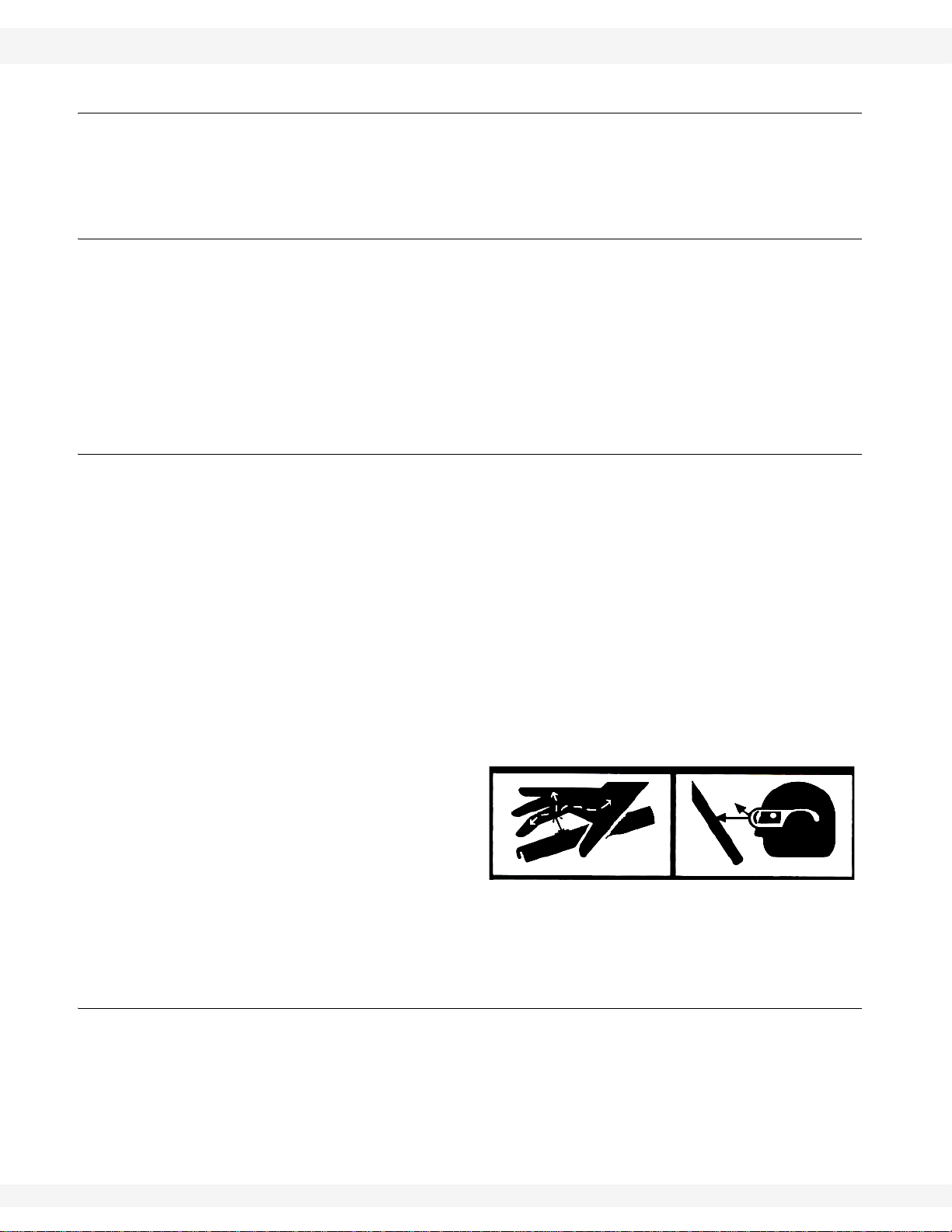

• Wear proper hand and eye protection when searching for a high-pressure

hydraulic leak. Do not use hands. Use a piece of wood or cardboard as a

backstop to isolate and identify a leak.

•If injured by a concentrated

high-pressure stream of

hydraulic fluid, seek medical

attention immediately. Seri-

ous infection or toxic reaction

can develop from hydraulic

fluid piercing the skin surface.

• Relieve pressure from hydrau-

lic circuit before servicing or disconnecting from tractor.

2.8. ELECTRIC MOTOR SAFETY

For units with electric motors.

