Baumalight FBS752 User manual

FBS752 Feller Buncher

OPERATOR’S MANUAL

Issue Date: April 2021

2

TABLE OF CONTENTS

1 INTRODUCTION ................................................................................................................................ 4

1.1 Overview..................................................................................................................................... 4

1.2 Intended Use And Foreseeable Misuse................................................................................... 4

2 SAFETY............................................................................................................................................... 5

2.1 Safety Alert Symbol And Safety Words................................................................................... 5

2.2 Operational Hazards.................................................................................................................. 5

Prepare For Emergencies ......................................................................................................... 6

Replace Safety Signs ................................................................................................................ 6

Do Not Allow Riders .................................................................................................................. 6

Lower Operating Speed ............................................................................................................ 6

Avoid Rollover ........................................................................................................................... 7

Avoid Powerlines....................................................................................................................... 7

Detach Feller Buncher Safely................................................................................................... 7

Hazards From Modifying Equipment ....................................................................................... 7

2.3 Maintenance Hazards................................................................................................................ 8

3 SAFETY SIGNS.................................................................................................................................. 9

4 OPERATION ..................................................................................................................................... 12

4.1 Preparation For Use ................................................................................................................ 12

4.2 Hydraulic Connections ........................................................................................................... 12

4.3 Control Box (Optional) ............................................................................................................ 13

4.4 Machine Components ............................................................................................................. 13

4.5 Attach To Skidsteer ................................................................................................................. 14

4.6 Detach From Skidsteer ........................................................................................................... 14

4.7 Transporting............................................................................................................................. 14

4.8 First Time User Tips ................................................................................................................ 14

4.9 Field Operation ........................................................................................................................ 15

4.10 Hydraulic Adjustments.......................................................................................................... 16

5 SERVICE AND MAINTENANCE..................................................................................................... 17

5.1 Lubrication ............................................................................................................................... 17

5.2 Inspect Hoses .......................................................................................................................... 18

5.3 Inspect And Rotate Or Replace Cutting Teeth ...................................................................... 18

5.4 Motor Shaft Seal ...................................................................................................................... 19

5.5 Remove And Install Rotor....................................................................................................... 19

6 TROUBLESHOOTING ..................................................................................................................... 21

7 WARRANTY...................................................................................................................................... 22

3

1 INTRODUCTION

Congratulations on your choice of a Baumalight

Feller Buncher to complement your operation. This

equipment has been designed and manufactured

to meet the needs of a discriminating buyer.

This new and unique design allows us to build it

very economically and makes it a very compact

unit for storage and transport. Hydraulic controls

are easy to adjust and operate.

Safe, efcient and trouble free operation of your

feller buncher requires that you and anyone

else who will be operating or maintaining the

feller buncher, read and understand the Safety,

Operation, Maintenance and Troubleshooting

information contained within the Operator’s

Manual.

This manual covers the Baumalight skidsteer

mounted Feller Buncher. Use the Table of Contents

as a guide to locate required information.

Keep this manual handy for frequent reference

and to pass on to new operators or owners. Call

your Baumalight dealer, distributor or the factory

if you need assistance, information or additional

copies of the manuals.

OPERATOR ORIENTATION - The directions left,

right, front and rear, as mentioned throughout this

manual, are as seen from the operator’s seat and

facing in the direction of travel.

1.1 Overview

The feller buncher is designed to be used by an

experienced operator. Operator must be trained

in the safe operation of a skidsteer and hazards

related to using the feller buncher and the safe use

of the feller buncher for the intended purpose.

Operators will require personal protective

equipment to reduce the risk from some hazards

that cannot be completely eliminated or controlled

by the design of the feller buncher.

Care is required to ensure that the feller buncher

will not come in contact with metallic objects,

stones or other materials.

Feller bunchers are not designed for use in

hazardous atmospheres where there is a risk

of re or explosion due to ammable gases or

vapors. Use in hazardous, explosive atmospheres

is prohibited. Serious injury or death of the operator

or bystanders may be caused if feller buncher is

misused. Misuse may also cause damage to the

machine carrying the feller buncher.

1.2 Intended Use And Foreseeable

Misuse

4

2 SAFETY

You must read, understand and follow the

instructions given by the operating unit

manufacturers, as well as the instructions in this

manual.

The safety information in this manual is denoted

by the safety alert symbol:

^

This symbol means ATTENTION! BECOME

ALERT! YOUR SAFETY IS INVOLVED!

The level of risk is indicated by the following signal

words:

^^ DANGER

DANGER - Indicates a hazardous

situation, which, if not avoided, WILL

result in death or serious injury.

^ WARNING

WARNING - Indicates a hazardous

situation, which, if not avoided, could

result in death or serious injury.

^ CAUTION

CAUTION - Indicates a hazardous

situation, which, if not avoided, could

result in minor or moderate injury.

NOTICE

NOTICE - Indicates a situation that could

result in damage to the equipment or

other property.

2.1 Safety Alert Symbol And Safety

Words

2.2 Operational Hazards

^ WARNING

Prevent death or serious injury.

Read and understand this manual before

operating feller buncher.

Always stop engine and remove key

before leaving operators seat.

Never allow anyone in near feller

buncher or in area where tree may fall

during operation.

Travel at a safe speed.

^ WARNING

Prevent death or serious injury from

moving parts.

Moving parts can crush and dismember.

Do not operate without guards and

shields in place.

Disconnect and lockout power source

before adjusting or servicing.

^ WARNING

Use feller buncher only for the designed

applications.

Any other use may result in personal

injury, damage to equipment and may

void the warranty.

5

^ WARNING

Prevent death or serious injury.

Verify feller buncher is locked to

quick attach hitch before operation or

transport.

^ WARNING

Protect from ying debris.

Wear proper safety glasses, goggles,

or a face shield to protect from ying

debris.

Carefully read all safety messages in this manual

and on equipment safety signs. Keep safety signs

in good condition and replace missing or damaged

safety signs.

New equipment components and repair parts must

include the current safety decal.

Learn how to properly operate equipment.

NEVER operate or work around this equipment

without proper instruction, while fatigued or under

the inuence of alcohol, prescription or non-

prescription medication or if feeling ill.

Keep your equipment in proper working condition.

Know the regulations and laws that apply to you

and your industry. This manual is not to replace

any regulations or laws. Additional information

may be found at: www.asae.org or www.osha.gov.

If you do not understand any part of this manual,

contact Baumalight at 866-820-7603.

Prepare For Emergencies

• Be prepared in case of emergencies.

• Keep a re extinguisher and rst aid kit close

to the machine.

• Keep emergency phone numbers in your

phone or close by.

• Know your address so emergency services

can locate you if an emergency arises.

Replace Safety Signs

• Replace missing or damaged safety signs.

• Safety signs are identied in Section 3 of this

manual.

• Replacement safety signs are available from

your Baumalight dealer.

Do Not Allow Riders

• NEVER lift or carry anyone on feller buncher.

• NEVER use feller buncher as a work platform.

• NEVER allow passengers on feller buncher.

Lower Operating Speed

Keep feller buncher low and move at slow speeds

on rough or uneven terrain.

6

Avoid Rollover

The equipment may rollover, resulting in death or

serious injury. To help prevent rollover:

• Travel at a slow speed.

• Avoid sharp turns & sudden movement on

slopes.

• Carry feller buncher close to the ground.

• Avoid holes, ditches and other obstructions

which may cause equipment to rollover.

• Balance load so weight is evenly distributed

and load is stable.

• Use caution when operating on slopes and do

not operate on excessively steep slopes.

• Do not exceed load capacity of equipment.

Avoid Powerlines

^ DANGER

Prevent electrocution.

Death or serious injury can result

if equipment or tree comes near or

contacts power line.

Electrocution can occur without direct

contact.