• To prevent serious injury or death, only qualified personnel should service

electrical components.

• Keep electrical components in good repair.

• Ground electric motor before using.

BATCO - PITSTOP 2. SAFETY FIRST

2500 SERIES 2.9. TIRE SAFETY

P1511025 R0 11

• Inspect drive belts before using. Replace if frayed or damaged.

2.9. TIRE SAFETY

• Failure to follow proper procedures when mounting a tire on a wheel or rim

can produce an explosion that may result in serious injury or death.

• Do not attempt to mount a tire unless you have the proper equipment and

experience to do the job.

• Have a qualified tire dealer or repair service perform required tire mainte-

nance.

2.10. SAFETY DECAL LOCATIONS

• Keep safety decals clean and legible at all times.

• Replace safety decals that are missing or have become illegible. See decal

location figures that follow.

• Replaced parts must display the same decal(s) as the original part.

• Safety decals are available from your distributor, dealer, or factory.

2.10.1. DECAL INSTALLATION

1. Decal area must be clean and dry, with a temperature above 50°F (10°C).

2. Decide on the exact position before you remove the backing paper.

3. Align the decal over the specified area and carefully press the small portion

with the exposed sticky backing in place.

4. Slowly peel back the remaining paper and carefully smooth the remaining

portion of the decal in place.

5. Small air pockets can be pierced with a pin and smoothed out using the sign

backing paper.

2.10.2. DECAL LOCATIONS

Replicas of the safety decals that are attached to the equipment are shown in the

figure(s) that follow. Proper safety procedures require that you familiarize

yourself with the various safety decals and the areas or particular functions that

the decals apply to as well as the safety precautions that must be taken to avoid

serious, injury, death, or damage.

Think SAFETY! Work SAFELY!

2. SAFETY FIRST BATCO - PITSTOP

2.10. SAFETY DECAL LOCATIONS 2500 SERIES

12 P1511025 R0

Figure 2.1 Safety Decals

BATCO - PITSTOP 2. SAFETY FIRST

2500 SERIES 2.10. SAFETY DECAL LOCATIONS

P1511025 R0 13

Figure 2.2 Safety Decal Locations

2. SAFETY FIRST BATCO - PITSTOP

2.10. SAFETY DECAL LOCATIONS 2500 SERIES

14 P1511025 R0

BATCO - PITSTOP 3. MACHINE COMPONENTS

2500 SERIES

P1511025 R0 15

3.Machine Components

The Batco PitStop Conveyor is designed to allow trucks to drive-over the

machine, and dump into the hopper and conveyor belt from on top.

The hopper or intake frame is ramped to allow the truck to drive over the intake

when positioning. The collapsible hopper sides drop for truck positioning and

raise for unloading.

A flat conveyor belt moves material from the hopper and out the discharge.

Normally, the discharge is directed into another conveying system. Electric or

hydraulic power options are available to drive the belt. The wheel assembly is

positioned with hydraulic cylinders, and is moved down for transport and up for

operation. A self-contained hydraulic package option is available if hydraulic

power is not available to raise and lower the wheel assembly.

See Figure 3.1 for a list of components.

Figure 3.1

3. MACHINE COMPONENTS BATCO - PITSTOP

3.1. CONTROLS 2500 SERIES

16 P1511025 R0

Figure 3.2 Wheel Assembly Lock Pin (in Transport Configuration)

3.1. CONTROLS

Before starting, all operators should familiarize themselves with the location and

function of the controls.

1. Electric Drive

• Move the switch up for ON and down for OFF.

2. Hydraulic Drive

• Refer to tractor operation manual.

3. Winch

• A winch is located on the top of the discharge tube and is used to raise

and lower the sides of the intake hopper. Turn the handle counterclock-

wise to lower, and clockwise to raise the sides.

4. Lift Valve

• This valve allows oil to flow into or out of the hydraulic cylinder that raises

or lowers the wheel assembly. Lift the handle to lower the wheels and

raise the frame. Move the handle down to lower the frame and raise the

wheel. Release the handle and it will return to its centered, neutral posi-

tion. The wheel assembly lock pins must be removed to raise and lower

the machine and secured in place with a hairpin washer transporting as

shown in Figure 3.2.

WARNING

Ensure that the operator is safely positioned

when raising or lowering the conveyor.