• Check clearance before raising equipment.

• Verify cut trees will not contact or come near

power line.

DO NOT leave the operator’s seat if any part of the

equipment or tree contacts electric line or cable.

Detach Feller Buncher Safely

Detach feller buncher on a rm and level surface.

Feller buncher may fall over if detached on unlevel

or soft surface. Keep clear of machinery.

Relieve hydraulic pressure before disconnecting

hydraulic hoses.

Raised Attachment

^ WARNING

Crushing hazard.

Raised, unsupported feller buncher can

fall, resulting in death or serious injury.

Never enter the area under a raised feller

buncher.

A raised feller buncher can lower unexpectedly,

resulting in death or serious injury.

NEVER enter area under a raised feller buncher.

Lower feller buncher to ground, engage parking

brake, shut off engine and remove key before

servicing.

Hazards From Modifying Equipment

Do not make any alterations to your feller buncher.

Altering may cause your equipment to be unsafe

and may void the manufacturers’ warranty.

7

Avoid High Pressure Fluids

^ WARNING

Pressurized uids can penetrate the

skin.

Hydraulic hoses can fail from age,

damage and exposure.

Use body and face protection while

searching for leaks. A tiny, almost

invisible leak can penetrate the skin,

thereby requiring immediate medical

attention.

Use wood or cardboard to detect

hydraulic leaks, never use your hands.

Escaping uid under pressure can penetrate the

skin causing serious injury.

Prevent the hazard by relieving pressure before

connecting or disconnecting hydraulic lines. Verify

all connections are tight before applying pressure.

Search for leaks with a piece of cardboard or wood.

Protect hands and body from high pressure uids.

If an accident occurs, see a doctor immediately.

Any uid injected into the skin must be surgically

removed within a few hours or serious infection

may result.

Doctors unfamiliar with this type of injury should

reference a knowledgeable medical source.

Avoid Loud Noise

^ WARNING

Prolonged exposure to loud noise can

cause impairment or loss of hearing.

Wear a suitable hearing protective device

such as earmuffs or earplugs to protect

against objectionable or uncomfortable

loud noises.

2.3 Maintenance Hazards

Before servicing, park machine on a rm and

level surface, set parking brake and place a “Do

Not Operate” tag on control panel. Read and

understand this manual. If you do not understand

any part of the manual, contact Baumalight at 866-

820-7603.

Always wear face and/or eye protection, safety

shoes, and other protective equipment appropriate

for the job.

Do not make unauthorized modications. Contact

Baumalight at 866-820-7603. Before you weld,

cut/drill holes, or make any other modications.

Always use Baumalight replacement parts.

^ WARNING

Moving parts can crush and cut.

Keep clear of moving components.

Follow lockout procedure before

servicing.

8

^ WARNING

Crushing hazard.

Before performing inspections, service

or maintenance:

Park machine on rm, level surface.

Engage parking brake.

Turn engine off and remove key.

Place “Do Not Operate” tag on skidsteer

control panel.

^ WARNING

Entanglement hazard.

Keep clear of moving components.

Wear proper protective equipment

appropriate for the job.

^ WARNING

Burn hazard.

Hot and high pressure hydraulic oil.

Allow oil to cool before servicing.

A

B

D

C

D

E

3 SAFETY SIGNS

9

E

C

G

F

D

A. D005253 ^ WARNING - Pressurized uid

hazard. Pressurized uids can penetrate the

skin. Do not check for leaks with your hands.

Keep back a safe distance when pressurized.

D005253

B. D005262 ^WARNING - P65 warning

information.

WARNING: This product can expose you to chemicals

including 1,3-Butadiene and lead, which are known to the state of

California to cause cancer and birth defects or other reproductive

harm. For more information go to www.P65Warnings.ca.gov.

D005262

C. D003190

10

D. D005127 ^WARNING - Rotating blade

hazard. Keep back while machine is operating.

D005127

E. D005223 ^WARNING - Rotating blade

hazard. Keep back 75 m while machine

is operating. Wait for blade to stop before

approaching machine.

D005223

75 M

F. D005125 ^WARNING - Read and

understand safety signs on the machine and

operating instructions in this manual before

operating machine.

D005125

G. D005517 ^WARNING - Remove key before

servicing.

D005517

11

Although the feller buncher has been carefully

inspected and checked prior to shipment from

manufacturer, it is recommended that the unit be

thoroughly inspected.

Check all bolts for tightness and remove all

shipping tags, bags, skids, and blocking.

Remove any masking materials afxed during

painting. Inspect equipment to verify that

nameplates and all safety warning, caution signs

and decals provided with the equipment are in

place and clearly visible.

Visually inspect the feller buncher before each

start up. Check for loose or missing parts and any

damage that may have occurred during moving or

shipping.

Review all skidsteer pre-start instructions, and

ensure that all recommended steps and procedures

have been followed.

4 OPERATION

4.1 Preparation For Use 4.2 Hydraulic Connections

^ WARNING

Pressurized uids can penetrate the

skin.

Disconnect and lock out power source

before disconnecting and/or connecting

hydraulic hoses.

The feller buncher is equipped with three hoses,

pressure, return and case drain. Hydraulic

couplers are not provided with the feller buncher.

You must install couplers and connect your

skidsteer pressure, return and case drain hoses

to the feller buncher hoses.

Skidsteer hoses must be the same size as the

feller buncher hoses. Using smaller diameter

hoses will decrease hydraulic ow.

D005405 D005411

12

A. Holding Arms - Operate independently of the

accumulator arm.

B. Hydraulic Hose Holder

C. Quick Attach

D. Operators Manual Holding Tube

E. Cutting Tooth

F. Rotor

G. Hydraulic Motor

H. Accumulator Arm - Operates independently of

the holding arms and allows the operator to

carry multiple trees at one time.

A

B

C

D

E

F

G

H

A

4.4 Machine Components

4.3 Control Box (Optional)

D004877

GRABBER ACCUMULATOR

13

^ WARNING

To prevent injury or machine damage

put transmission in park.

Never position yourself between

skidsteer and feller buncher.

Only experienced and properly trained

operator’s may operate skidsteer and

feller buncher.

1. Read and follow all safety instructions.

2. Attach skidsteer to feller buncher. See skidsteer

operator’s manual.

3. Connect hydraulic hoses. Verify hydraulic

hoses are clear of pinch areas and moving

parts.

4. Connect control box to skidsteer 12 volt power

supply, or connect 14 or 8 pin auxiliary plug.

5. Move to a clear open area to test functions.

4.5 Attach To Skidsteer

1. Verify all reectors and Slow Moving Vehicle

(SMV) sign are visible.

2. Raise feller buncher slightly off ground.

3. Travel at a reasonable and safe speed.

4.8 First Time User Tips

Operate all functions in an open area with skidsteer

at idle to get a good feel for the controls.

Run throttle only at half speed for rst time users.

^ WARNING

Always stop engine and remove key

before leaving operators seat.

4.7 Transporting

4.6 Detach From Skidsteer

^ WARNING

Prevent serious injury or death caused

by unexpected movement:

1. Park skidsteer on a level surface.

2. Lower feller buncher to ground.

3. Engage skidsteer parking brake.

4. Shut off engine and remove key.

1. Park skidsteer on a level surface.

2. Lower feller buncher to the ground.

3. Shut off engine and remove key.

4. Disconnect hydraulic hoses.

5. Disconnect electrical connector.

6. Detach skidsteer from feller buncher. See

skidsteer Operator’s Manual.

14

4.9 Field Operation

^ WARNING

Prevent serious injury or death caused

by unexpected movement:

1. Park skidsteer on a level surface.

2. Lower feller buncher to ground.

3. Engage skidsteer parking brake.

4. Shut off engine and remove key.

^ WARNING

Prevent serious injury or death.