BATCO - PITSTOP 3. MACHINE COMPONENTS

2500 SERIES 3.2. MATCHING EQUIPMENT

P1511025 R0 17

3.2. MATCHING EQUIPMENT

To ensure the safe and reliable operation of the PitStop, it is necessary to have a

power source with the appropriate specifications. As a guideline, ensure that

these requirements are met:

HYDRAULIC SYSTEM (HYDRAULIC DRIVE):

• The tractor hydraulic system must be capable of 19-22 gpm (US) at 2000

psi (13,800 kPa) to operate the hydraulic drive motor and the wheel pivot

system.

ELECTRICAL:

• An electric motor with a minimum of 7.5 HP is required to power the

machine. Have a licensed electrician provide power per the National Elec-

tric Code ANSI/NFPA70 and local codes. Install ON/OFF switch next to

the motor for the convenience of the operator. Cover or protect power

cords to prevent damage during operation.

3. MACHINE COMPONENTS BATCO - PITSTOP

3.2. MATCHING EQUIPMENT 2500 SERIES

18 P1511025 R0

BATCO - PITSTOP 4. ASSEMBLY

2500 SERIES 4.1. ELECTRIC TOP DRIVE ASSEMBLY

P1511025 R0 19

4.Assembly

4.1. ELECTRIC TOP DRIVE ASSEMBLY

Note: Refer to Table 4.1 for the quantity of each component used, and Figure 4.1 and

4.2 for illustrations of the assembly of the electric drive kit.

1. Install two u-clamps (4) with two 1/2” x 2-1/2” bolts (9) and locknuts (10) as

seen in Figure 4.1 and Figure 4.2.

2. Position the electric motor clamp (6) on top of the tube and fasten with a 3” u-

clamp (5), 1/2” x 2-1/2” bolts (9), and locknuts (10). Ensure it is level before

crimping to tube.

3. Install the motor mount plate (1) with the motor mount pin (14) and a 3/16” x

1-1/2” cotter pin (13). Secure by spreading cotter pin.

4. Position electric motor (not shown) on motor mount plate (1) and fasten with

the appropriate bolts and locknuts. Leave bolts finger tight for now.

5. Install a key in the motor shaft. Mount drive pulley (17) so the hub is flush

with the end of the shaft, then secure.

6. Install a key (2) in the drive roller shaft. Mount driven pulley (16) so the hub is

flush with the end of the shaft, then secure.

7. Use a straight edge to align the pulleys.

8. Tighten motor base bolts.

9. Install drive belts (15) and set belt tension by adjusting the 3/4” x 6” tap bolt

(8).

Warning: Before continuing, please read the safety information relevant to this section in the

safety section of this manual. Failure to follow the safety instructions can result in serious

injury, death, or property damage.