Never operate feller buncher within 300

ft (92 m) of any person.

On steep terrain, fell trees while traveling

up hill.

Do not exceed rated cutting,

accumulating or carrying capacities of

skidsteer and feller buncher.

Cut stumps as short as possible.

Do not open holding or accumulator

arms until trees are leaning away from

skidsteer.

Do not allow riders.

1. Attach feller buncher to skidsteer. See Attach/

Detach in this section.

2. If equipped with a control box, move switch to

select holding arms and accumulator arm.

3. Operate hydraulics to open holding arms and

accumulator arm.

4. Position feller buncher so rotor is close to tree

and as low to the ground as possible. Position

with the head tilted slightly forward (about 5°).

This will push the top of the tree away slightly

preventing saw jam.

5. Operate hydraulics to start rotor.

6. Move forward into tree while closing holding

arms to hold cut tree. If multiple small trees

will be cut, close accumulator arm to hold tree

and open holding arms. Move forward into tree

while closing holding arms to hold cut tree.

7. Move to drop site, tilt head forward and open

holding arms and accumulator arm if holding

multiple trees to drop trees.

15

4.10 Hydraulic Adjustments

^ WARNING

Prevent serious injury or death caused

by unexpected movement:

1. Park on a level surface.

2. Lower feller buncher the to ground.

3. Engage parking brake.

4. Shut off engine and remove key.

1. Park skidsteer on a level surface.

2. Lower feller buncher to the ground.

3. Engage parking brake, shut off engine and

remove key.

(A) Flow Adjust - Adjusting the ow determines how

much oil is sent to cylinders and rotor. The more

oil that is sent to the rotor will result in cylinders

moving slower. If more oil is sent to the cylinders,

rotor speed will decrease. Typical adjustment is

5/8 turn out from closed position when we ship. To

adjust this, hold hex screw with hex wrench and

loosen lock nut. Turn hex screw 1/2 turn and hold

in position while tightening lock nut. Test operation

and adjust again if desired.

(B) Pressure Relief - 1/4 turn out from closed

position is approximately 3000 psi (207 bar). Relief

must be set lower than skidsteer relief. Image below

is shown with top plate removed for adjustments.

Do not operate with top plate removed.

A

B

Note: Skid steers with high/low hydraulic ow

switching capability may need a jumper wire on

the pin 14 plug to keep the skid steer at high ow.

Contact your skid steer dealer or Baumalight for

more information.

16

5 SERVICE AND

MAINTENANCE

^ WARNING

Prevent serious injury or death caused

by unexpected movement:

1. Park skidsteer on a level surface.

2. Lower feller buncher to ground.

3. Engage skidsteer parking brake.

4. Shut off engine and remove key.

1. Pump grease into all pivot point lubrication

ttings until adequately lubricated.

5.1 Lubrication

17

5.2 Inspect Hoses

^ WARNING

Prevent serious injury or death caused

by unexpected movement:

1. Park skidsteer on a level surface.

2. Lower feller buncher to ground.

3. Engage skidsteer parking brake.

4. Shut off engine and remove key.

^ WARNING

Pressurized uids can penetrate the

skin.

Hydraulic hoses can fail from age,

damage and exposure.

Use body and face protection while

searching for leaks. A tiny, almost

invisible leak can penetrate the skin,

thereby requiring immediate medical

attention.

Use wood or cardboard to detect

hydraulic leaks, never use your hands.

Inspect hydraulic hoses for damage and wear.

Replace damaged or worn hoses before operating.

5.3 Inspect And Rotate Or Replace

Cutting Teeth

^ WARNING

Prevent serious injury or death caused

by unexpected movement:

1. Park skidsteer on a level surface.

2. Lower feller buncher to ground.

3. Engage skidsteer parking brake.

4. Shut off engine and remove key.

Check cutting edge (A) of teeth for wear and

damage. Keep cutting teeth in good condition. Unit

will cut faster and remaining teeth will last longer if

broken teeth are replaced.

Each tooth can be rotated 180° from its original

position before replacement is necessary.

1. Park skidsteer and feller buncher on a level

surface.

2. Lower feller buncher to the ground.

3. Shut off engine and remove key.

4. Inspect cutting teeth for damage and wear.

Once cutting edges (A) is worn, remove bolt,

pull tooth out and rotate tooth 180° so new

edge is on outside (cutting) edge.

5. Replace individual teeth as needed.

6. Install tooth and tighten bolt to 37 lb-ft (50 Nm)

of torque.

A

18

5.4 Motor Shaft Seal

If oil emerges, safety seal in motor has been activated.

This is caused by an undersized, momentarily pinched

or disconnected case drain.

Please request the motor seal repair manual from the

manufacturer before attempting a repair.

Damage will result if this line is plugged.

NOTICE

D004707

If case drain line is not properly connected, is

blocked or restricted, motor shaft seal will fail. If

this happens, oil will leak out through over hung

load adapter vent line (A).

A

Motor Shaft Seal Replacement manual can be

found at www.baumalight.com/support.

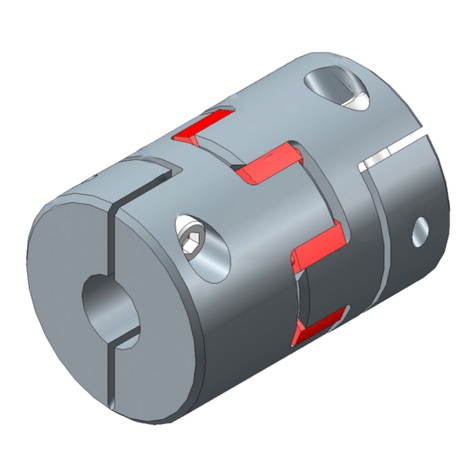

5.5 Remove And Install Rotor

^ WARNING

Prevent serious injury or death caused

by unexpected movement:

1. Park skidsteer on a level surface.

2. Lower feller buncher to ground.

3. Engage skidsteer parking brake.

4. Shut off engine and remove key.

1. Park skidsteer on a level surface.

2. Lower feller buncher to the ground.

3. Shut off engine and remove key.

4. Disconnect hydraulic hoses.

5. Disconnect electrical connector.

6. Detach skidsteer from feller buncher. See

skidsteer Operator’s Manual.

^ WARNING

Crushing and severing hazard.

Feller buncher weight is 2512 lbs (1140

kg).

Use a properly rated lifting device to lay

feller buncher down for rotor removal.

7. Connect a properly rated lifting device to feller

buncher and lay machine down on the quick

attach side.

19

8. Remove covers (A), (B) and (C).

A

B

C

^ WARNING

Crushing and severing hazard.

Rotor weight is 375 lbs (170 kg).

Use a properly rated lifting device to lift

rotor.

9. Attach a properly rated lifting device to holes

(D) in rotor. Apply a slight tension on lifting

device.

10. Remove eight socket head cap screws (E) and

plate (F). Carefully remove rotor with lifting

device.

F

E

D

G

11. Position rotor on motor shaft with lifting device.

12. Install plate (F).

13. Apply a medium strength thread lock to cap

screw (E) threads.

14. Install socket head cap screws (E).

15. Tighten caps screws (E) to 188 lb-ft (255 Nm)

of torque.

16. Remove rotor lifting device.

17. Position feller buncher in the upright position

with lifting device.

18. Remove lifting device.

20

Table of contents

Other Baumalight Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Sterling

Sterling 2000HG Installation and maintenance manual

ABB

ABB HT604070 Operation manual

ABB

ABB Relion 670 series Applications manual

Siemens

Siemens TNKM Series installation instructions

American Lubrication Equipment

American Lubrication Equipment TIM-315-COMP2 manual

KTR

KTR POLY PKZ Series Operating & assembly instructions