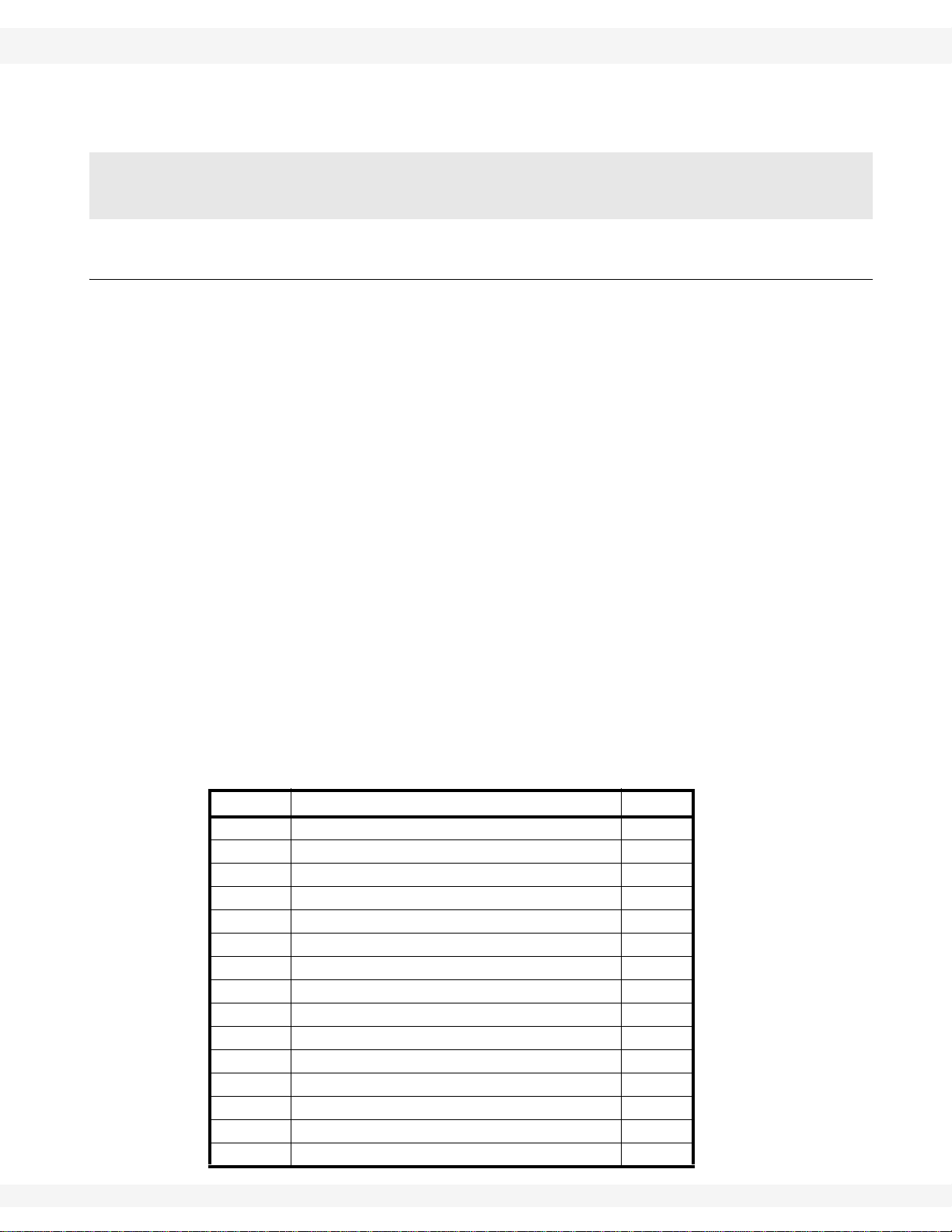

Table 4.1

ITEM DESCRIPTION QTY

1Motor Mount Plate 1

2Key 1/4” x 1-1/2” 1

3Spout Assembly 1

42" U-Clamp 2

53" U-Clamp 1

6Electric Motor Clamp 1

7Guard Mount 2

8Bolt Tap 3/4” x 6” 1

9Bolt Hex 1/2” x 2-1/2” GR8 6

10 Nut Nylock 1/2” 6

11 Self-Tapping Screw 1” 10

12 Flat Washer 1/4” USS Plated 4

13 Cotter Pin 3/16” x 1-1/2” 1

14 Motor Mount Pin 1

15 Belt B 105 2

4. ASSEMBLY BATCO - PITSTOP

4.1. ELECTRIC TOP DRIVE ASSEMBLY 2500 SERIES

20 P1511025 R0

Note: Belts should deflect 1/2” to 3/4” when pushed on with a 5 lb (2.3 kg) force. Check

frequently during the first 10 hours of operation to maintain proper tension.

10. Mount a keyed shaft guard (not shown) over the left drive roller shaft with a

1/4” x 1/2” bolt, 1/4” lock washer, and a 1/4” flat washer.

Note: Be sure the shaft guard is seated against the bearing. It may be necessary to tap

cover with a hammer for it to seat properly.

11. Attach safety sign

on the plastic

pulley guard and

on spout plate.

12. Hold plastic pulley

guard (19) over

the belt and mark

suitable mounting

bracket locations.

13. Place mounting

brackets (7) on

plastic guard (19)

and drill holes

through the

bracket and

guard. Attach the

brackets (7) to the

spout with self-

tapping screws

(11).

14. Mount plastic guard (19) to the machine with self-tapping screws (11) and

1/4” flat washers (12) as shown in Figure 4.1.

Figure 4.2

16 Pulley 2BK140H 1

17 Pulley 2BK34H 1

18 Bushing H 1.25 1

19 PitStop Plastic Pulley Guard 1

Table 4.1

ITEM DESCRIPTION QTY

Figure 4.1

This manual suits for next models

1

Table of contents